Packing structure

A technology of packaging structure and snap-fit components, which is applied in the field of packaging boxes and can solve the problem that the loading rate cannot be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

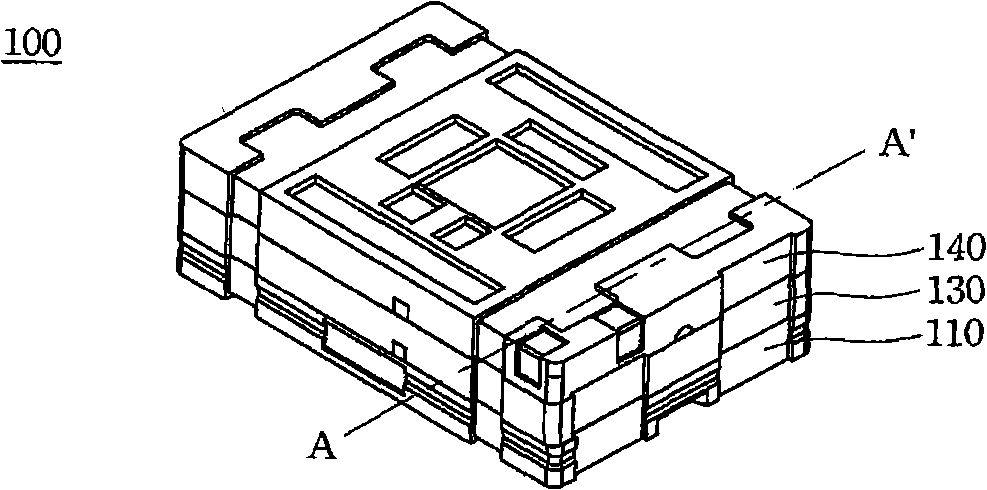

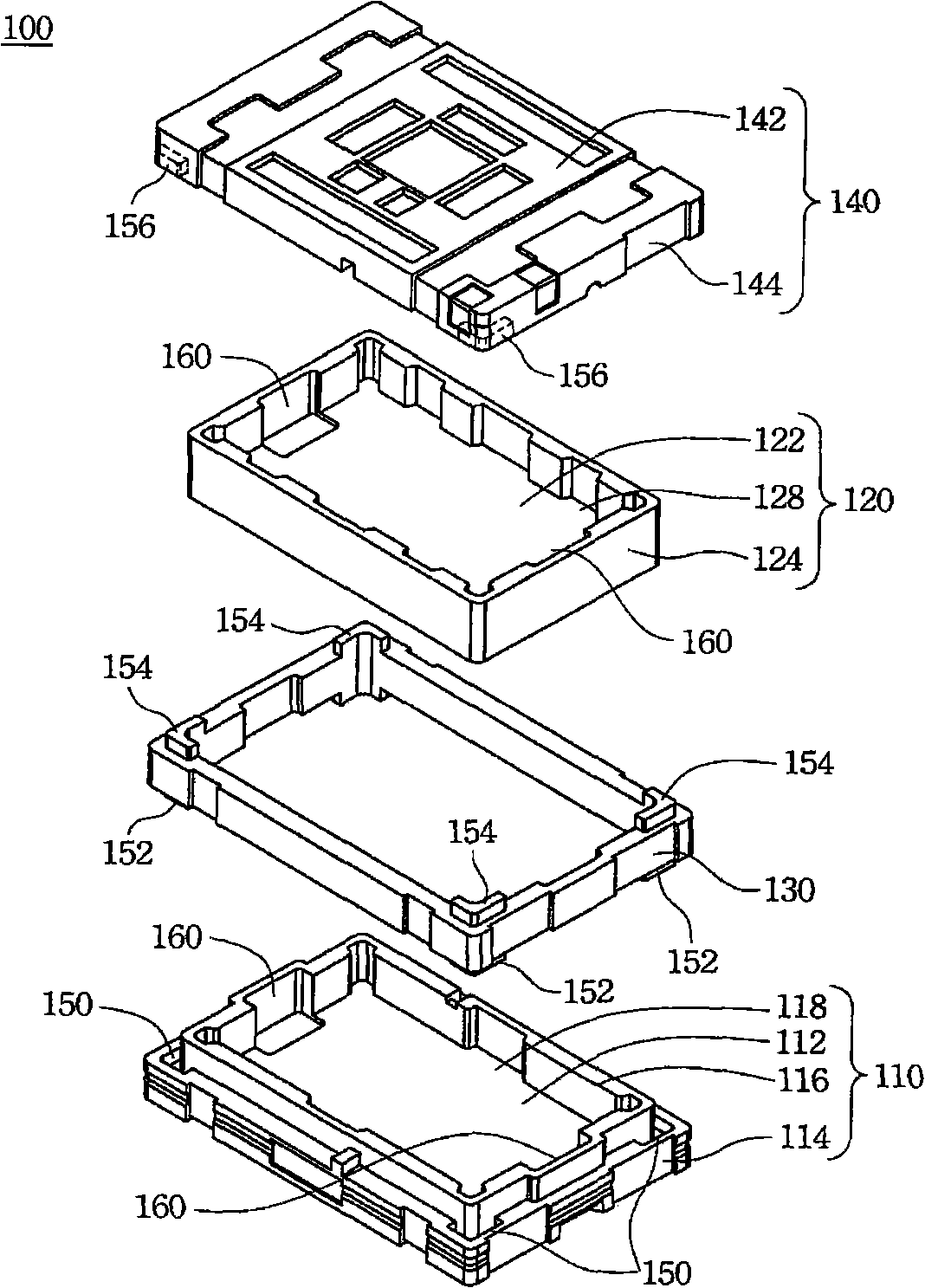

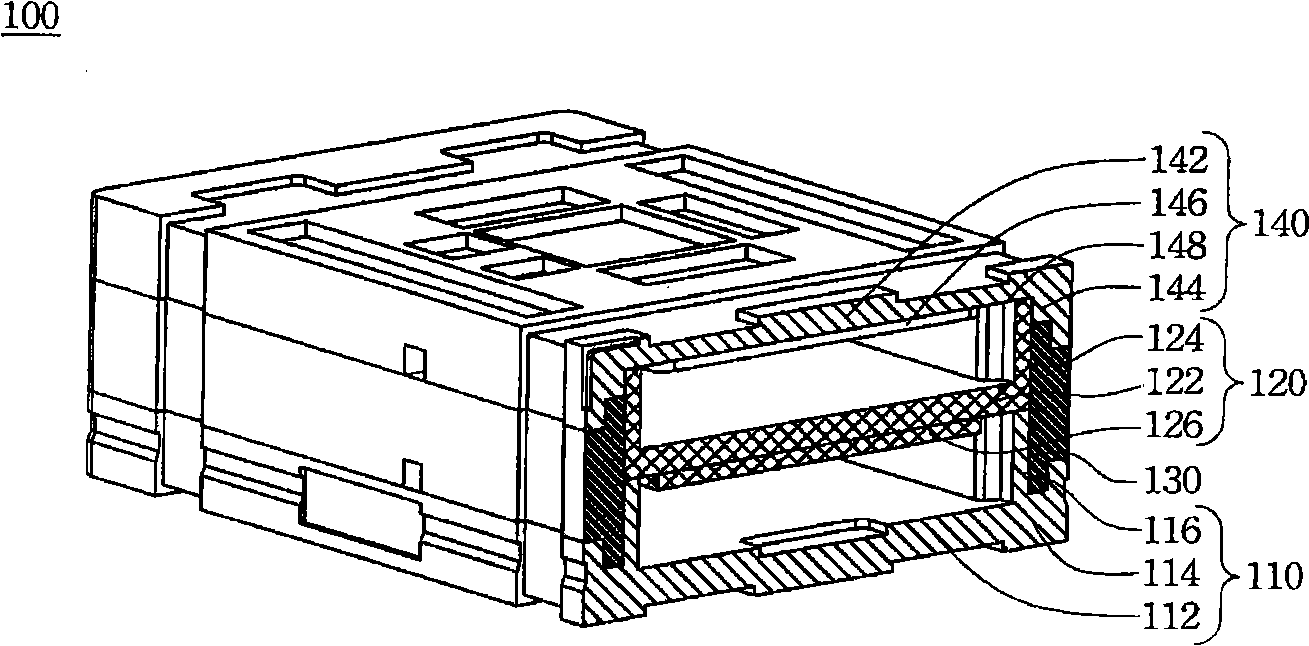

[0043] Please also refer to Figure 1A and Figure 1B . Figure 1A Shown is an assembled perspective view of a packaging structure 100 according to an embodiment of the present invention, Figure 1B An exploded view of the packaging structure 100 is shown. The packaging structure 100 can be used to package glass substrates, or fragile items of the same nature as the glass substrates, such as color filters or display panels.

[0044] The packaging structure 100 mainly has a bottom box body 110 , a middle box body 120 , an annular enclosure 130 and an upper cover 140 . Note that although the Figure 1A and Figure 1B Only a single middle box 120 and a single annular enclosure 130 are shown in FIG. However, the number of the middle box 120 and the annular enclosure 130 may be multiple. See the follow-up instructions for details.

[0045] The bottom box body 110 is mainly composed of a bottom plate 112 and side walls 114 . The bottom surface of the side wall 114 surrounds th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com