Inductance coupling coil and inductance coupling plasma apparatus using the same

A technology of inductively coupled coils and inductive coupling, which is applied in the direction of plasma, coils, inductors, etc., can solve the problems of inability to adjust, small window, and inability to effectively adjust the uniformity of etching rate, etc., to achieve the adjustment of uniformity and distribution Uniform, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

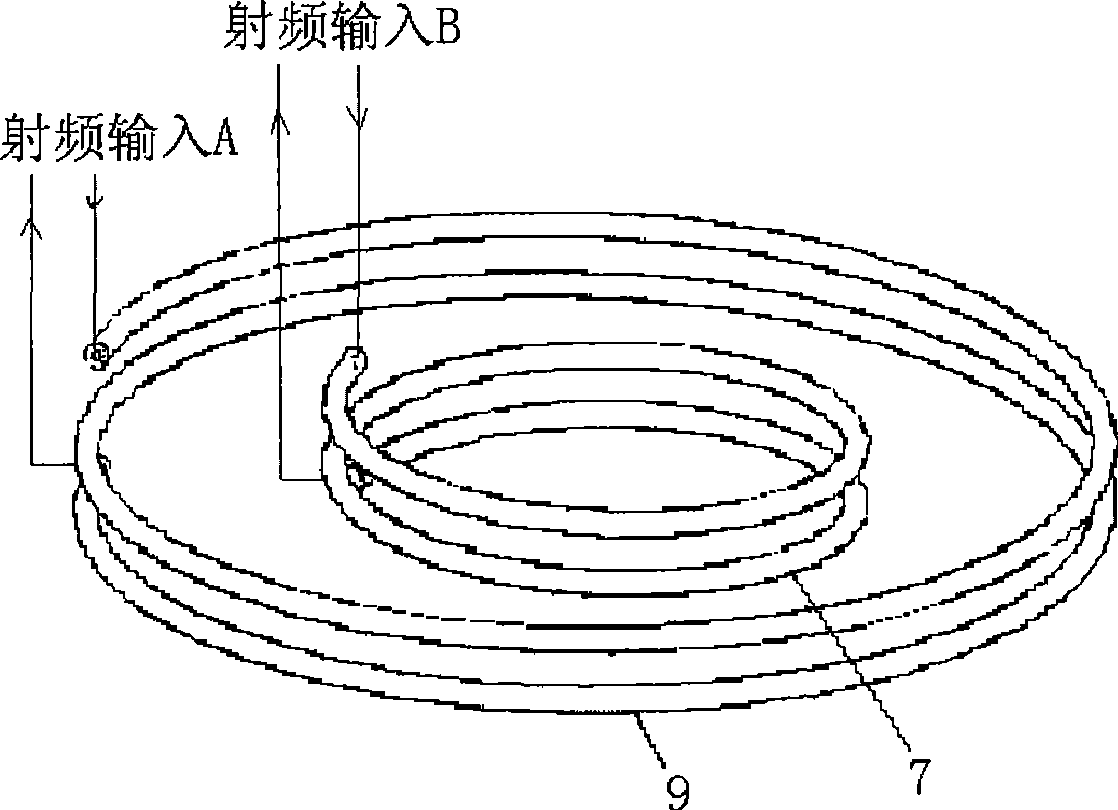

[0025] A rack 14 is fixed on the outer winding support 15 , and a gear 6 is provided on the wall 11 of the reaction chamber 3 , and the gear 6 meshes with the rack 14 . The rotation of the gear 6 drives the rack 14 to move up and down, and then drives the outer winding support 15 and the outer winding 9 on it to move up and down, so that the position of the outer winding 9 relative to the inner winding 7 and the reaction chamber 3 is adjusted up and down. In this embodiment, the inner winding support 10 can be fixed on the dielectric window 1 so that the position between the inner winding 7 and the reaction chamber 3 is relatively fixed.

[0026] The outer winding support 15 can also be fixed, the inner winding support 10 can be adjusted, and both the outer winding support 15 and the inner winding support 10 can be adjusted. The adjustment method is not limited to the rack and pinion transmission system. To be simple, a set of pads of different thicknesses can be used to raise...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap