Electric connector terminal and manufacturing method thereof

A technology for electrical connectors and terminals, which is applied in the field of electrical connector terminals and its manufacturing, can solve the problems of insufficient elastic deformation, uneven force, small elastic deformation, etc., achieve low cost, good clamping force, and simple manufacturing method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate a better understanding of the present invention, the present invention will now be further described.

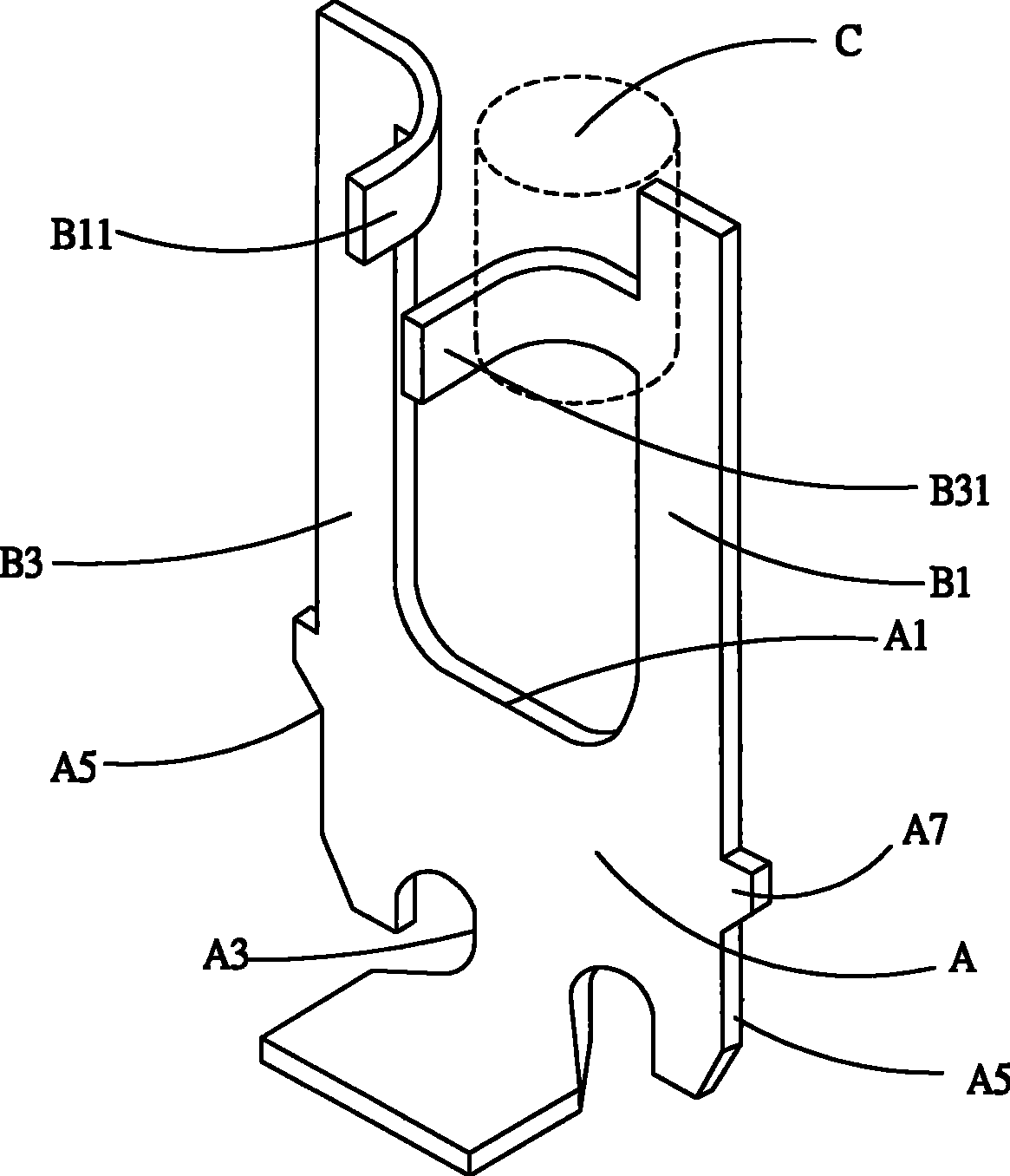

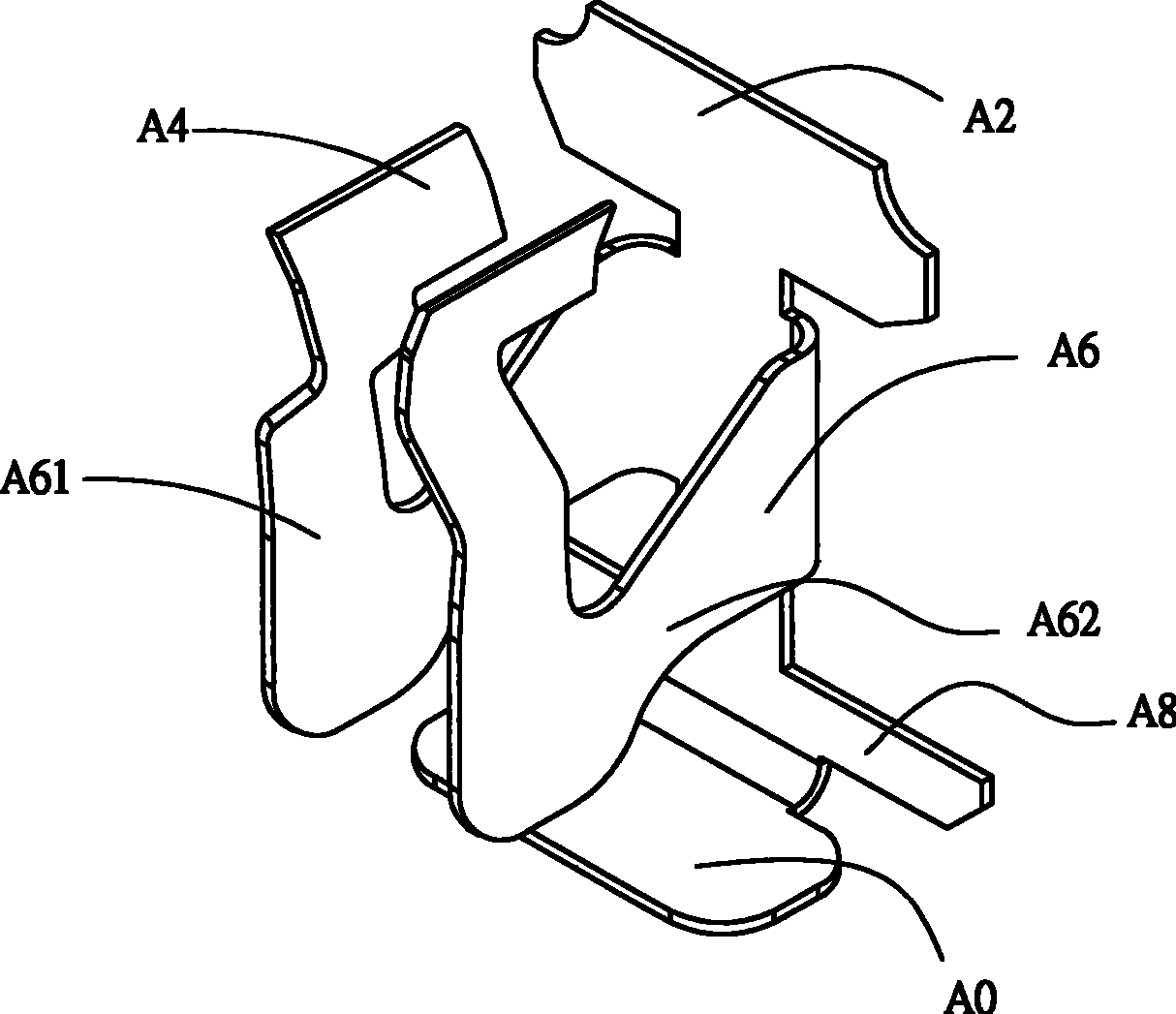

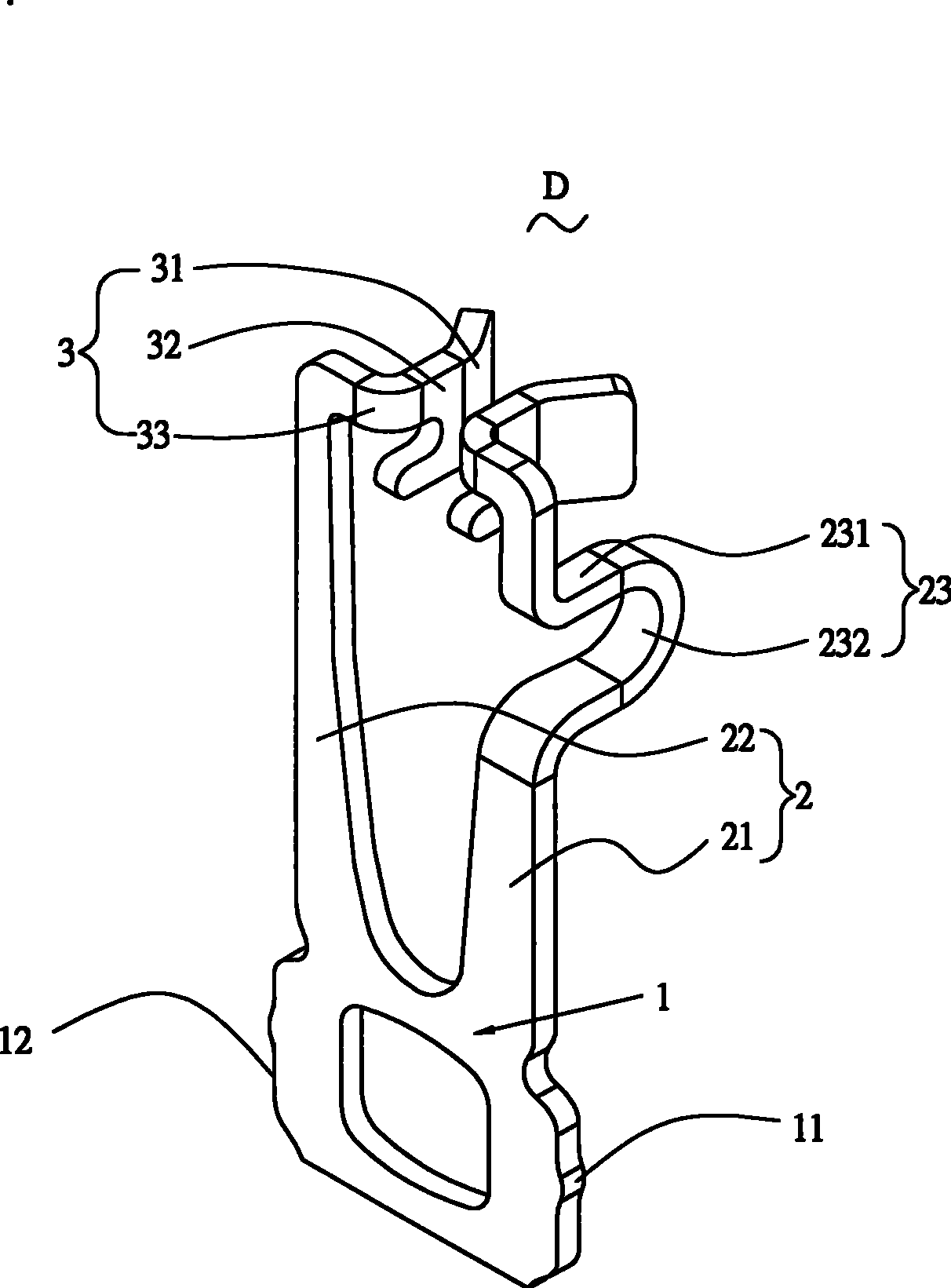

[0036] see Figure 3 to Figure 10 , the electrical connector terminal D of the present invention is mainly used for electrically connecting chip modules (not shown) and circuit boards (not shown), such as image 3 As shown, the electrical connector terminal D is formed by stamping, bending, electroplating, and removing residual material strips from a metal plate. The electrical connector terminal D includes a main body 1, two terminal arms 21, 22 , Two contact parts 3 .

[0037] The main body 1 is located at the bottom of the electrical connector terminal D, and can be used to solder the electrical connector terminal D to a circuit board (not shown). The two side edges 12 of the main body 1 are provided with at least one protrusion 11 for interference Hold the terminal D of the electrical connector.

[0038] Two terminal arms 21, 22 extend ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com