Device for limiting the advance during a drilling operation

A drilling operation, step drill bit technology, applied in drilling/drilling equipment, components of boring machine/drilling machine, positioning measurement in boring machine/drilling machine, etc. The effect of trimming and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

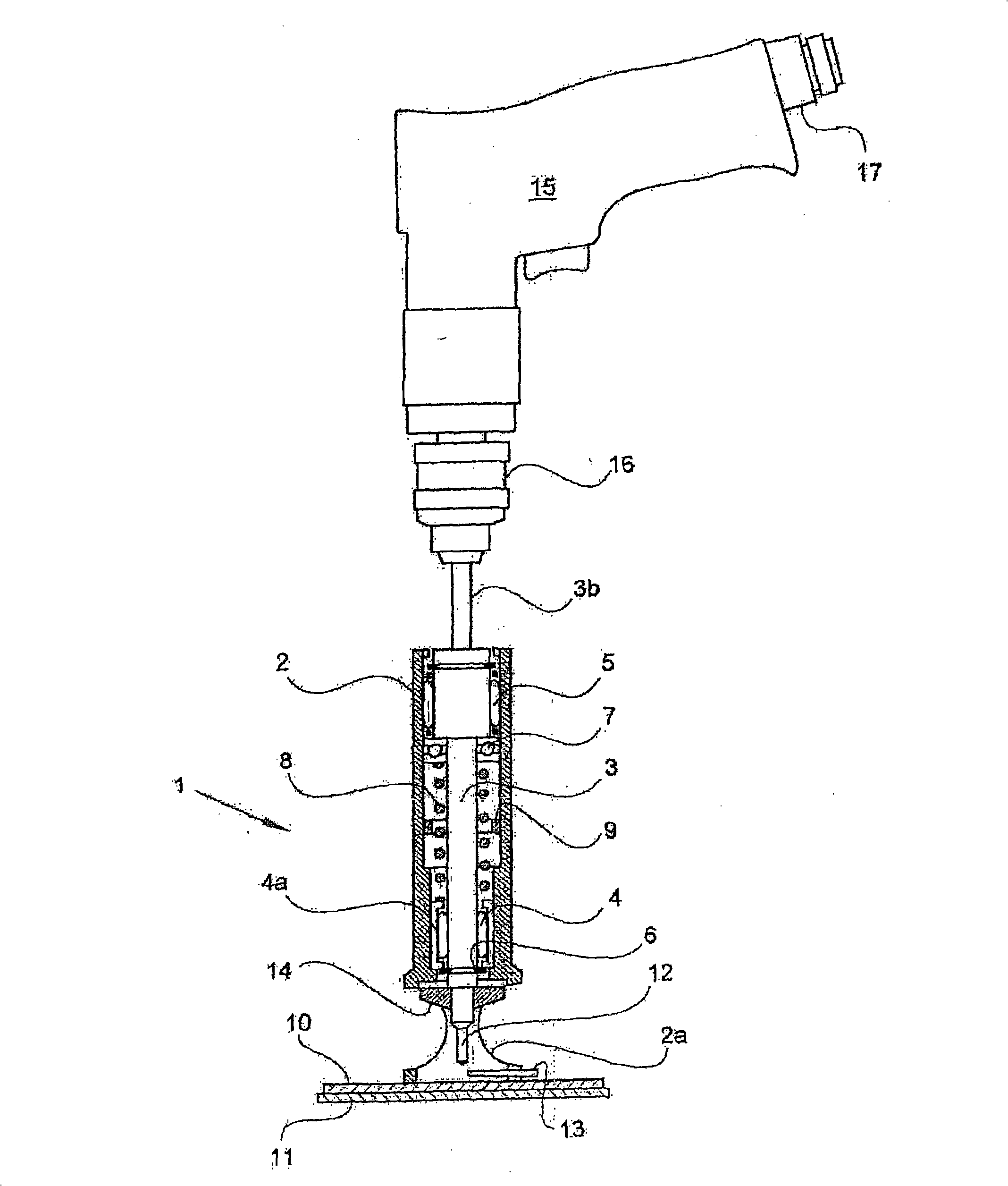

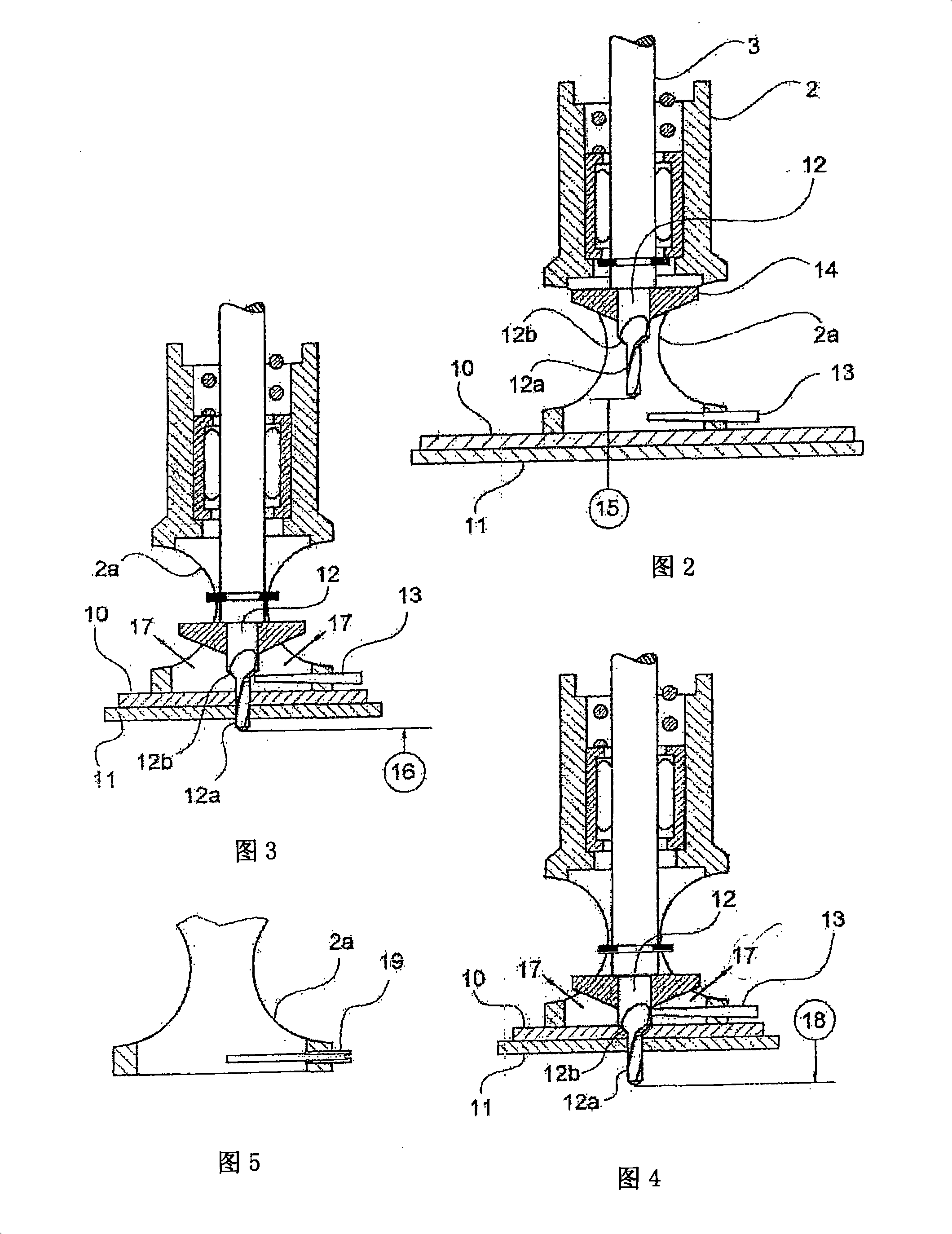

[0012] figure 1 There is shown a device 1 of a known kind for limiting advancement by connection, for example, with a hand drill, the device 1 comprising a housing 2 and a shaft 3 rotatably mounted therein with a widened portion 3a and a shank portion 3b. The lower needle bearing 4 and the upper needle bearing 5 are used for mounting the shaft 3 . The shaft 3 is shown in its upper position. In this position, the axial confinement ring 6 arranged on the shaft 3 bears against the part 4a of the needle bearing 4 fixed to the housing. The lower end of the widened portion 3 a forms a shoulder against which the thrust ball bearing 7 abuts. Compression spring 8 , for its part supported with its lower end against part 4 a of needle bearing 4 fixed to the housing, acts on thrust ball bearing 7 from below in the figure. An axially adjustable stop 9 is arranged inside the housing 2 . The compression spring 8 is dimensioned such that, shown as a result of the prestressing, the shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com