System and method for optically inspecting glass panes

An optical inspection and glass plate technology, applied in the direction of material analysis, scientific instruments, measuring devices, etc. by optical means, can solve the problem of not being able to determine and display the optical characteristics and production quality of the plate, and other defect types or characteristics that are not suitable for glass plates, etc. problems, to improve inspection results, save costs, and save system components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

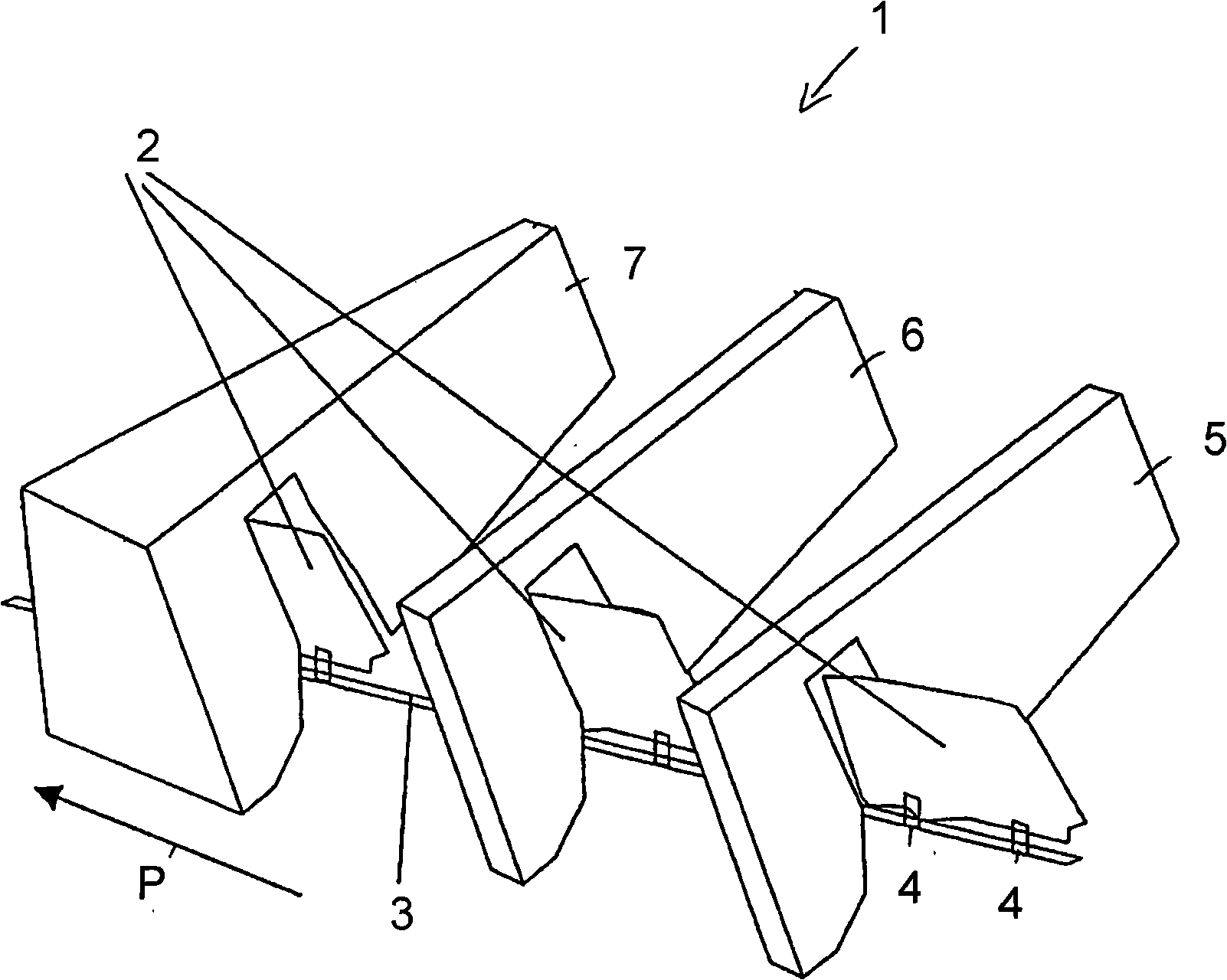

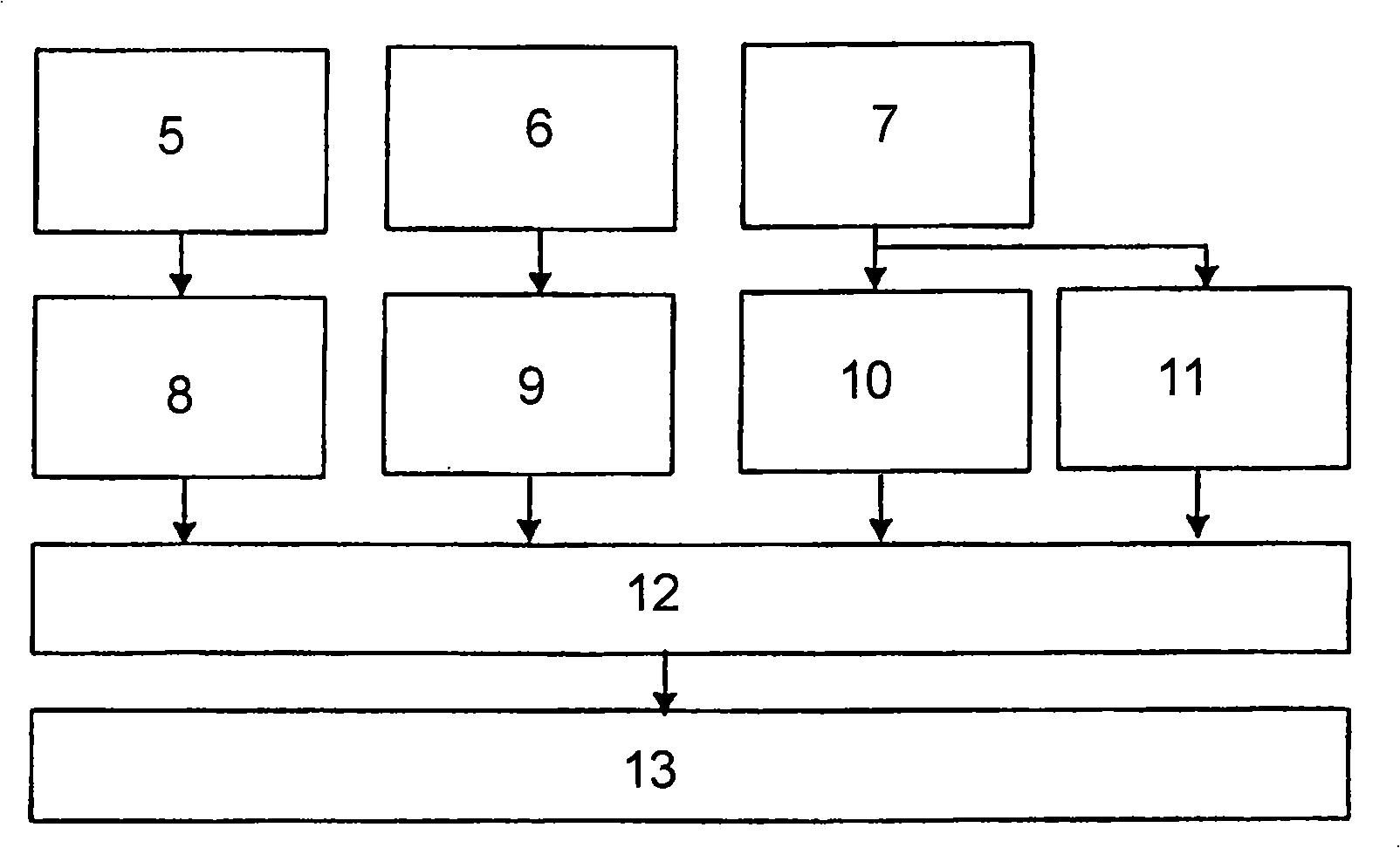

[0033] exist figure 1 The system 1 for the optical inspection of glass panes 2 shown in is arranged on a conveyor belt 3 designed as a conveyor, on which the glass panes 2 are held by suitable grippers 4 . The system 1 has a plurality of inspection modules 5, 6, 7 which are arranged on the conveyor belt 3 in such a way that when they pass the optical inspection system 1 on the conveyor belt 3 in the direction of the arrow P, they surround the glass to be inspected plate 2.

[0034] According to the invention, the first module 5 is a module with a grating illumination device and a transmission device in which the glass sheet 2 is inspected for optical defects in transmission to determine optical distortions / distortions. If the windshield of a motor vehicle is preferably inspected with this system 1 , the pane 2 is usually inspected in the direction of observation through which the driver of the vehicle looks when the pane 2 is installed. For windshields, this is approximately...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com