Method for processing an ultrasonic analog signal, digital signal processing unit and ultrasonic inspection device

an analog signal and ultrasonic technology, applied in the field of processing ultrasonic analog signals, digital signal processing units and ultrasonic inspection devices, can solve the problems of difficult detection of such flaws in test objects, limited application, and inability to reliably detect flaws, etc., to achieve a high degree of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

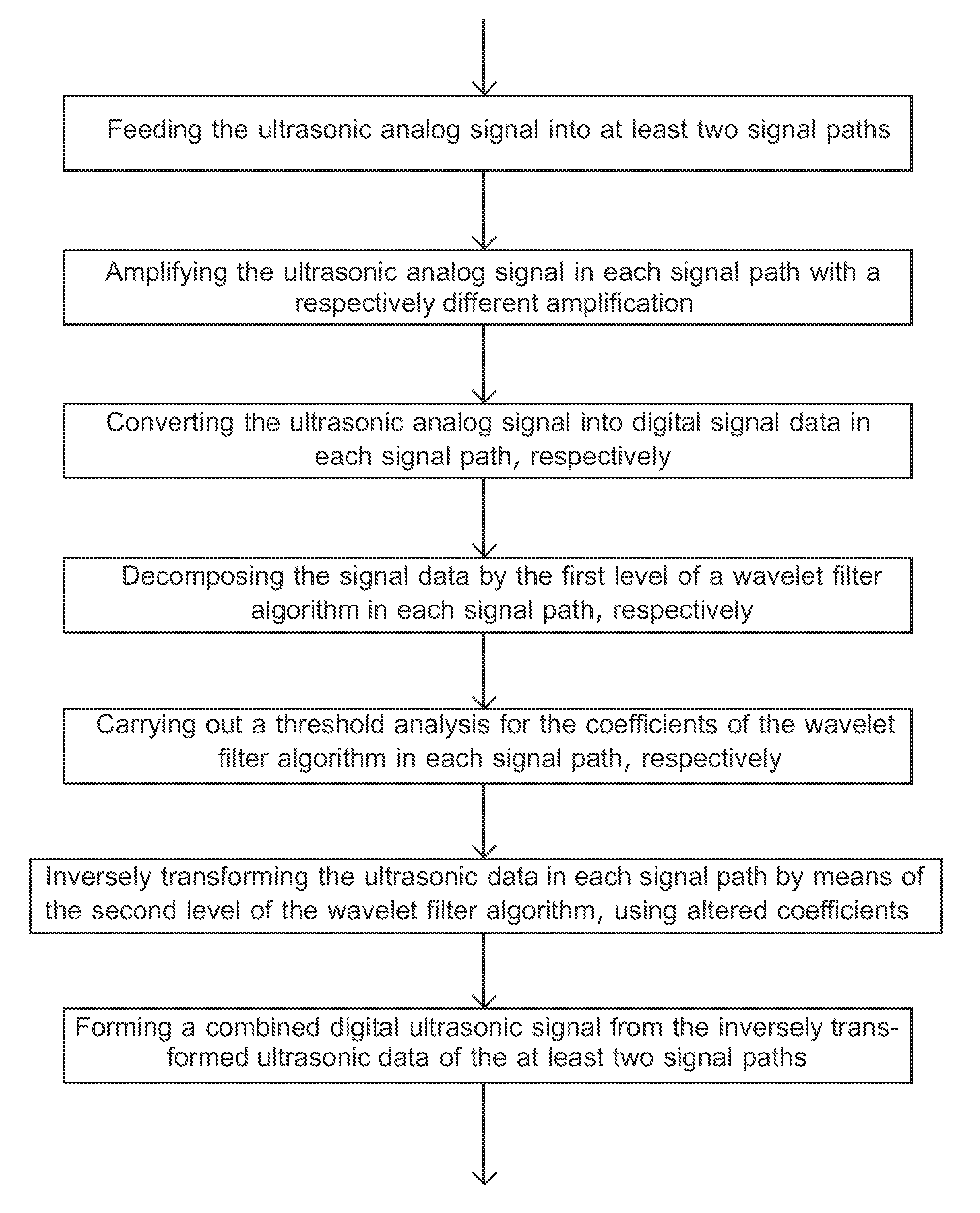

[0049]These main steps of the method according to the present invention for processing an ultrasonic analog signal and their order are also shown in the flow chart of FIG. 4.

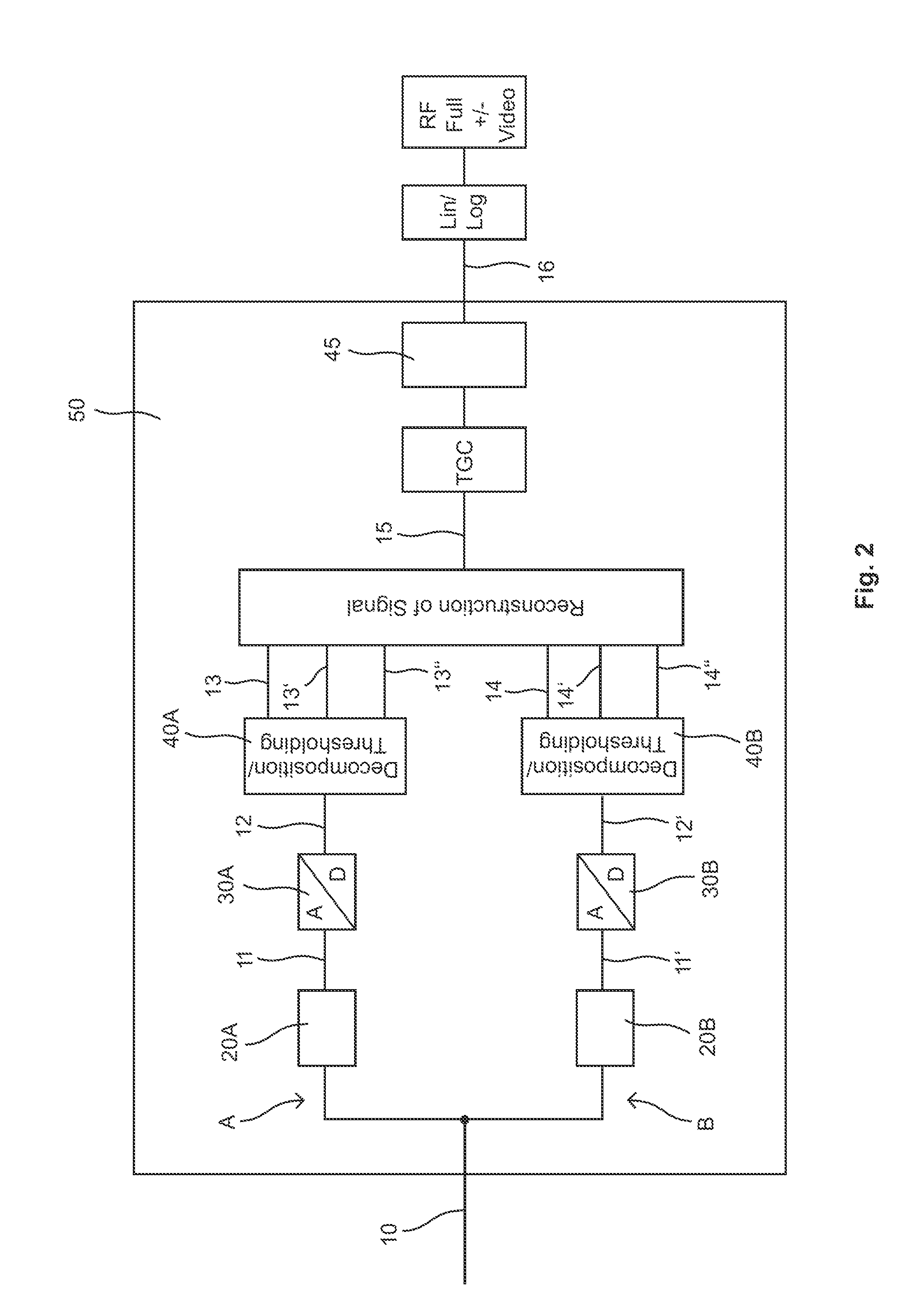

[0050]FIG. 5 shows a schematic representation of the mode of operation of the components of an inventive signal processing unit according to the second embodiment of the present invention. This corresponds completely to the first embodiment of the present invention shown in FIG. 2, with the exception of the differences described below. In the two signal paths A and B, three signal data 13, 13′, 13″ and 14, 14′, 14″, two of which, however, are immediately set to zero for the purpose of reducing the DC offset, are generated for each signal path by separate decomposition and threshold analysis from the digitized signals 12, 12′. Thus, two signal data 13′ and 13″, respectively, as well as 14′ and 14″, respectively, result in each case for the two signal paths, which are separately inversely transformed in each signa...

second embodiment

[0051]The main steps of the method according to an embodiment of the present invention for processing an ultrasonic analog signal and their order are also shown in the flow chart of FIG. 6.

[0052]The digital ultrasonic signal 15 obtained in this manner can then be subjected to further processing steps in both embodiments of the present invention. For example, a time gain compression (TGC) can take place and the signal can be supplied to another band-pass filter 45. Shrinkable coefficients and individually selectable wavelets can be used for the band-pass filter. Moreover, the wavelet coefficients are subjected to a threshold analysis also in this case.

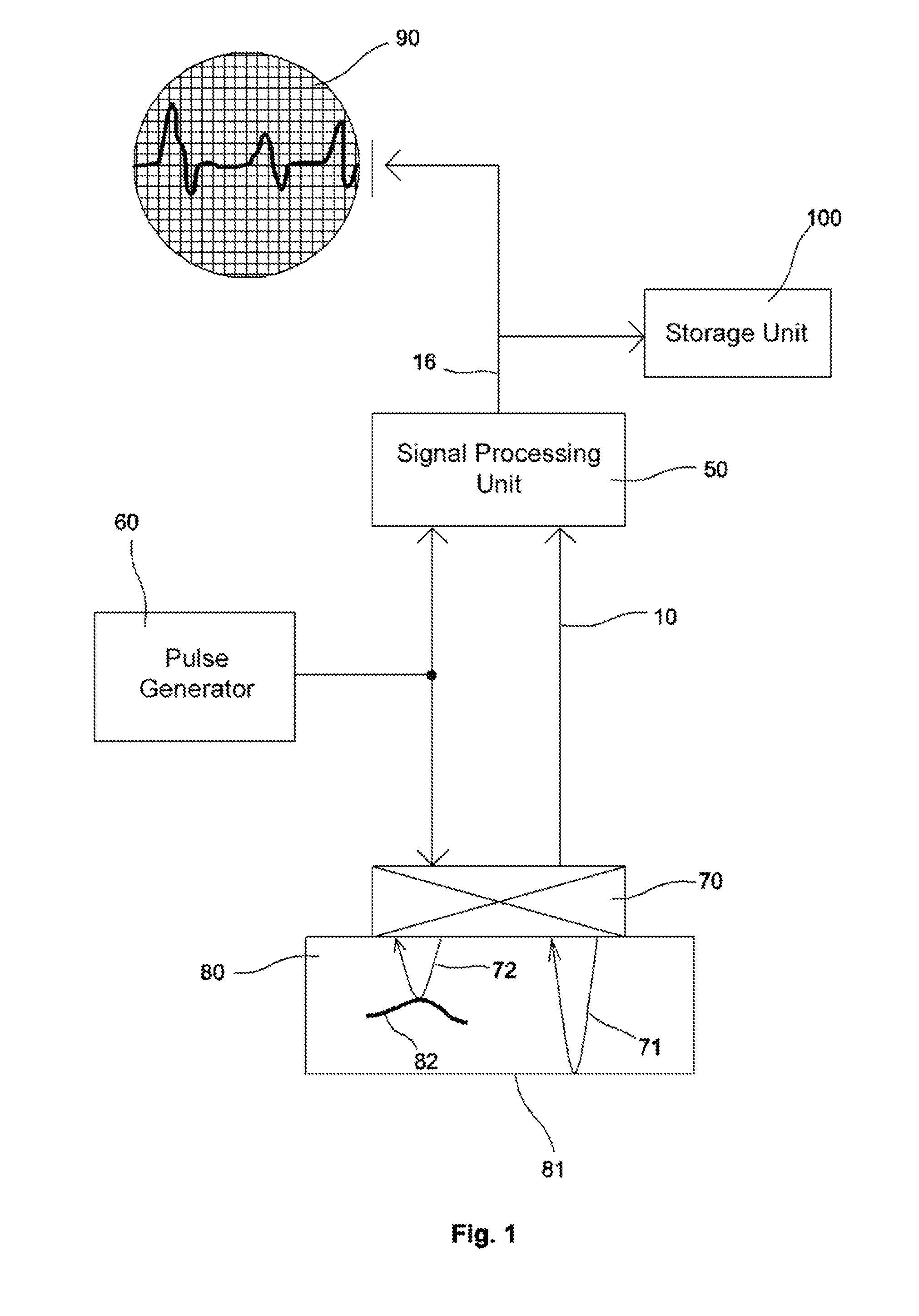

[0053]Following this signal processing, the generated output signal 16 can be displayed on a display 90, such as an oscilloscope, and / or stored in a storage unit 100. Due to the completed compensation of the direct-current offset, the ratio S / N of wanted signals to unwanted signals is increased as compared with solutions without any com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| direct-current | aaaaa | aaaaa |

| ultrasonic | aaaaa | aaaaa |

| threshold analysis | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com