Multy-membered heating radiator

A heater and multi-stage technology, applied in the field of a multi-stage heater, can solve the problems of internal leakage, failure to ensure that the flow of heat-carrying medium is only controlled by the built-in valve, and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

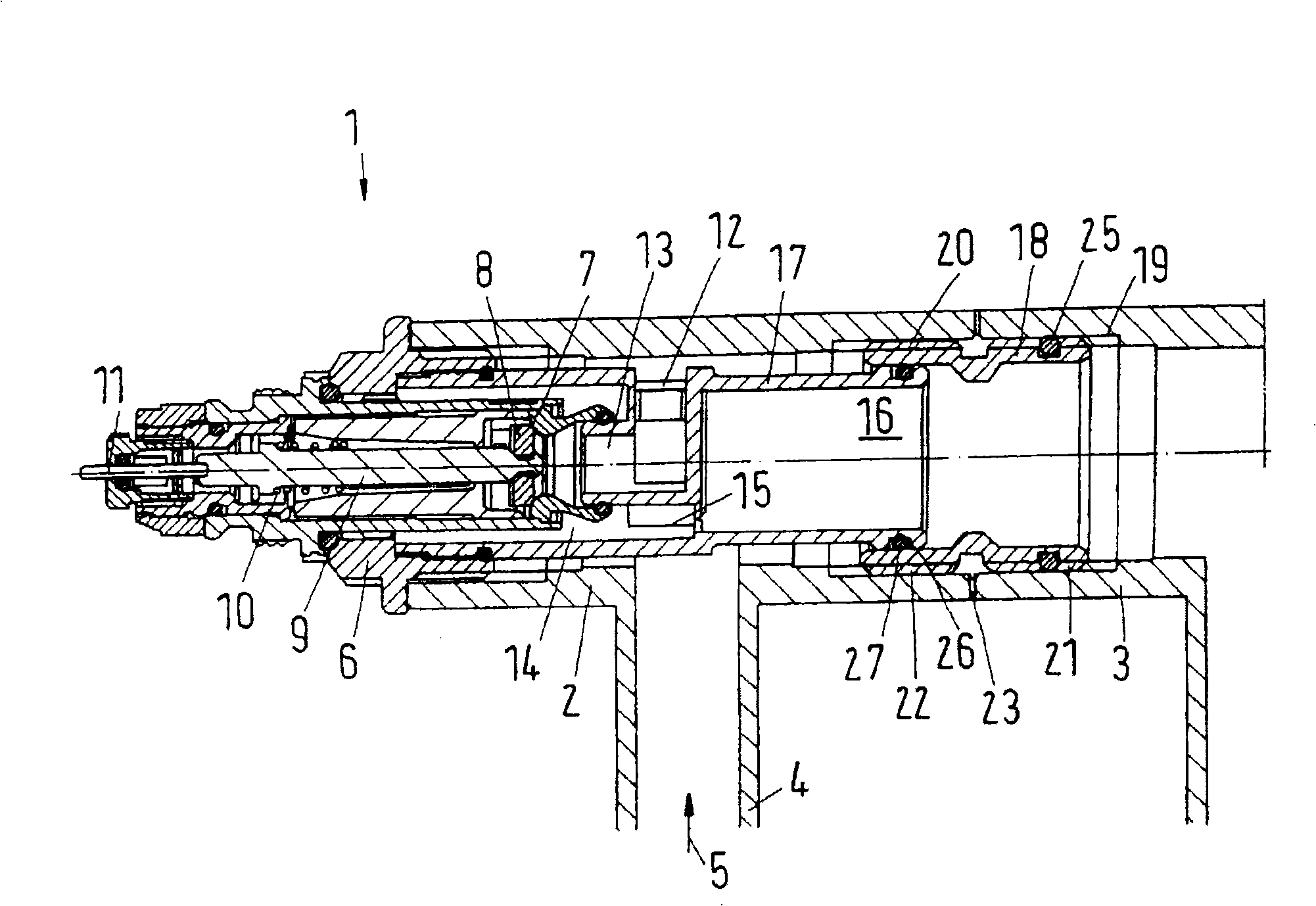

[0023] The multi-section heater 1 has a first section 2 and a second section 3 . Further segments can be connected to the second segment 3 in a well-known manner not shown in detail,

[0024] The first section 2 serves as a pressure duct through which a heat transfer medium, for example hot water, flows in the direction of the arrow 5 .

[0025] In order to control the heat transfer medium, an integral valve 6 is screwed into the first section 2 . The built-in valve 6 has a valve seat 7 with which a valve part 8 cooperates. The valve element 8 is fastened to a push rod 9 which is biased away from the valve seat 7 by an opening spring 10 . The push rod 9 is actuated by an actuating pin 11 , usually acting on a thermostat valve cover (not shown in detail), in such a way that it presses the valve part 8 again in the direction of the valve seat 7 . Therefore, the distance between the valve element 8 and the valve seat 7 determines the volumetric flow rate of the heat transfer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com