High-stability water-soluble coenzyme Q10 inclusion compound and preparation method thereof

A water-soluble, clathrate technology, applied in the chemical field, can solve the problems of reducing the stability of CoQ10 clathrates, without further consideration of the instability of CoQ10 clathrates, the limitation of CoQ10 clathrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

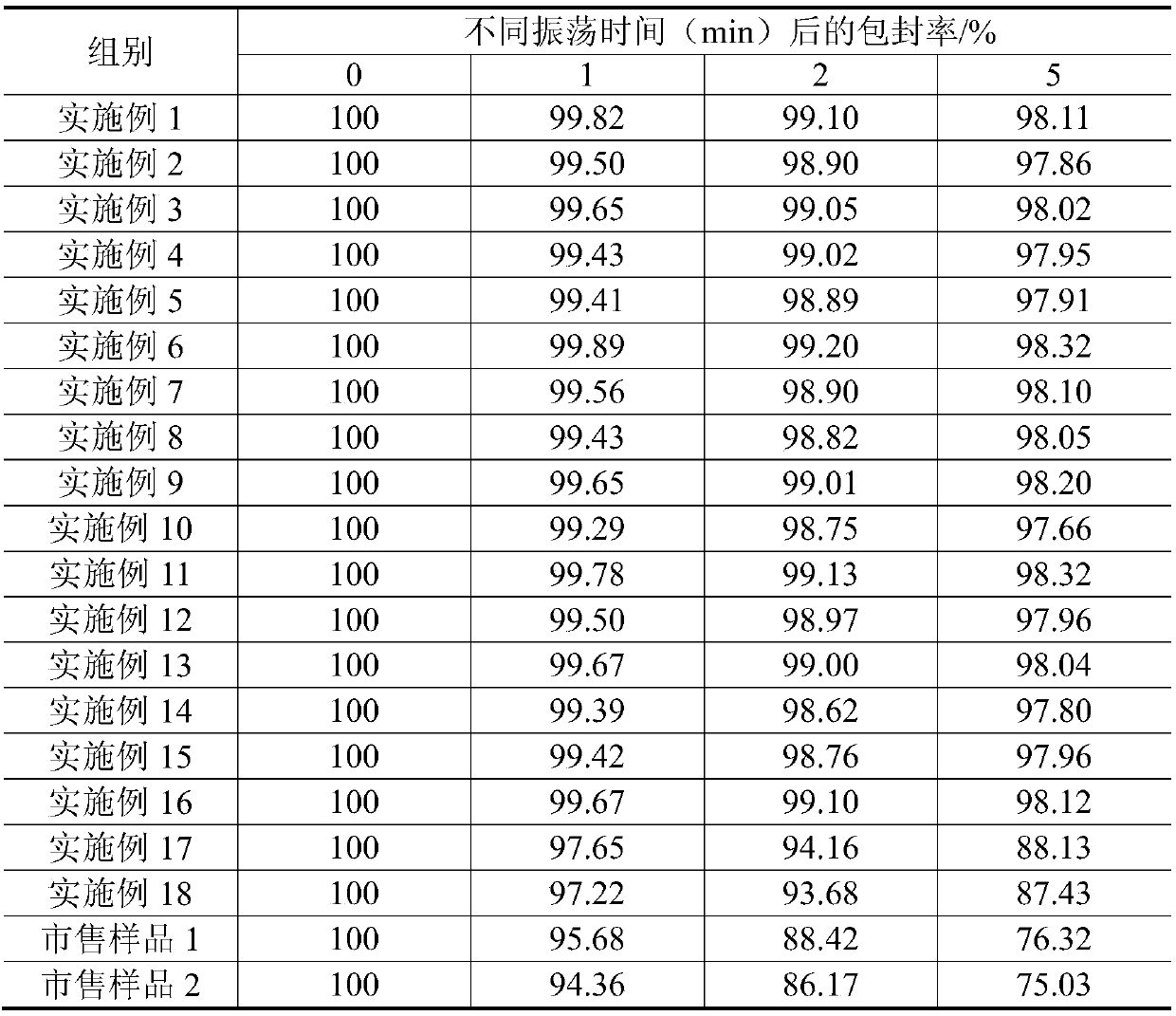

Examples

Embodiment 1

[0046] Embodiment 1, preparation water-soluble coenzyme Q10 clathrate

[0047] The preparation method of water-soluble coenzyme Q10 clathrate comprises the following steps:

[0048] (1) Add 95g of maltodextrin and 0.5g of Tween 80 into 475g of water, heat to 55°C, add 1g of coenzyme Q10, shear at 3000r / min for 15min at high speed, and then use 600bar high pressure in a high pressure homogenizer Homogenize 3 times, discharge, and obtain homogeneous material.

[0049] (2), add 6g of low molecular weight chitosan to the homogeneous material of step (1), after stirring and dissolving, obtain the aqueous solution of water-soluble coenzyme Q10 clathrate.

[0050] (3) Heat the water-soluble coenzyme Q10 clathrate aqueous solution in step (2) to 35°C, add 0.0475g of cross-linking agent N,N-methylenebisacrylamide, stir for 3 hours, filter, and pass through the low-pressure Spray drying to obtain the highly stable water-soluble coenzyme Q10 inclusion compound of this embodiment.

[0...

Embodiment 2

[0052] Embodiment 2, preparation water-soluble coenzyme Q10 clathrate

[0053] The preparation method of water-soluble coenzyme Q10 clathrate comprises the following steps:

[0054] (1) Add 55g of oxidized starch and 2g of Span 20 into 550g of water, heat to 70°C, add 40g of coenzyme Q10, shear at a high speed of 7000r / min for 25min, and then homogenize in a high-pressure homogenizer at 1200bar 8 times, discharge to obtain homogeneous material.

[0055] (2) Add 3 g of low molecular weight chitosan to the homogeneous material in step (1), stir and dissolve to obtain a water-soluble coenzyme Q10 clathrate aqueous solution.

[0056] (3) Heat the water-soluble coenzyme Q10 clathrate aqueous solution in step (2) to 55° C., add 0.0055 g of cross-linking agent glutaraldehyde, stir and react for 6 hours, filter, and freeze-dry to obtain the present embodiment Water-soluble coenzyme Q10 inclusion complex.

[0057] Wherein, the addition amount of the cross-linking agent is 0.01% of t...

Embodiment 3

[0058] Example 3, preparation of water-soluble coenzyme Q10 inclusion compound

[0059] The preparation method of water-soluble coenzyme Q10 clathrate comprises the following steps:

[0060] (1) Add 80g of β-cyclodextrin and 1.0g of Tween 20 into 600g of water, heat to 60°C, add 20g of coenzyme Q10, shear at 1000r / min for 50min at high speed, and then heat it in a high-pressure homogenizer at 1000bar Homogenize under high pressure for 5 times, discharge to obtain homogeneous material.

[0061] (2), add 4.5g low molecular weight chitosan to the homogeneous material of step (1), after stirring and dissolving, obtain the aqueous solution of water-soluble coenzyme Q10 clathrate.

[0062] (2) Heat the water-soluble coenzyme Q10 clathrate aqueous solution in step (1) to 45°C, add 0.024g of cross-linking agent sodium trimetaphosphate, stir and react for 5 hours, filter, and spray dry under low pressure to obtain this example Water-soluble coenzyme Q10 inclusion complex.

[0063] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com