Apparatus and method for monitoring epoxy resin base gel preparation course by ultrasonic wave

A preparation process, epoxy resin technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as ultrasonic monitoring applications that have not been seen

Inactive Publication Date: 2009-01-21

NINGBO UNIV

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, there is no application of ultrasonic monitor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

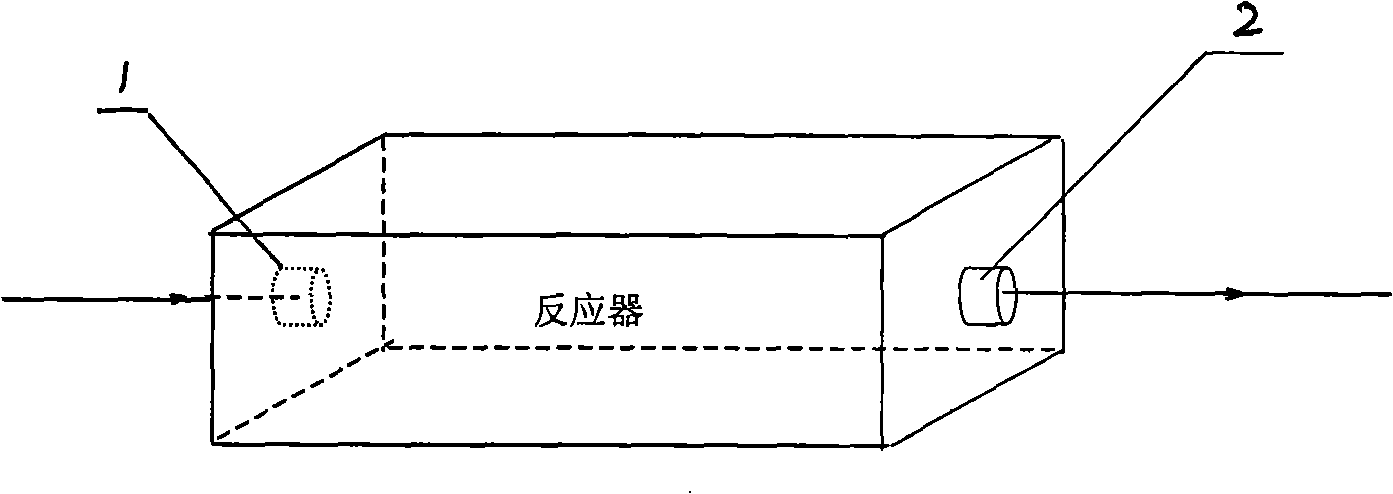

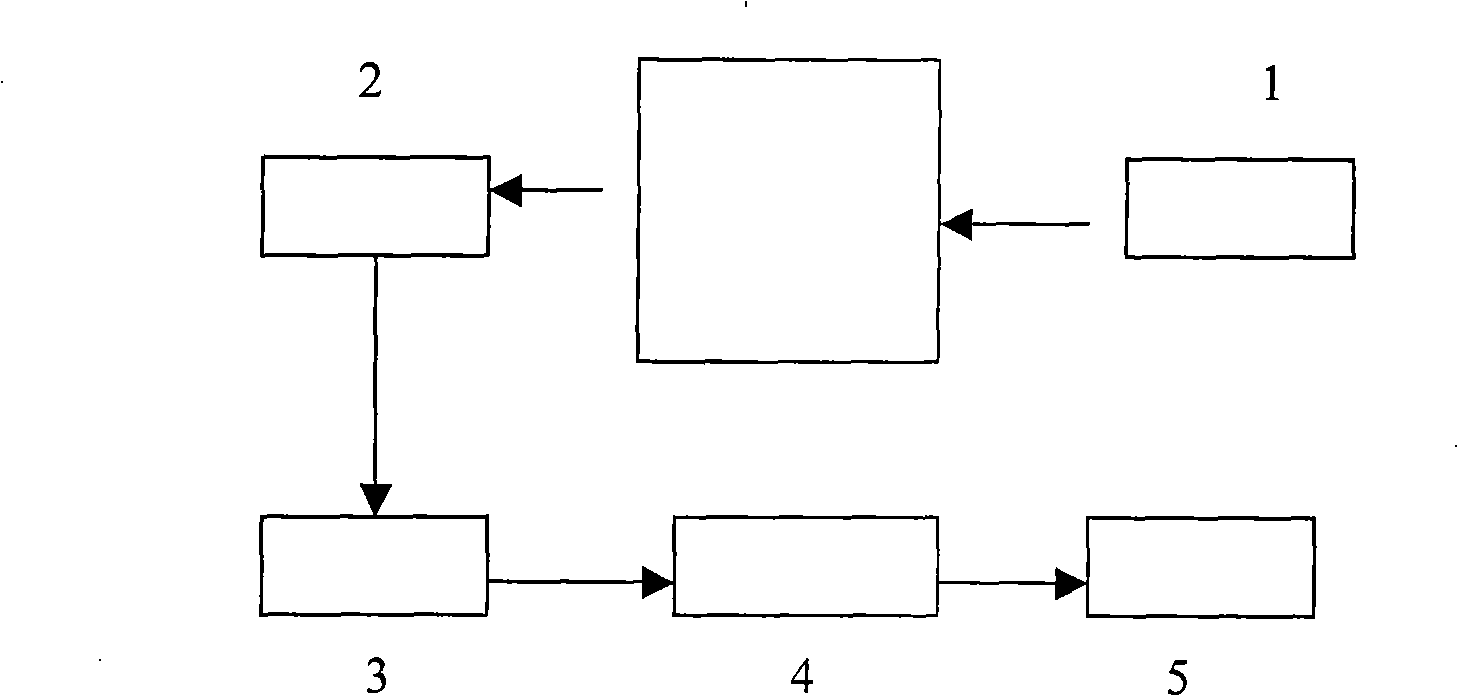

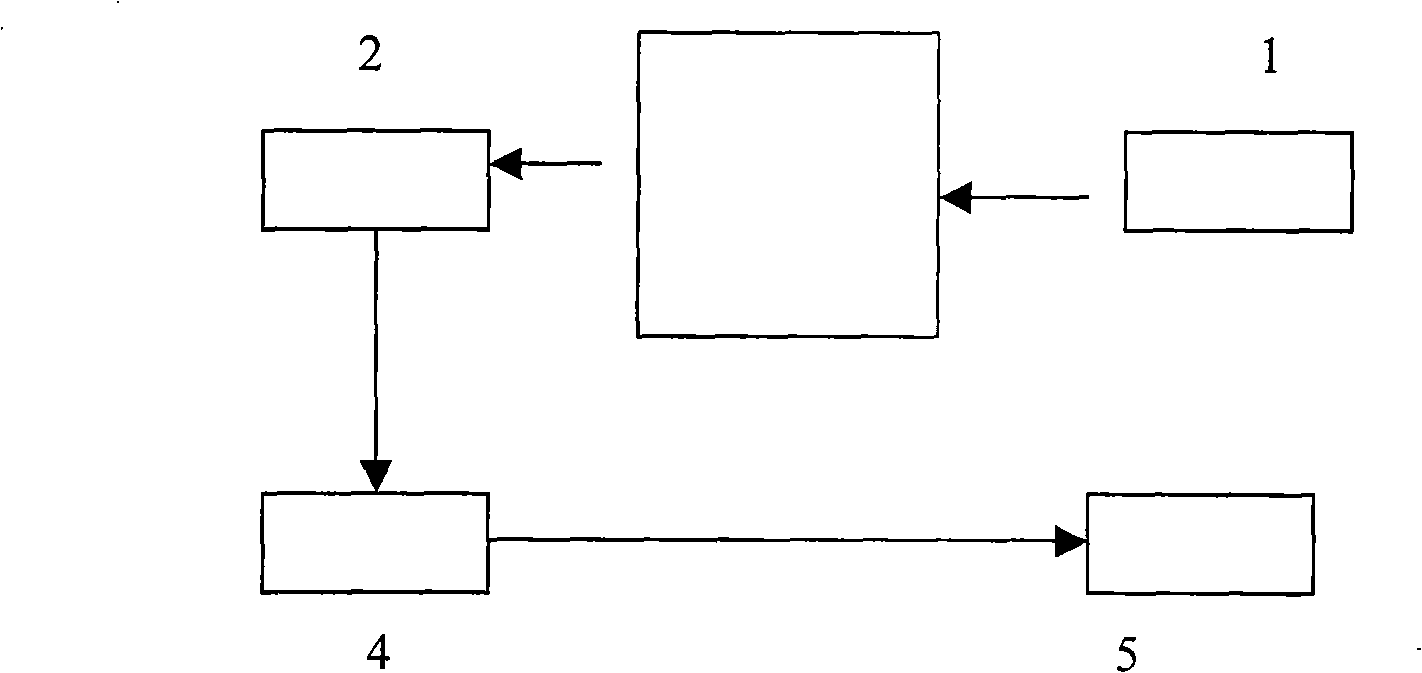

The invention relates to a device and a method for monitoring ultrasonic wave in the process of preparing epoxy resin based gelatin, wherein the device comprises an ultrasonic wave emission source, an ultrasonic wave emitting and receiving device, a power magnification device, a signal collecting device and a signal processing device which are arranged on a reactor for preparing gelatin, and the method comprises emitting and receiving ultrasonic wave signals which pass through a gelatin reactor, choosing the combined parameter of frequency f, amplitude A, energy E and sonic velocity sonic velocity V of ultrasonic wave signals to be an ultrasonic wave characteristic value, analyzing the gelatin generation process, the phase separating point forming process and the reaction degree in the process of preparing gelatin according to the variation of the characteristic value, and controlling the phase separating point according to the analysis results, thereby solving the problem that the phase separating point is difficult to control in the process of preparing epoxy resin based gelatin.

Description

technical field [0001] The invention relates to an ultrasonic monitoring device and related monitoring method in the preparation process of epoxy resin-based gel, which can be used for ultrasonic monitoring in the preparation process of polymer gel porous materials, and especially relates to epoxy resin-based micro / nanoporous gels. Sonic monitoring of phase separation points during glue preparation. Background technique [0002] In recent years, the preparation technology of polymer microporous materials has been greatly developed, and a variety of molding processes and methods that can produce microscopic holes in the polymer matrix have been developed, such as phase separation method, stretching method, nuclear track method, Sintering method, thermal decomposition method, suspension polymerization method, macromolecular structure template method, colloidal crystal template method, micro-foaming technology, etc. The materials prepared by these methods are very important in ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N29/04C08L63/00C08J3/075C08G59/50

Inventor 侯琳熙王邃干宁

Owner NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com