Sound wave detecting method for catalyzer coke content in reactor

A sonic detection and catalyst technology, which is applied in the direction of material analysis, instruments, and measuring devices using sound waves/ultrasonic waves/infrasonic waves. problem, to achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The sonic detection method of catalyst coke amount in the reactor comprises the following steps:

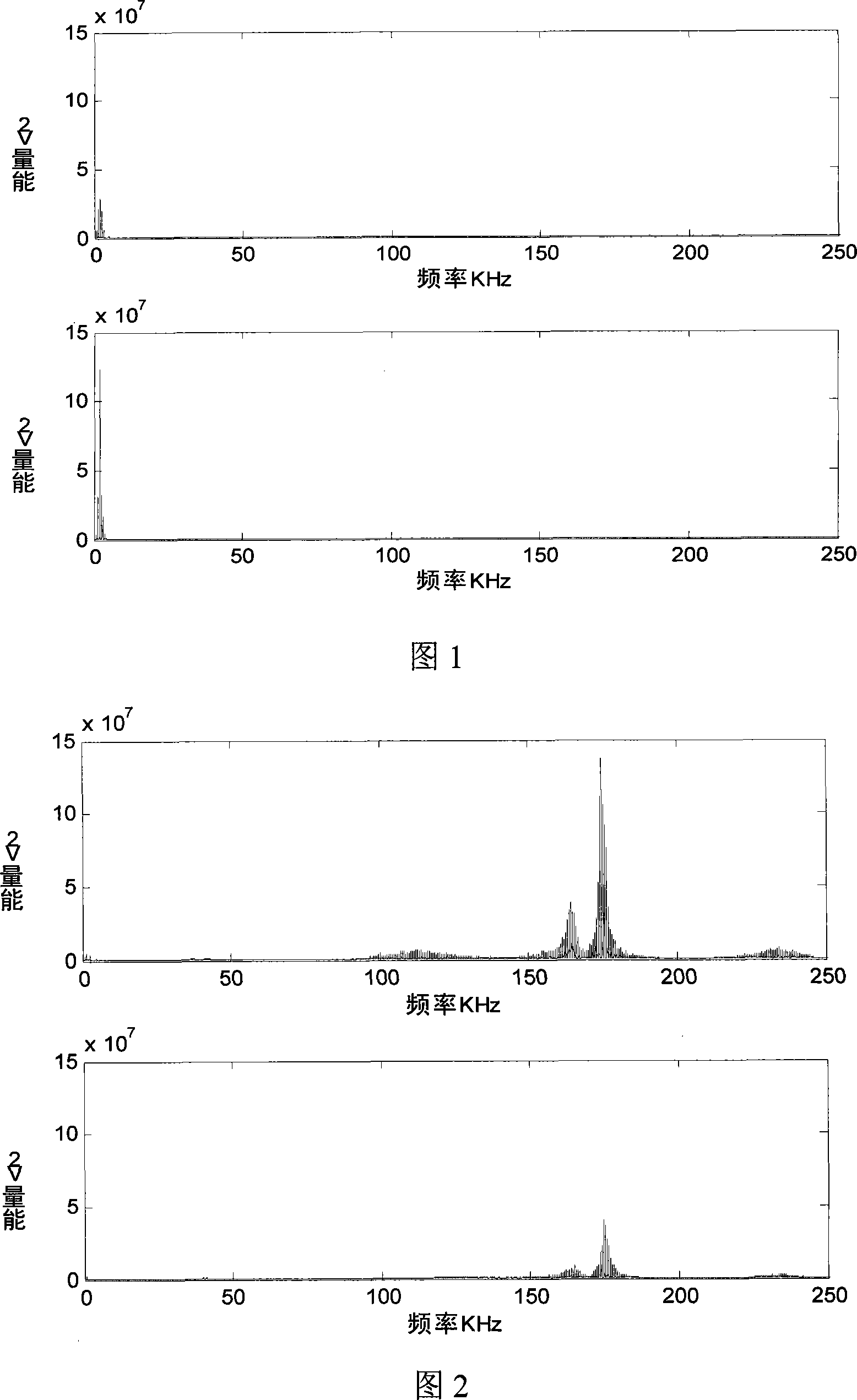

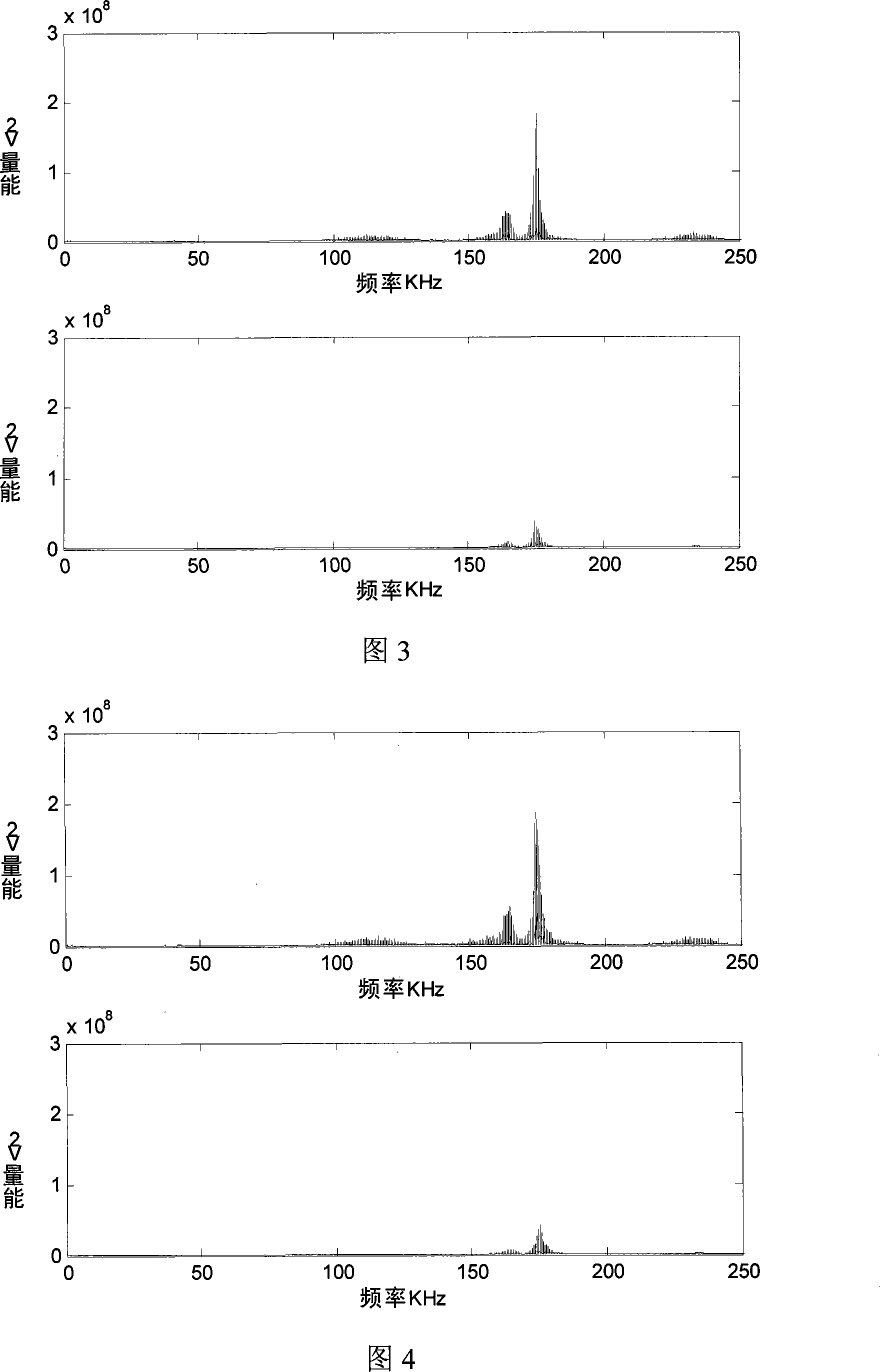

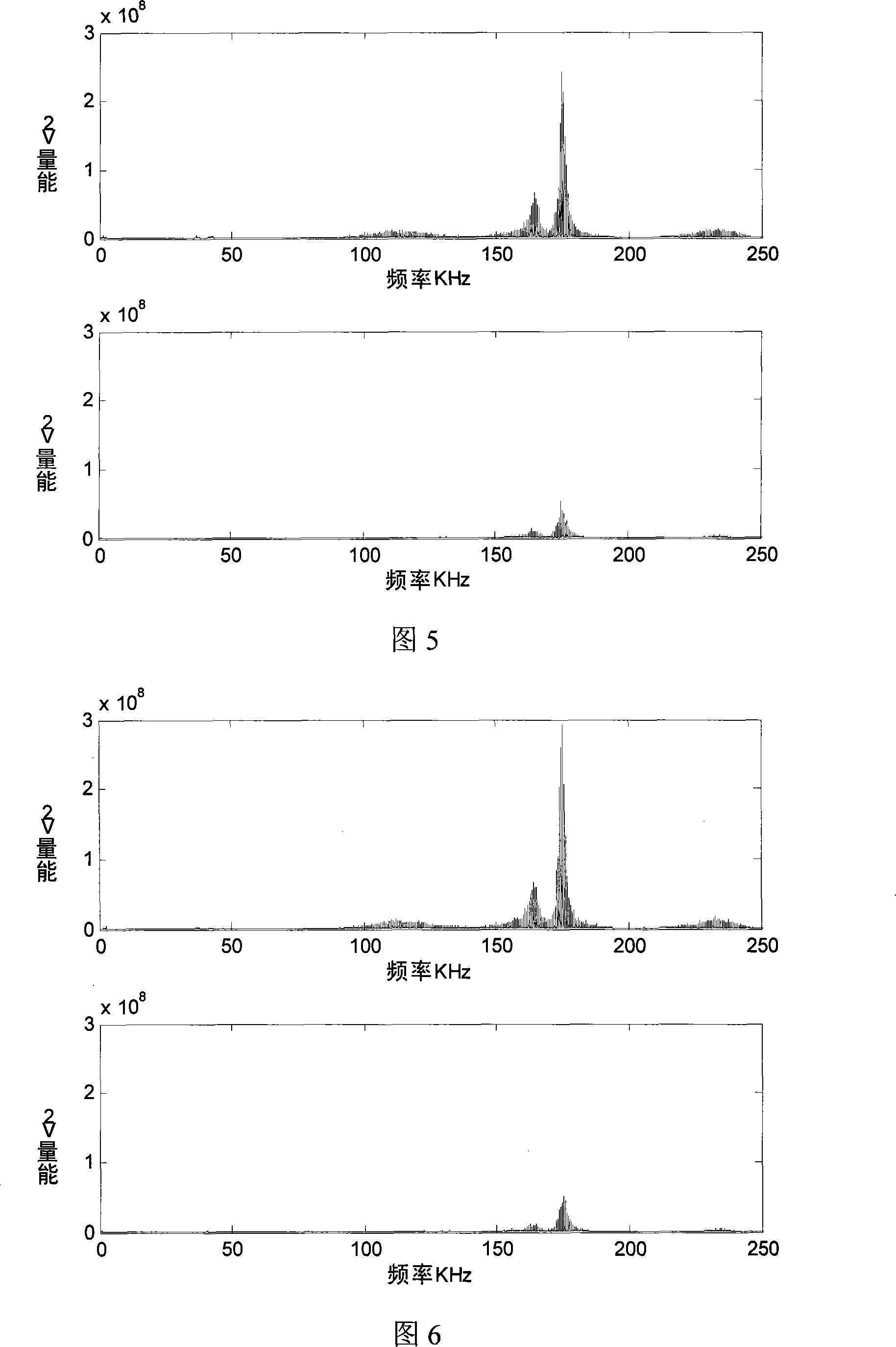

[0042] 1) Receive the acoustic emission signal generated by the catalyst inside the reactor or regenerator hitting the wall; the gas-solid circulation is made of plexiglass with a height of 1000mm, an inner diameter of 150mm, a distribution plate of 2.0mm in diameter, and an opening rate of 2.6%. In the fluidized bed, air is used as the fluidizing gas, the superficial gas velocity v=0.057, 0.071, 0.085, 0.099, 0.13m / s, and the passive acoustic emission transducer is attached 25mm above the distribution plate. Under the above conditions, the acoustic emission signals of the FCC fresh catalyst and the coked catalyst at the above gas velocities were respectively measured. The acoustic emission signal frequency is 0Hz-20MHz. The frequency of the acoustic emission signal is preferably 0 Hz-1 MHz. Acoustic signals of fresh FCC catalysts at the above-mentioned gas velocities we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com