Composite current sensor for XLPE power cable in switch cabinet

A composite current and power cable technology, applied in the direction of only measuring current, measuring current/voltage, instruments, etc., can solve the problem of unreserved installation position of high-frequency current sensor, avoid power outages and major accidents, easy installation, monitoring responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

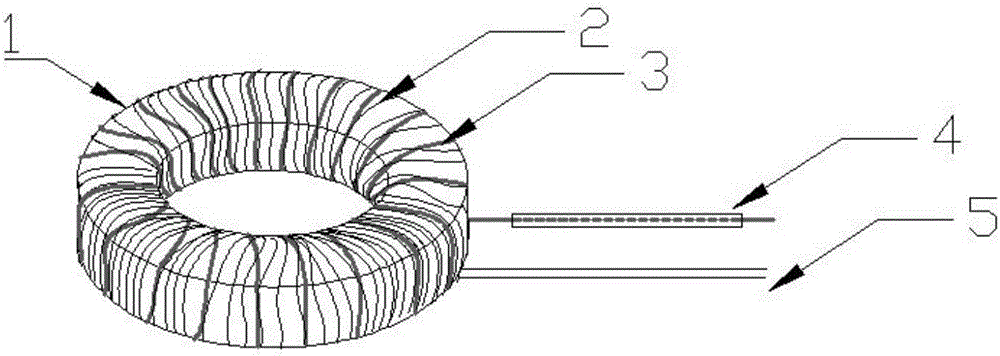

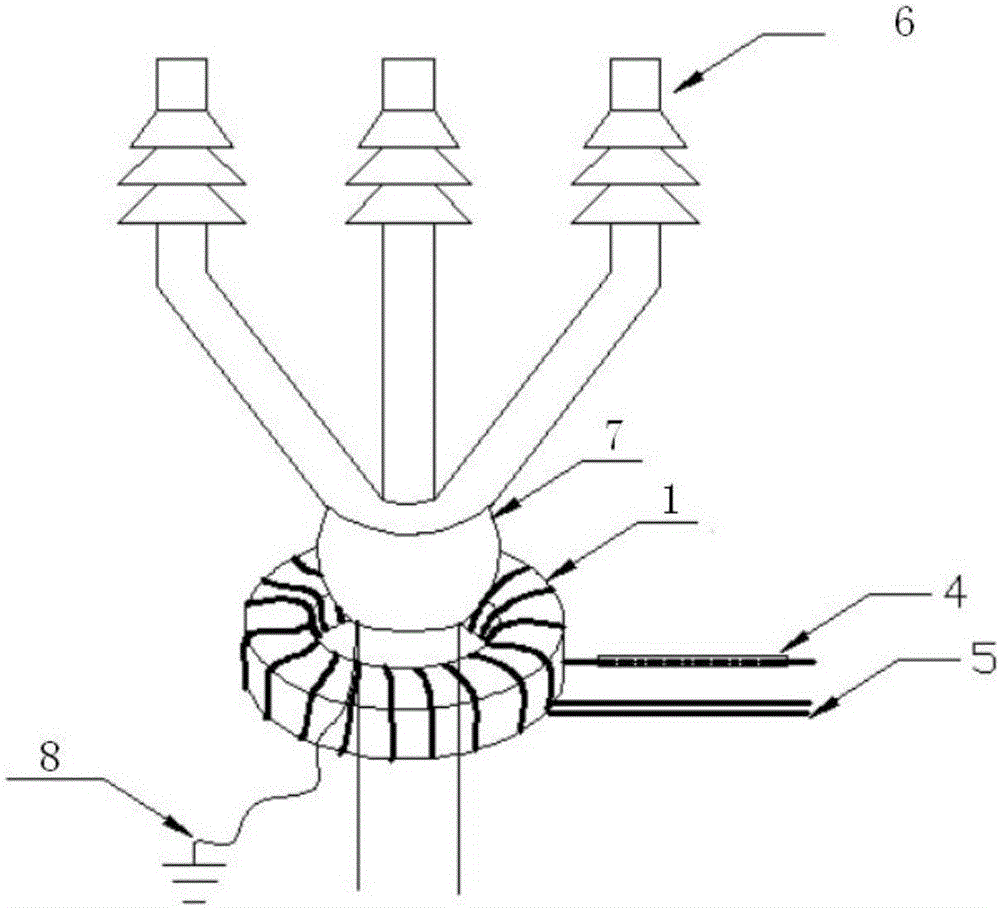

[0022] In this composite current sensor, the ferrite core 1 is used as the core of the composite current sensor. On the core, a high-frequency current transformer coil 3 with a small number of turns and a thick wire diameter is wound first. After the coil is wound, The coil is led out with a coaxial cable 4, and a zero-sequence current transformer coil 2 with a large number of turns and a thin wire diameter is wound outside the coil. After winding, it is led out with an ordinary wire 5. Finally, pour the composite current transformer with epoxy resin. Protect the coil inside the transformer. The lead-out line of the zero-sequence current transformer is the secondary line of the zero-sequence current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com