Operation apparatus for three-position switch

An operating device and three-position technology, which is applied in the direction of electric switches, contact operating parts, high-voltage/high-current switches, etc., to achieve the effect of simple switching operation and labor-saving maintenance operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

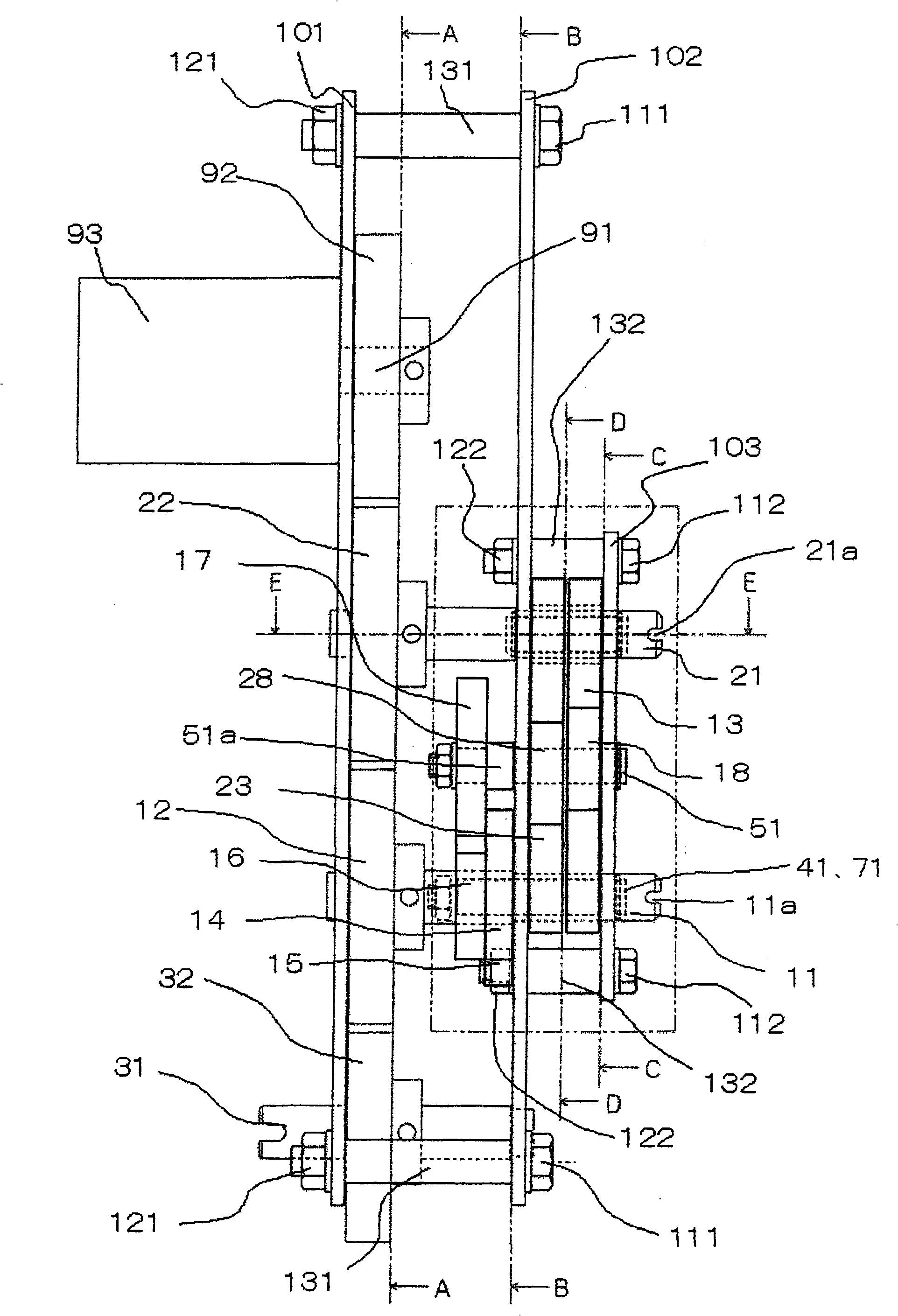

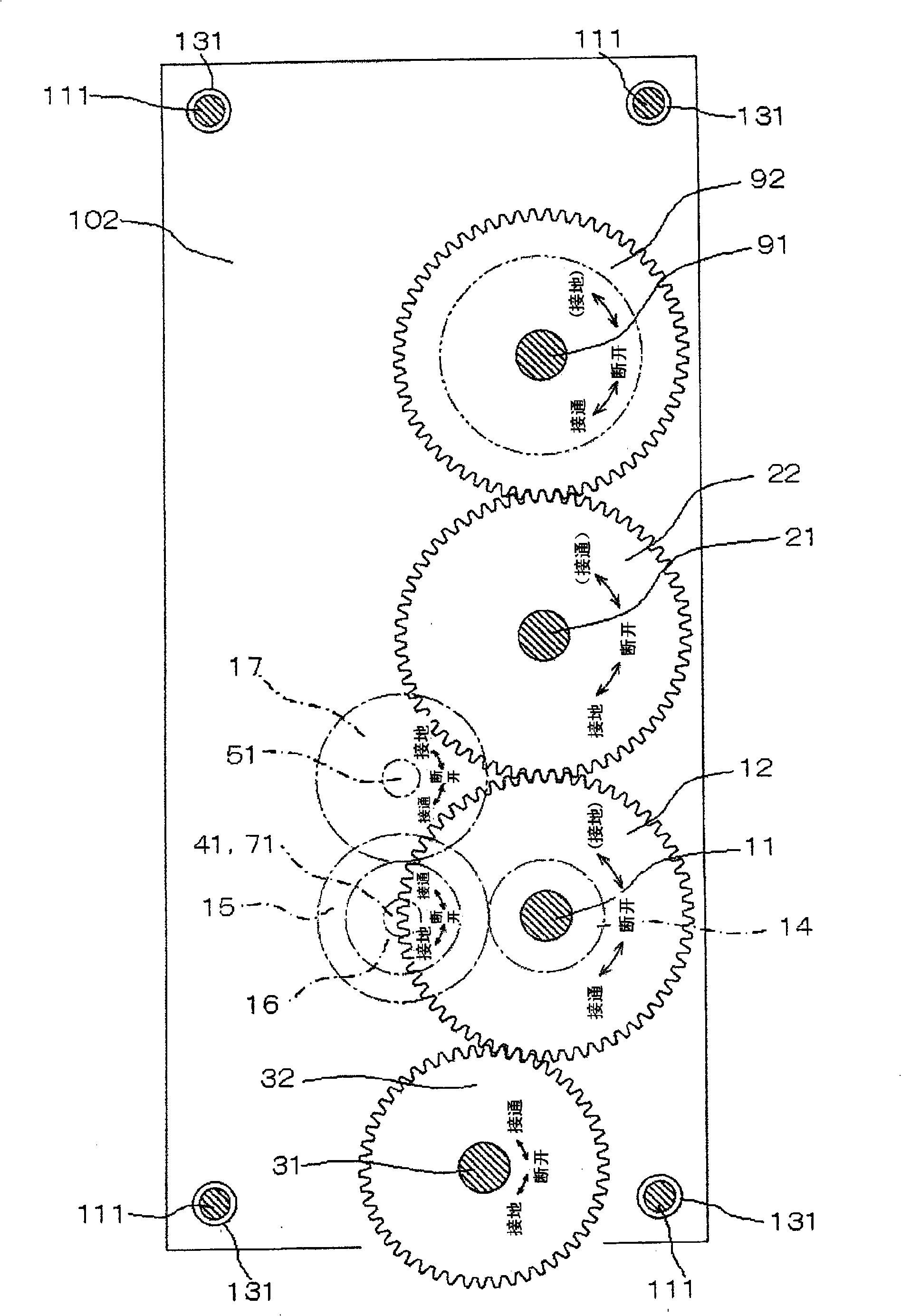

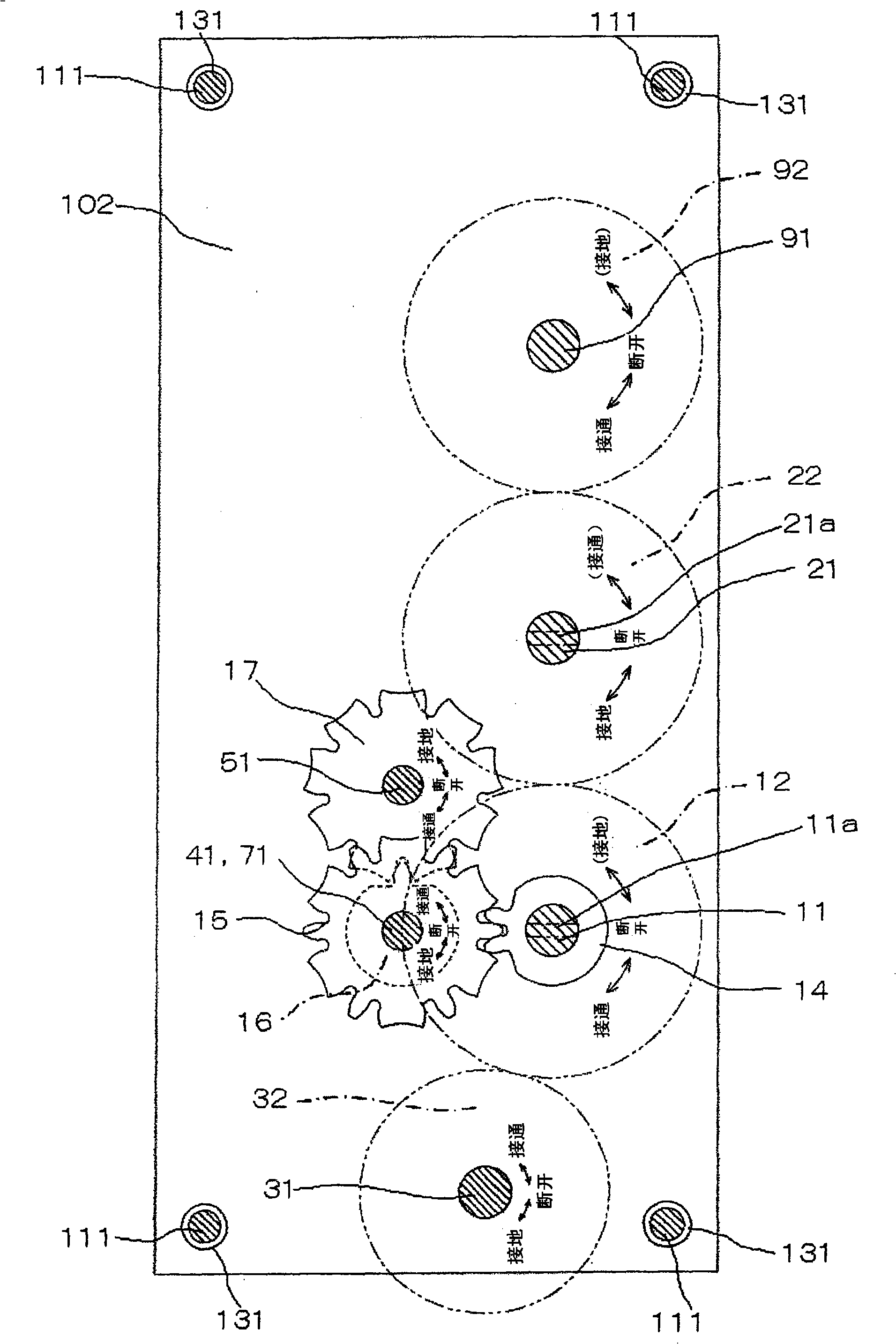

[0046] Hereinafter, Embodiment 1 of the present invention will be described in detail based on the drawings. figure 1 It is a side view showing a schematic configuration of the operating device for a three-position switch of the present invention. figure 2 yes figure 1 The A-A section diagram, image 3 yes figure 1 The B-B section diagram, Figure 4 yes figure 1 The E-E profile, Figure 5 is a side view showing the operating handle, Image 6 yes means figure 1 The C-C sectional view of the "disconnected" position in the middle, Figure 7 yes means figure 1 C-C sectional view of switching operation between "OFF" and "ON" positions in Figure 8 yes means figure 1 The C-C cross-sectional view of the "on" position in the middle, Figure 9 yes means figure 1 The D-D cross-sectional view of the "disconnected" position in the middle, Figure 10 yes means figure 1 D-D sectional view of switching operation between "disconnected" and "grounded" positions in Figure 11 ye...

Embodiment approach 2

[0089] Such as Figure 12 As shown, an engaging member 80 is embedded on the second operating shaft 21, and the engaging member 80 can slide freely between positions engaged with the first hook 13 and the second hook 23 along the axial direction. , and rotate integrally with the second operating shaft 21, in the state where the operating handle 84 is not connected to the second operating shaft 21, it is moved to a position where it can be engaged with the first hook 13 due to the action of the coil spring 83, And since the operating handle 84 is connected to the second operating shaft 21 and moves to a position where it can be engaged with the second hook 23 , the difference from the first embodiment is that there is no electromagnetic solenoid 81 .

[0090] The opening and closing operation between the "OFF" position and the "ON" position by remote operation in the above configuration will be described below. At this time, in the state where the operating handle 84 is not co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com