Cylinder material mixing device

A mixer and cylinder technology, applied in the direction of mixers, mixers with rotating containers, dissolution, etc., can solve the problems of increased length, high power consumption of motors, high energy consumption of equipment, etc., to achieve increased stability, enhanced rigidity, The effect of reducing motor power and equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

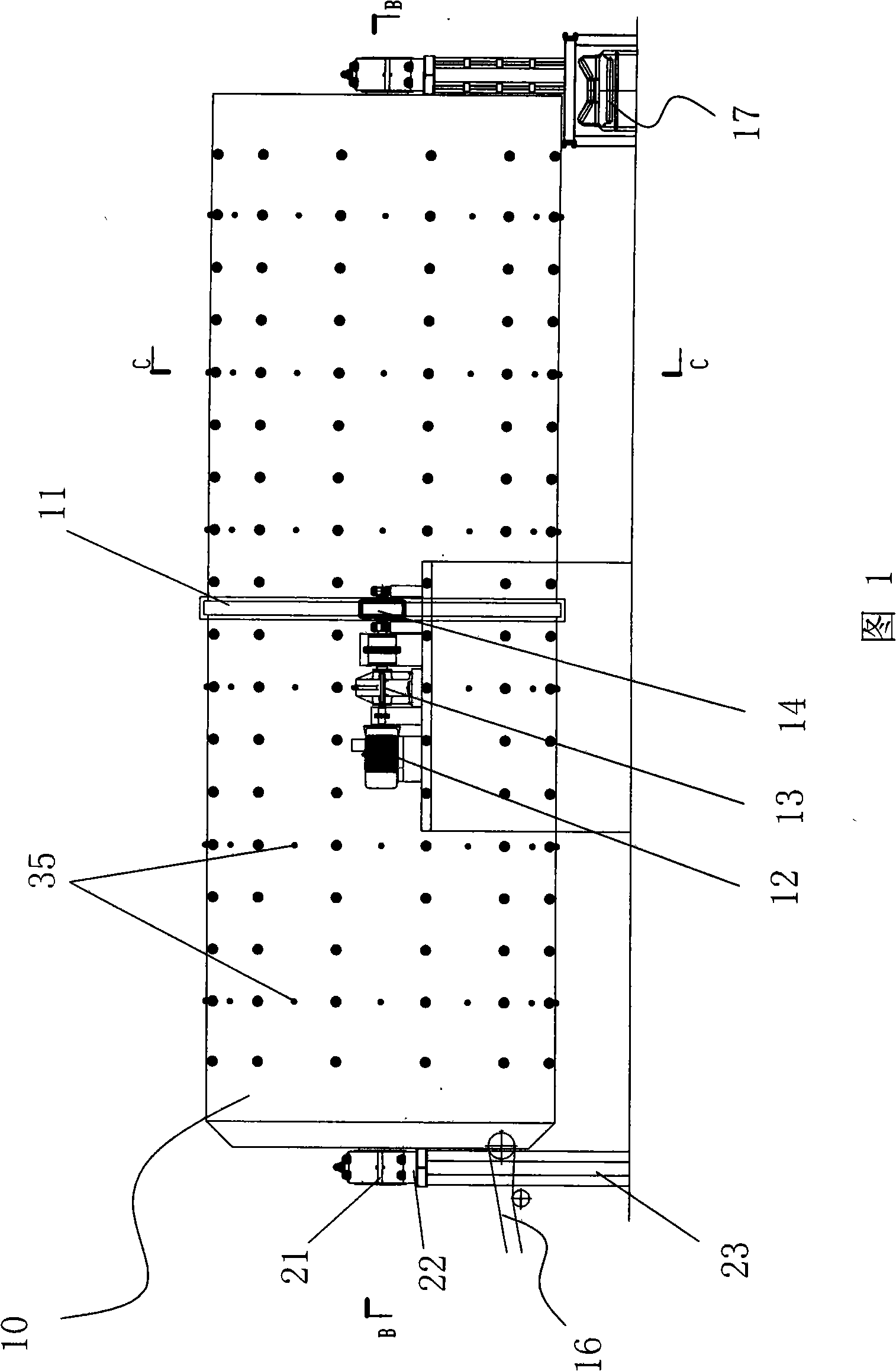

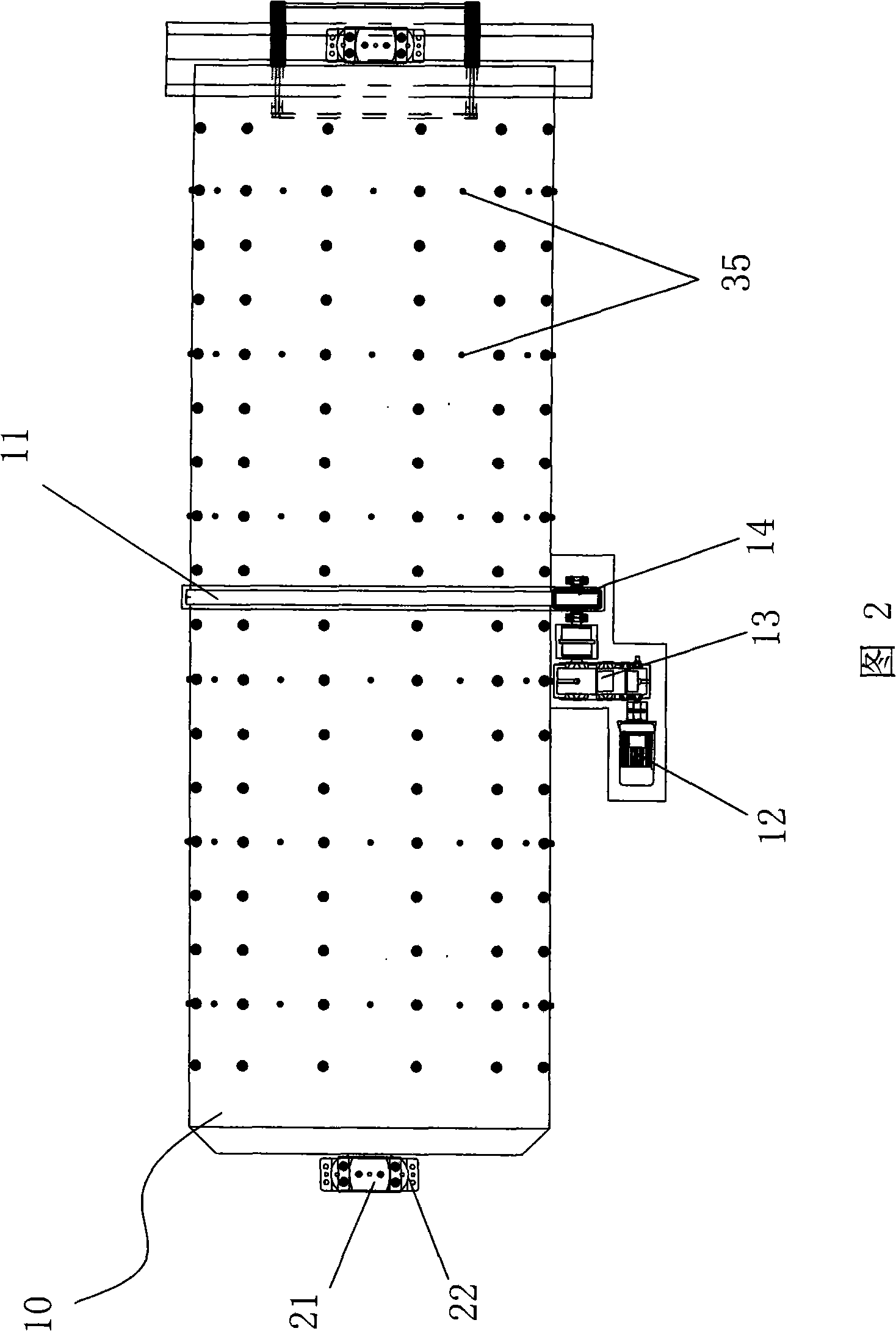

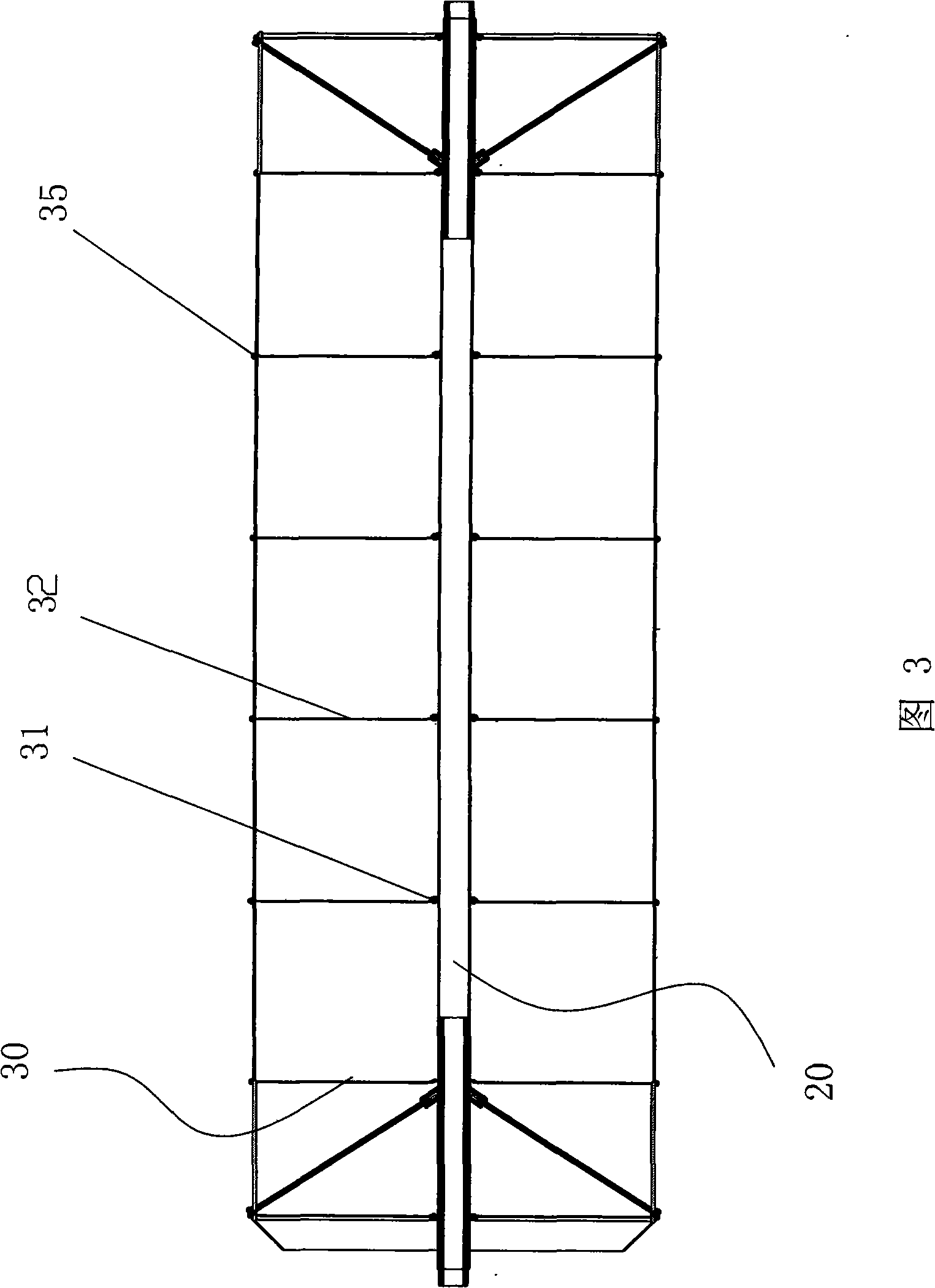

[0020] As shown in Figure 1, Figure 2, Figure 3, Figure 4 As shown, the embodiment of the cylindrical mixer provided by the present invention includes a cylinder 10 with openings at both ends, a ring gear 11 is hooped on the outer peripheral surface of the middle part of the cylinder 10, and a motor 12 arranged outside the cylinder 10 is passed through a deceleration The machine 13 is connected with the transmission gear 14, and the transmission gear 14 cooperates with the ring gear 11 to drive the cylinder body 10 to rotate; the cylinder body 10 is provided with a feeding belt conveyor 16 and a discharge belt conveyor 17...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap