Bridge type pump reactor

A reactor and bridge-type technology, applied in the field of reactors, can solve the problems of not performing the reaction function well, and achieve the effect of improving manufacturing economy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

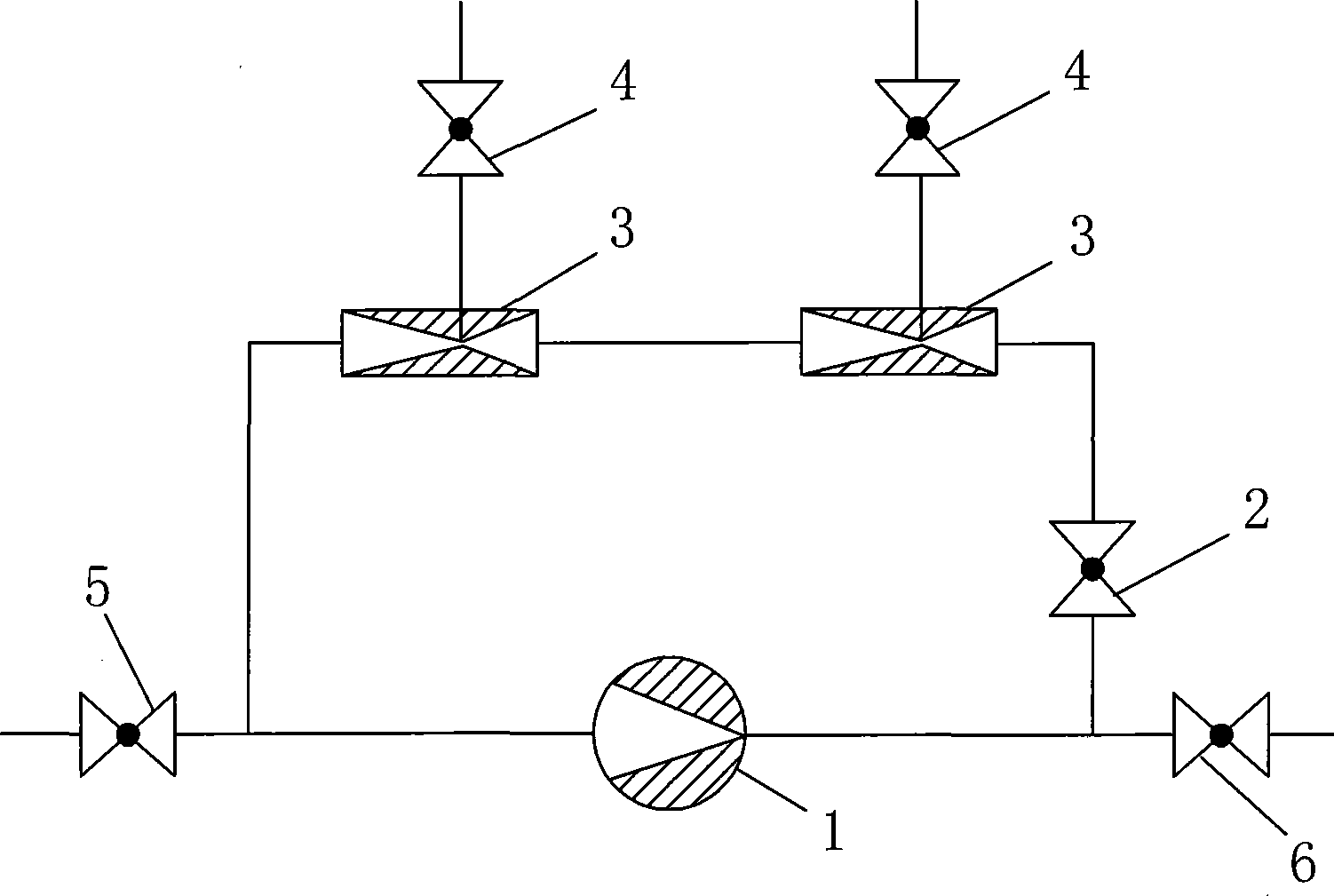

[0012] figure 1 It is a schematic flow diagram of the first preferred embodiment of the present invention. The bridge pump reactor includes a mechanical pump 1, and two jet pumps 3 are connected in series across the inlet and outlet ends of the mechanical pump 1 through pipes. Form a bridge recirculation. The outlet end of the mechanical pump is connected with a discharge port, and the negative pressure port of the jet pump is connected with the feed port. The outlet pipe of the mechanical pump is also provided with a reflux valve 2, and the discharge port is connected with a discharge valve 6. The reflux valve 2 and the discharge valve 6 are used to control the reflux and reaction intensity. The feed port of the jet pump 3 is connected with a feed valve 4 for controlling the feed ratio. The pipeline at the inlet of the mechanical pump 1 is also provided with an activation valve 5, which is used or not according to the type of mechanical pump selected, and the passage is cance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com