Nuclear fuel assembly guiding tube

A nuclear fuel assembly and fuel assembly technology, applied in nuclear engineering, nuclear power generation, nuclear reaction control, etc., can solve the problems of difficult rolling process of guide tubes, increase of buffer pipes and end plugs, failure of fuel assembly skeleton, etc., and achieve improvement Manufacturing economy, increased rigidity, and high manufacturing economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

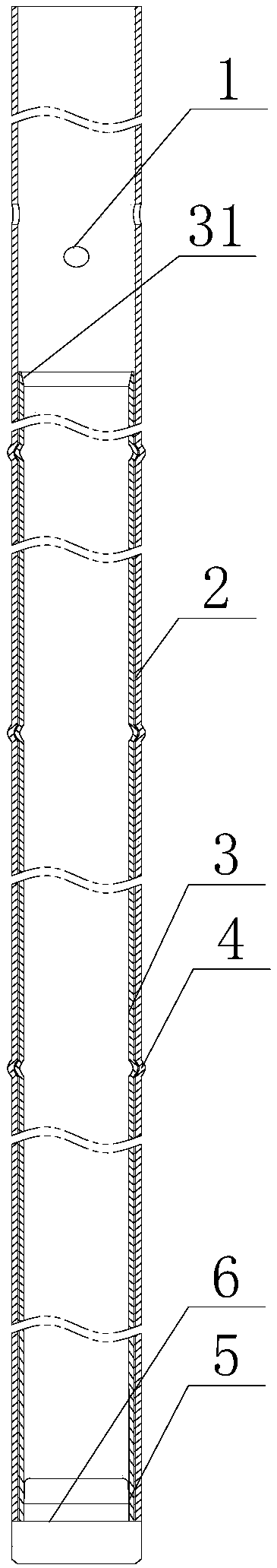

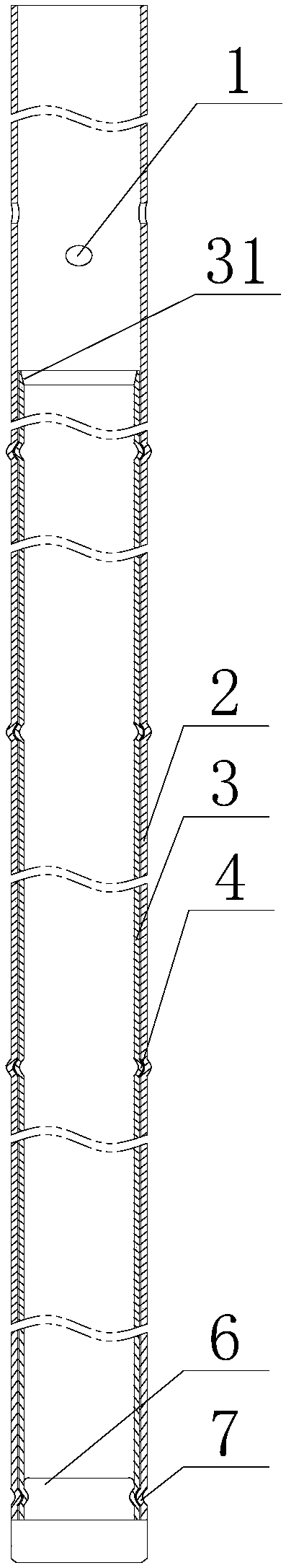

[0022] Such as Figure 1~2 As shown, this embodiment includes an outer tube 2 with both ends open, and an end plug 6 for sealing the lower end opening of the outer tube 2, at least one inner tube 3 is fixed on the inner peripheral wall of the outer tube 2, and the The lower end surface of the outer tube 2 is flush with the lower end surface of the inner tube 3 . In view of the complex structure of the guide tube in the prior art, the difficulty in positioning and matching after expansion, and the expansion part of the guide tube is prone to failure, which in turn leads to the failure of the skeleton of the entire fuel assembly. In this regard, the applicant abandoned the traditional guide tube design method , using a double-layer design of the outer tube 2 and the inner tube 3, and the lower end surface of the inner tube 3 is flush with the lower end surface of the outer tube 2 and then connected to the end plug 6, so as to meet the buffering effect required by the fuel assemb...

Embodiment 2

[0025] Such as Figure 1~2 As shown, in this embodiment, on the basis of Embodiment 1, the end plug 6 is fixed on the lower opening of the outer tube 2 by welding, and it is not limited to welding. Other fixing methods can be carried out according to specific conditions, as long as the end plug 6 is ensured. It only needs to be stably fixed at the opening of the lower end of the outer tube 2, that is, the connection point II5 is formed, and the outer tube 2 and the end plug 6 after welding or spinning form a complete composite guide tube, which consists of guide tube parts and grids, etc. Other components are assembled to obtain the fuel assembly skeleton, and expansion or welding failure only affects a single guide tube part, not the fuel assembly skeleton, which improves the manufacturing economy of the fuel assembly.

[0026] The inner tube 3 is fixed on the lower part of the inner wall of the outer tube 2 by welding or expansion, and is not limited to welding or expansion....

Embodiment 3

[0028]like Figure 1~2 As shown, in this embodiment, the lower opening of the outer tube 2 and the lower opening of the inner tube 3 are fixed on the end plug 6 by welding or spinning. The lower end of the outer tube 2 and the lower end of the inner tube 3 are fixed together with the end plug 6 by welding or spinning process, and a spinning groove is formed on the outer wall of the end plug 6, so that the outer tube 2, the inner tube 3 and the end plug 6 The guide tube part is formed, and the fuel assembly frame is obtained by assembling the guide tube part and other parts such as the grid. Expansion or welding failure only affects a single guide tube part and does not affect the fuel assembly frame, which improves the manufacturing economy of the fuel assembly.

[0029] As preferably, a chamfer 31 is provided on the inner peripheral wall of the upper end of the inner tube 3, so that the control rod plays a guiding role when it falls, and avoids the outer wall or the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com