Winding device

A winder and rotor technology, applied in the direction of bundling materials, bundling machine parts, etc., can solve troublesome, labor-intensive, time-consuming problems, and achieve the effects of scientific and reasonable structure, time-saving, labor-saving efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

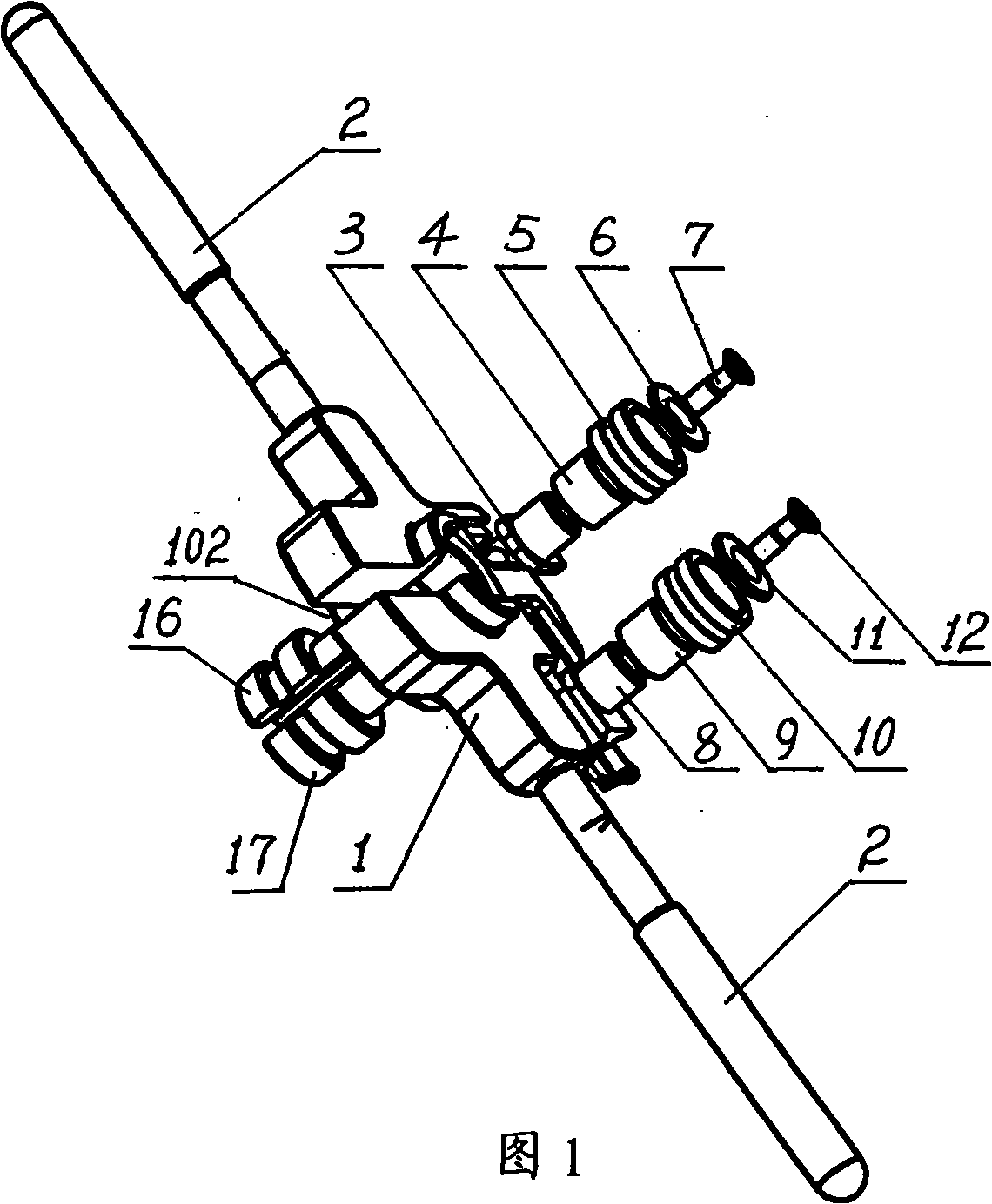

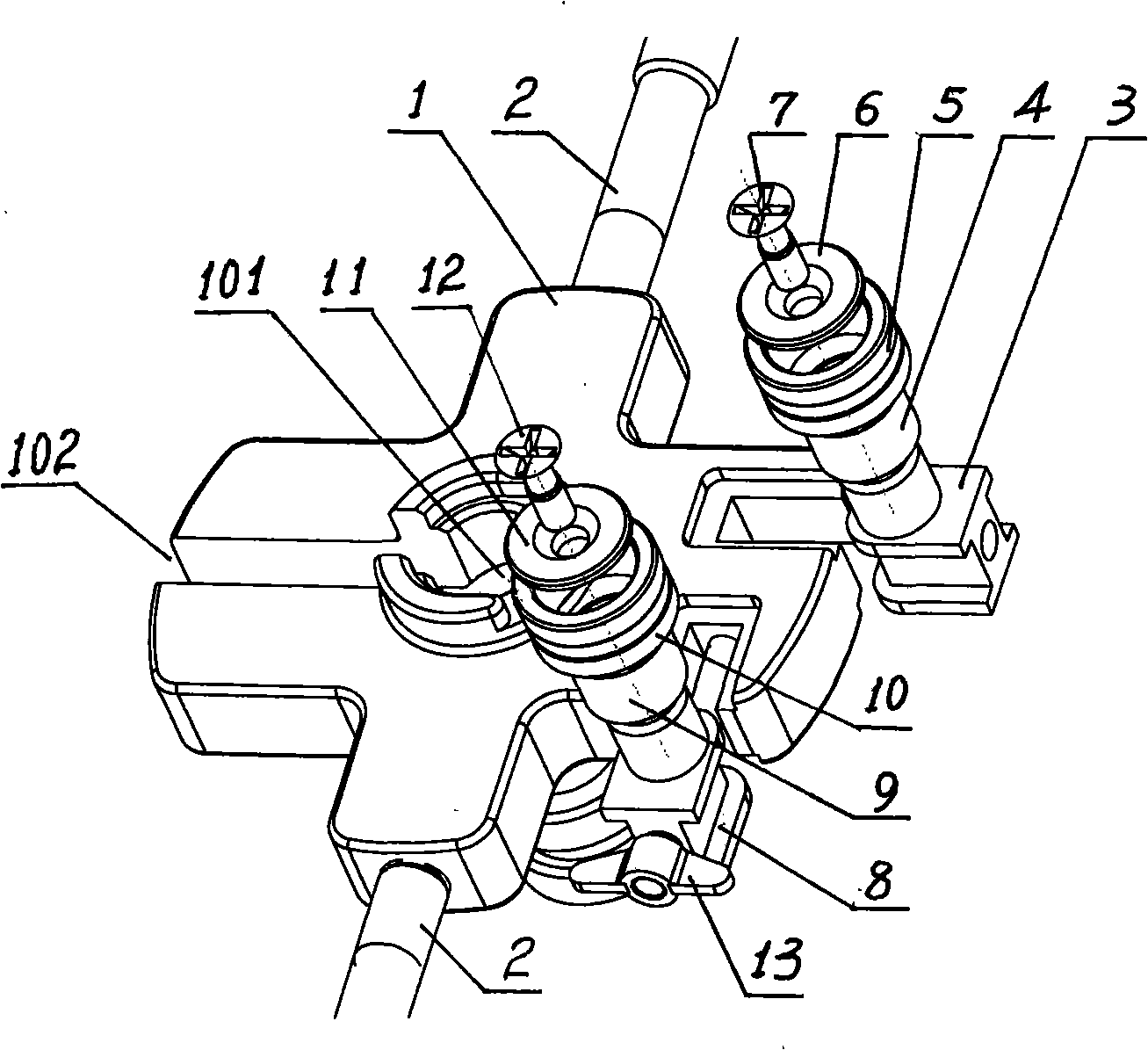

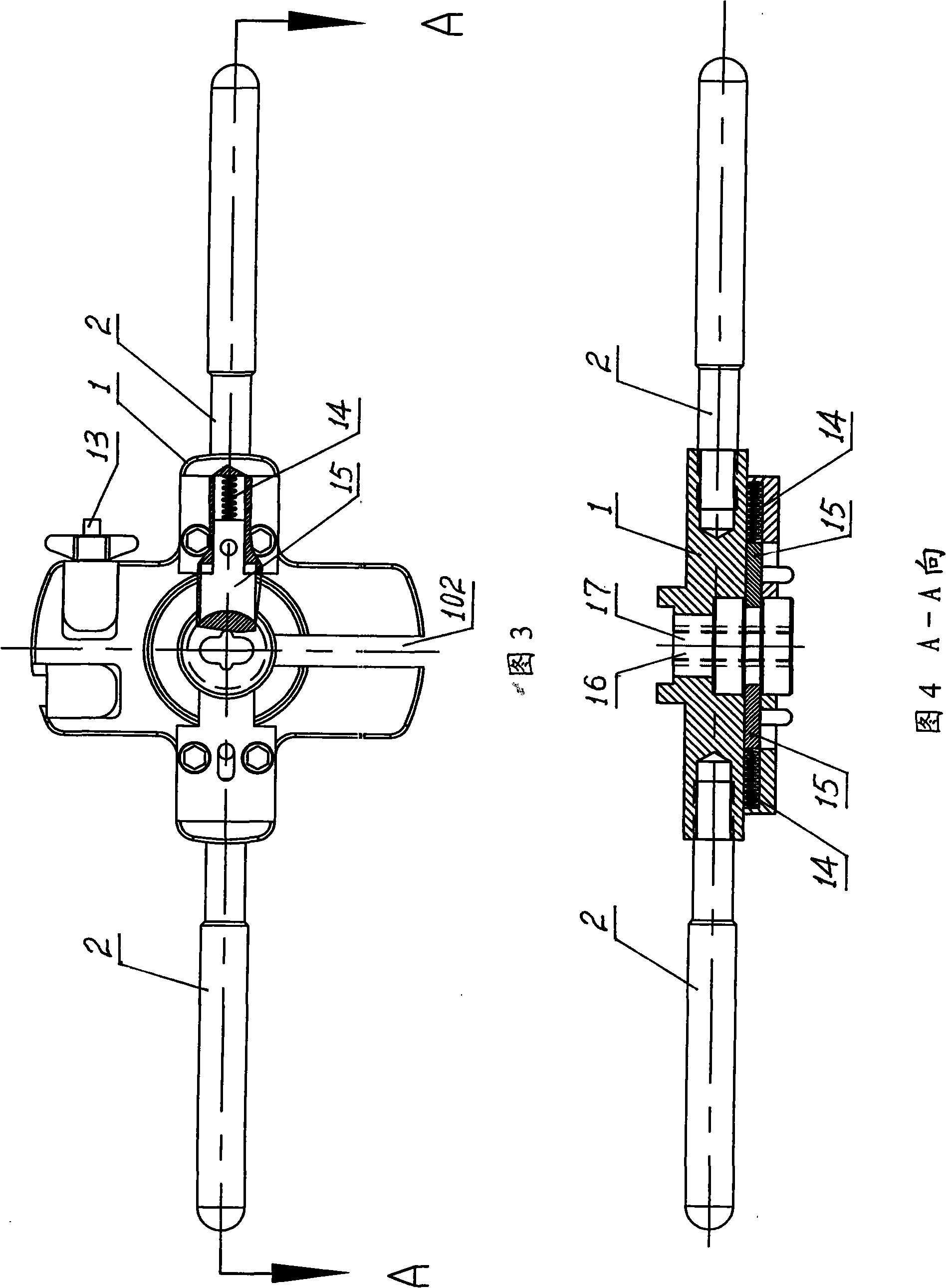

[0032] The present invention will be described in detail below with reference to the accompanying drawings. As shown in the attached drawings:

[0033] A winder mainly consists of a rotor 1, a central hole 101 on the rotor 1, a channel 102 on the rotor 1, a handle 2, a fixed slider 3, a fixed bearing 4, a fixed pressure wheel 5, a fixed pressure cover 6, and a fixed screw 7 , the movable slider 8, the movable bearing 9, the dynamic pressure wheel 10, the dynamic pressure cover 11, the movable screw 12, the adjustment screw 13, the spring 14, the radial slider 15, the half stator A16, and the half stator B17;

[0034] For the winder, the front and rear ends of the rotor 1 are connected with the handle 2 in a screw thread, and the half stator A16 and the half stator B17 together form a stator, and the outer circle of the stator is rotatably connected with the central hole 101 on the rotor 1. The circumferential waist groove of the diabolo-shaped stator is connected with the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com