Microwave starting current dividing circuit for barbecue mechanical type micro-oven

A technology of shunt circuit and microwave oven, which is applied in the direction of microwave heating, etc., can solve the problems of reducing starting current, human body electric shock risk, leakage, etc., and achieves the effect of saving cost and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

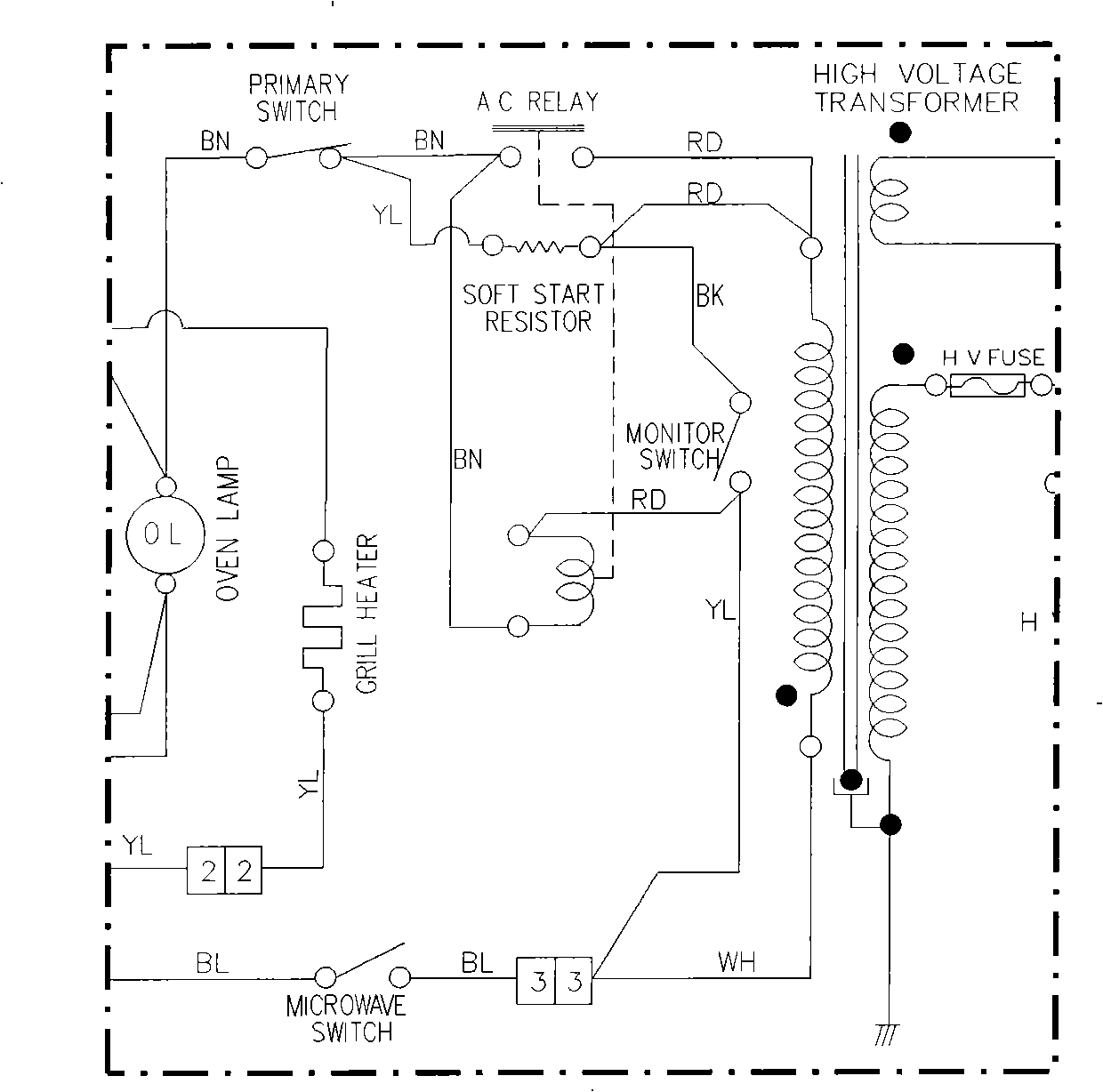

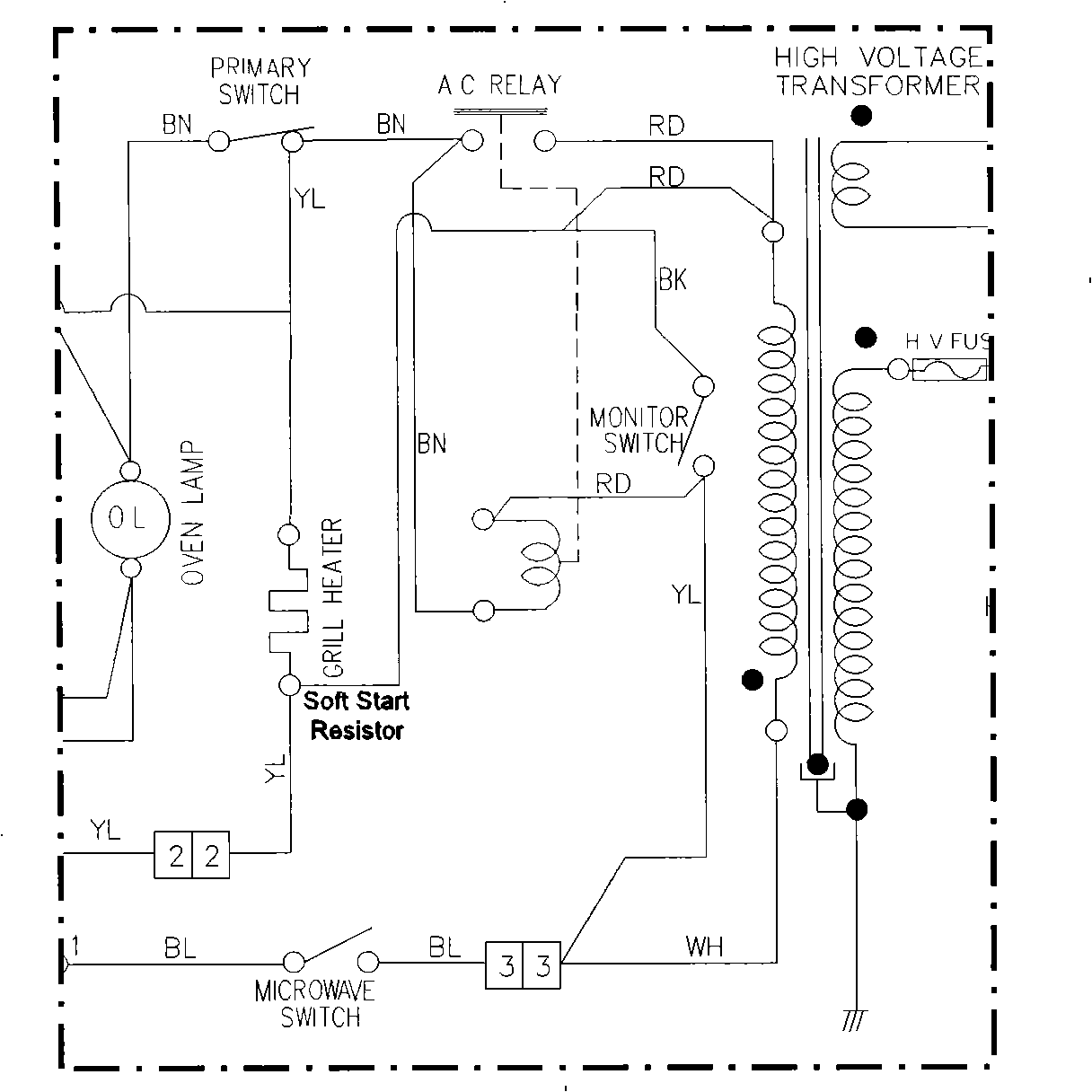

[0009] The shunt circuit of the barbecue mechanical microwave oven of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

[0010] Such as figure 2 Shown is the schematic diagram of the shunt circuit of the barbecue mechanical microwave oven of the present invention. A microwave starting shunt circuit for a barbecue mechanical microwave oven, including an AC starting relay controlled by a main switch, the controlled end of the relay is controlled to connect the primary of the high-voltage transformer and the zero line of the power supply, and the controlled end of the relay is respectively connected to the barbecue The two ends of the tube are connected. The live wire of the power supply is connected to the primary phase of the high-voltage transformer through a microwave switch. When the primary switch is turned on, the live wire of the power supply is connected to the neutral wire of the power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com