A process for extracting purees from food products and a plant for carrying out the process

A technology for puree and food, applied in the field of extracting puree from food and equipment for implementing it, capable of solving problems such as adverse effects of product viscosity, pectin destruction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

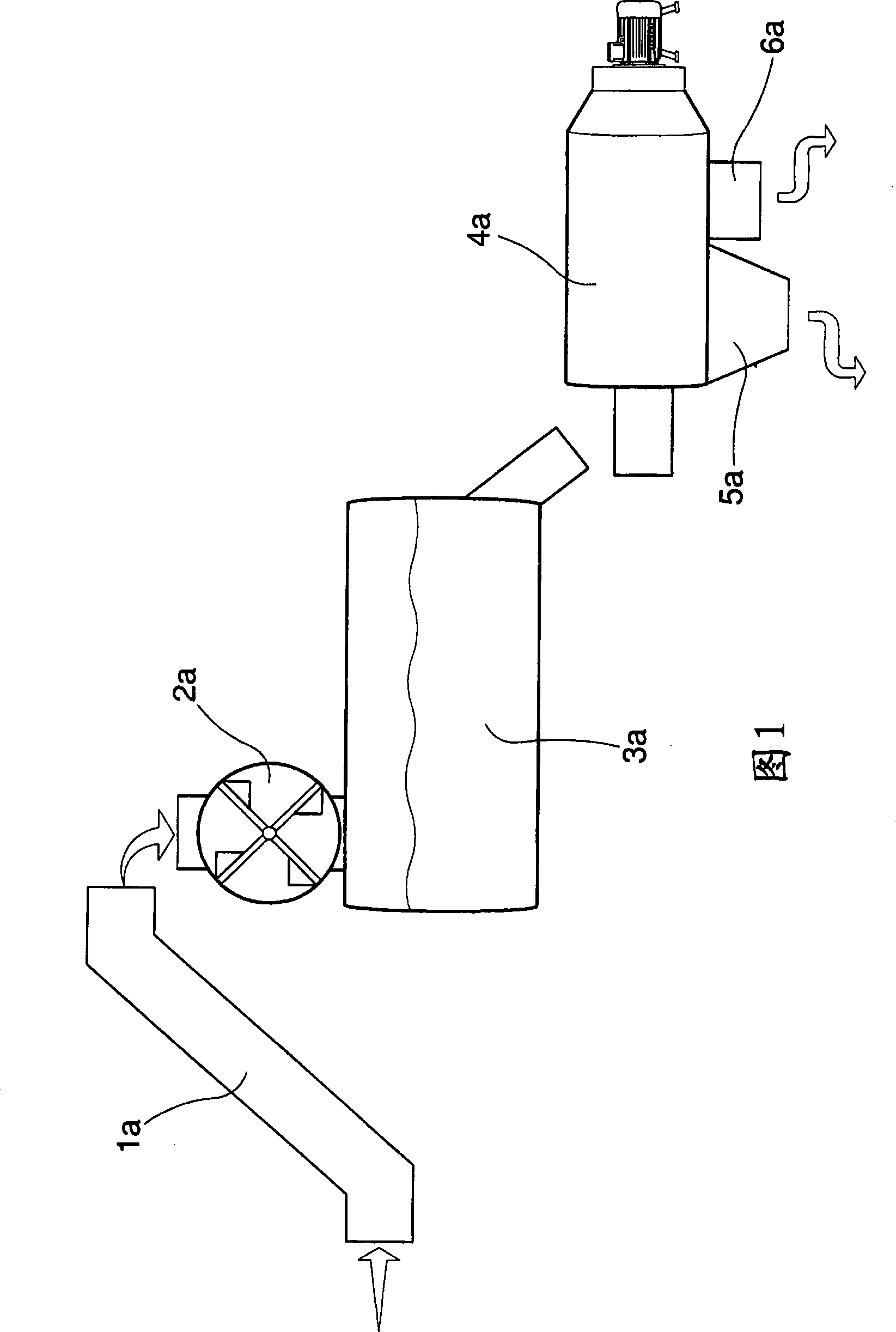

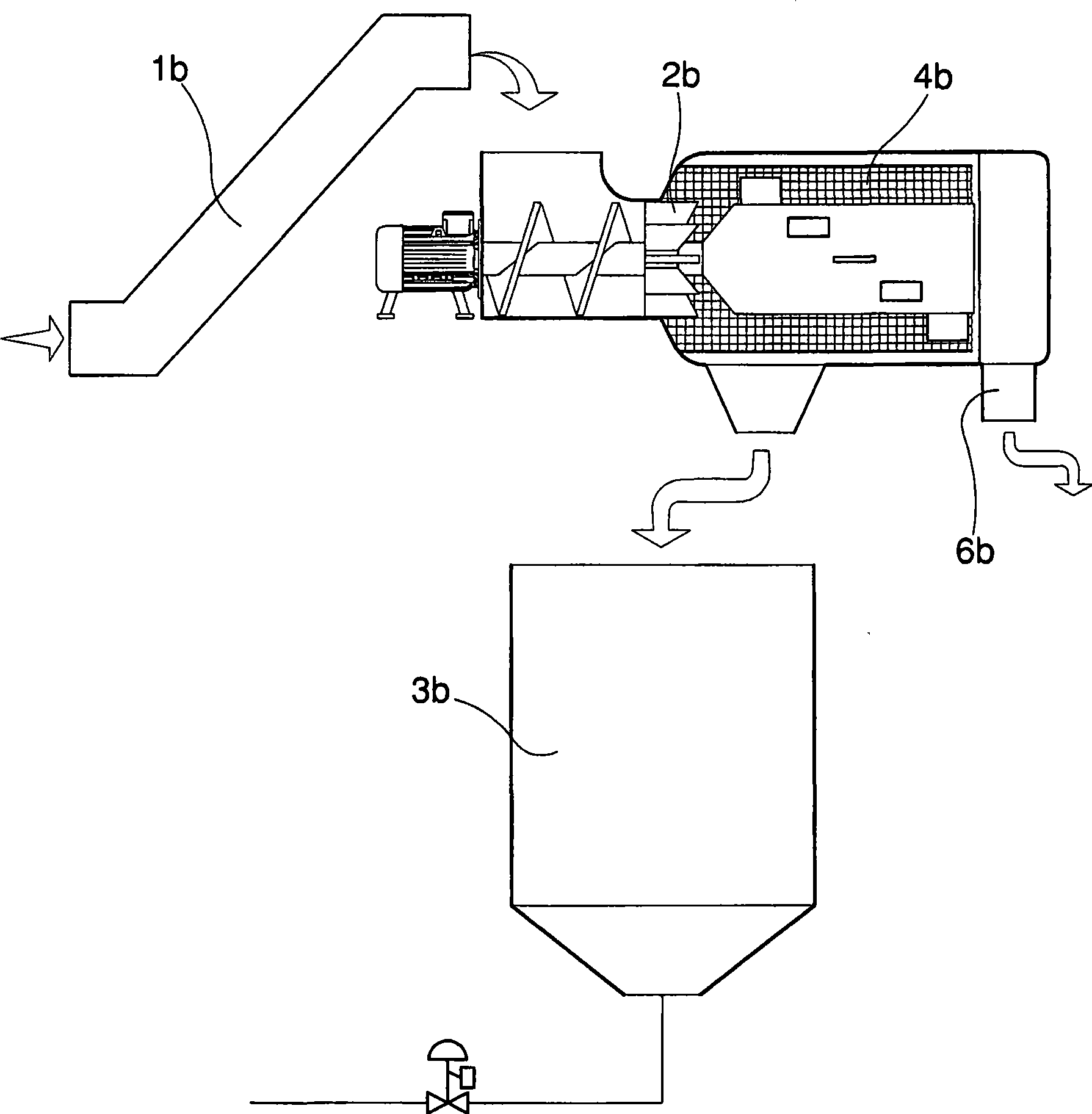

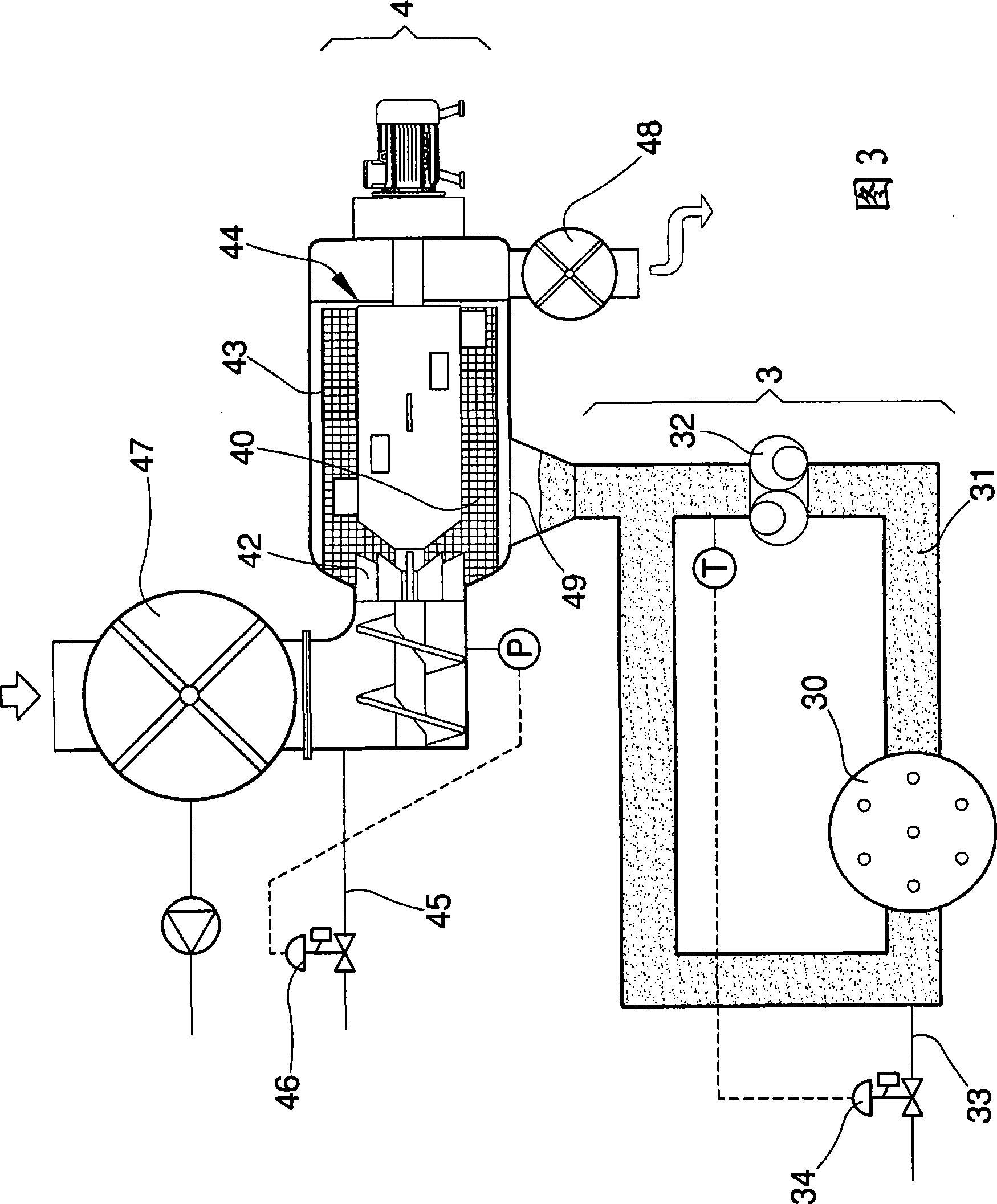

[0019] The invention relates to a method for extracting puree from food, especially suitable for extracting puree from fruit. The method of the present invention comprises the following steps: mash the food; separate the waste from the product; refine the mashed product inside the refining chamber 40 until a puree is obtained; heat the puree in order to inactivate the enzymes contained therein and prevent its going bad. As can be seen from the foregoing description of the prior art, these steps are essentially included in the known cold extraction process, in which a heating step (described as a cooking step) is carried out on a puree, ie on a product that has been refined and separated from waste. In the method of the present invention, unlike the cold extraction method of the prior art, the step of heating the puree is carried out immediately after the puree is obtained through the step of refining the mashed product, and it is determined that the temperature of the puree it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com