Feed apparatus of calender press

A technology of feeding device and roller press, applied in grain processing and other directions, can solve the problems of affecting the extrusion effect of the roller press, unable to adjust the load moment of the fixed roller, affecting the service life of the bearing, etc., to eliminate the leakage of the roller end phenomenon, the phenomenon of material leakage at the end of the roll is eliminated, and the effect of improving the extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

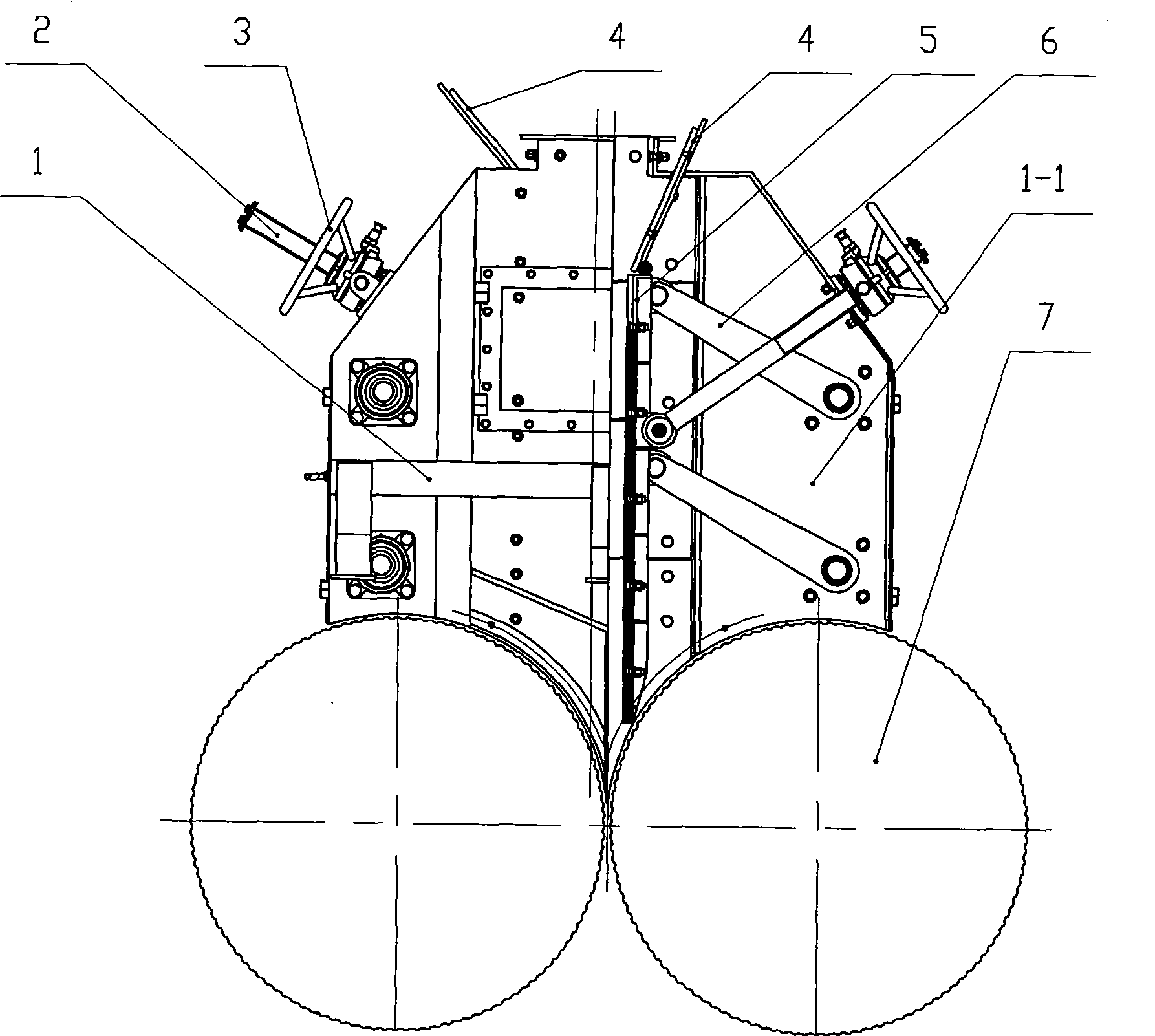

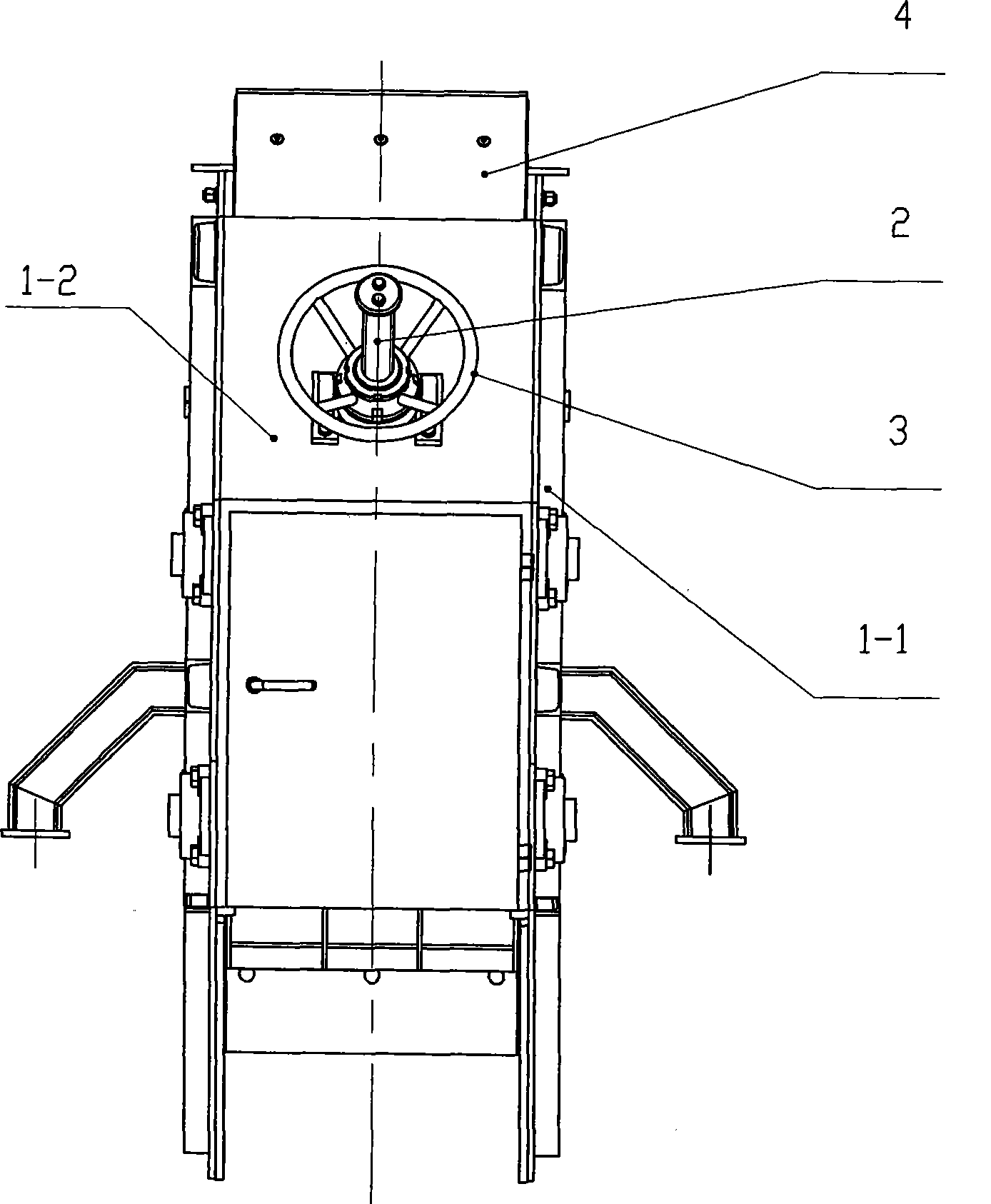

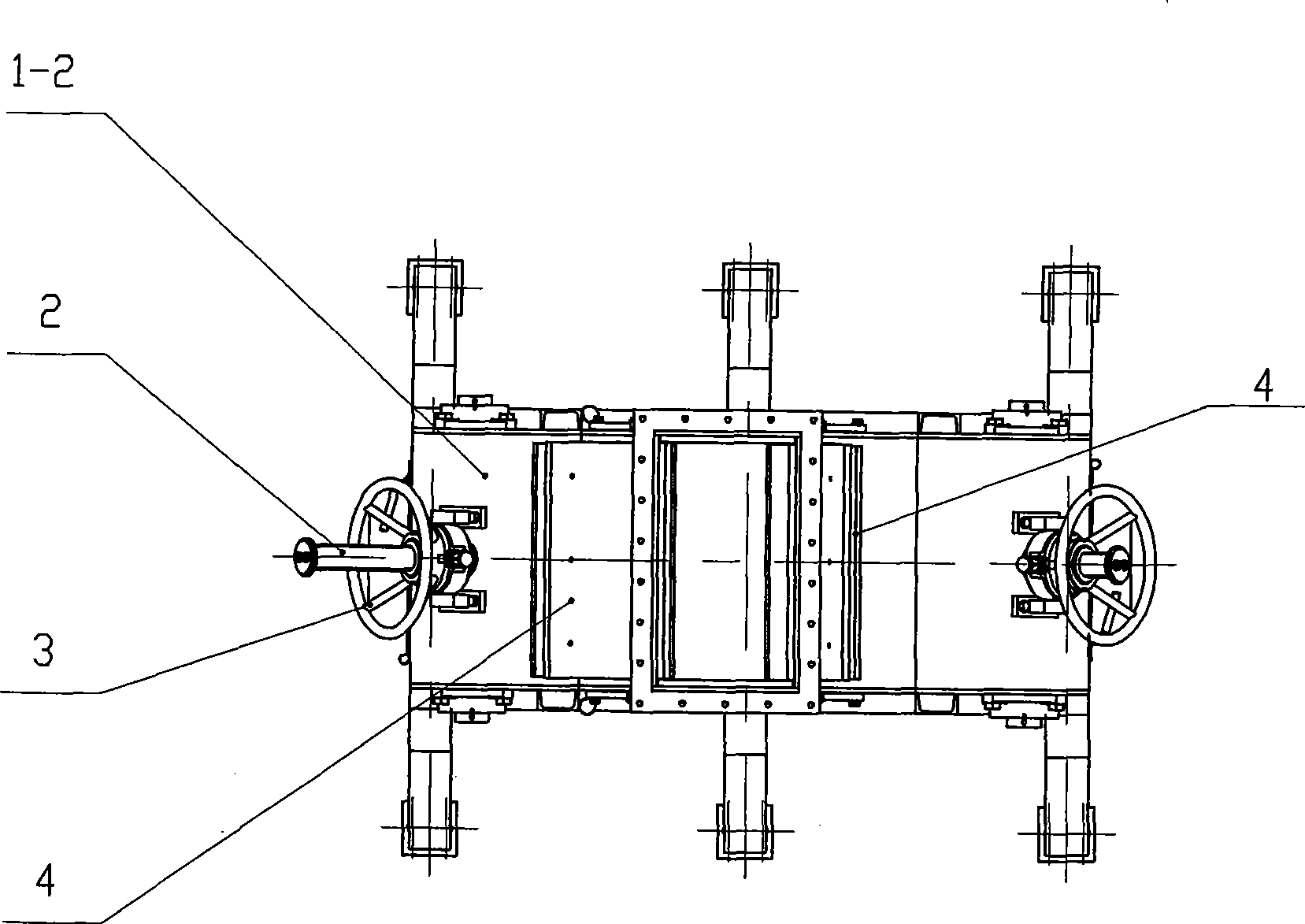

[0018] Such as Figure 1 ~ Figure 3 As shown, it includes a housing 1 (side wall panels 1-1, end wall panels 1-2), an adjusting screw 2, an adjusting mechanism 3, a retaining plate 4, an adjusting plate 5, a supporting mechanism 6, and the like.

[0019] The housing 1 of the present invention consists of two end wall panels 1-2 and two side wall panels 1-1 connected into one body by welding, and the hand wheel nut part support of the adjustment mechanism 3 is fixed on the housing end wall panel by bolts. One end of the upper and supporting mechanism 6 runs through the shaft and is fixed on the side wall plate 1-1 of the housing 1 through an outer spherical ball bearing with a square seat, and the other end is connected with the adjustment plate 5 through a hinged joint; the thread of the adjustment screw 2 Part of it is screwed with the internal threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com