Preparation method and device of no-agglomeration nano nickle granules

A technology of nano-nickel and particles, which is applied in the field of preparation of nano-nickel particles, can solve the problems of being easily oxidized, having many fibrous products, and being difficult to put into use, so as to achieve the effect of preventing agglomeration, eliminating fibrous products, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

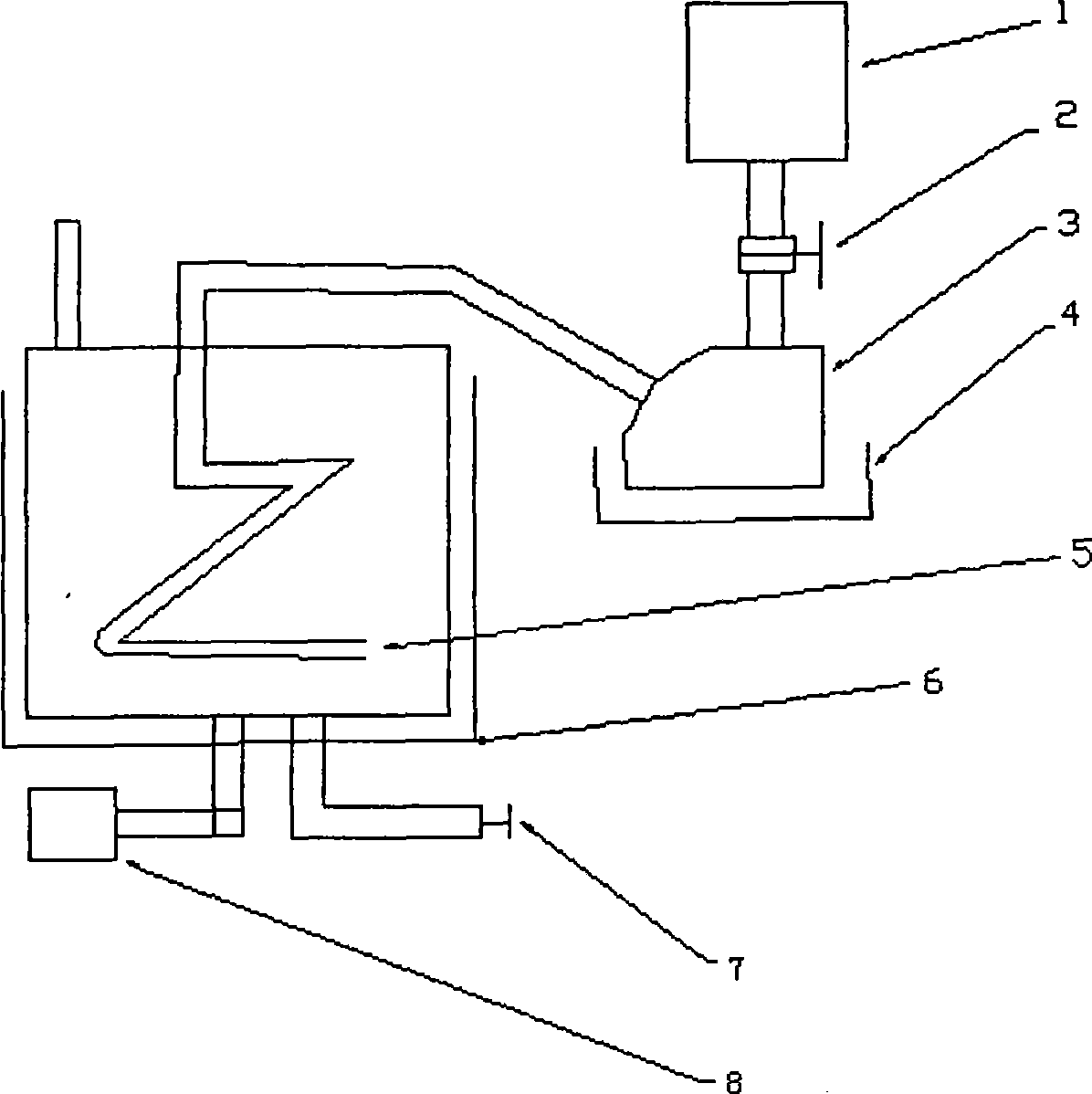

[0011] The equipment of the present invention comprises a nickel tetracarbonyl storage tank 1, a control valve 2, an evaporator 3, a heater 4, a "Z" pipe 5, an insulating liquid container and a heater 6, a finished product control valve 7, and a rotating device 8.

[0012] The specific implementation steps are:

[0013] Vacuumize the whole system, put nickel tetracarbonyl into the nickel tetracarbonyl storage tank 1, start the heater 4, heat the nickel tetracarbonyl evaporator and the carrier liquid, and wait until the carrier liquid is close to the temperature it can withstand (depending on the carrier liquid ), when the evaporator is higher than the evaporation temperature of nickel tetracarbonyl (>45°C), open the control valve 2, put nickel tetracarbonyl into the evaporator 3 according to the flow rate requirement, start the rotating device 8 of the liquid carrier container, and the nickel tetracarbonyl vapor passes through The conduit enters the "Z"-shaped tube 5, enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com