Chitosan-finishing iron nanowire, method for producing same and application thereof

A technology of iron nanowires and chitosan, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of increased cost of final products, harsh storage, complicated processes, etc. Conducive to industrialized production, less material and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The concrete steps of preparation are:

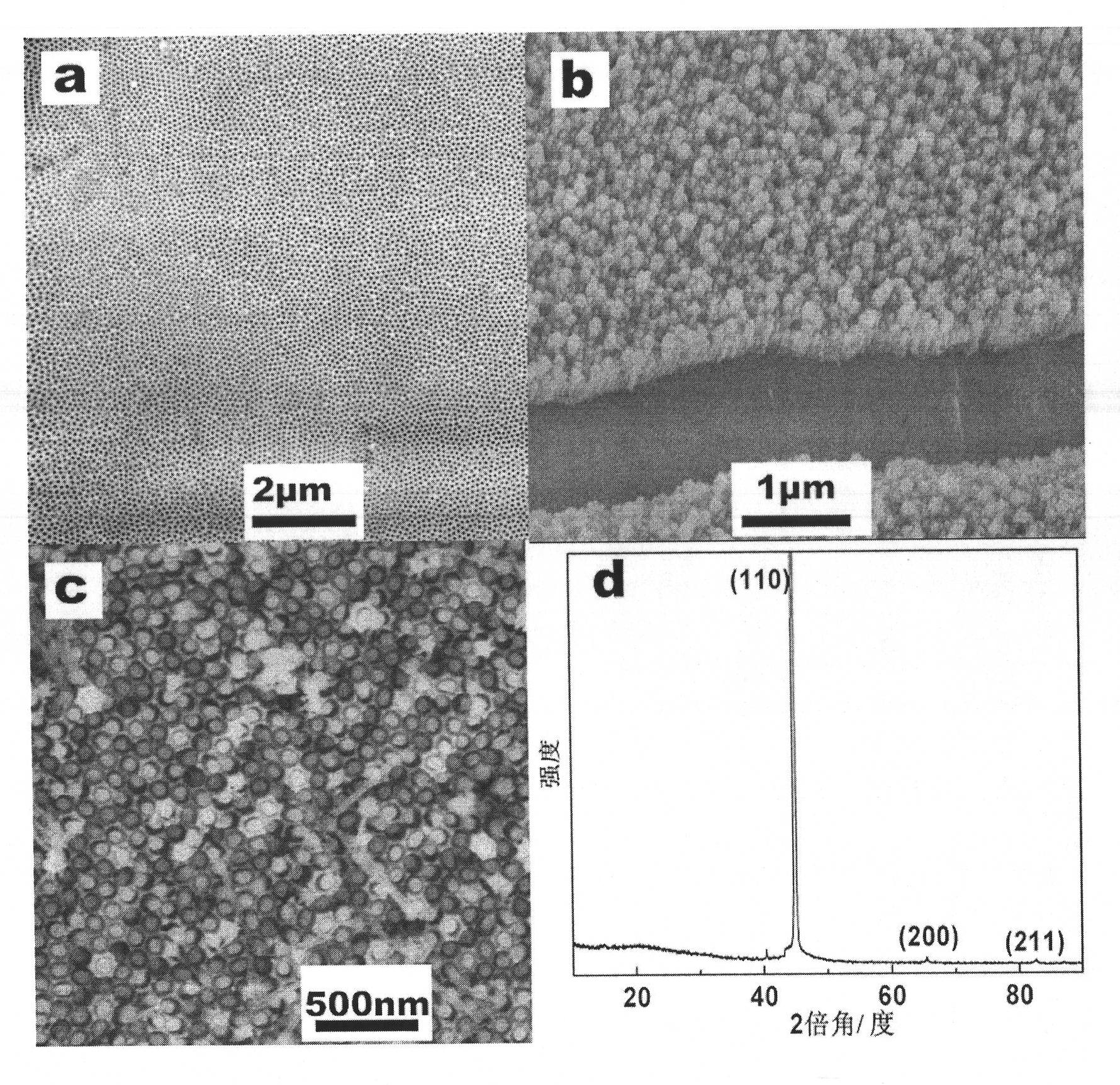

[0027] Step 1, first place the aluminum sheet in an oxalic acid solution with a concentration of 0.2M, and anodize it at a DC voltage of 35V for 35 minutes; At figure 1 The porous alumina template shown in a.

[0028] In step 2, the porous alumina template is first placed in the iron electrolyte, and electrodeposited at an AC voltage of 7V for 5 minutes to obtain a porous alumina template with iron nanowires placed in the holes. Then place the porous alumina template with iron nanowires in the holes and corrode it in a strong alkali solution for 2min; wherein, the strong alkali solution is a sodium hydroxide solution with a concentration of 5wt% and a temperature of 35°C to obtain iron in the holes A porous alumina template with gaps between the nanowires and the pore walls.

[0029]In step 3, the porous alumina template with a gap between the iron nanowire in the hole and the hole wall is placed in a chitosan solution with a ...

Embodiment 2

[0031] The concrete steps of preparation are:

[0032] Step 1, first place the aluminum sheet in an oxalic acid solution with a concentration of 0.25M, and anodize it at a DC voltage of 38V for 33 minutes; then soak it in a phosphoric acid solution with a temperature of 38°C and a concentration of 4.5wt% for 23 minutes to obtain similar to figure 1 The porous alumina template shown in a.

[0033] In step 2, the porous alumina template is first placed in the iron electrolyte, and electrodeposited at an AC voltage of 7.5V for 4 minutes to obtain a porous alumina template with iron nanowires placed in the pores. Then place the porous alumina template with iron nanowires in the holes and corrode it in a strong alkali solution for 3 minutes; wherein, the strong alkali solution is a sodium hydroxide solution with a concentration of 5wt% and a temperature of 35°C to obtain iron in the holes A porous alumina template with gaps between the nanowires and the pore walls.

[0034] In s...

Embodiment 3

[0036] The concrete steps of preparation are:

[0037] Step 1, first place the aluminum sheet in an oxalic acid solution with a concentration of 0.3M, anodize it at a DC voltage of 40V for 30min; then soak it in a phosphoric acid solution with a temperature of 40°C and a concentration of 5wt% for 22min to obtain figure 1 The porous alumina template shown in a.

[0038] In step 2, the porous alumina template is first placed in the iron electrolyte, and electrodeposited at an AC voltage of 8V for 3 minutes to obtain a porous alumina template with iron nanowires placed in the holes. Then place the porous alumina template with iron nanowires in the holes and corrode it in a strong alkali solution for 3.5min; wherein, the strong alkali solution is a sodium hydroxide solution with a concentration of 5wt% and a temperature of 35°C to obtain the Porous alumina template with gaps between iron nanowires and pore walls.

[0039] In step 3, the porous alumina template with a gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com