Cutting method of circuit board

A cutting method and circuit board technology, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of uneven force, holes on the board, uneven force, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

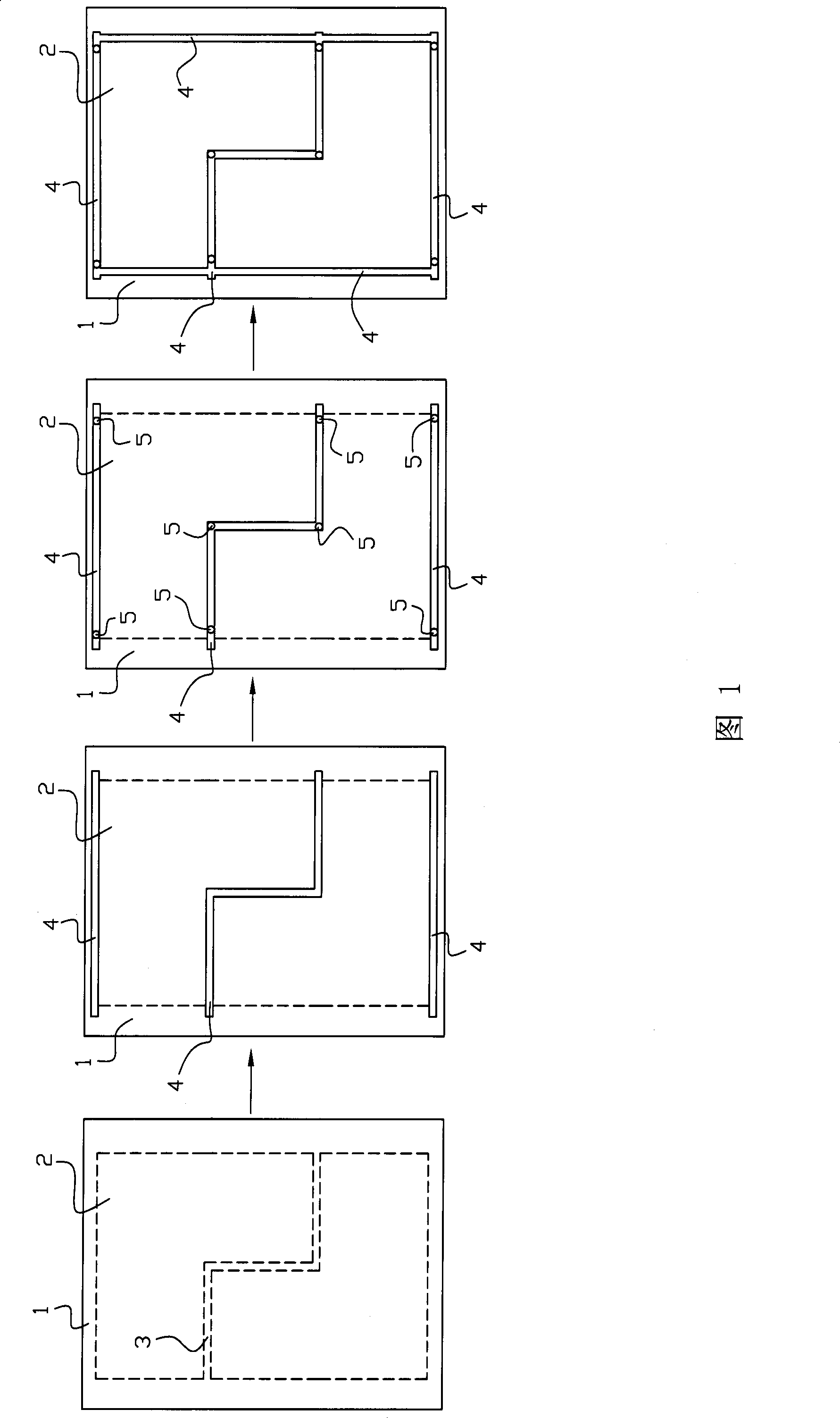

[0023] The specific embodiments of the present invention will be described below in conjunction with the drawings:

[0024] The circuit board cutting method implemented according to the present invention includes the following steps:

[0025] 1. Typesetting: Arrange two L-shaped circuit board small pieces 2 symmetrically into a large piece 1, leaving a cutting position 3 between the two small pieces 2 and their outer edges. The size of the small piece is 5×5 mm, and positioning pins cannot be set in the board.

[0026] 2. One-time cutting: The purpose of this cutting is to cut out the positioning groove 4 for inserting the pin 5. In this embodiment, since the L-shaped circuit board has an S-shaped edge with a turning point, the S-shaped edge and its opposite side edges are selected as the edge for one cut. Cut along the upper, middle, and lower three cutting positions 3, and cut out three positioning grooves 4 with a width of 1 mm.

[0027] 3. Pin positioning: Insert the pin 5 int...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap