Paper pickup device of paper feeder for stenograph

A speed printing machine and paper feeding technology, applied in the direction of transportation and packaging, separation of objects, separation of piles, etc., can solve problems such as double sheets or follow-up paper, complex structure assembly, and affect printing speed, so as to reduce production costs and improve device structure. Simple, Adaptable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

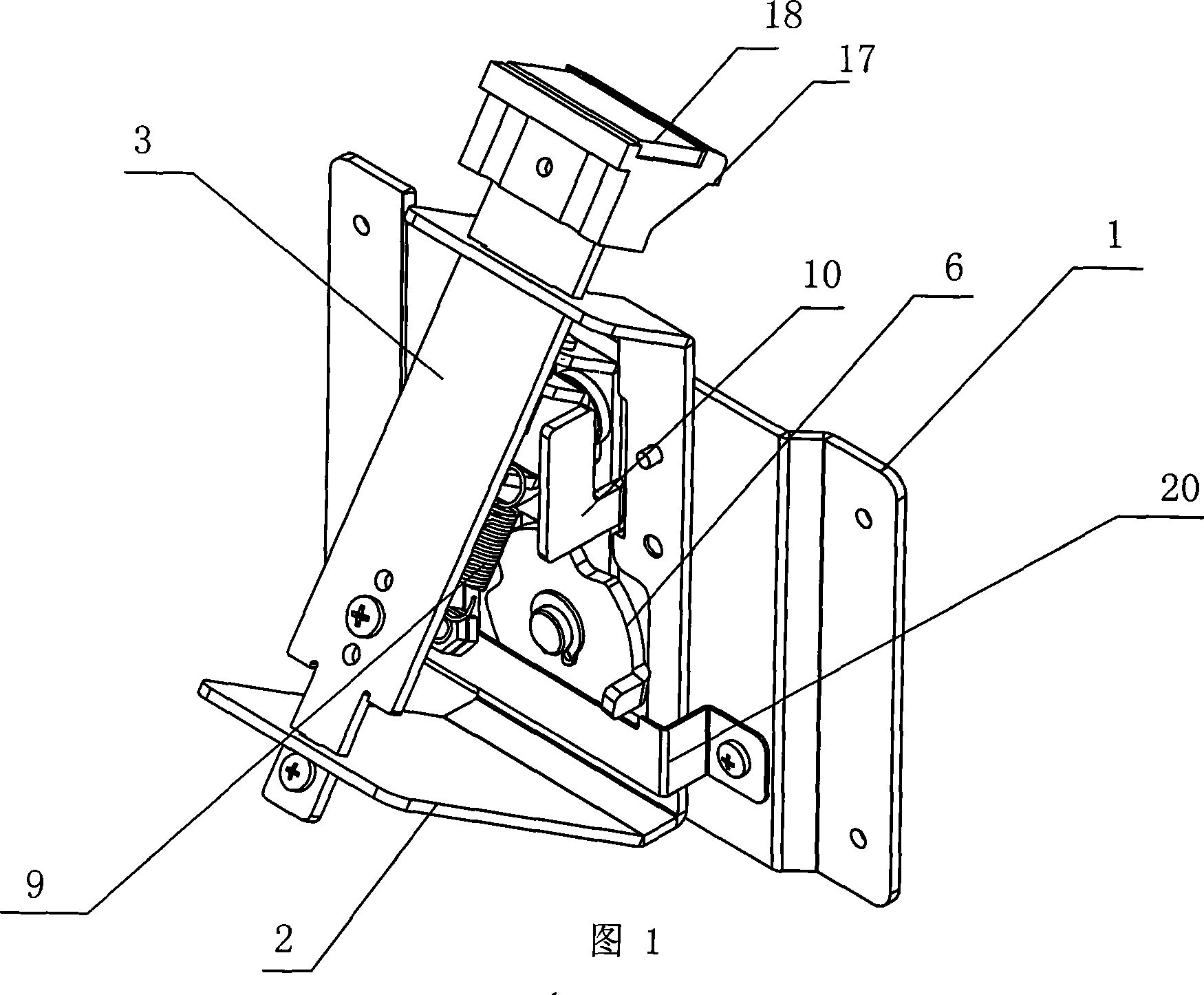

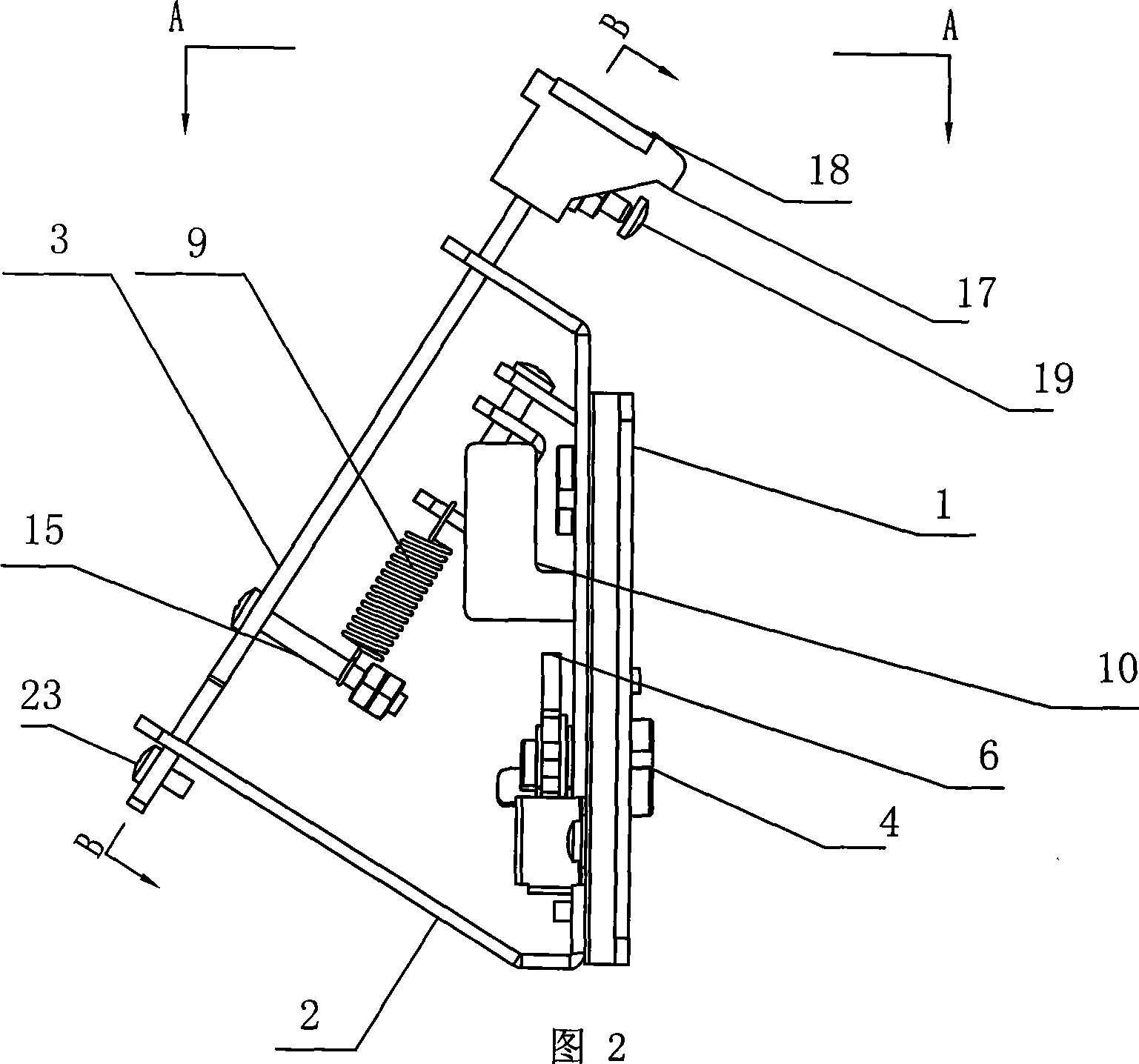

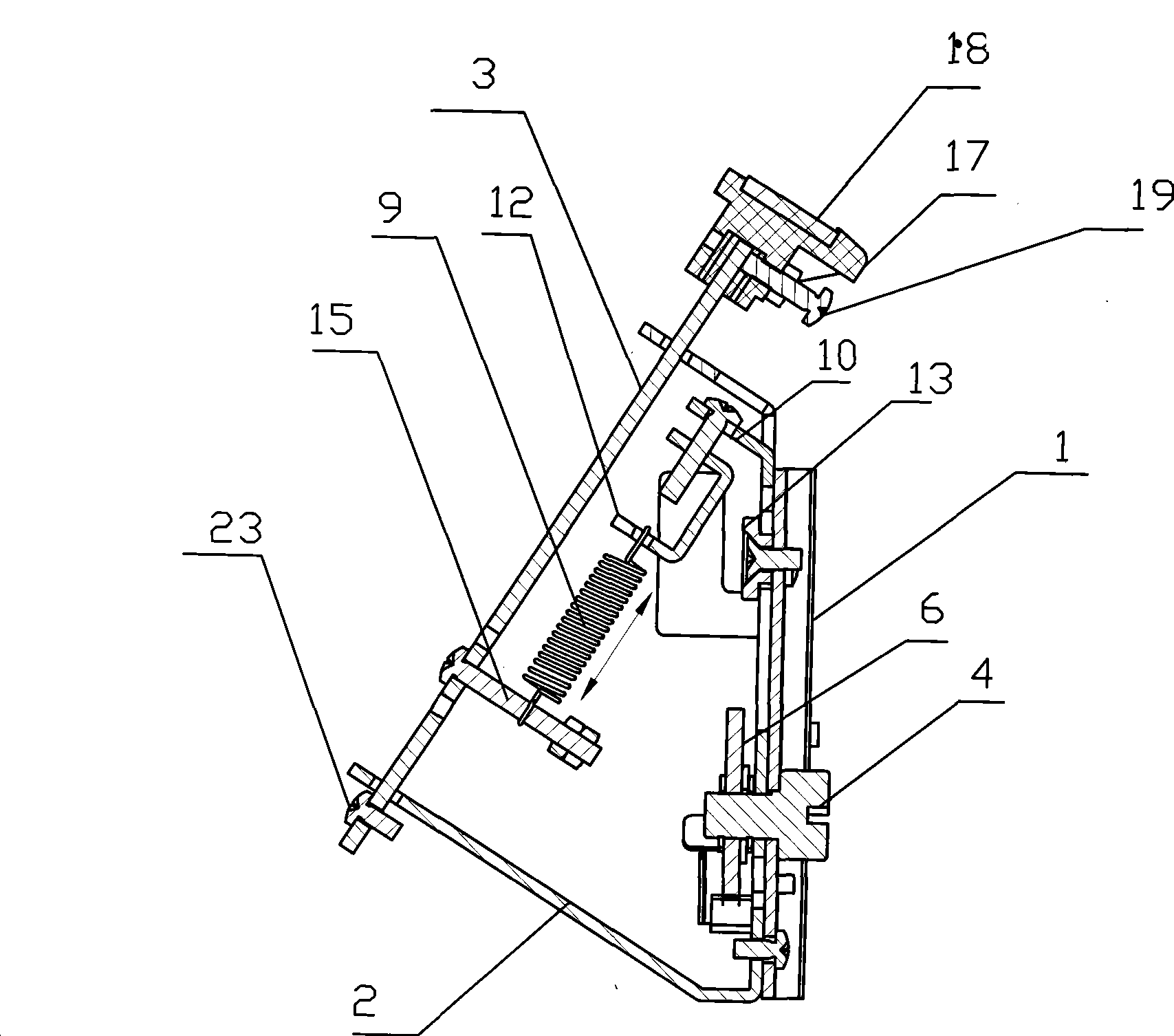

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 9 It can be seen that a paper feeding device of the speed printing machine of the present invention includes a base 1, a group of paper pickup wheels 24, a support 2, and a support plate 3, and the support 2 is fixedly connected to the base 1, the bottom of the bracket 2 has a long guide hole 26, the planes where the two bent ends of the bracket 2 are parallel to each other, and the two bent ends are respectively opened with a guide hole 27, the support plate 3 The two ends of the two ends are slidingly fitted in the two guide holes 27 of the bent end of the bracket 2, and a fixed shaft 15 is also provided under the support plate 3, and a cam assembly that can rotate around the axis is provided on the base 1, and the elongated A pressure adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com