Method for axial correction in a processing machine, as well as a processing machine

一种加工机、加工轴的技术,应用在印刷机、轮转印刷机、容器制造机械等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

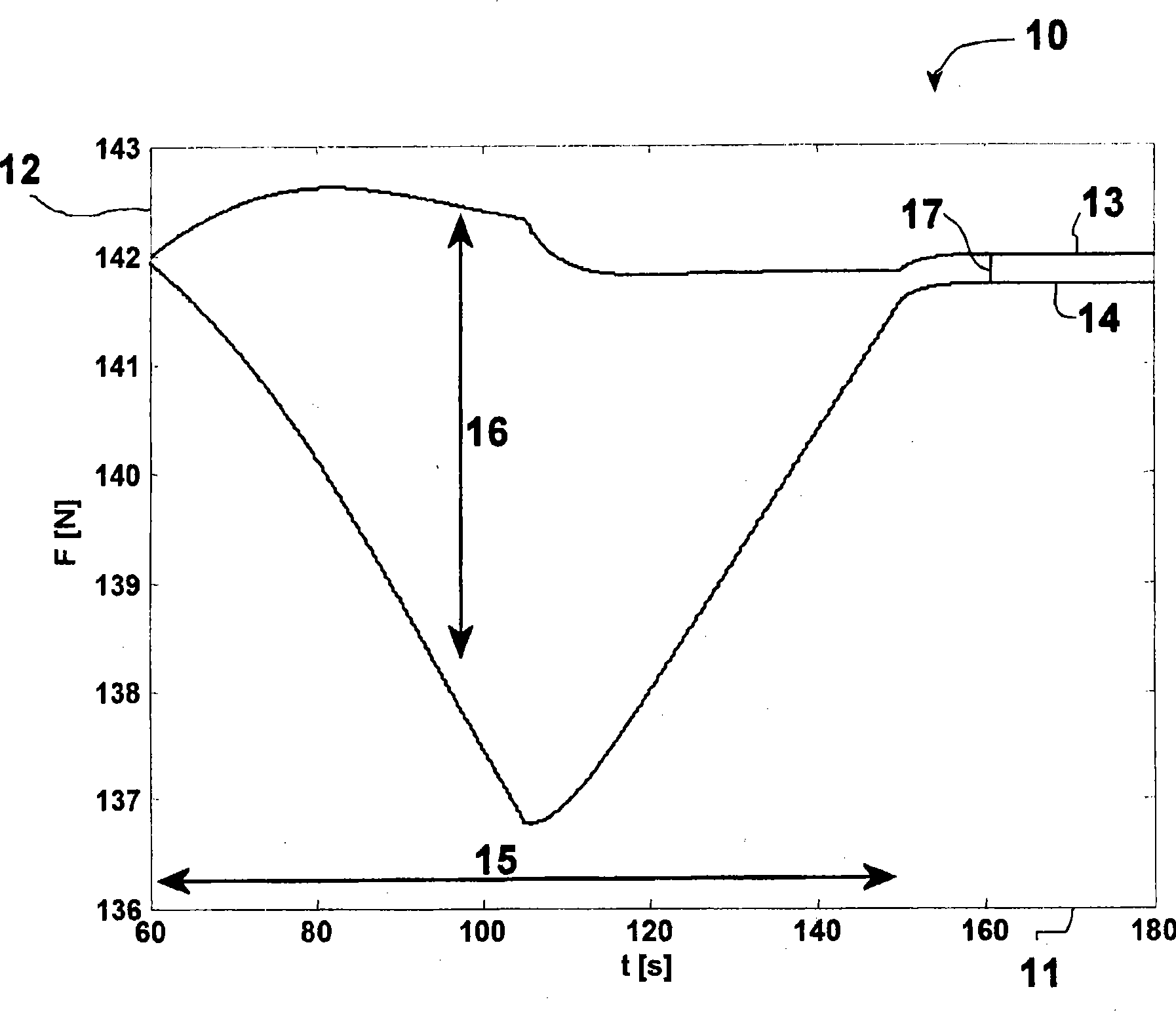

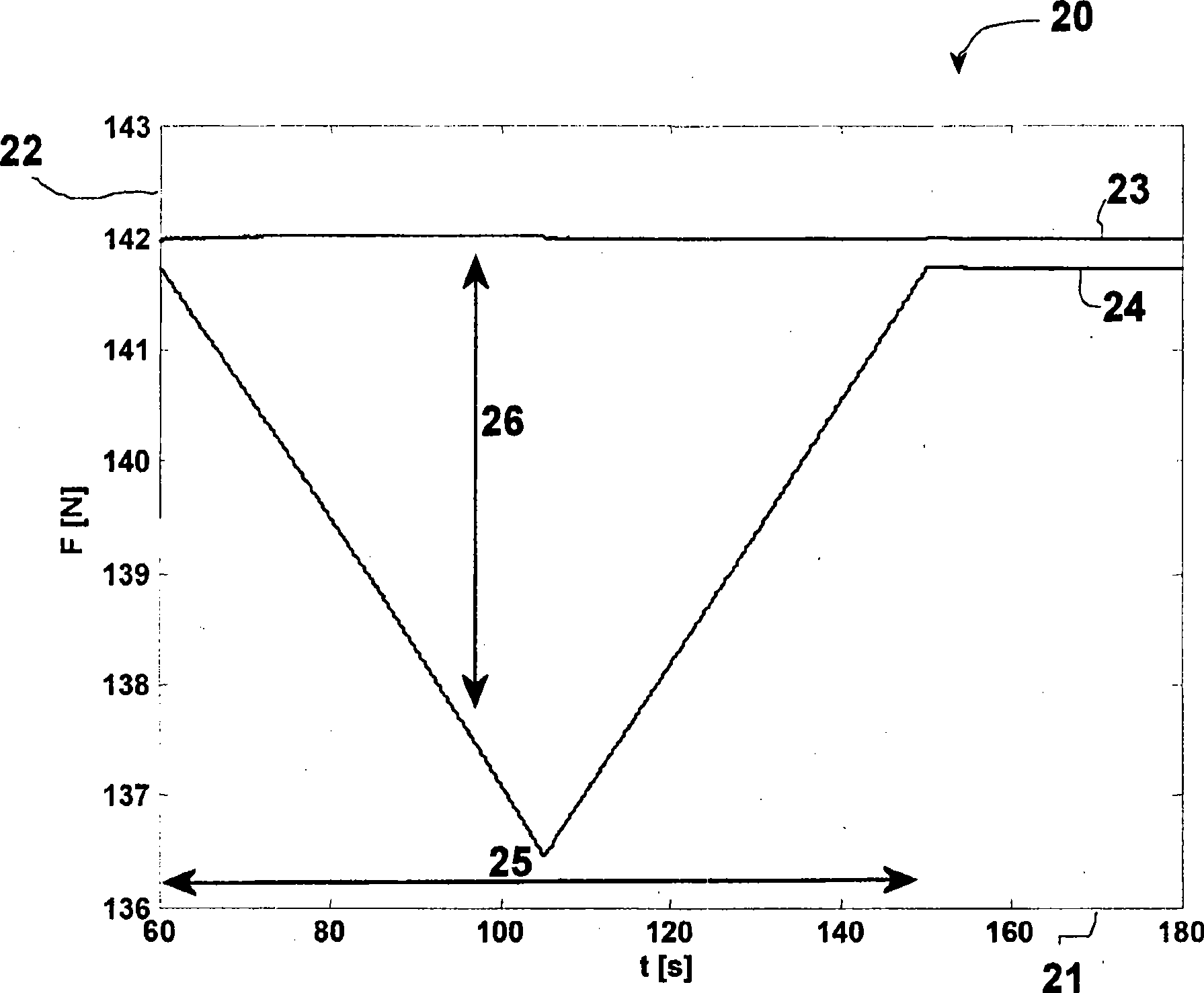

[0036] figure 1 The course of the web tension is plotted against time in diagram 10 in which two web tension courses 13 and 14 are shown. The web tension is plotted on the y-axis 12 in diagram 10 against time t on the x-axis 11 . figure 1 The profile of the web tension is shown in a dynamic situation in which the rollers involved in the work are accelerated.

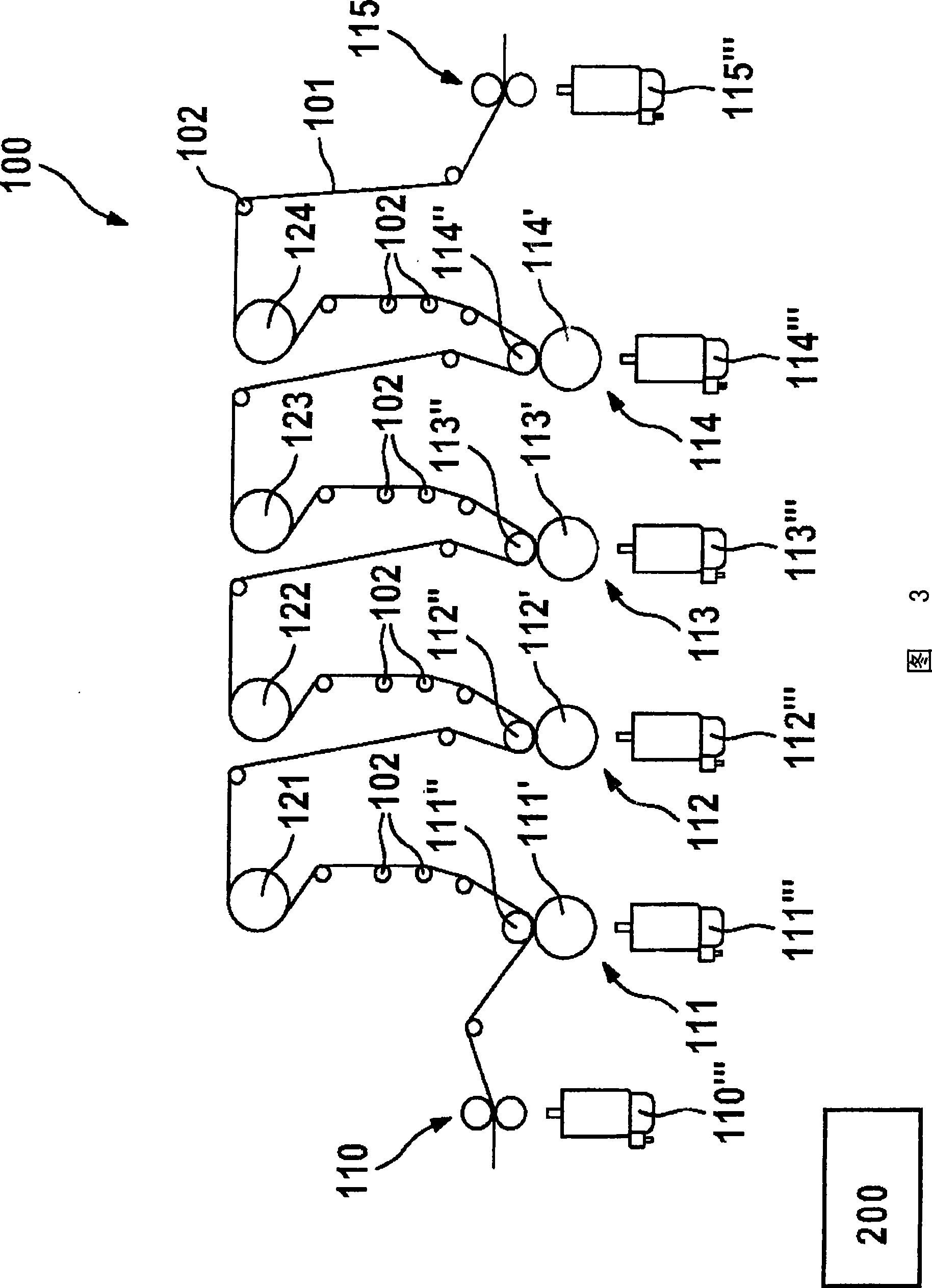

[0037] Diagram 10 shows two web tension curves 13 and 14 which are supposed to correspond to different web tension subsections. A web tensioning section is considered here, which is divided by a non-driven shaft, in the exemplary embodiment shown, by a cooling roller into two adjacent web tensioning subsections. At the ends of the web tensioning sections there are in each case a clamping point (driven shaft), in the illustrated exemplary embodiment a driven pressure roller. Referring to FIG. 3 , for example, between the printing unit 112 and the printing unit 113 , a web tensioning section as described can be seen, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com