Vane compressor

A compressor and vane technology, which is applied in the field of vane compressors, can solve problems such as increased start-up delay and longer start-up oscillation generation time, and achieve the effect of improving compression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

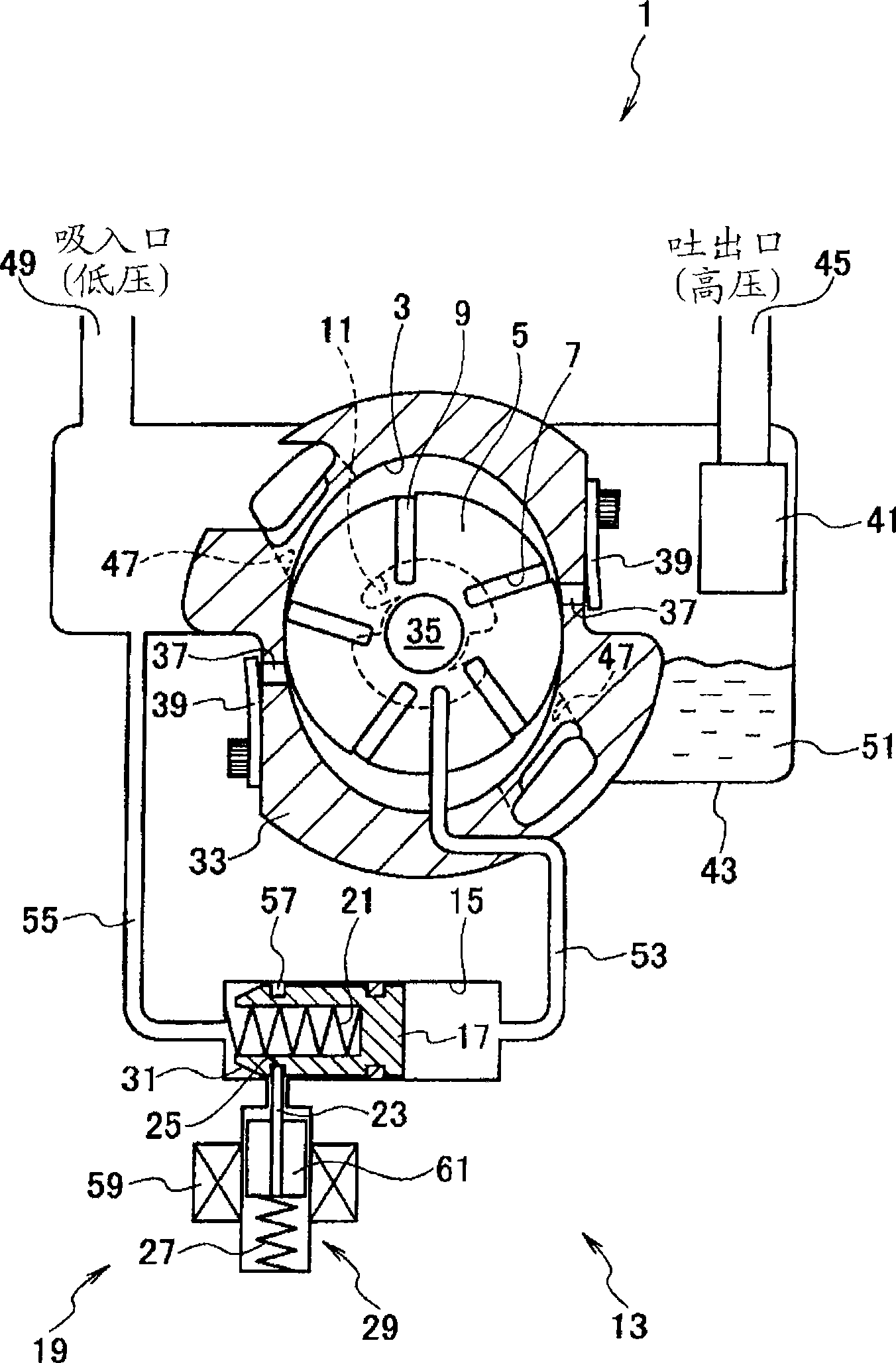

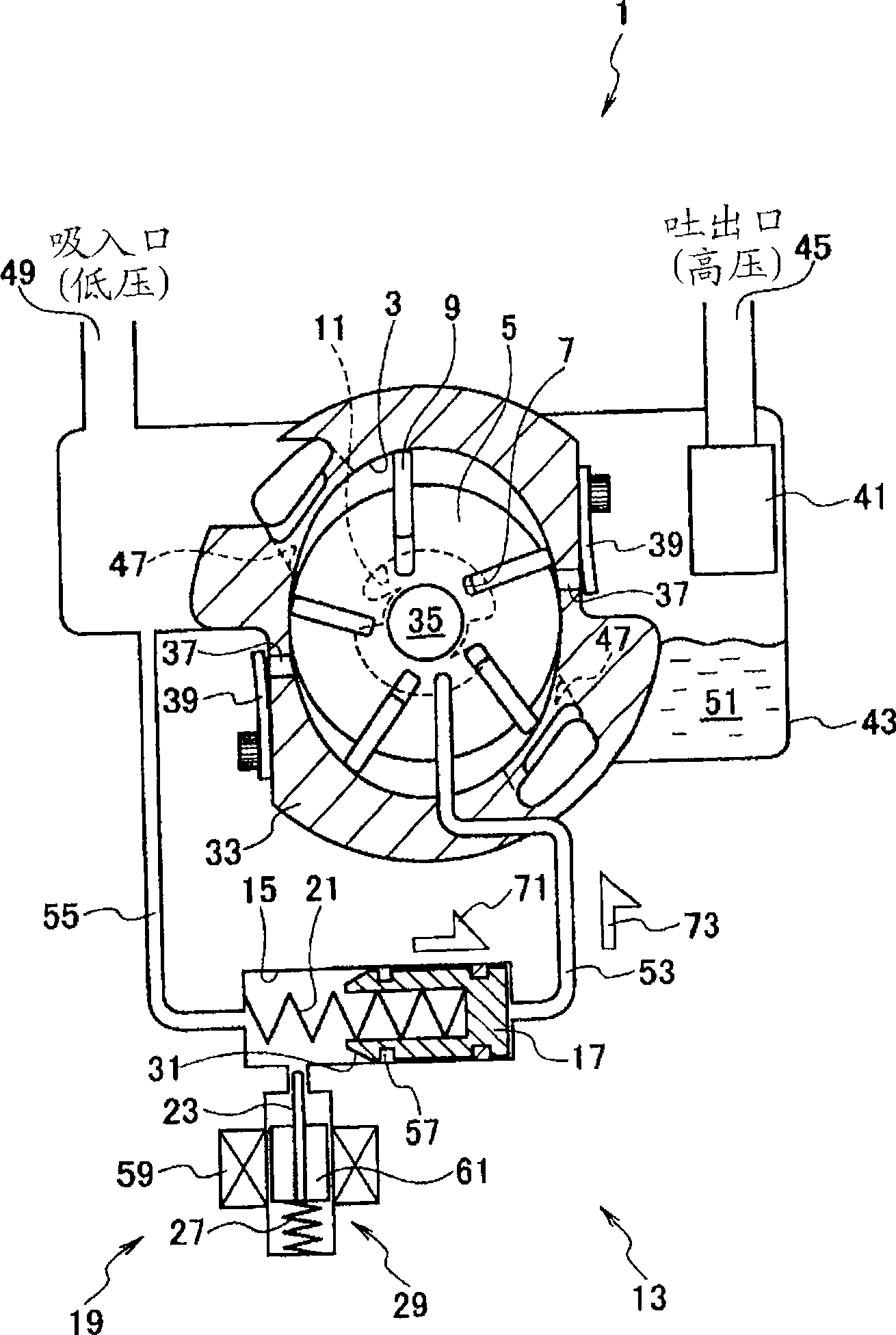

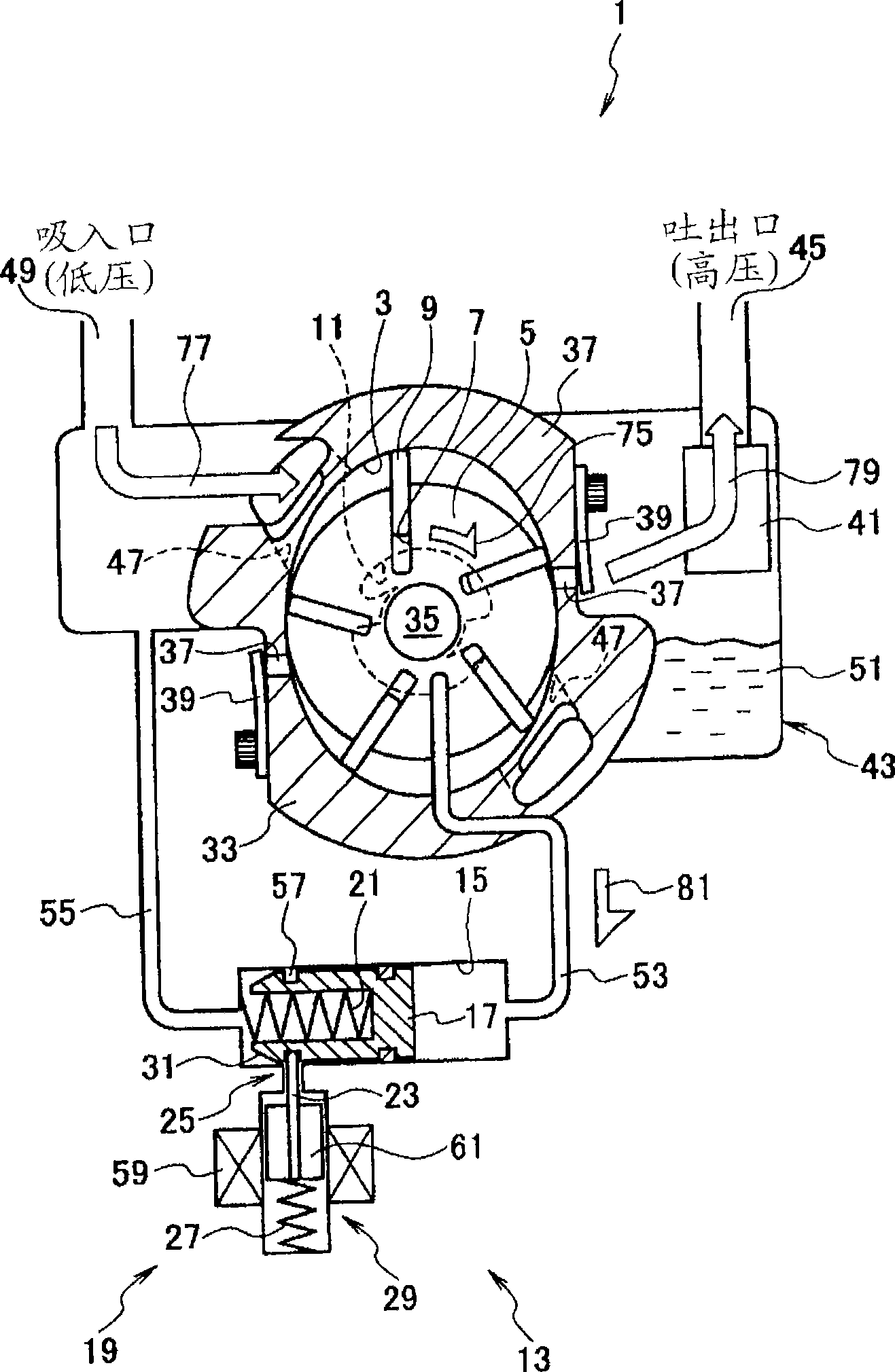

[0037] Figure 1 ~ Figure 3 Showing the first embodiment of the present invention, figure 1 is a sectional view of main parts of the vane compressor 1 in a standby state, figure 2 is a sectional view of main parts of the vane compressor 1 when the startup mode is selected, image 3 It is a cross-sectional view of main parts of the vane compressor 1 in a state where the back pressure supply member 13 and the position maintaining member 19 are reset.

[0038]The vane compressor 1 includes a cylinder chamber 3, a rotor 5, a vane groove 7, a vane 9, a vane back pressure chamber 11, and a back pressure supply member 13; the rotor 5 is freely rotatably arranged in the cylinder chamber 3; Arranged on the rotor 5 at equal intervals in the circumferential direction; the above-mentioned blades 9 are arranged in the blade grooves 7 and can freely protrude into the cylinder chamber 3 and sink into the blade grooves 7; the above-mentioned blade back pressure chambers 11 communicate with...

no. 2 Embodiment approach

[0064] Figure 4 ~ Figure 6 Showing the second embodiment of the present invention, Figure 4 is a sectional view of main parts of vane compressor 101 in a standby state, Figure 5 is a sectional view of main parts of the vane compressor 101 when the startup mode is selected, Figure 6 It is a cross-sectional view of main parts of the vane compressor 101 in a state where the back pressure supply member 103 and the opening and closing member 109 are reset.

[0065] The vane compressor 101 includes a cylinder chamber 3, a rotor 5, a vane groove 7, a vane 9, a vane back pressure chamber 11 and a back pressure supply member 103; the rotor 5 is freely rotatably arranged in the cylinder chamber 3; the vane groove 7 is arranged along the Arranged on the rotor 5 at equal intervals in the circumferential direction; the above-mentioned blades 9 are arranged in the blade grooves 7 and can freely protrude into the cylinder chamber 3 and sink into the blade grooves 7; the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com