Mobile joint unit for switch and switch device using the same

A technology for moving contacts and switches, applied in the field of movable contact units for switches, can solve problems such as the inability of the movable contacts to operate normally, the insufficient light intensity of the operation keys, and the malfunction of the switch elements, etc., to achieve good assembly operability and improve assembly operability. , the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

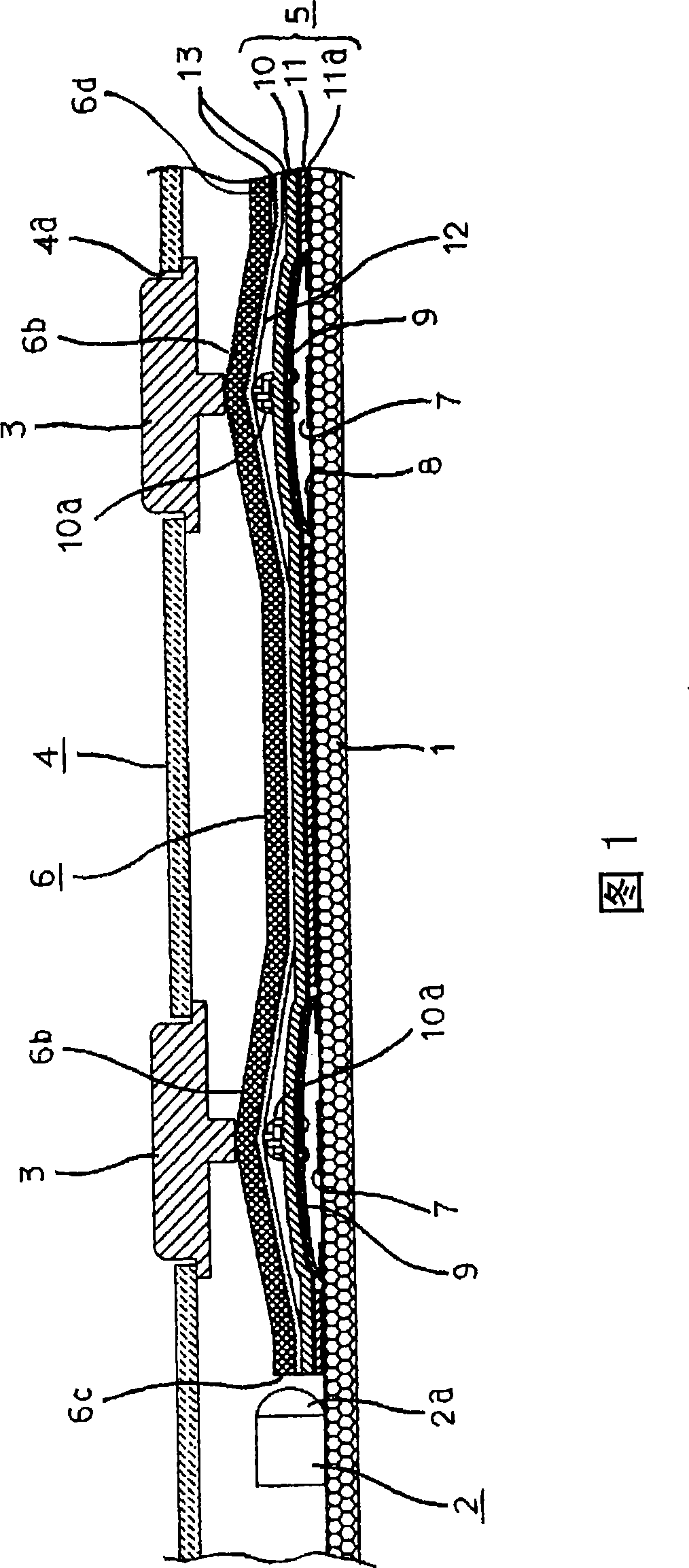

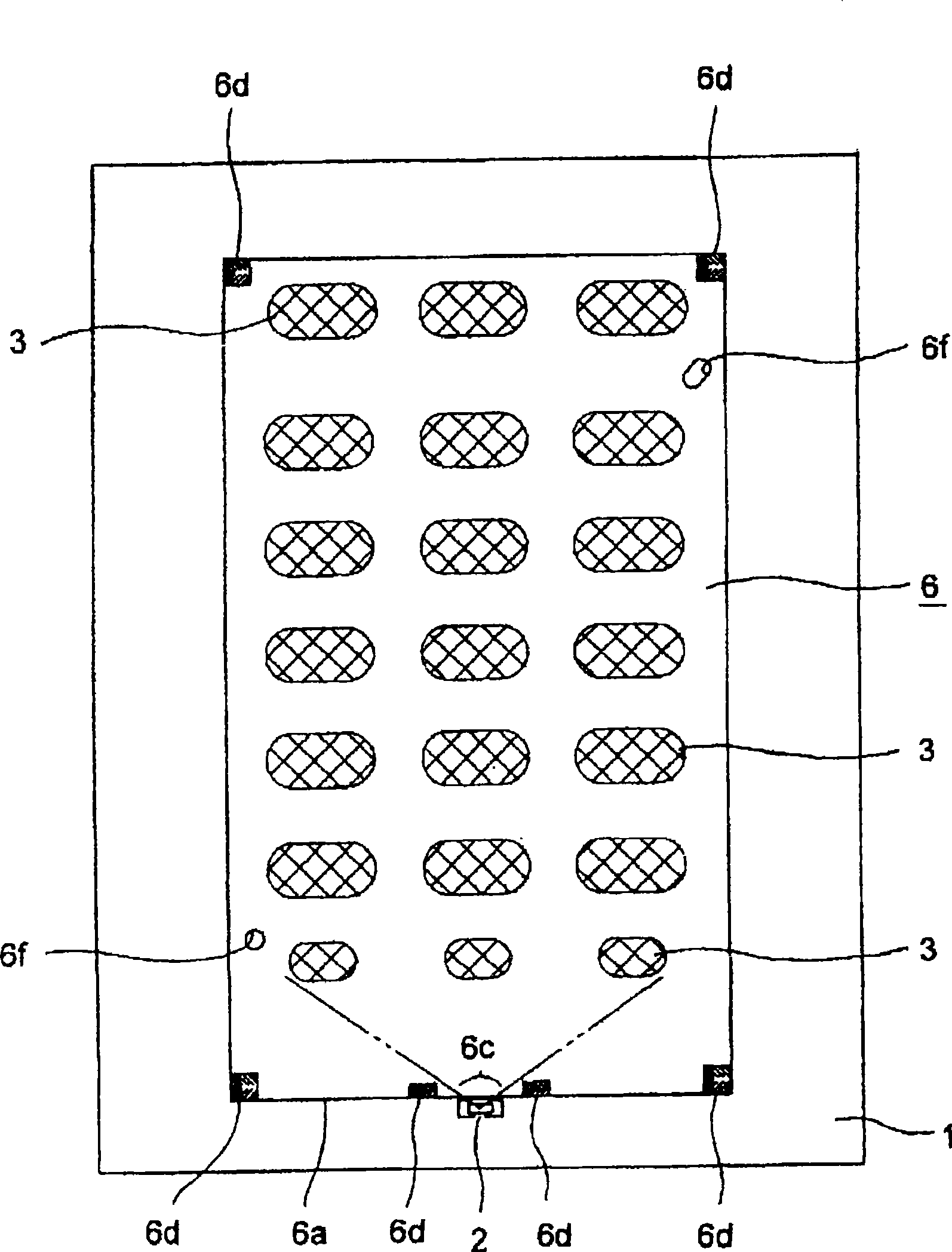

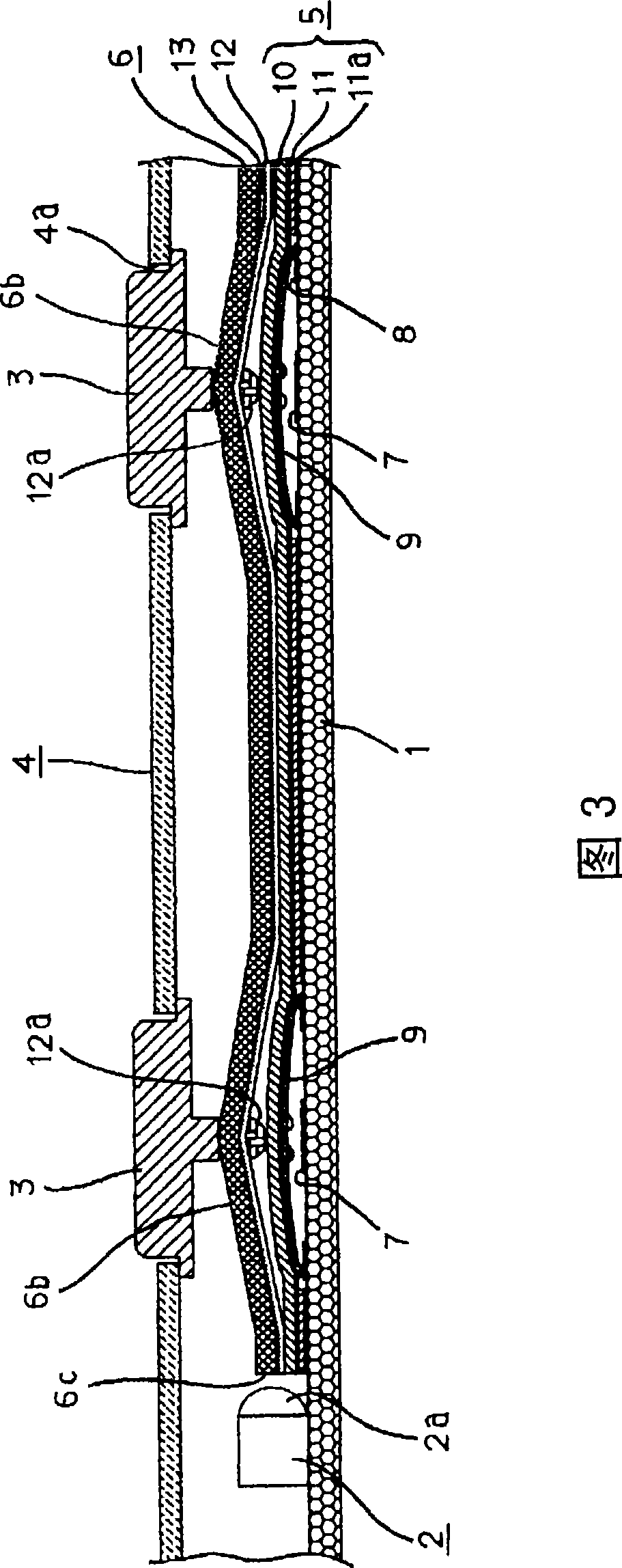

[0021] Next, with reference to the accompanying drawings, the embodiment of the present invention will be described. Fig. 1 is a sectional view of main parts of a switchgear according to Embodiment 1 of the present invention, figure 2 It is a top view showing the switchgear shown in FIG. 1 omitting a cover body.

[0022] The switch device shown in these figures mainly includes: a substrate 1 on which LED 2 is mounted, a plurality of operation keys 3 arranged in the opening 4a of the cover body 4, an attached contact thin plate member 5 placed on the substrate 1, and an attached contact on the attached contact. The flexible light guide plate 6 that prevents the thin plate 12 from being laminated is interposed on the thin plate member 5 . On the upper surface of the substrate 1, fixed contacts 7 and common contacts 8 are disposed below the respective operation keys 3, and the two contacts 7, 8 are exposed at regular intervals. In addition, on the substrate 1 , unillustrated wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com