Axial backlash-adjusted transmission drive unit

A drive unit, axial clearance technology, applied in the direction of components with teeth, transmission boxes, transmission parts, etc., to achieve the effect of eliminating the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

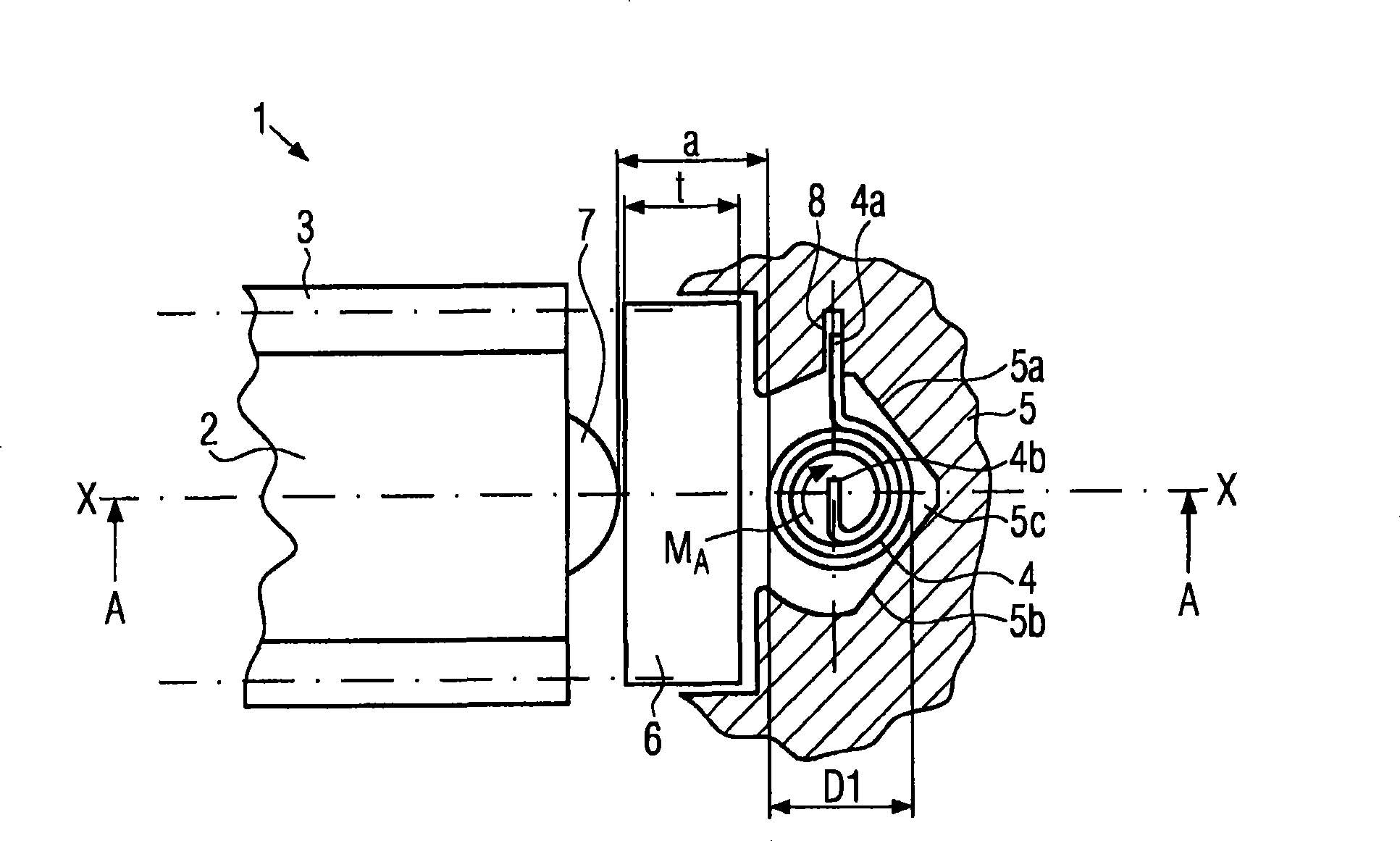

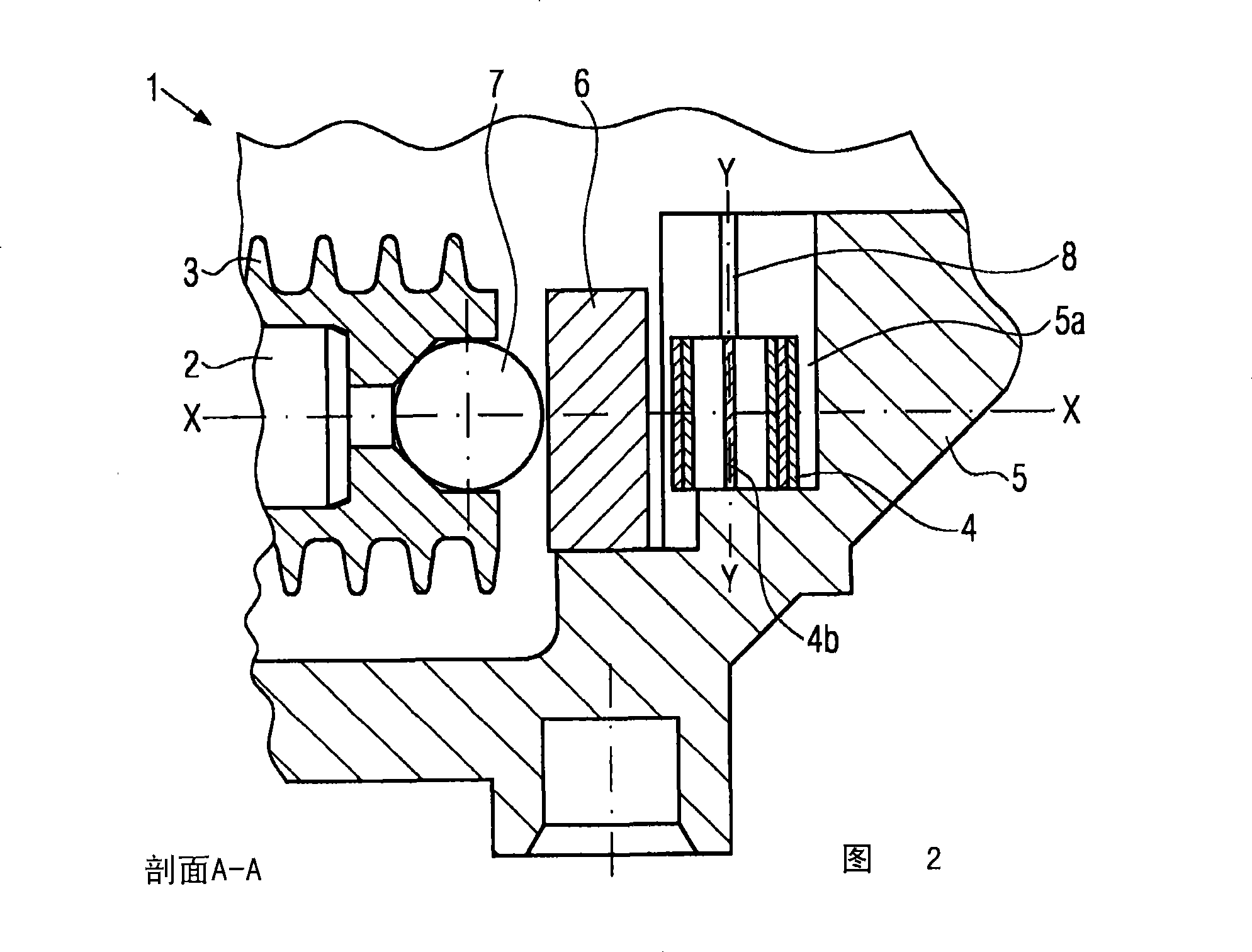

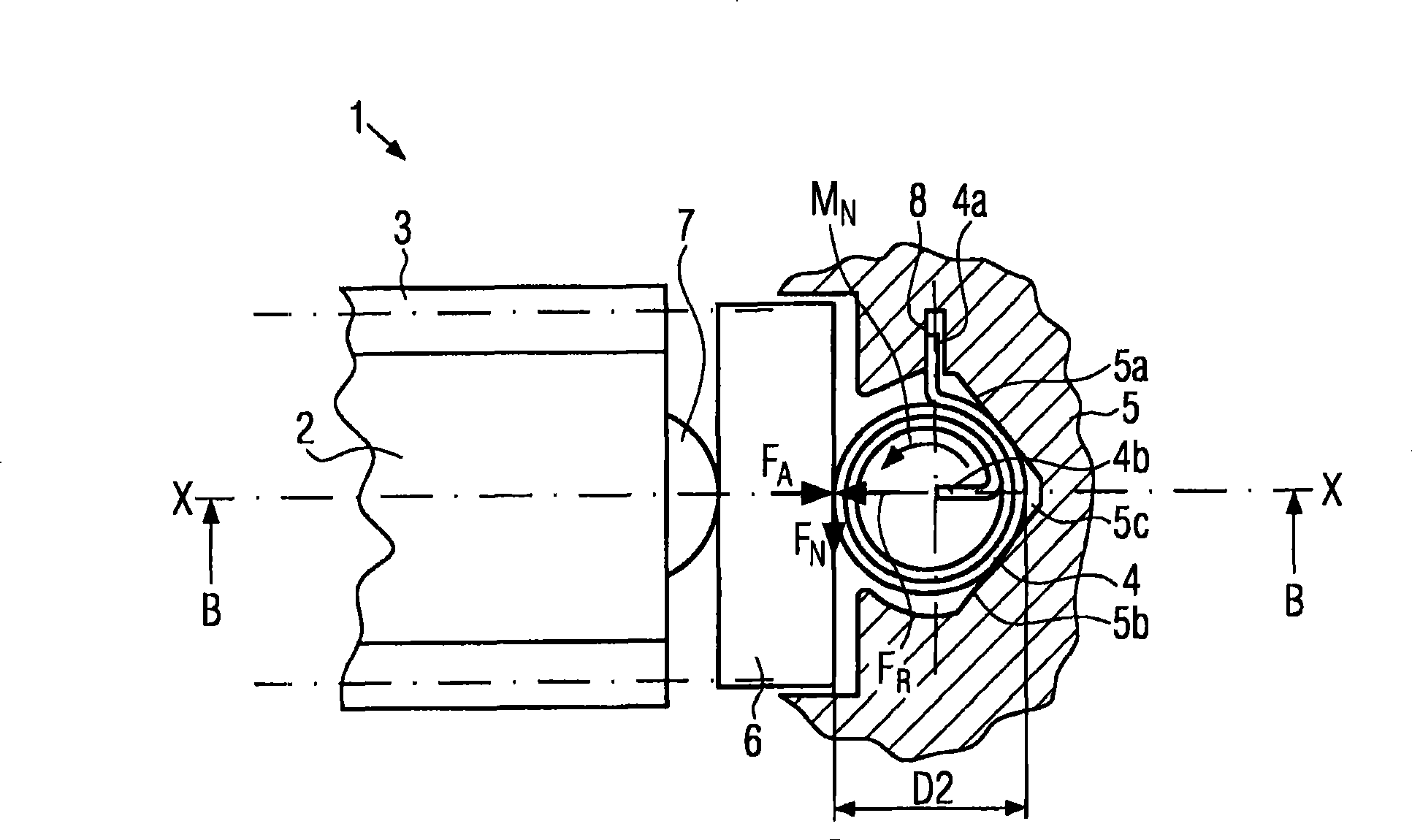

[0024] Refer below Figures 1 to 6 A transmission drive unit 1 according to a first embodiment of the invention will be described.

[0025] The transmission drive unit 1 comprises an electric motor with a shaft 2 on which a worm gear 3 is arranged. Here, shaft 2 is the armature shaft of the electric motor. As can be seen in particular from FIG. 2 , balls 7 or spherical axial projections are arranged on the end of the shaft, which can also be configured, for example, as domes and form point-shaped axial support.

[0026] The shaft 2 is arranged in a housing part 5 . In addition, in order to compensate the axial play of the shaft 2 , the compensating element 4 is arranged along the axial direction X-X of the shaft 2 . In this case, the compensating element 4 is arranged between the locking disk 6 and the housing part 5 at the end of the shaft 3 , which in this exemplary embodiment is formed by a ball 7 . The housing part 5 serves as a support part for the compensating eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com