Novel FPC two-sided glue adhesion method

A double-sided tape, black and white double-sided tape technology, used in adhesives, light source fixing, film/sheet adhesives, etc., can solve the problems of poor product visual effect, bright spots, light leakage from lamp sockets, etc. Bright spots, good stability, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

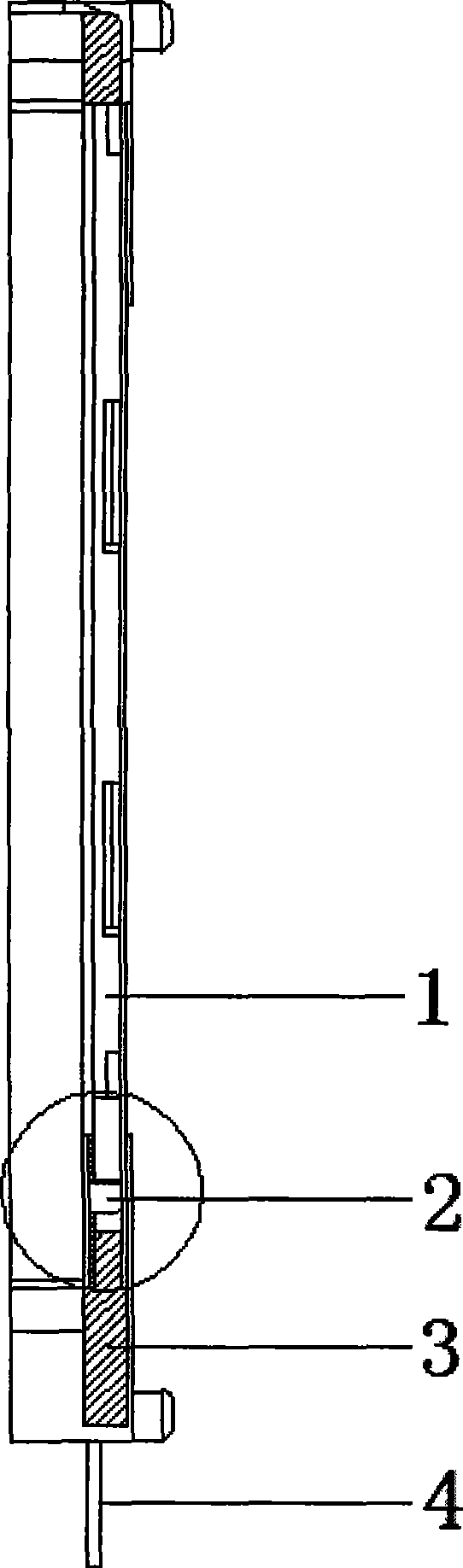

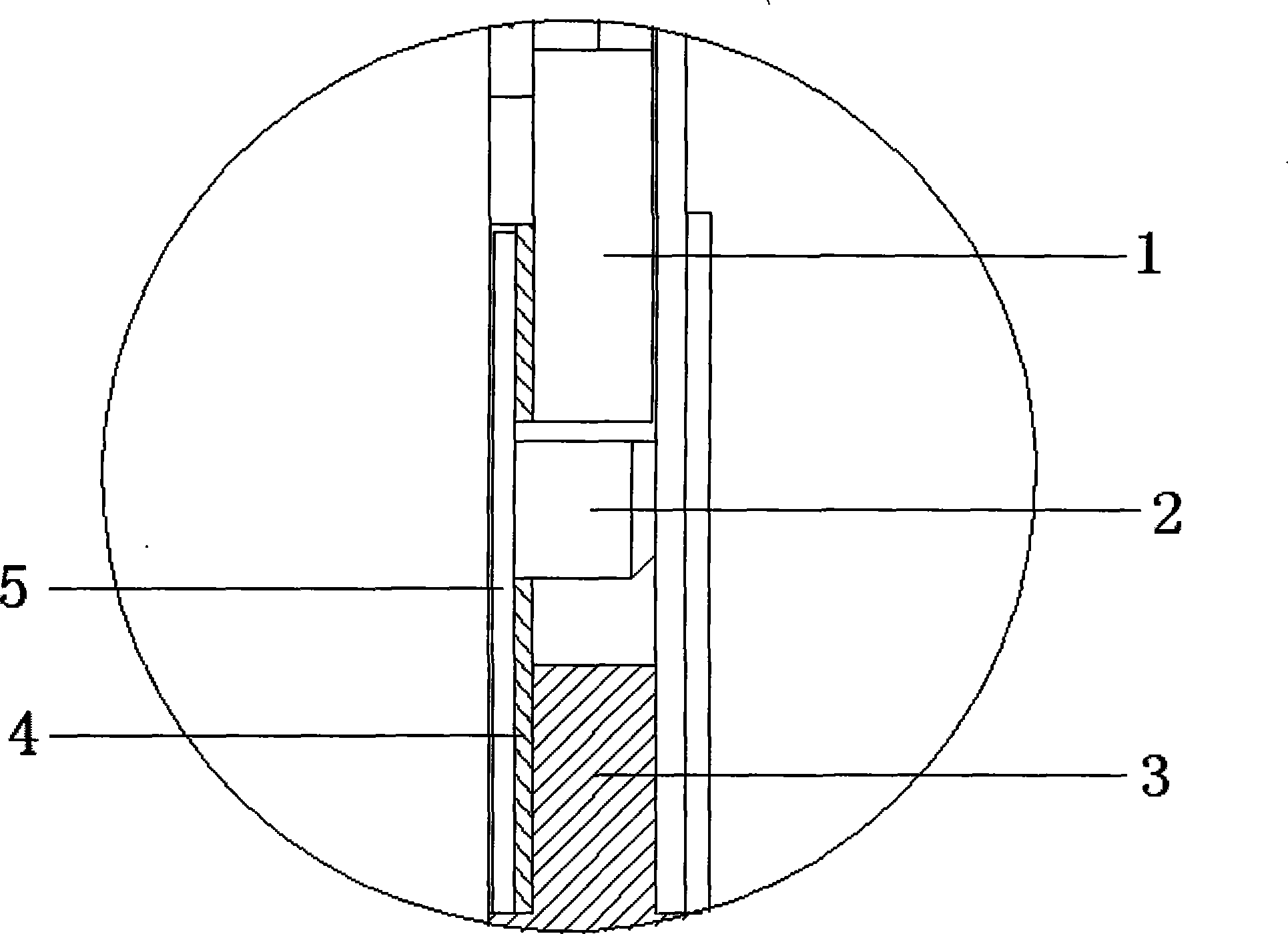

[0014] refer to Figure 1 to Figure 3 As shown, the present invention adopts opaque black and white double-sided adhesive tape instead of conventional transparent double-sided adhesive tape, glues the new FPC double-sided adhesive 4 on the FPC5, and then sticks the FPC5 on the plastic frame 3 and the light guide plate 1, or puts the new type The FPC double-sided tape 4 is first glued to the plastic frame 3 and the light guide plate 1, and then glued to the FPC5, which specifically includes the following steps:

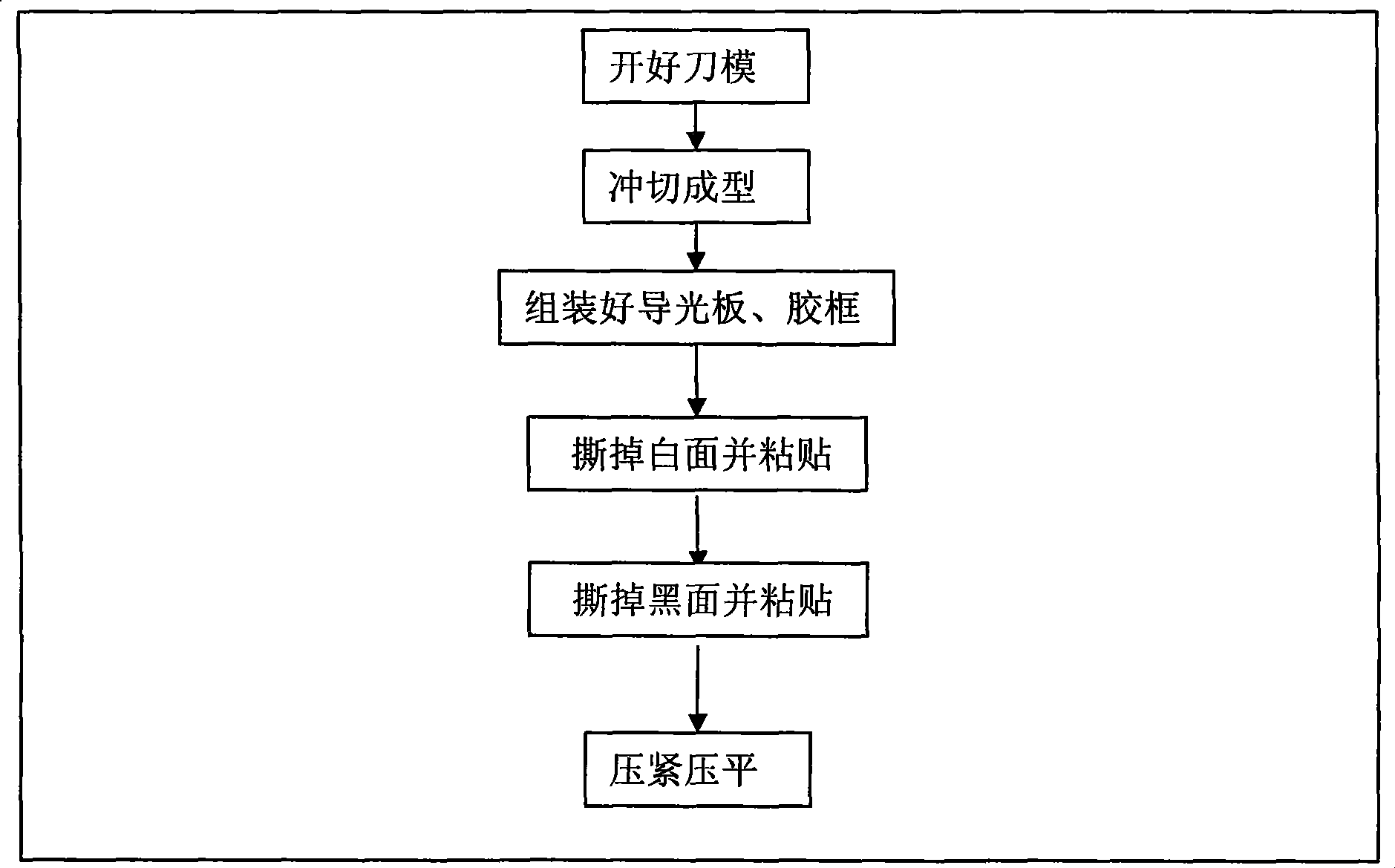

[0015] a. Open the knife mold, punch and cut the new FPC double-sided adhesive 4 on the film cutter, assemble the light guide plate 1 and the plastic frame 3, and take out the punched new FPC double-sided adhesive 4;

[0016] b. When pasting, after aligning the new FPC double-sided adhesive 4 with the plastic frame 3, first tear off the release paper on the white side of the new FPC double-sided adhesive 4, and stick the white side on the plastic frame 3 and the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com