Device and method for detecting obstruction degree of dustproof mesh, and electronic equipment thereof

A blockage detection and electronic equipment technology, applied in the detection field, can solve problems such as false detection, limited scope of application, high sensitivity requirements of detection switches, etc., and achieve the effect of ensuring heat dissipation and operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

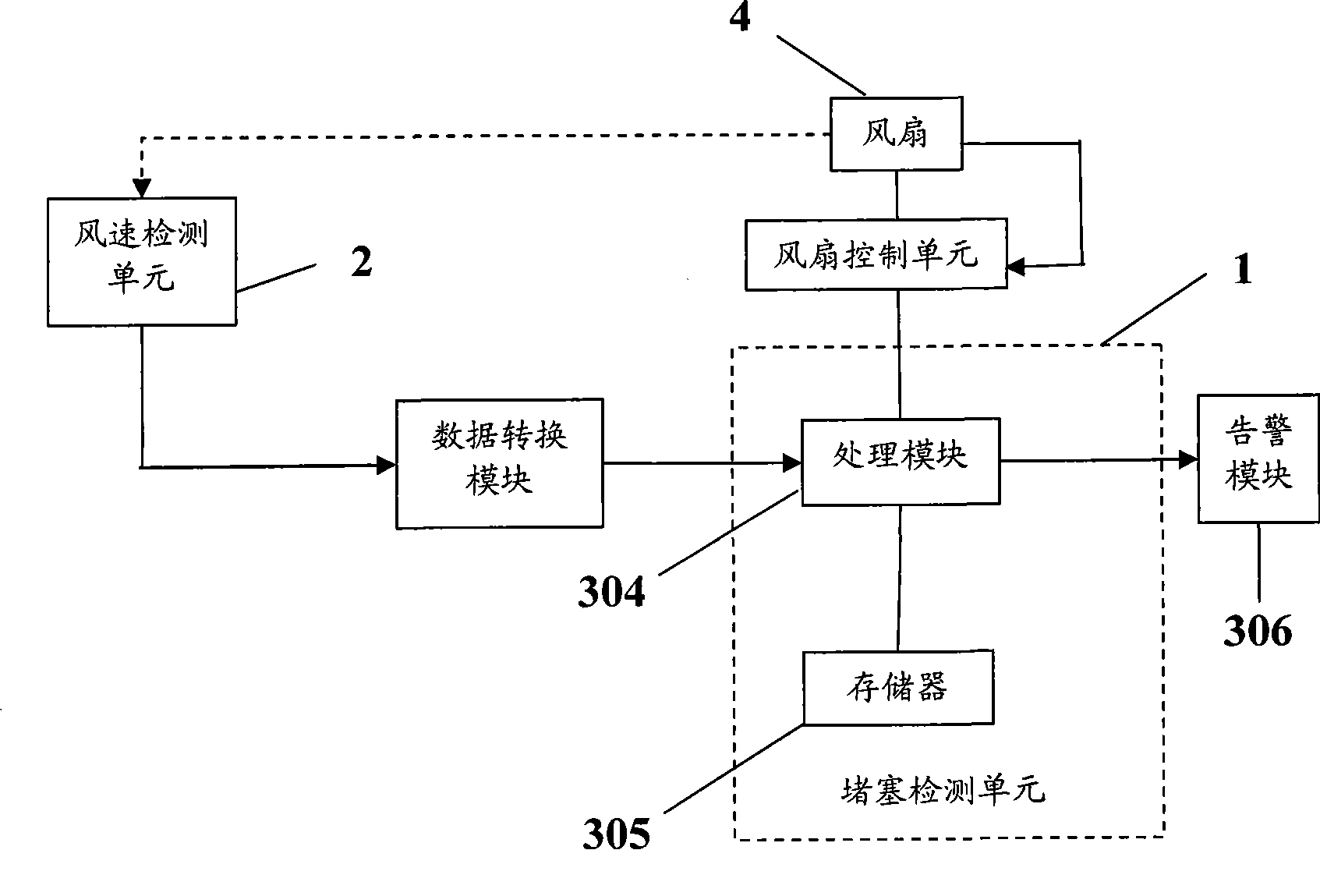

[0040] The device for detecting the clogging degree of the dust-proof net in this embodiment is applied to electronic equipment. The device for detecting the clogging degree of the dust-proof net will be described in detail below.

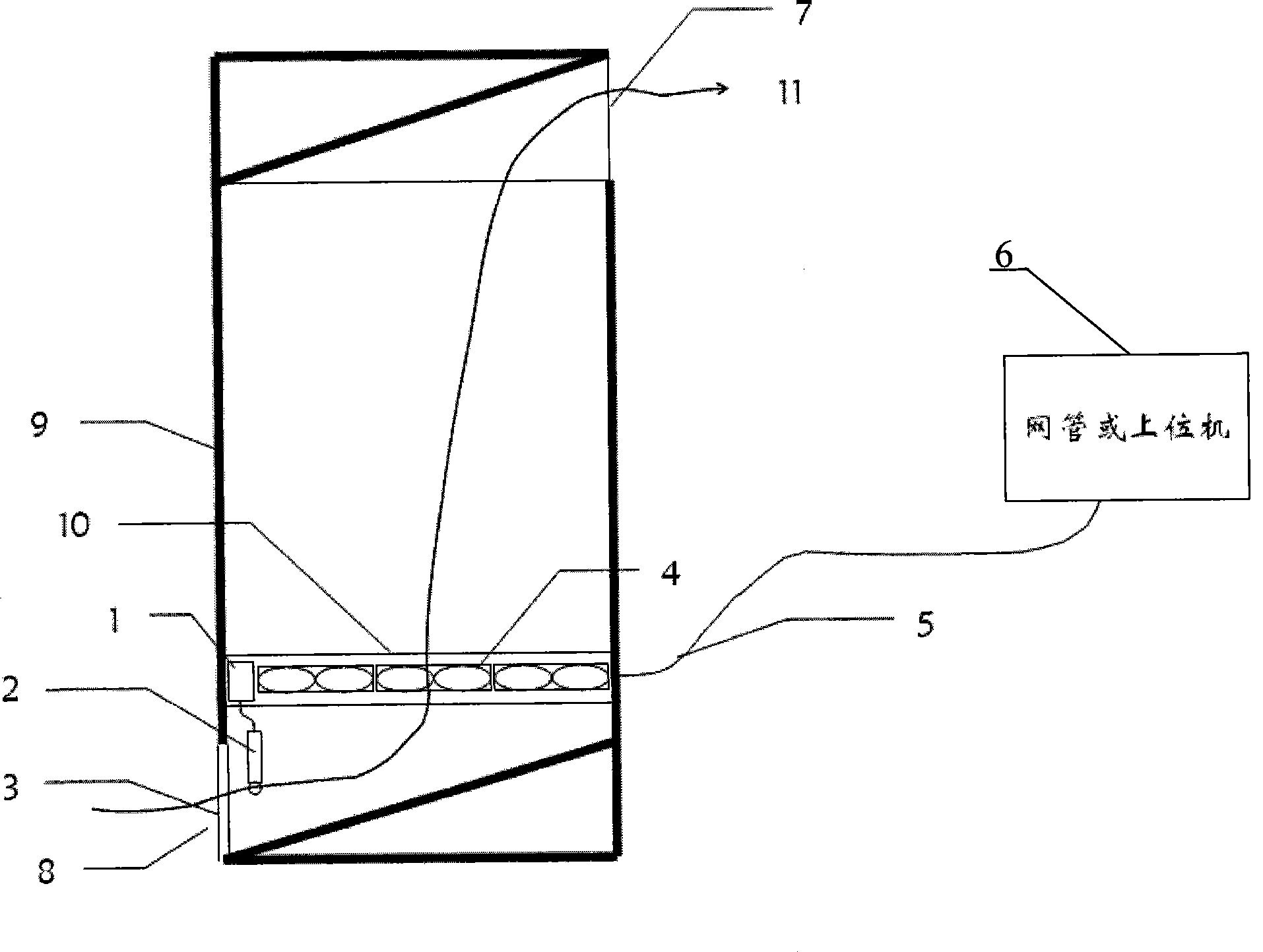

[0041] see figure 2 , figure 2 It is an electronic device with a detection device for the degree of clogging of the dust filter. The electronic equipment is provided with a single board (not shown in the figure), a fan 4, and an air inlet 8 and an air outlet 7 are provided on the electronic equipment, and the fan 4 is used to generate air flow, and make the air flow It flows in from the air inlet 8 and flows out from the air outlet 7, thereby forming an airflow channel 11 to dissipate heat to the single board. Wherein, a dust-proof net 3 is provided at the air inlet 8 to prevent dust from entering the electronic device. Furthermore, the fan 4 is installed on the fan frame 10, and the air inlet 8 and the air outlet 7 are opened on the cabinet ...

Embodiment 2

[0061] This embodiment describes a method for detecting the degree of blockage of the dust filter, including: collecting the speed of the fan and the wind speed parameters at the speed; obtaining the wind resistance characteristic parameters according to the speed of the fan and the wind speed parameters at the speed; The parameters and alarm thresholds determine the clogging degree of the dust filter. The wind speed parameter may be a digital wind speed signal.

[0062] Refer below Figure 4 , the method for detecting the clogging degree of the dust filter will be described in detail. The detection method comprises the following steps:

[0063] Step 41, power on the dust-proof net blockage detection device, and configure the system;

[0064] Step 42, collect the initial characteristic parameters of the system, and calculate the initial wind resistance characteristic parameter K1 and the alarm threshold X of the system;

[0065] Step 43, determine whether the timing detect...

Embodiment 3

[0098] An electronic device, the electronic device is provided with a single board and a fan, and an air inlet and an air outlet are provided on the electronic device, the fan is used to generate airflow, and the airflow flows in from the air inlet, from The air outlet flows out to form an airflow channel to dissipate heat for the veneer, and a dust-proof net is provided at the air inlet, wherein the electronic equipment includes a dust-proof net clogging degree detection device, and the device includes: a wind speed detection unit , a data conversion module and a blockage detection unit, wherein:

[0099] The wind speed detection unit is arranged in the airflow channel, and is used to obtain an analog wind speed signal, and provide the analog wind speed signal to the data conversion module;

[0100] The data conversion module is connected to the wind speed detection unit, and is used to convert the analog wind speed signal into a digital wind speed signal, and provide the dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com