Method for inkjet printing with light-curable ink

A light-curable ink and inkjet printer technology, applied in printing devices, printing, typewriters, etc., can solve problems such as inability to achieve wiping resistance, insufficient irradiation intensity, and printing image curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

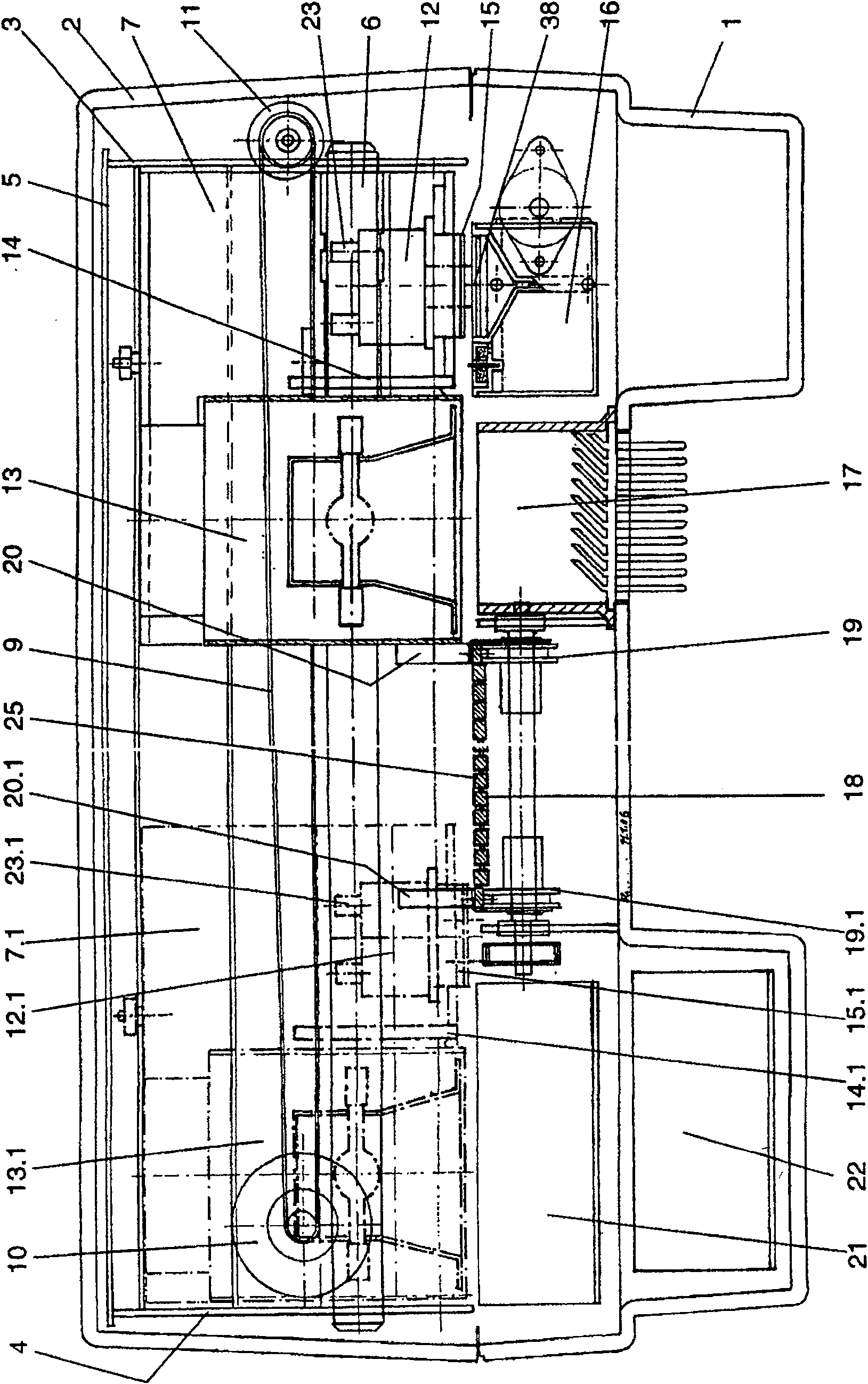

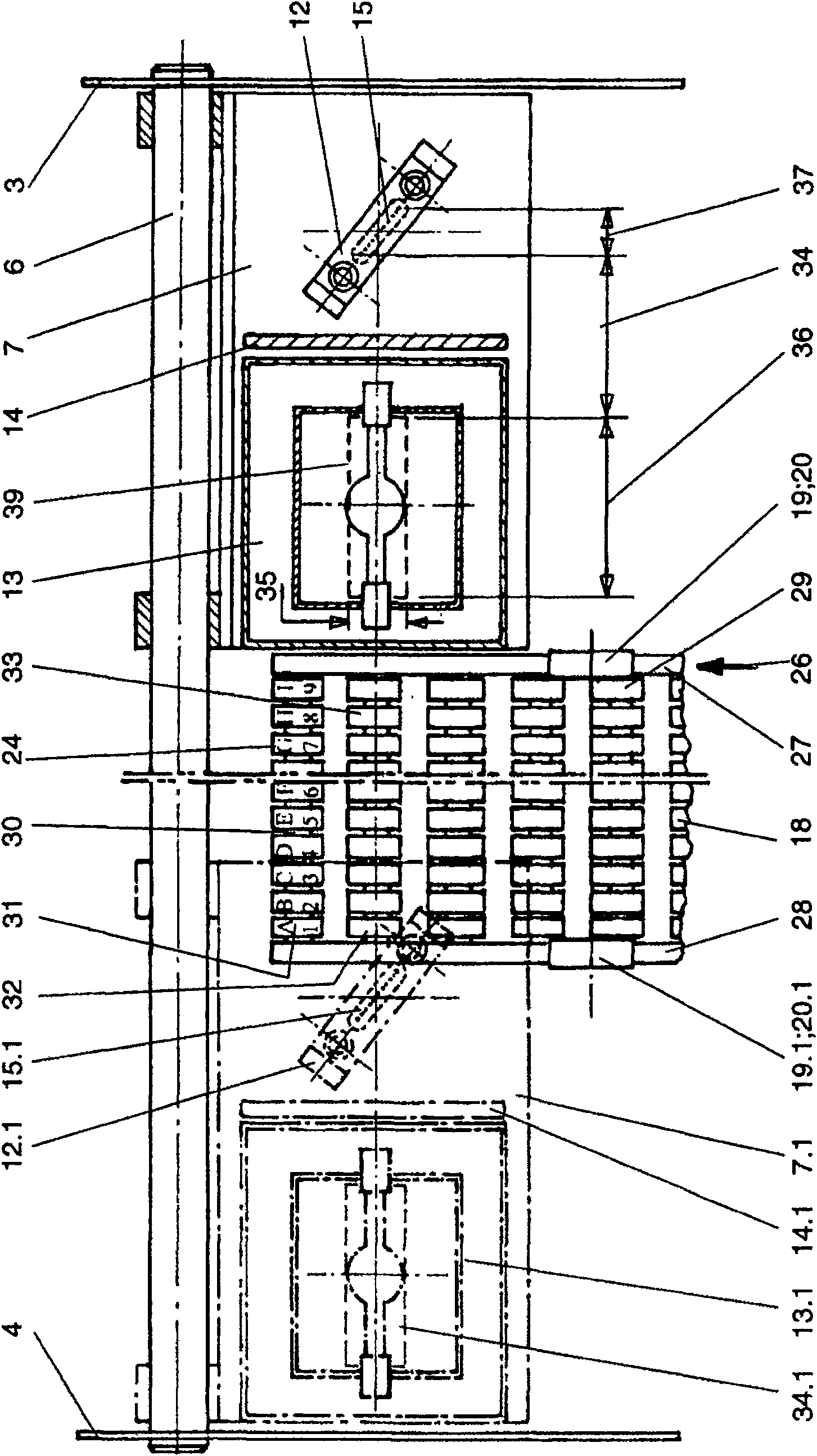

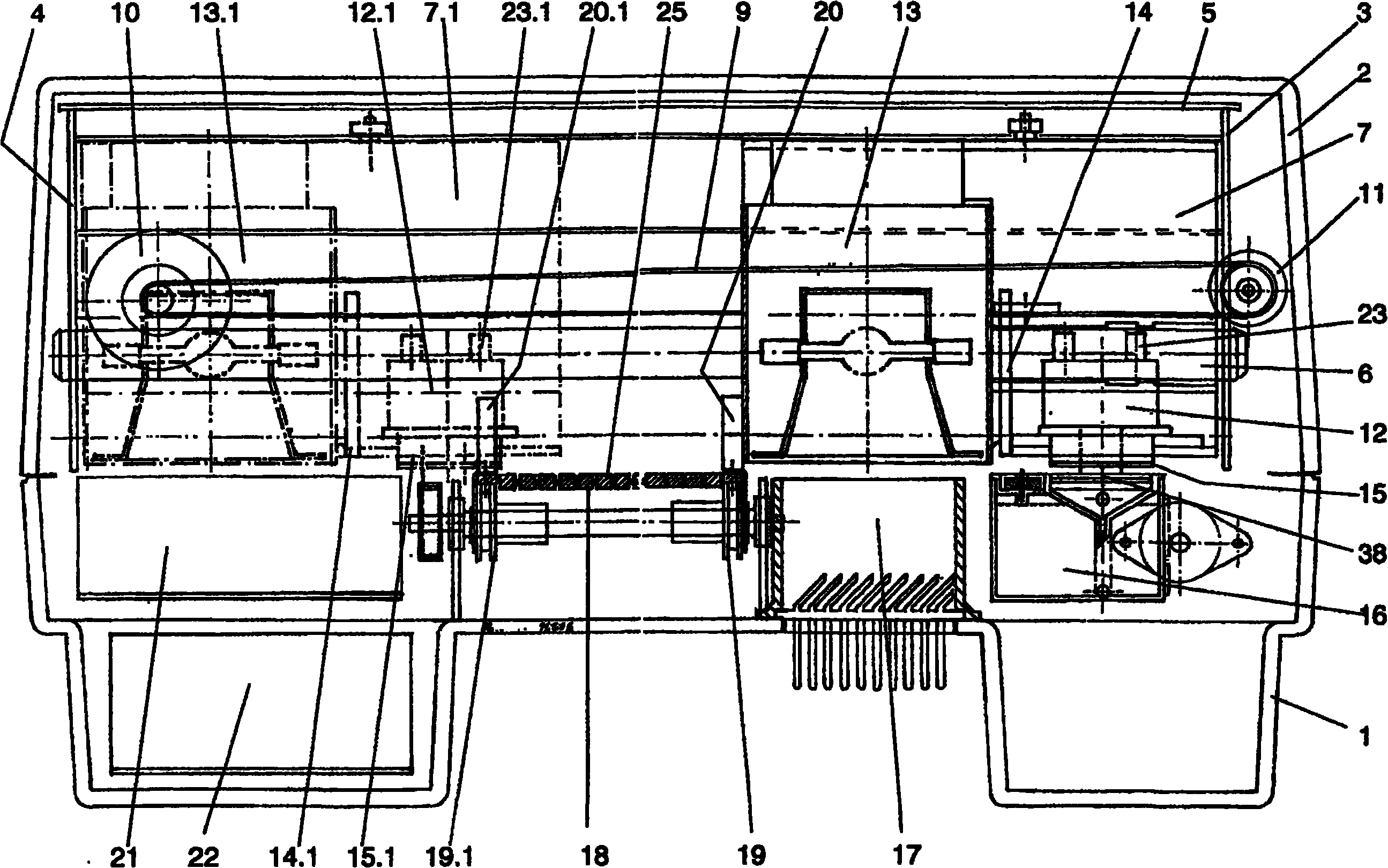

[0016] figure 1 and figure 2 A printer according to the invention with a printing head and an exposure head connected thereto is shown in longitudinal section and plan view. The printer according to the invention is preferably designed as a desktop printer and essentially consists of a housing slot 1 and a housing upper part 2 in which a printer support with side walls 3 , 4 is arranged. The two side walls are separated by an angular beam 5 . A slide rail 6 is attached to the printer stand, on which slide carriages 7, 7.1 are mounted. The carriages 7 , 7 . 1 are driven by a motor 10 via a ring-shaped traction device 9 , which is steered here by deflection wheels 11 . Mounted on the carriage 7, 7.1 are the printing heads 12, 12.1 and beside them the exposure heads 13, 13.1. Between them is a heat shield 14, 14.1, which protects the print heads 12, 12.1 from the thermal radiation of the exposure heads 13, 13.1.

[0017] Below the nozzle arrangement 15 of the print head 12 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap