Molded motor

A motor and molding technology, applied in the direction of casing/housing/support, electrical components, electromechanical devices, etc., can solve problems such as thermal degradation of molding resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

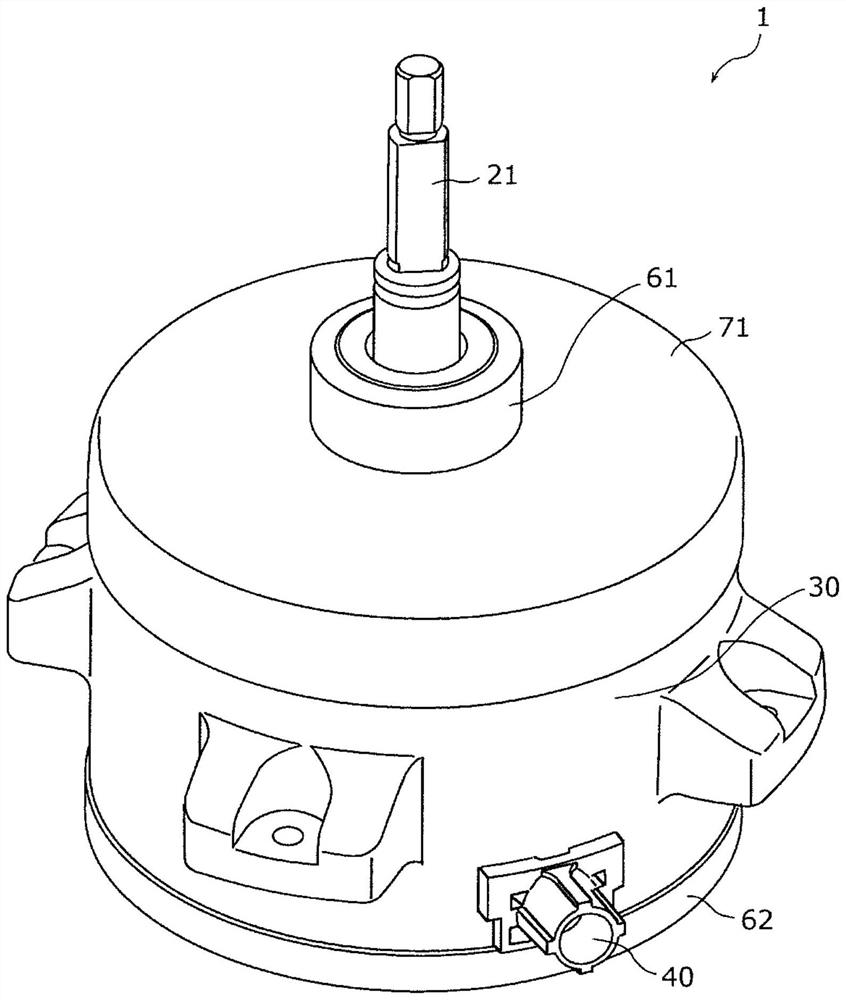

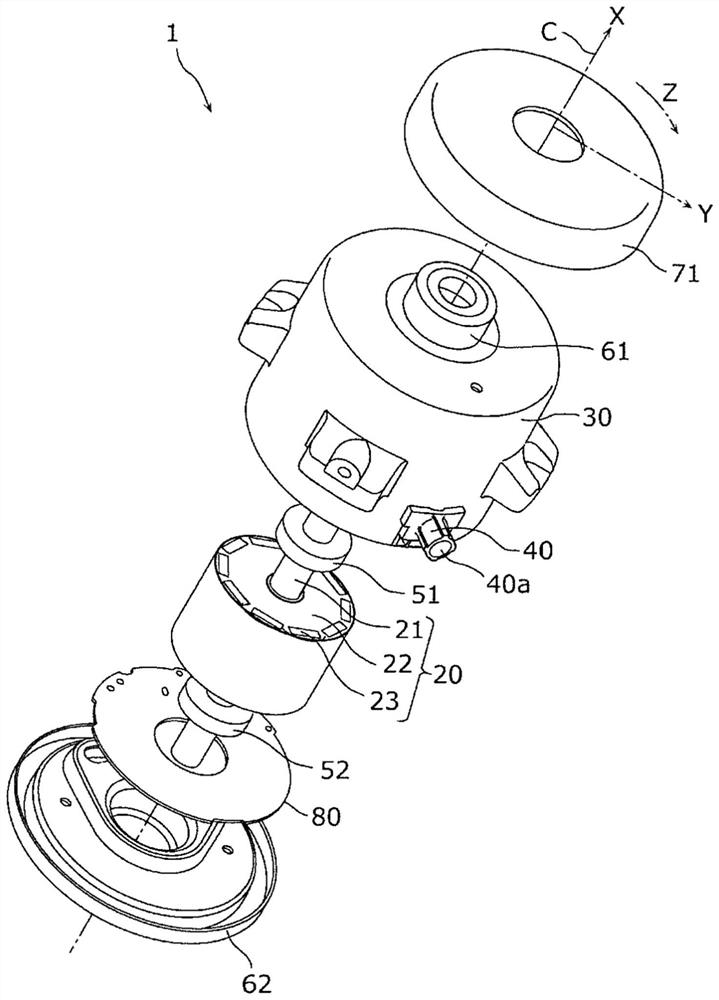

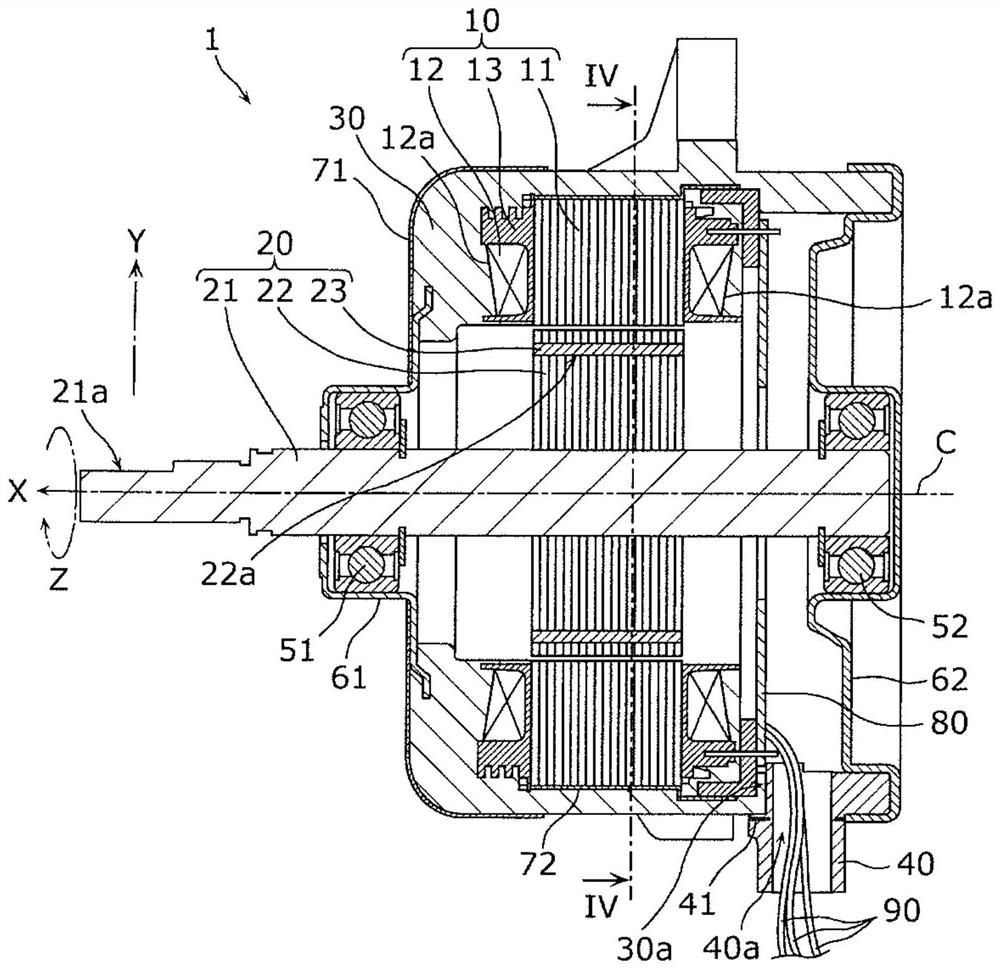

[0048] First, use Figure 1 ~ Figure 4 The overall structure of the molded motor 1 according to Embodiment 1 will be described. figure 1 It is a perspective view of the molded motor 1 of Embodiment 1. figure 2 is an exploded perspective view of the molded motor 1 . image 3 is a sectional view of the molded motor 1 . Figure 4 is the molded motor 1 in image 3 Sectional view at line IV-IV. In addition, in Figure 2 ~ Figure 4 Here, the direction in which the rotating shaft 21 of the rotor 20 extends is defined as an axial direction X, and on a plane perpendicular to the axial direction X, the direction extending from the axis C around the axis C of the rotating shaft 21 is defined as The radial direction is defined as Y, and the direction surrounding the axis C around the axis C is defined as a circumferential direction Z. In addition, in Figure 4 In FIG. 2 , hatching is omitted for the sake of convenience for the core portion of the stator core 11 and the core porti...

Embodiment approach 2

[0100] Next, use Figure 12 and Figure 13 The molded motor 2 of the second embodiment will be described. Figure 12 It is a figure showing the structure of the lead wire bushing 40B used for the molded motor 2 of Embodiment 2, Figure 12 (a) is the main view, Figure 12 (b) is a side view, Figure 12 (c) is a plan view. In addition, in Figure 12 In , hatching is also given to the metal member 41 for the sake of convenience. In addition, in Figure 12 In (b), the figure shows Figure 12 The cross-section of the metal member 41 at the B-B line of (a), in Figure 12 In (c), the figure shows Figure 12 The section of the metal member 41 at line C-C of (b). in addition, Figure 13 It is an enlarged cross-sectional view of a main part of the molded motor 2 according to the second embodiment.

[0101] In the above-mentioned molded motor 1 of Embodiment 1, the metal member 41 included in the lead wire bushing 40 is composed of a single metal plate, but as Figure 12 and...

Embodiment approach 3

[0110] Next, use Figure 15 ~ Figure 17 The molded motor 3 of the third embodiment will be described. Figure 15 It is a sectional view showing the peripheral structures of the molded resin 30 and the lead bushing 40C of the molded motor 3 according to the third embodiment. Figure 16 is a perspective view of a metal member 41C included in a lead bushing 40C used in the molded motor 3, Figure 17 It is a plan view of this metal member 41C.

[0111] like Figure 15 As shown, in the molded motor 3 of the present embodiment, the lead wire bushing 40C is a connector type, and has a protruding portion 41c protruding outward from the side wall portion of the molded resin 30 . The through hole 40 a formed in the lead bush 40C of this embodiment is a fine hole for immobilizing the electric wire 90 . In the present embodiment, three electric wires 90 are inserted through the lead bush 40C, so three through-holes 40 a are provided. The electric wires 90 are inserted into the respec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap