Method for producing fermented malt beverage using cereals treated with thiophanate methyl

A technology of thiophanate-methyl and malt beverages is applied in the preparation of malt, beer brewing, botanical equipment and methods, etc., and can solve problems such as undocumented

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

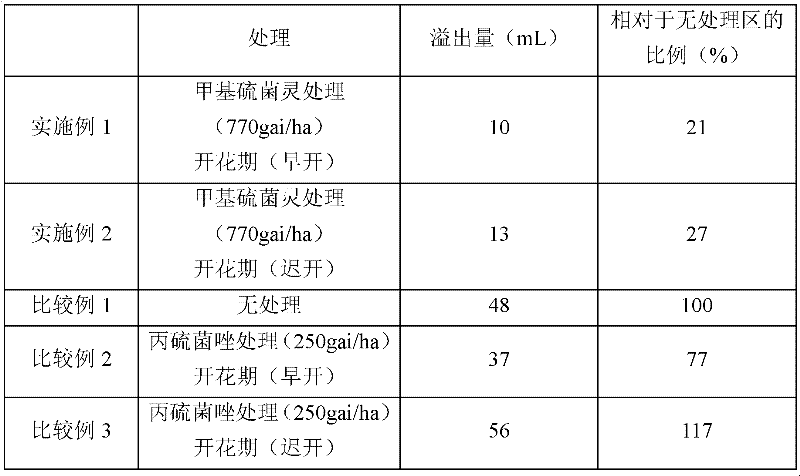

Embodiment 1~2 and comparative example 1~3

[0050] Fields were artificially sown with Fusarium spores at the grain formation stage, and after 1 day or 7 days, thiophanate-methyl was spread at a rate of 770 g ai / ha (in addition, ai in ai / ha is The abbreviation of "active ingredient", which means "active ingredient itself" or "converted to the original body"). Harvested barley goes through a germination process and a drying process to make malt.

[0051] Using the obtained malt, beer is produced according to the usual method.

[0052] The prepared beer was put into bottles, and the spray test of beer after uncapping was carried out according to the following method.

[0053]

[0054] The bottle to be tested was shaken for 22 hours, then left to stand for 1 minute, weighed, and then opened. The weight after opening the lid was measured again, and the ejection of the contents was calculated. Calculate the amount of overflow from the weight difference before and after opening the cap.

[0055] As a comparative example,...

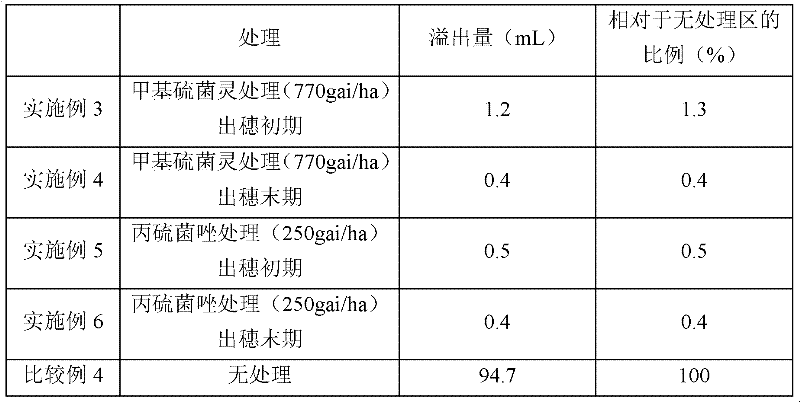

Embodiment 3~6、 comparative example 4

[0060] In Examples 3 and 4, experiments were carried out in the same manner as in Examples 1 and 2, except that the grain formation period was replaced with the early and late ear emergence stages, and barley was replaced with wheat.

[0061] Examples 5 and 6 were tested in the same manner as in Examples 3 and 4, except that prothioconazole was used instead of thiophanate-methyl and the distribution ratio was changed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap