Waveform plate web girder

A corrugated web, plate beam technology, applied in joists, girders, truss beams, etc., can solve the problems of shear buckling strength and shear bearing capacity to be improved, achieve good designability and practicability, and improve bearing capacity. Powerful, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

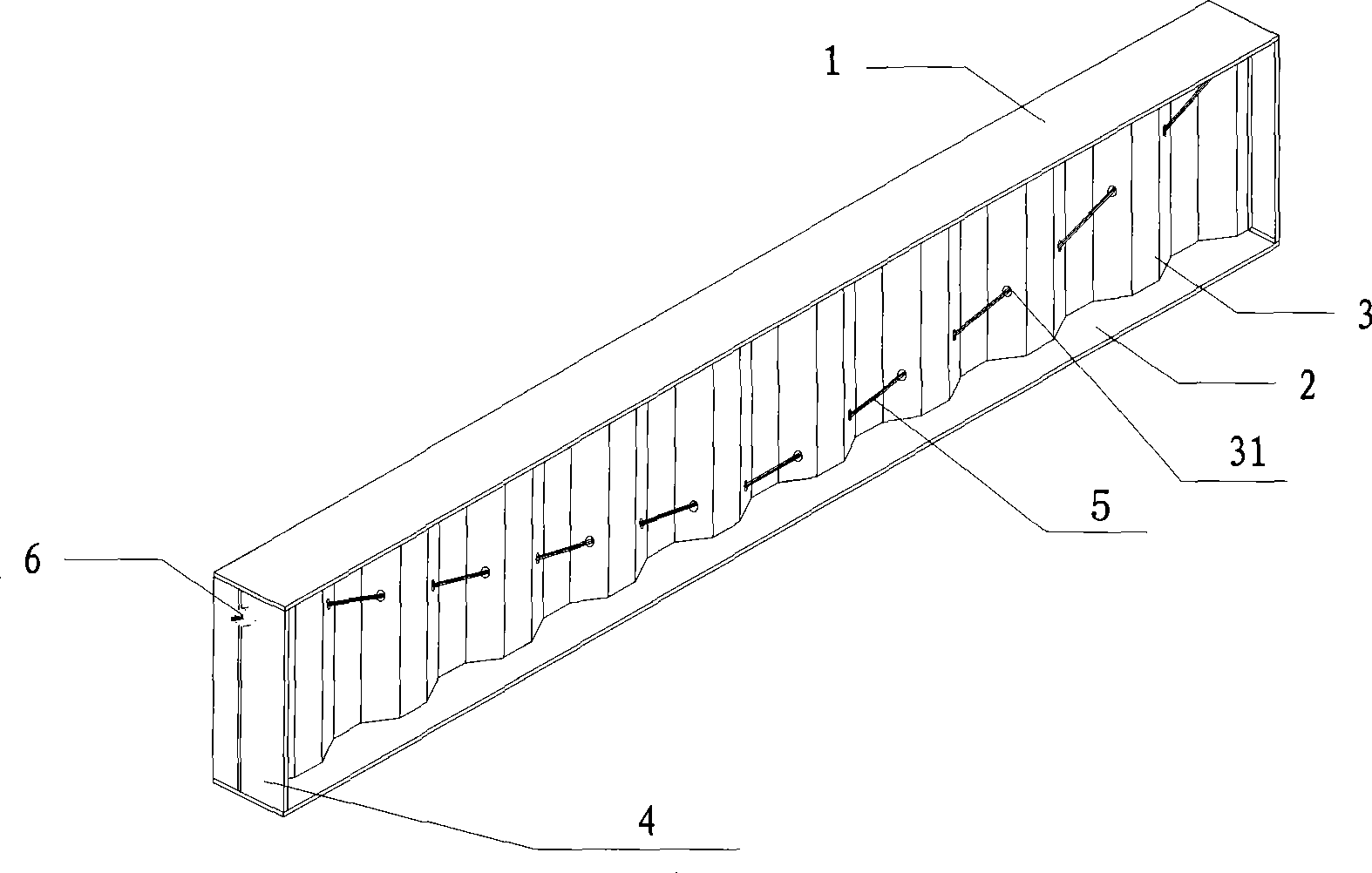

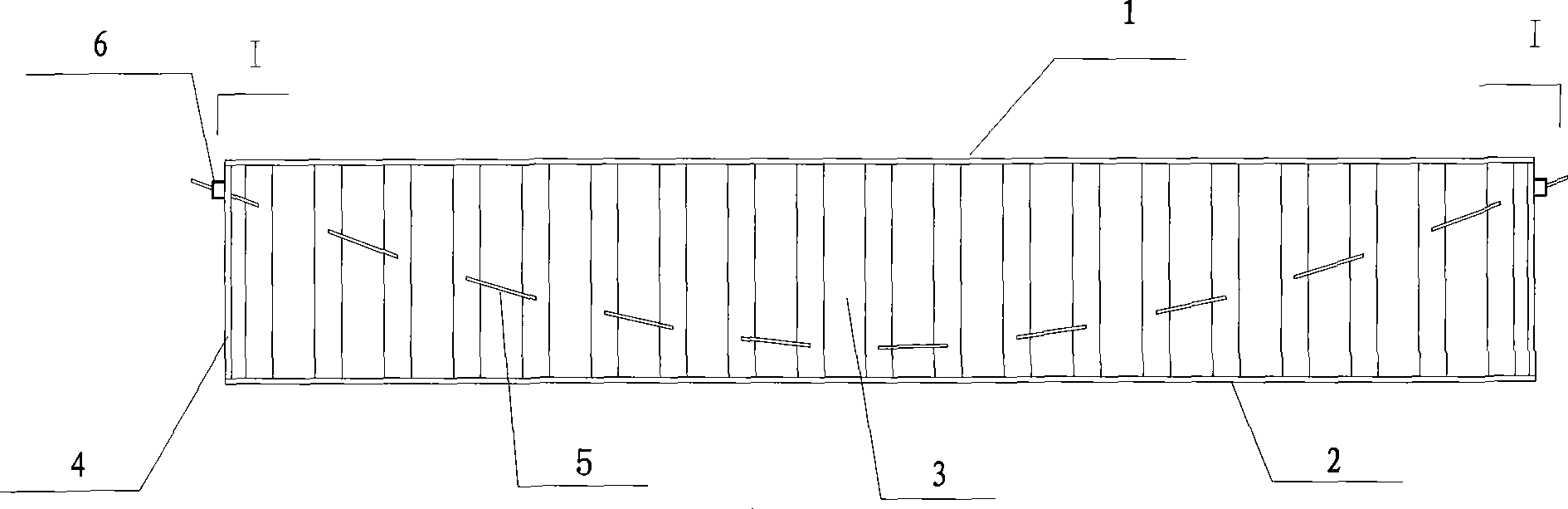

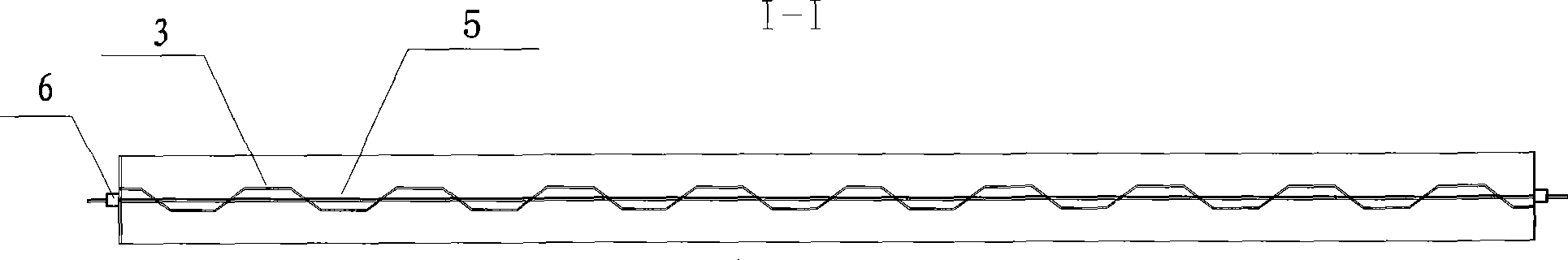

[0023] Such as Figure 1-3 , a corrugated web beam, consisting of an upper flange plate 1, a lower flange plate 2, a corrugated web plate 3, a hole 31 on the corrugated web plate, a beam end plate 4, a prestressed tendon 5 and an anchor 6; the beam The end plates 4 are located at both ends of the beam, and are connected with the upper flange plate 1, the lower flange plate 2 and the corrugated plate 3, and the holes 31 are located in the obliquely folded plate part of the corrugated web 3, relative to a prestressing tendon 5 The holes are lowered sequentially from both ends to the middle, and the prestressed tendons 5 pass through the holes 31 on the corrugated web 3, and after being stretched, they are fixed on the end plates 4 at both ends of the beam by the anchors 6, forming a line shape with upward notches . The corrugated web 3 is made of metal material, and the prestressing rib 5 is made of metal or carbon fiber material.

Embodiment 2

[0025] It is basically the same as Embodiment 1, except that there are two prestressed tendons with upward notches on the corrugated web. The prestressing tendons are made of carbon fiber material; the corrugated web is made of resin-based fiber-reinforced plastic.

Embodiment 3

[0027] refer to Figure 4-6 , a corrugated web beam, consisting of an upper flange plate 1, a lower flange plate 2, a corrugated web plate 3, a beam end plate 4, a stiffened rib plate 7, a hole 71 on the stiffened rib plate, and prestressed ribs 5 Composed of an anchor 6, a plurality of stiffened ribs 7 are arranged symmetrically on both sides of the corrugated web 3, and the stiffened plates 7 are connected with the upper flange plate 1, the lower flange plate 2 and the corrugated web 3. The prestressed tendons 5 pass through the holes 71 on the stiffened plates 7 on both sides of the corrugated web 3 to form a line with notches upward, and are fixed on the beam end plates 4 at both ends of the beam by anchors 6 after being stretched. The corrugated web 3 is made of metal material, and the prestressing rib 5 is made of metal material or carbon fiber material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com