Method and device for measuring weighting function of electromagnetic flowmeter

An electromagnetic flowmeter and weight function technology, applied in measuring devices, test/calibration devices, liquid/fluid solid measurement, etc., can solve the problems of inaccurate calculation results, complex mathematical derivation and calculation ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

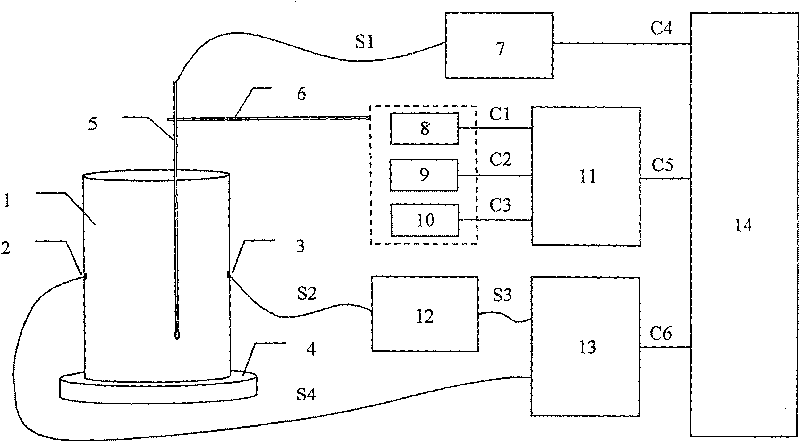

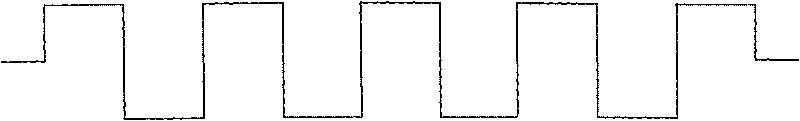

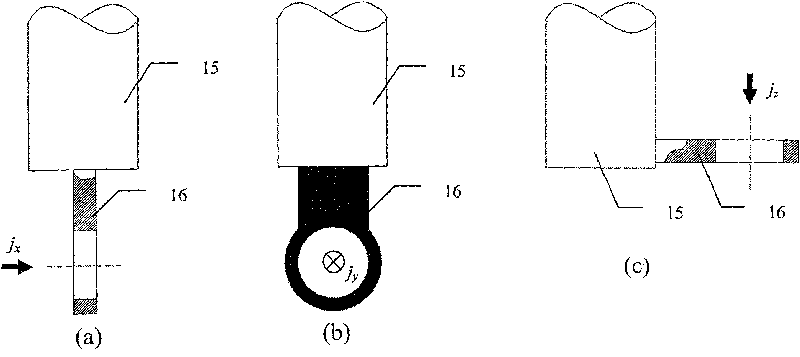

[0018] Such as figure 1 As shown, one end of the electromagnetic flowmeter pipe section 1 is sealed through the sealing flange 4, and filled with water after being placed upright, and a positive and negative inverted rectangular wave electric signal is added to the electrodes 2 and 3 of the electromagnetic flowmeter by using the excitation module 12. An alternating current field will be formed in the pipe section, and the current density in the current field with the electromagnetic flowmeter weighting function have the same distribution characteristics. The computer 14 drives the current density meter probe 5 to measure the current density at a certain point through the existing three-dimensional positioning mechanism products composed of x, y, and z linear electric displacement stages 8, 9, and 10. Simultaneously by ammeter 13, measure the current total amount I that flows through on the electrode at this moment, utilize relational expression at last Calculate the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com