Patents

Literature

103results about How to "Easy to derive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

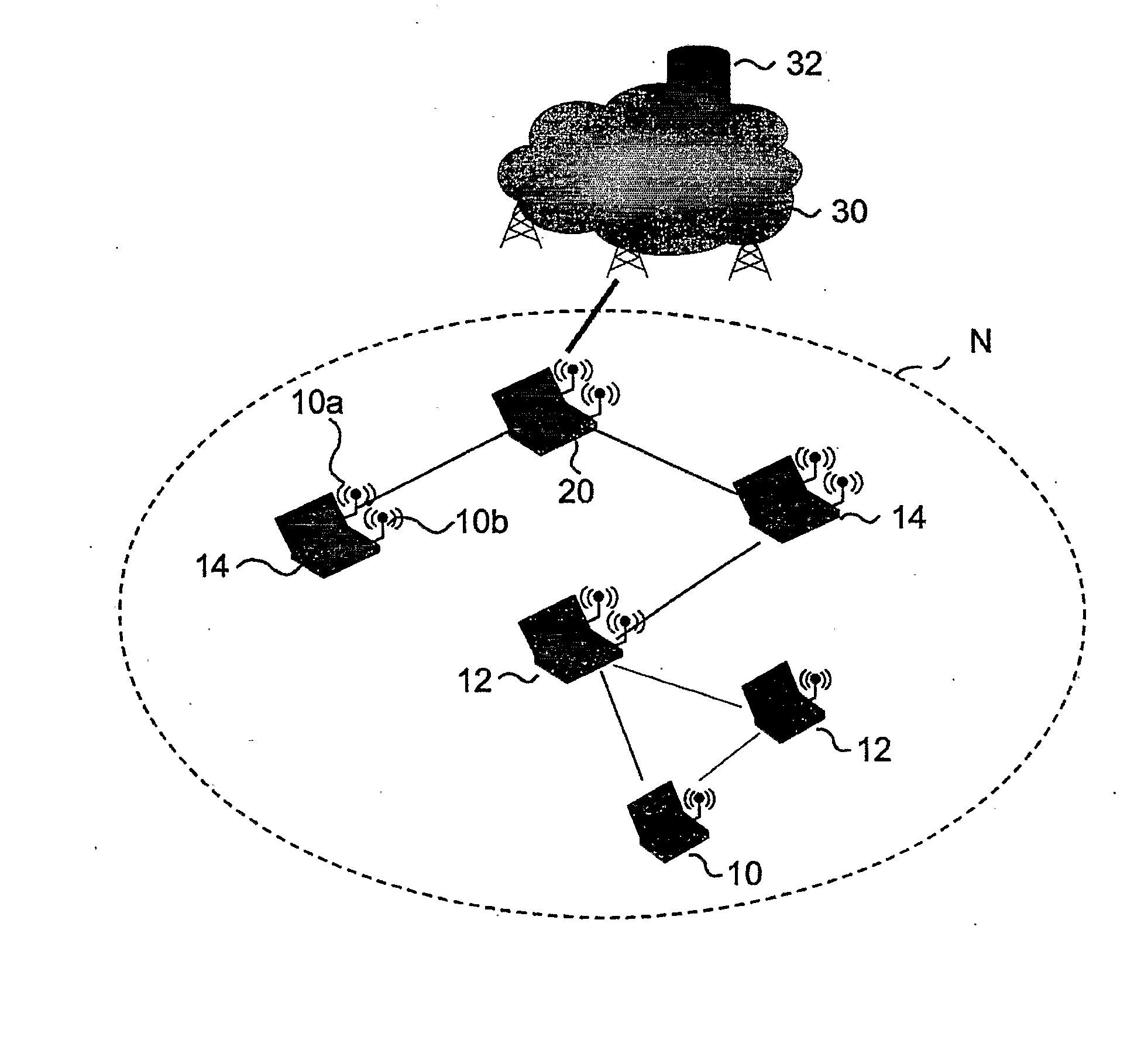

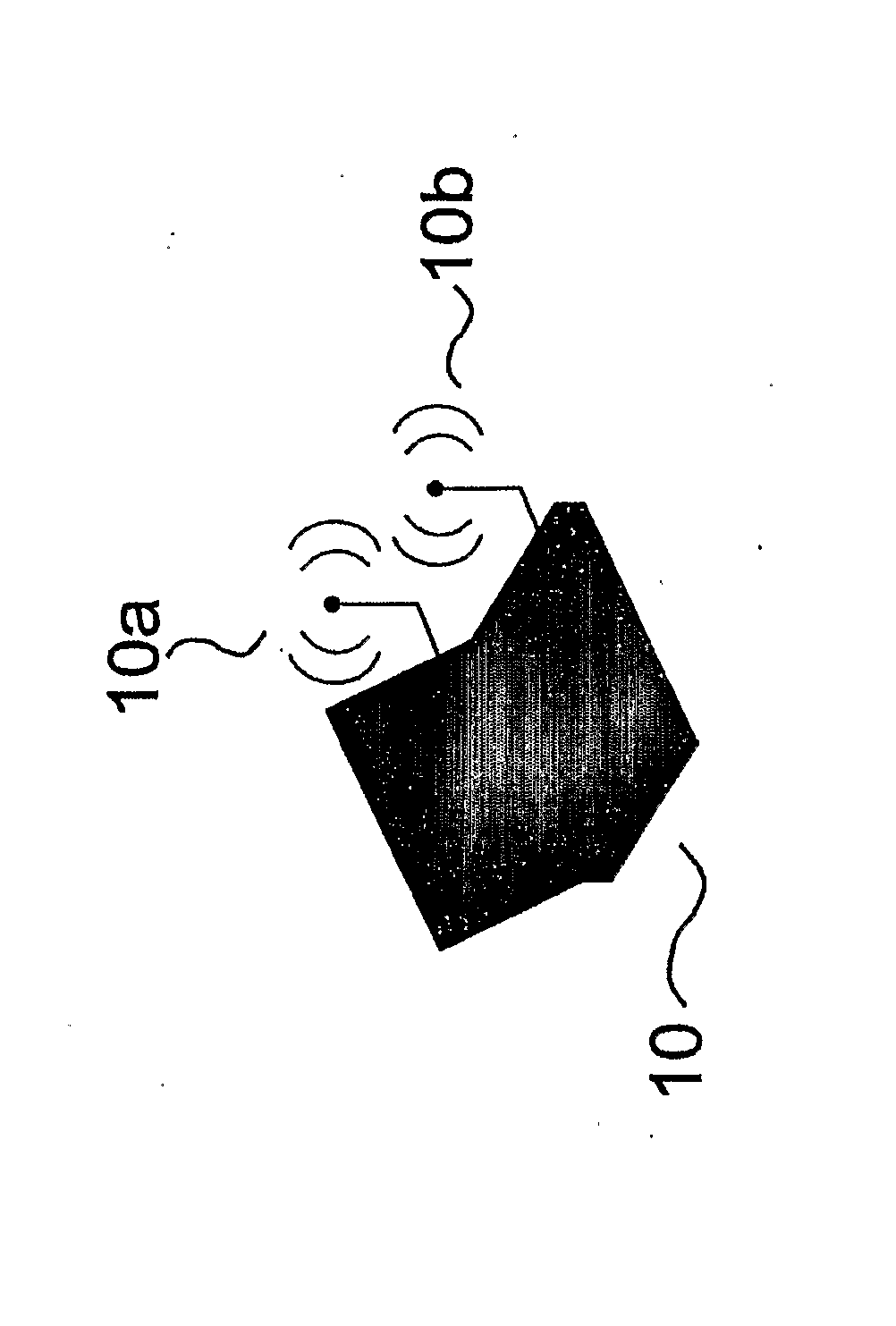

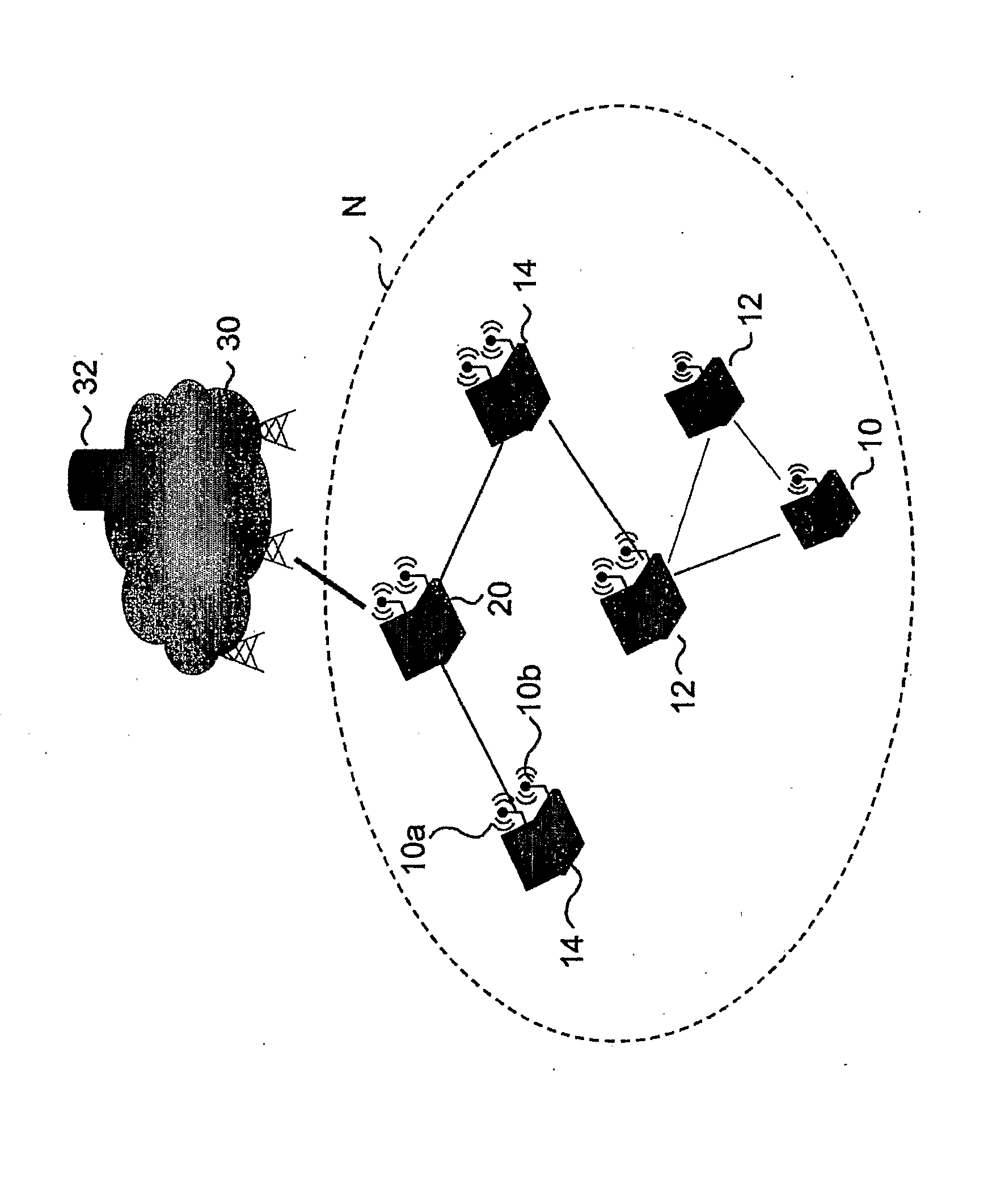

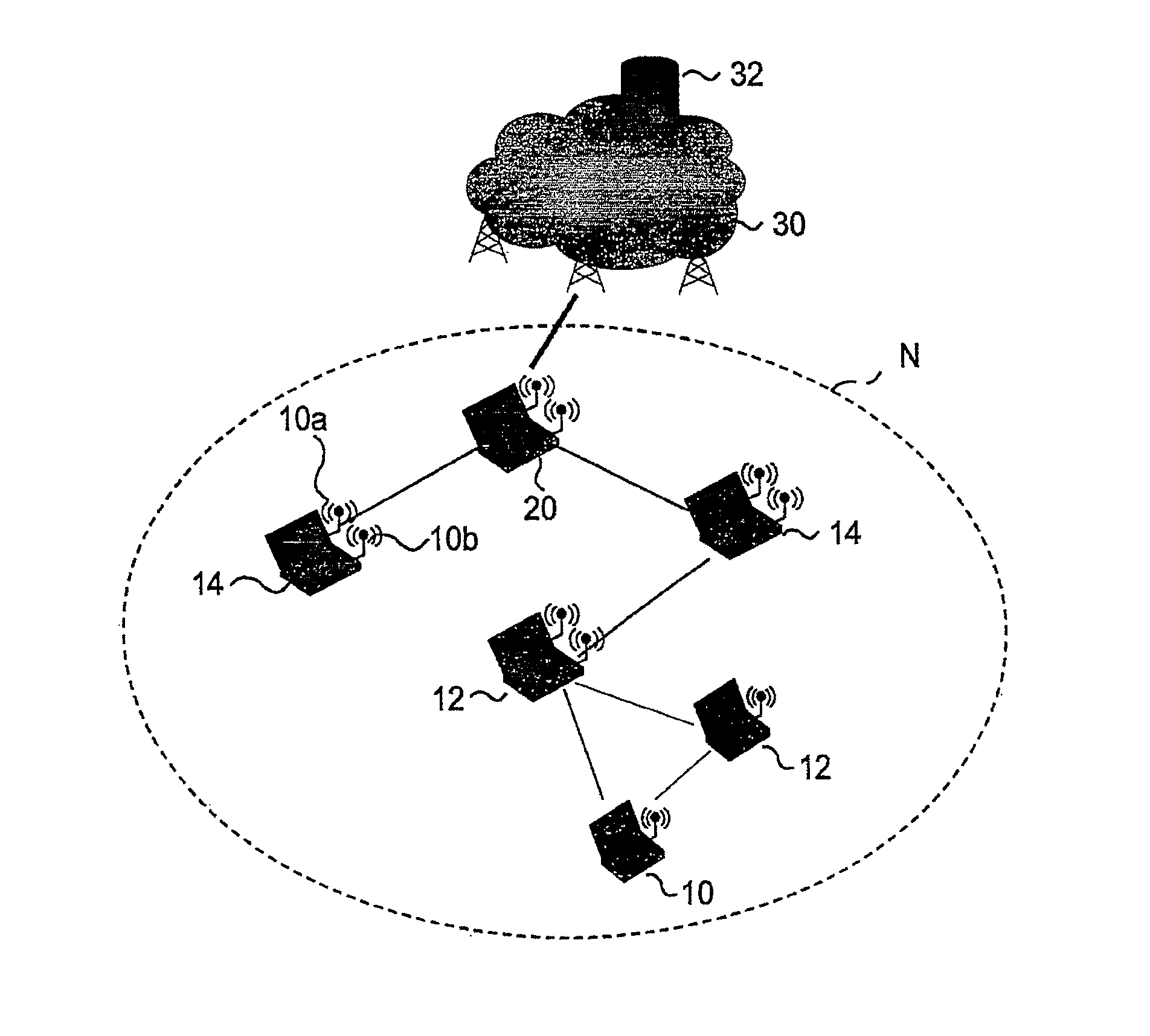

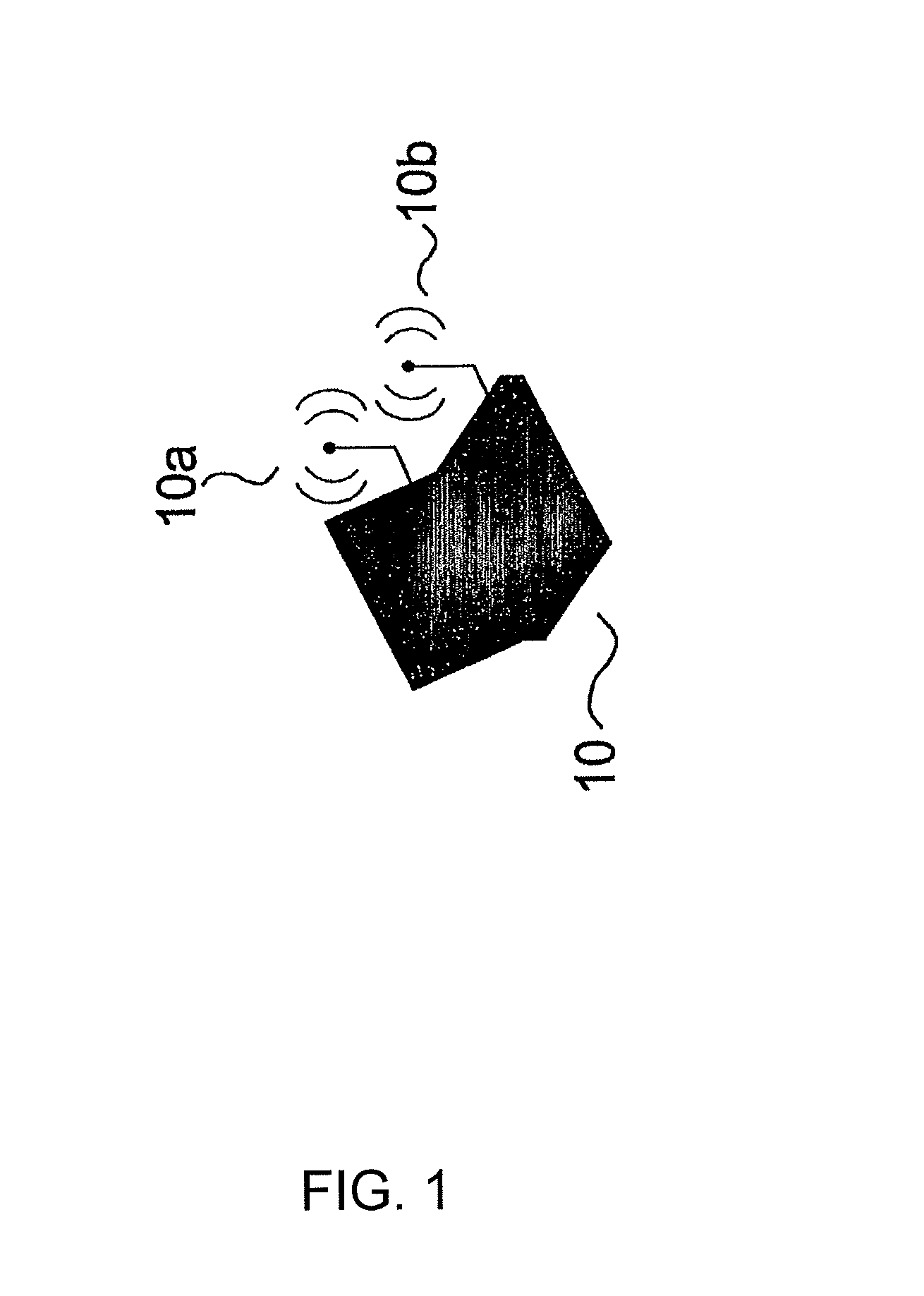

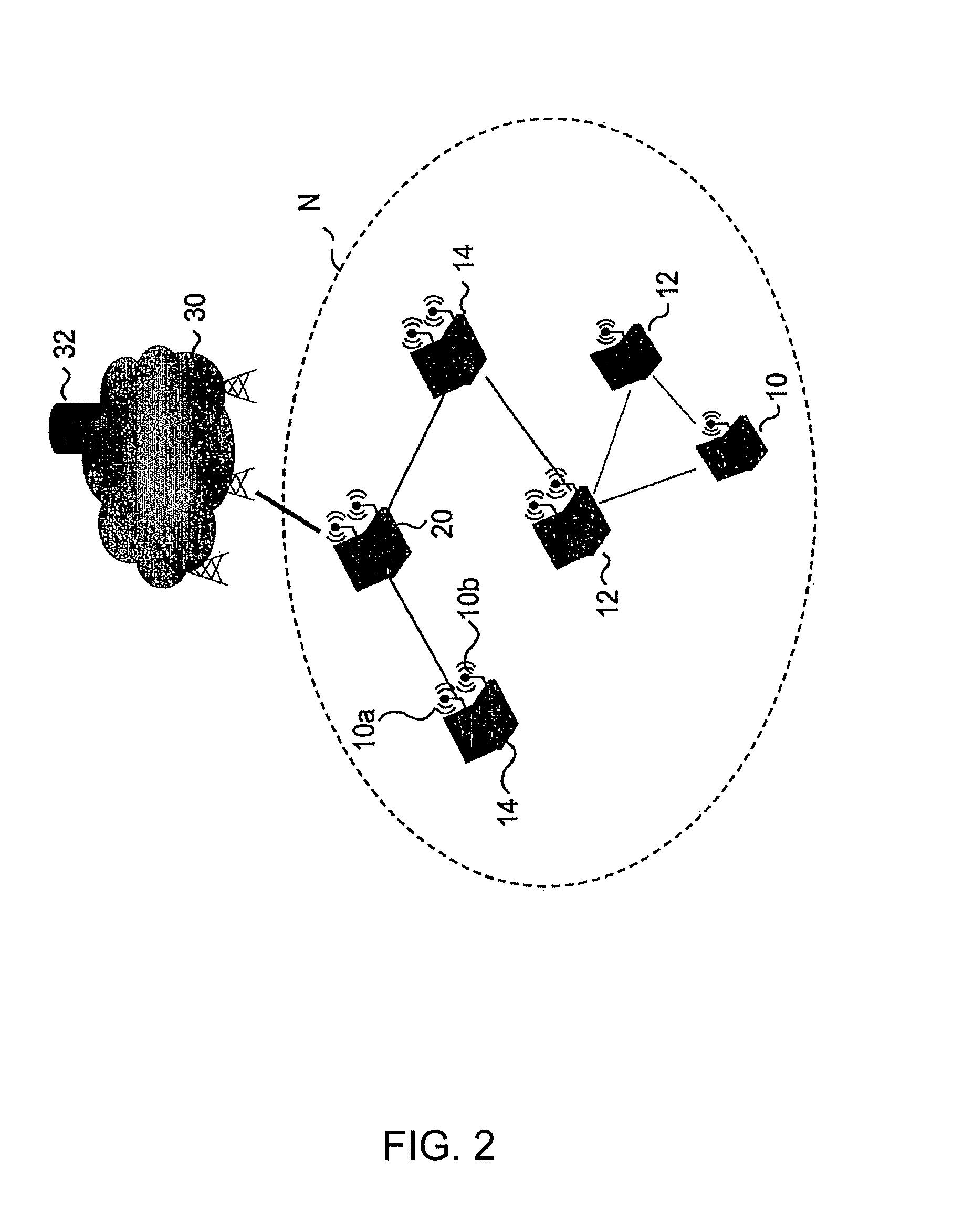

Method and System for Controlling Access to Communication Networks, Related Network and Computer Program Therefor

InactiveUS20080069105A1Easy to deriveDigital data processing detailsNetwork topologiesControl communicationsAuthentication

A system for controlling access of a mobile terminal to a communication network including a set of terminals, wherein said mobile terminal obtains access to the network as a result of a successful authentication procedure. The system includes an authenticator module for performing the authentication procedure of the mobile terminal and a communication mechanism configured for making the successful outcome of the authentication procedure known to the terminals in the set. The mobile terminal is thus permitted to access the network via any of the terminals in the set based on the authentication procedure.

Owner:TELECOM ITALIA SPA

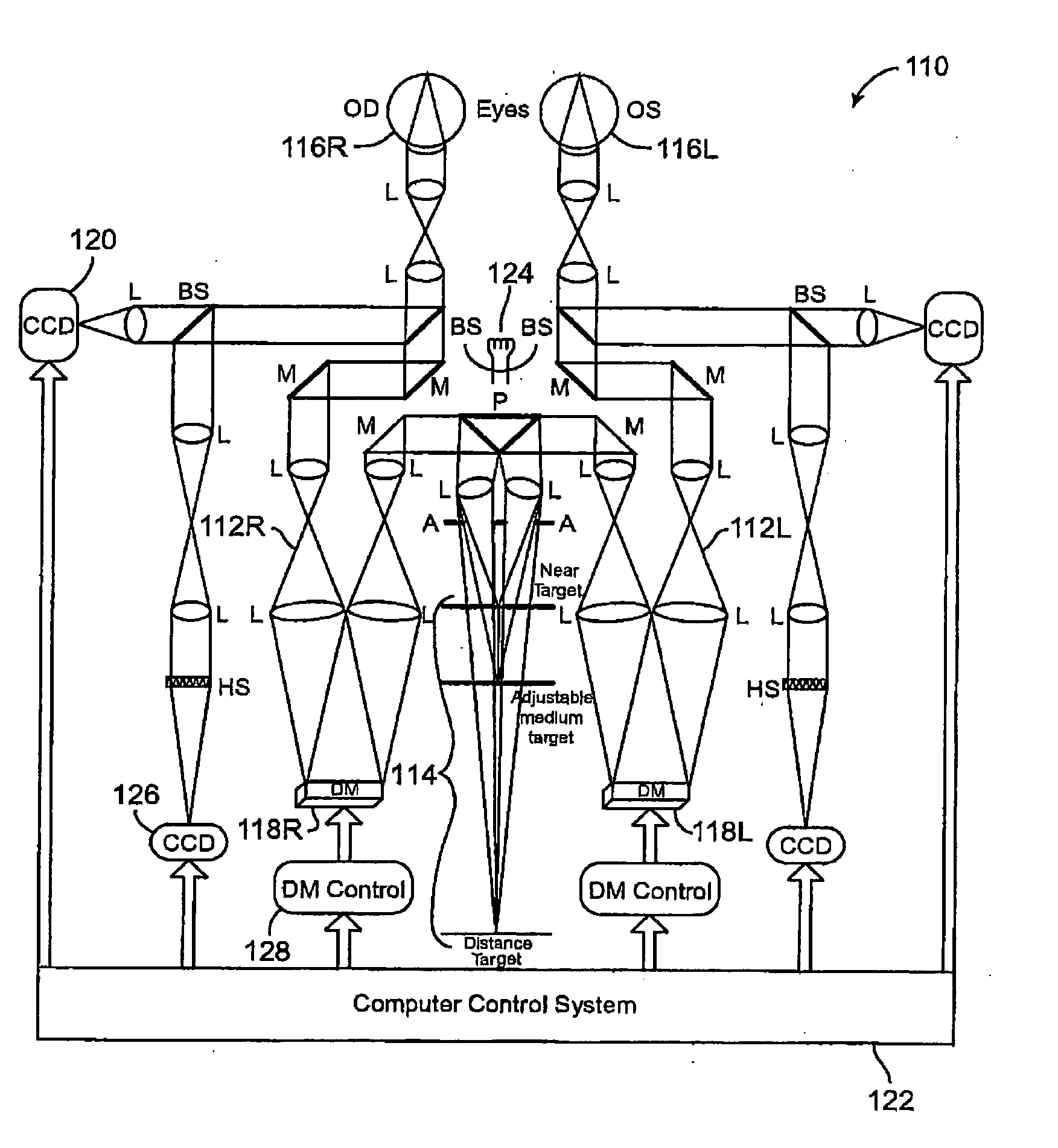

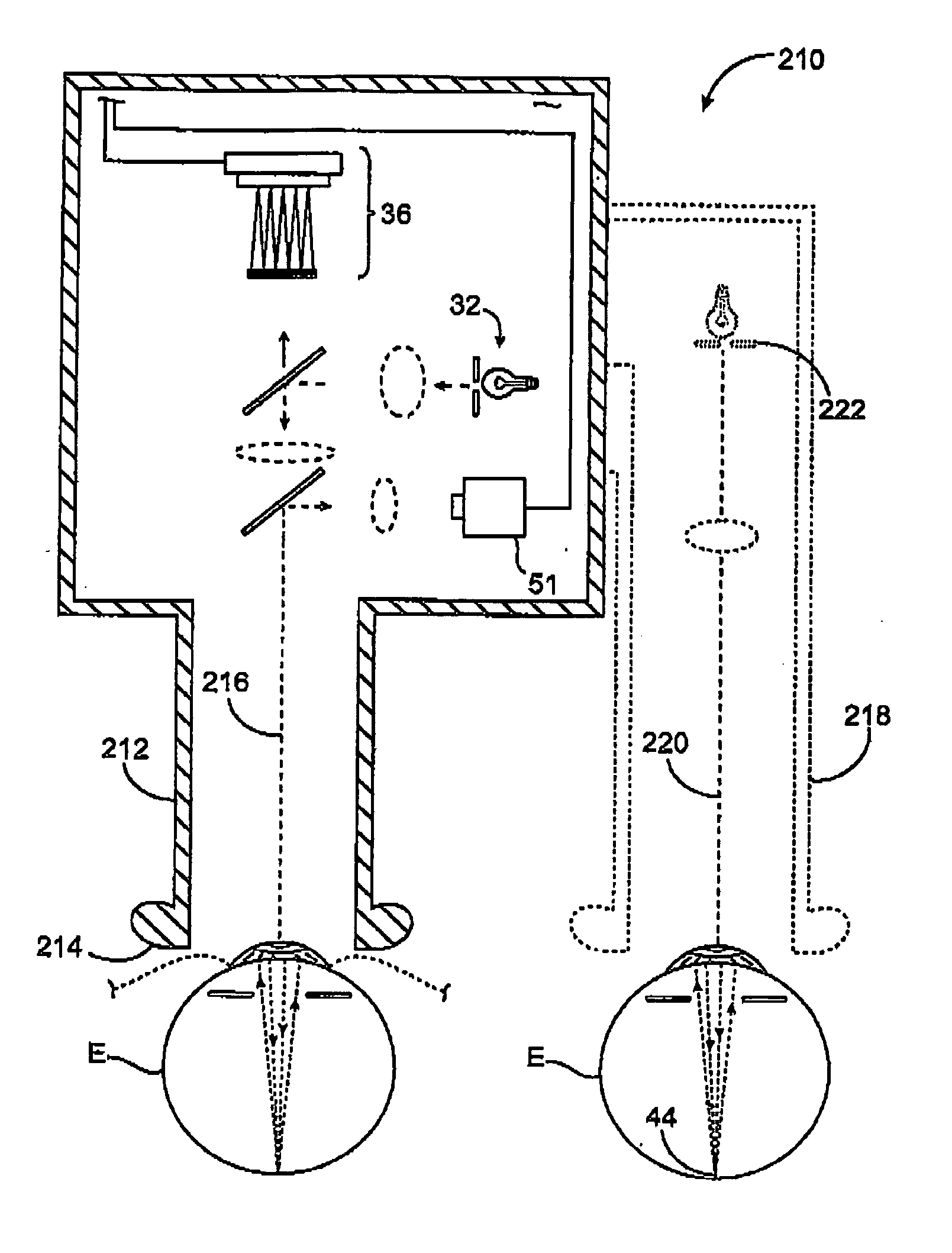

Correction of presbyopia using adaptive optics and associated methods

Devices, systems, and methods measure, diagnose, and / or treat one or both eyes of a patient. Adaptive optics systems (such as those having a deformable mirror) may be configured to an aspherical or multi-spherical presbyopia-mitigating prescriptive shape to allow objective and / or subjective measurements of a candidate prescription. A plurality of viewing distances allow subjective and / or objective evaluations of performance using a light spot or a test viewing image. Measurements of aberrations at selected viewing conditions (including distances and / or brightness) with correlating pupil sizes may also be provided.

Owner:AMO MFG USA INC

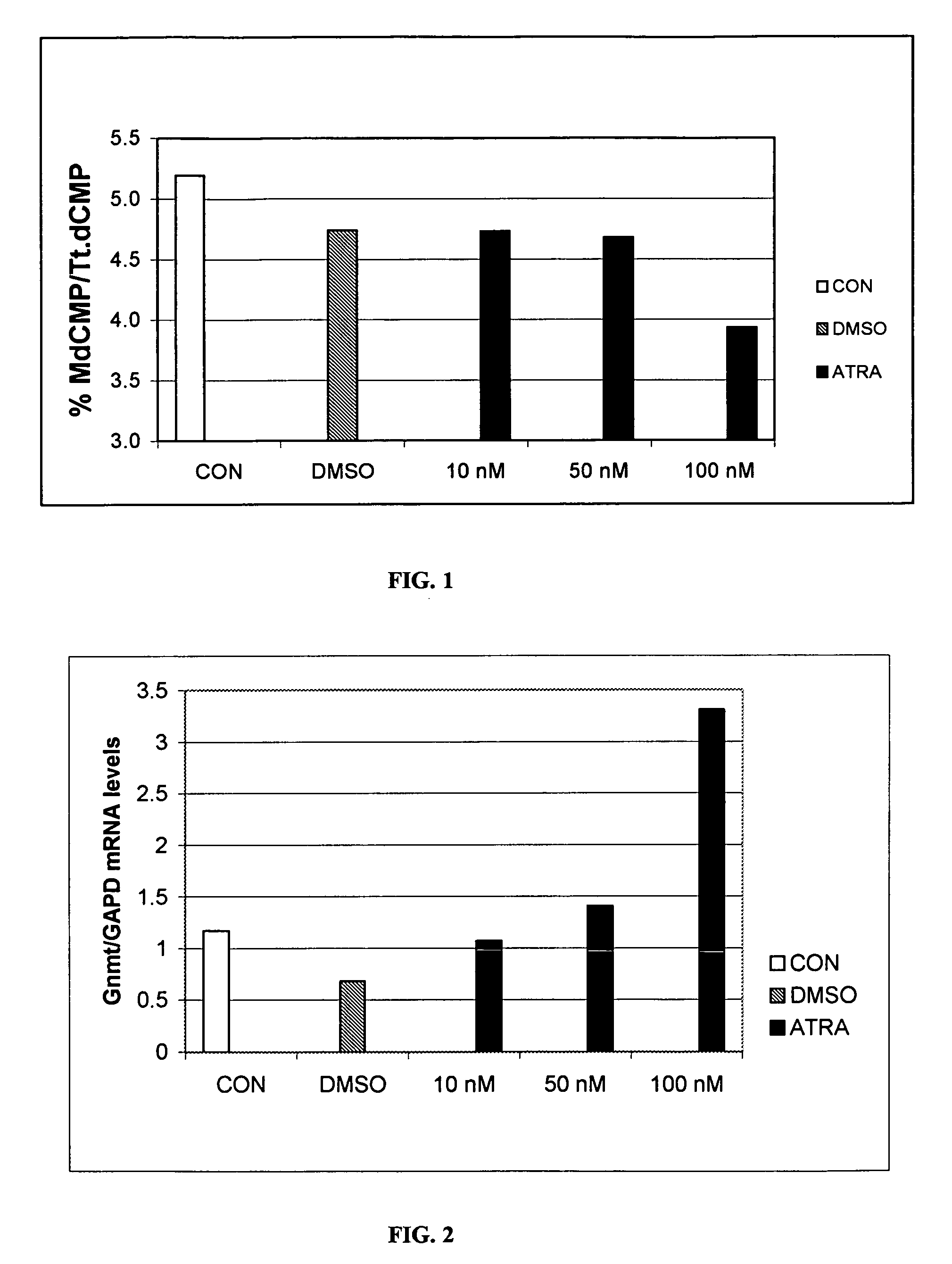

Production of reprogrammed cells with restored potential

InactiveUS20070032447A1Reduce in quantityDifferentiation potential in differentiatedBiocideHydroxy compound active ingredientsNuclear transferGenome

A method for treating cells and / or nuclear transfer units and / or stem cells in culture with such compounds, individually or in combinations, is described. The method results in a globally hypomethylated genome and a restoration of cell differentiation and / or developmental potential, or potentiality. In addition, a method for the in vitro production of reprogrammed cells which have had differentiation potential (totipotential, pluripotential, or multipotential) restored by demethylating the genome is described.

Owner:NUPOTENTIAL INC

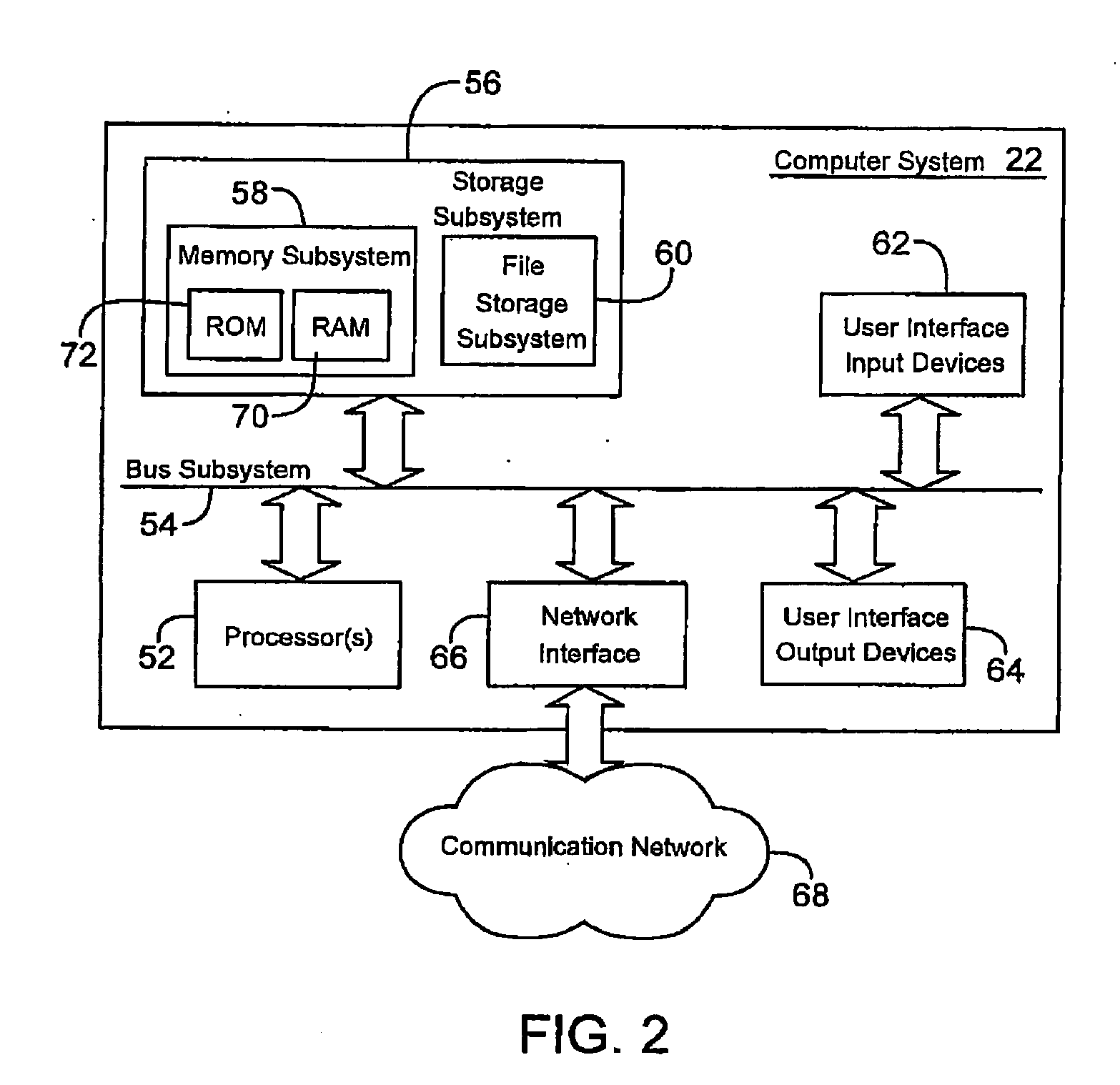

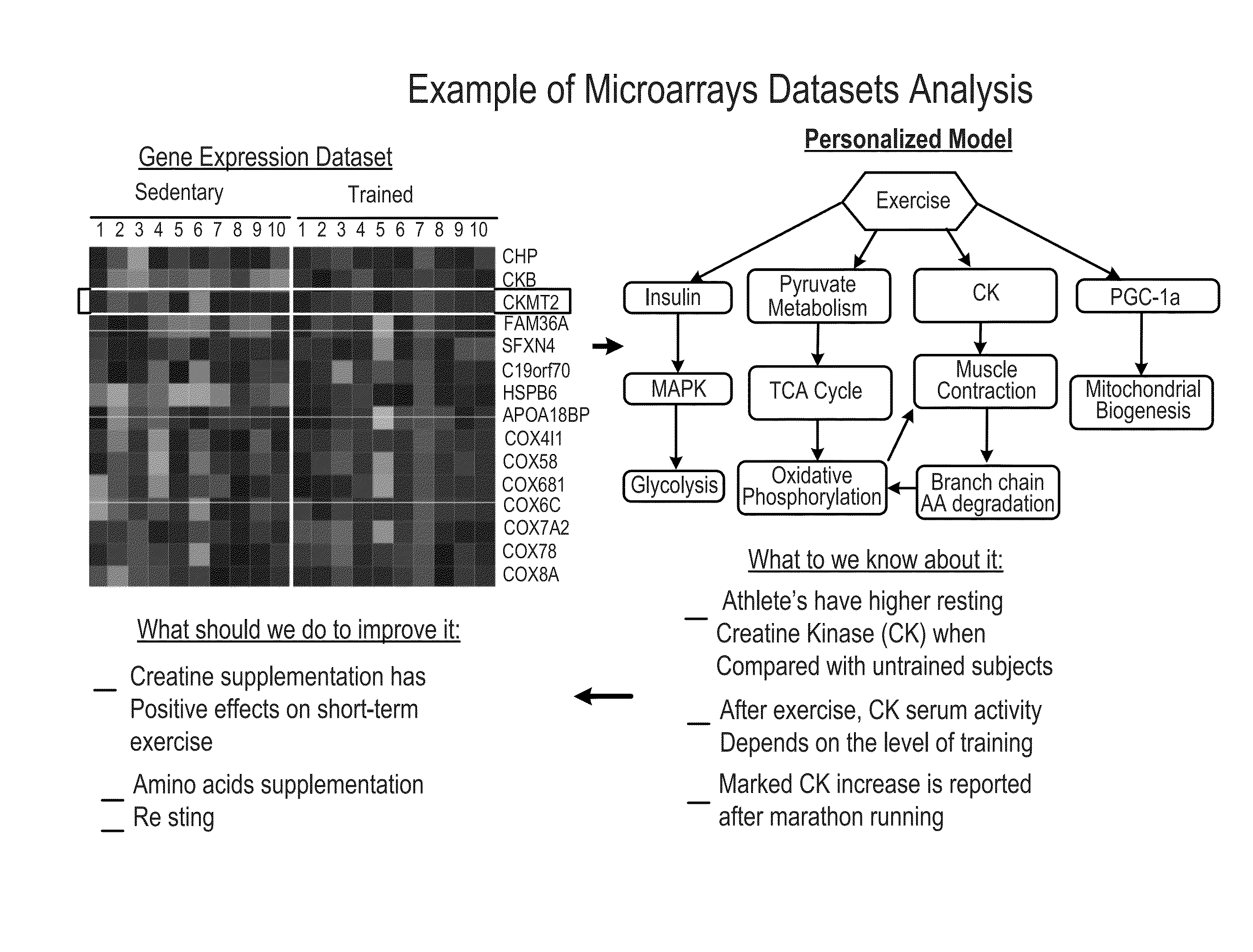

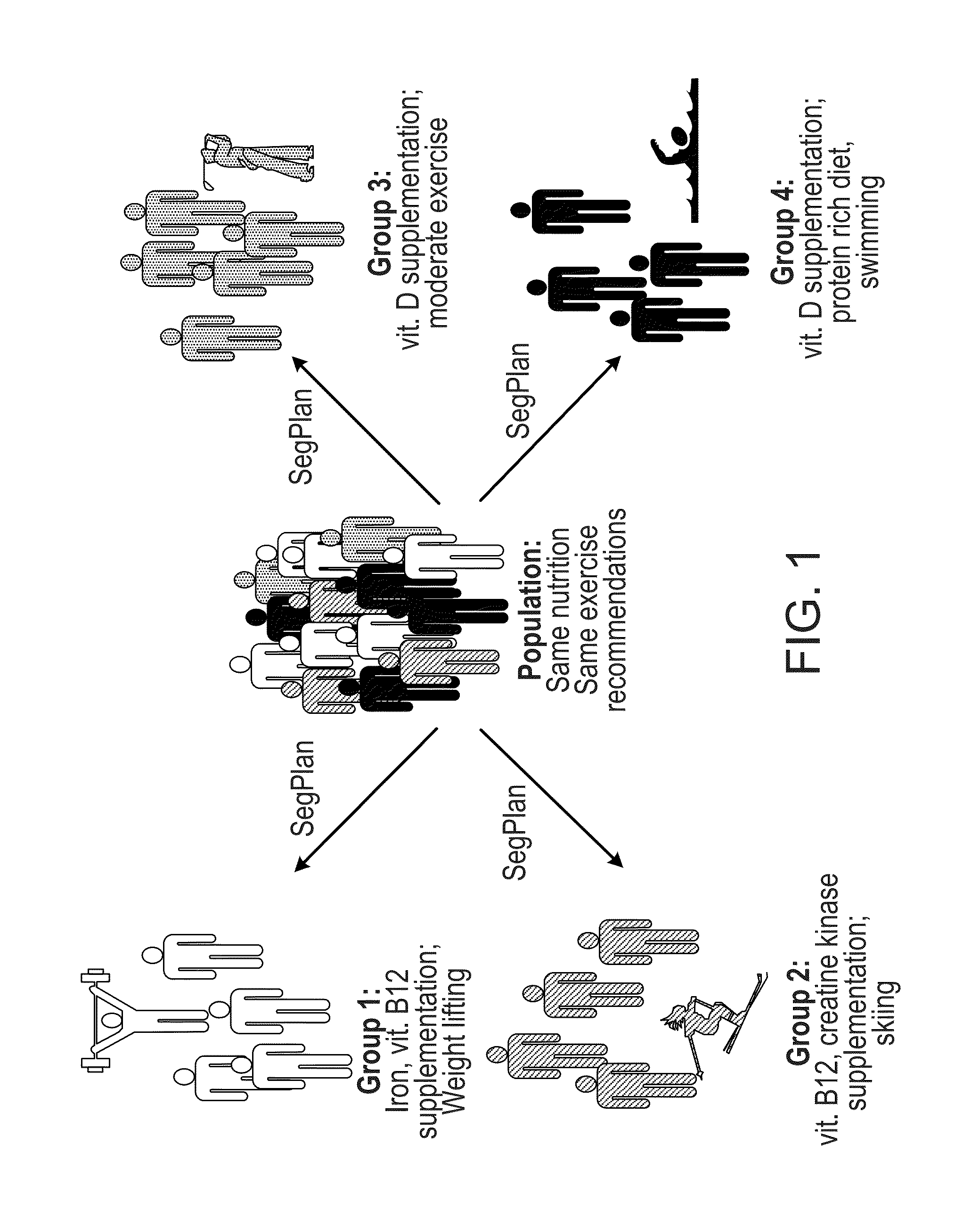

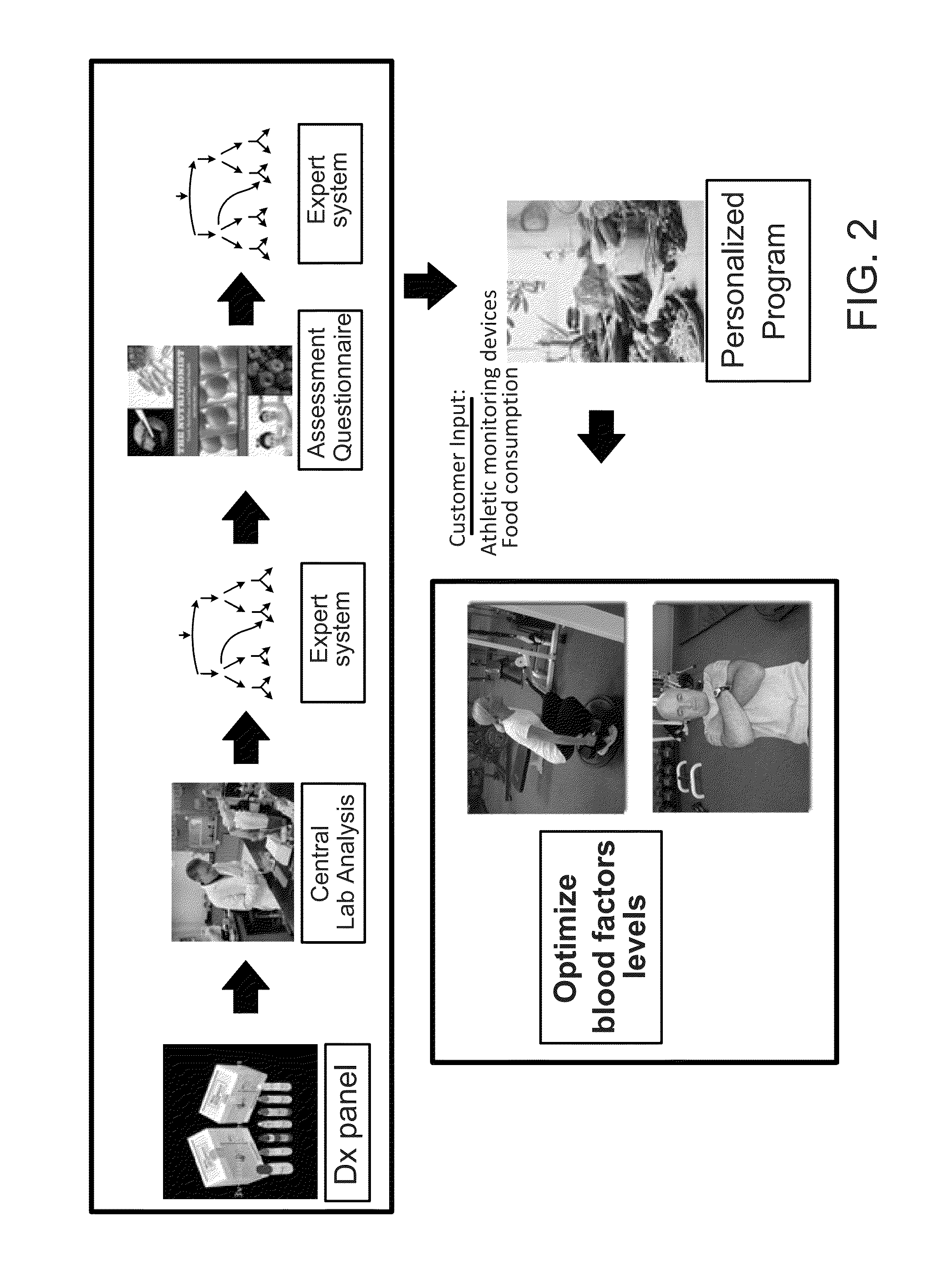

Methods and systems for generation of personalized health plans

ActiveUS8762167B2Easy to derivePhysical therapies and activitiesBiostatisticsDiagnostic testNutrition

Personalized, health and performance programs are generated for individuals based on various biomarkers and performance and lifestyle assessments. In one embodiment, a diagnostic test of blood or other biological specimen(s) is used to determine key biological marker levels. Information and assessments of the user's physical performance, life style and health and wellness goals is also collected and provided to an expert system that matches the biomarker levels and assessments to a knowledgebase of scientific knowledge about biomarker levels and health and fitness outcomes. Personal recommendations and advice on nutrition and exercise is then generated, which may be used to help individuals reach their diet, fitness, and wellness goals and improve their physical and mental performance and well being in measurable ways.

Owner:SEGTERRA

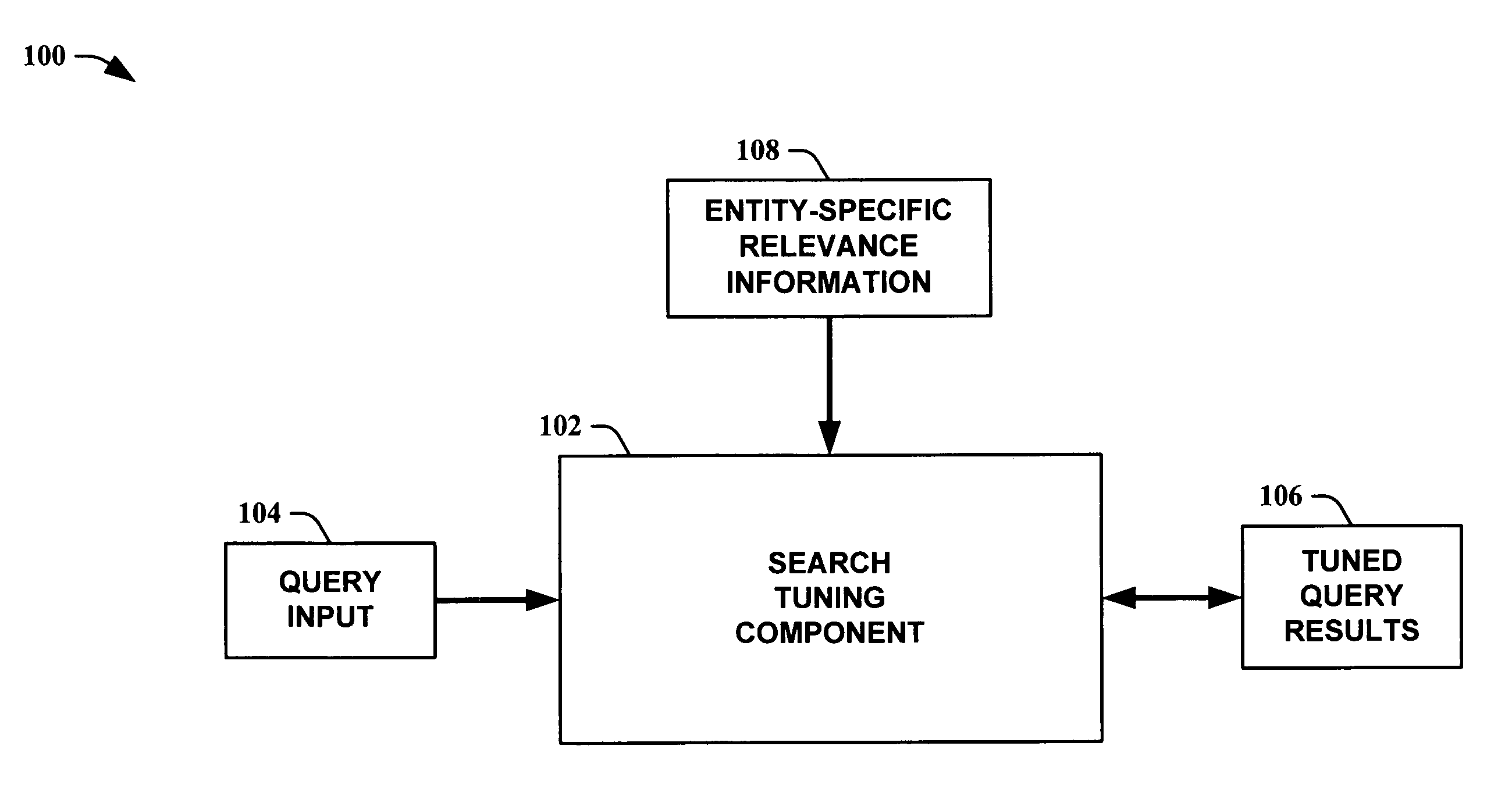

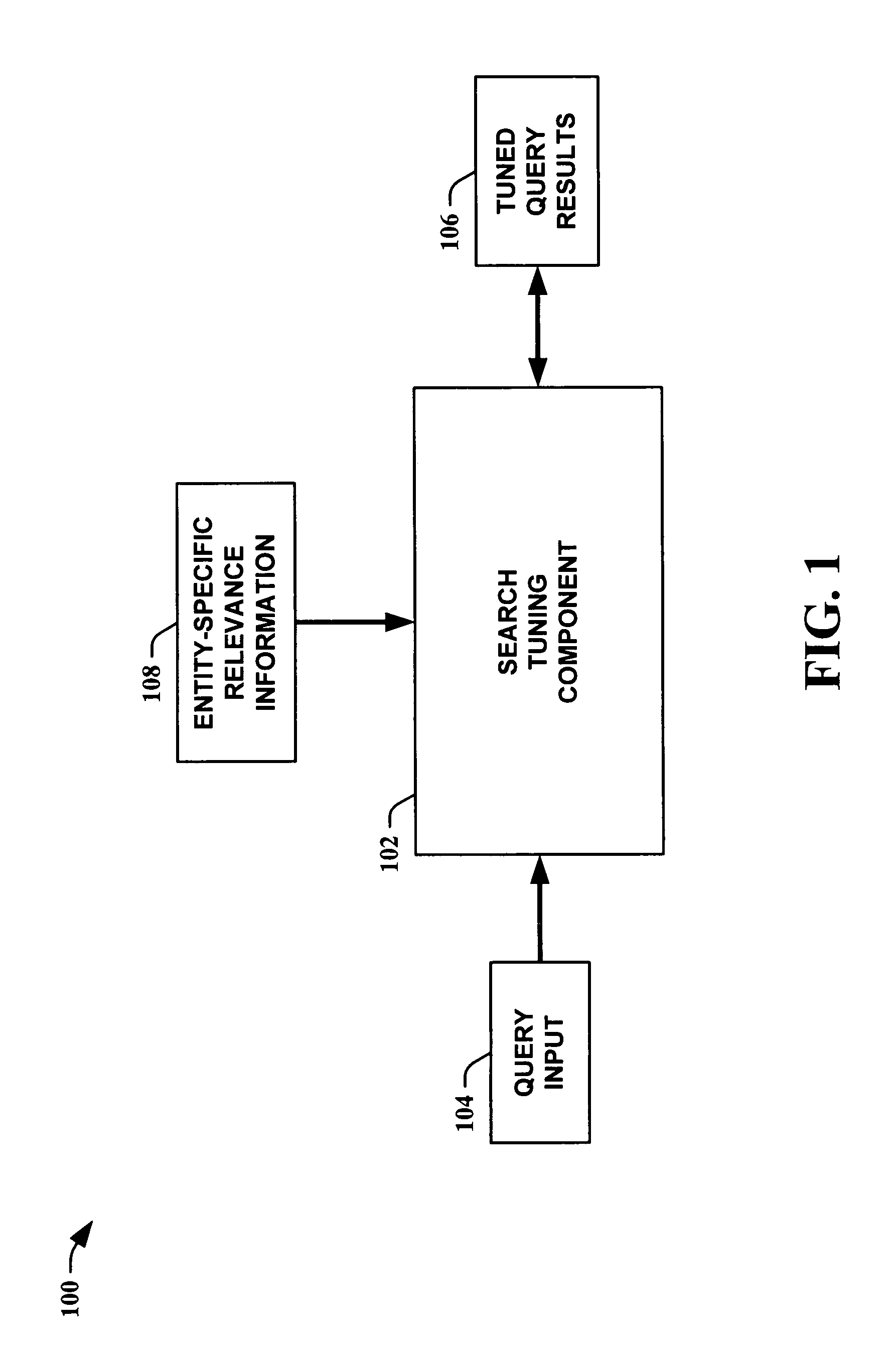

Entity-specific tuned searching

ActiveUS20060122978A1Enhanced search query resultEasy to deriveDigital data information retrievalDigital data processing detailsInformation retrievalSatisfaction level

Owner:MICROSOFT TECH LICENSING LLC

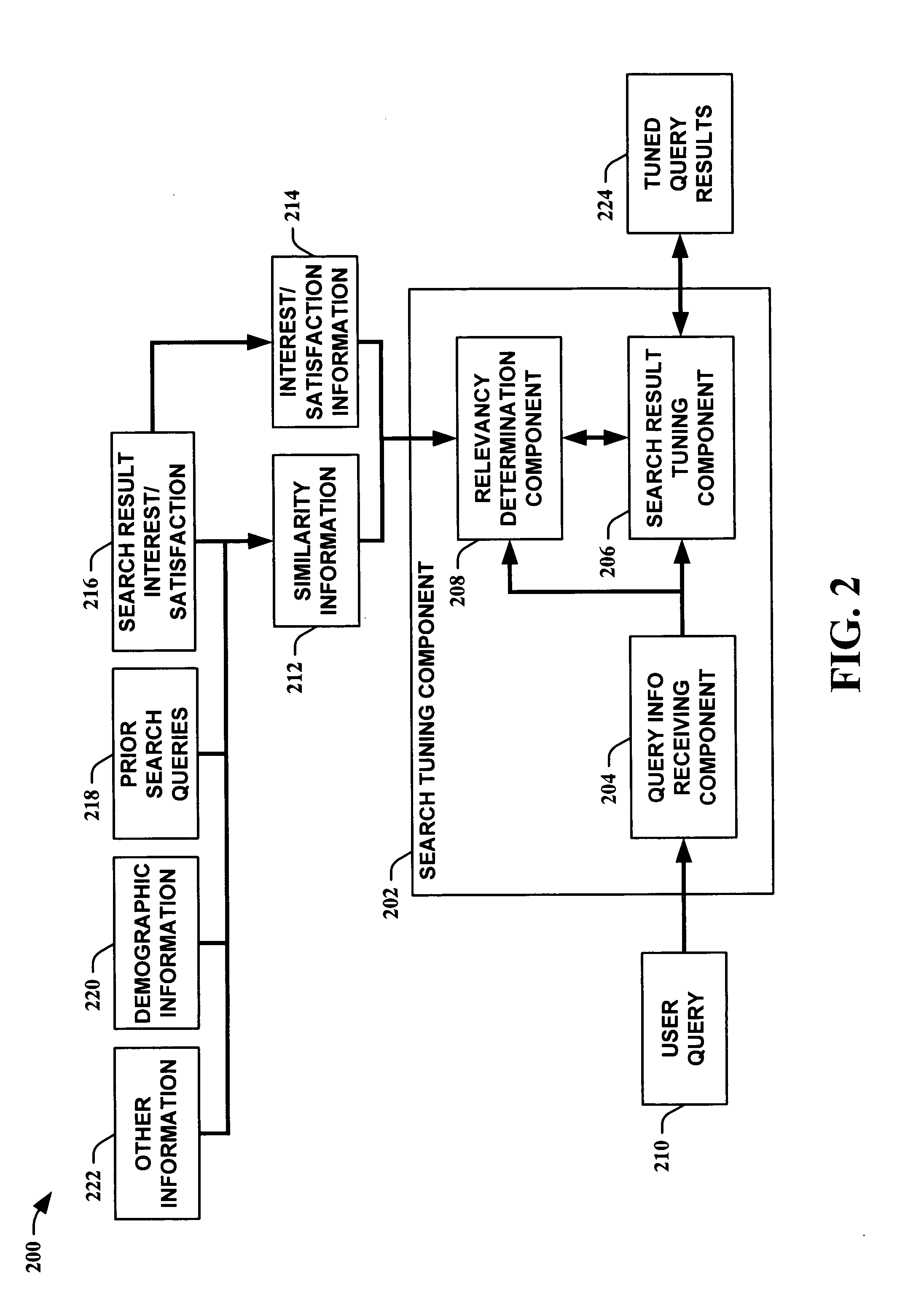

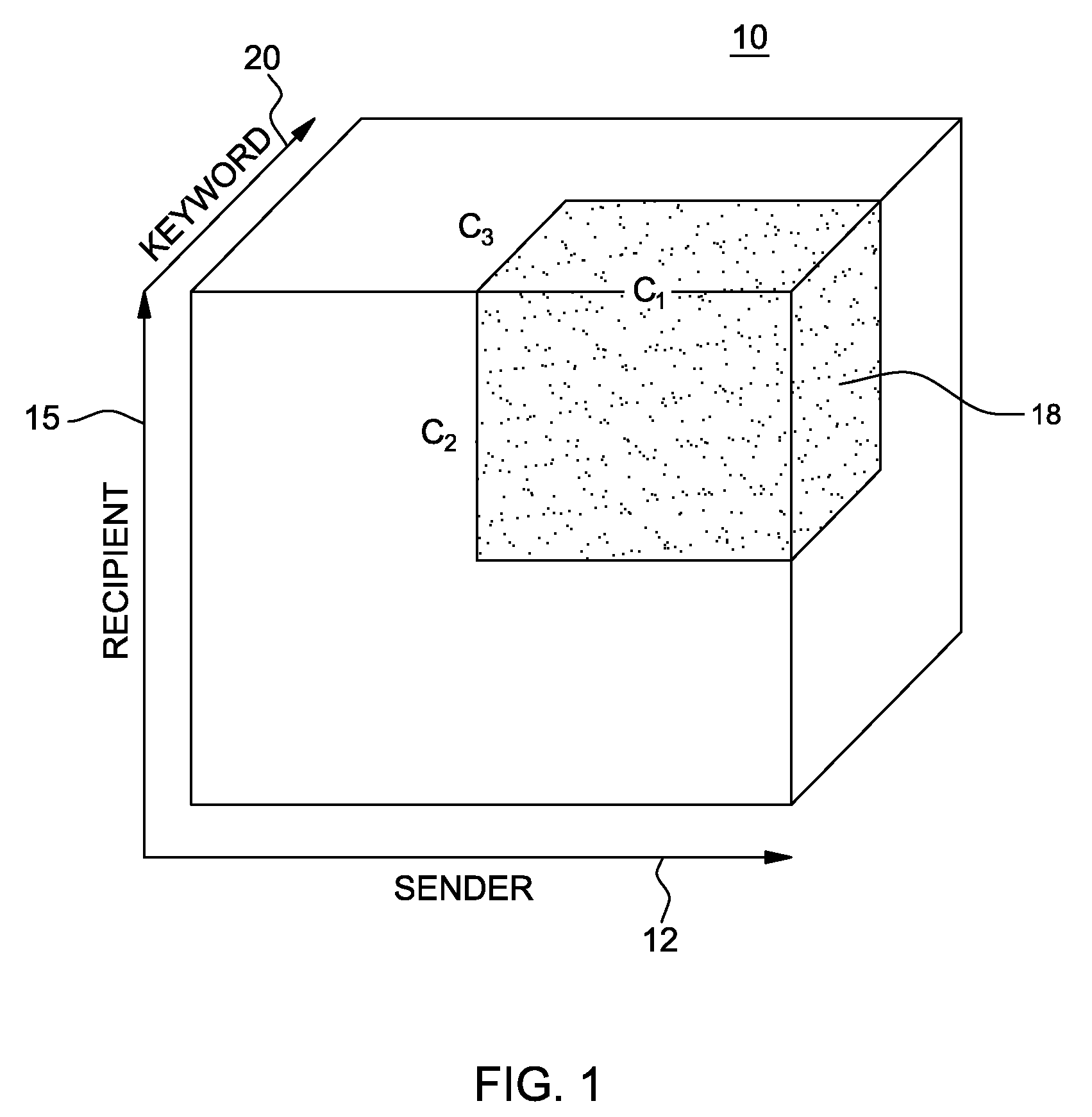

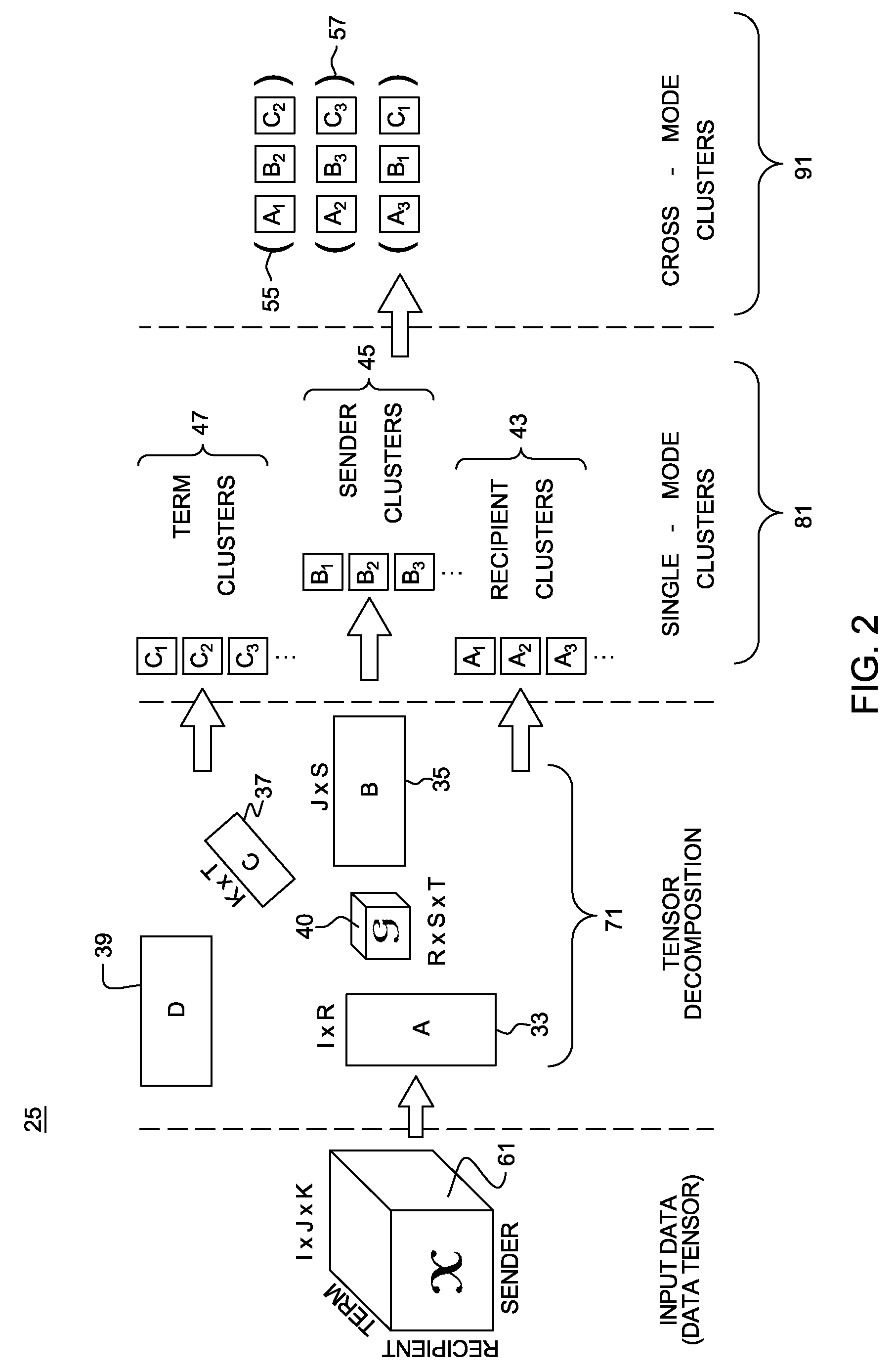

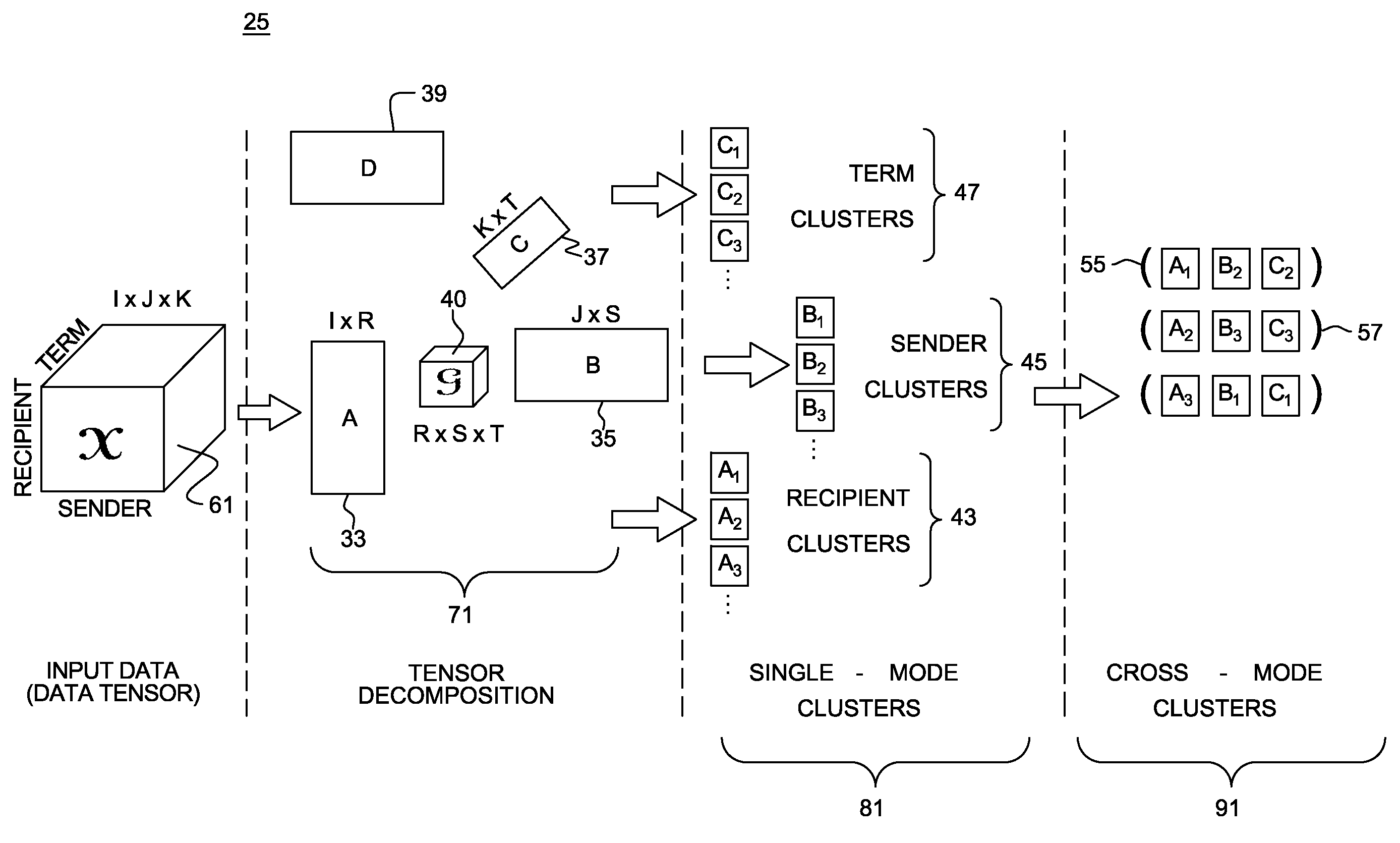

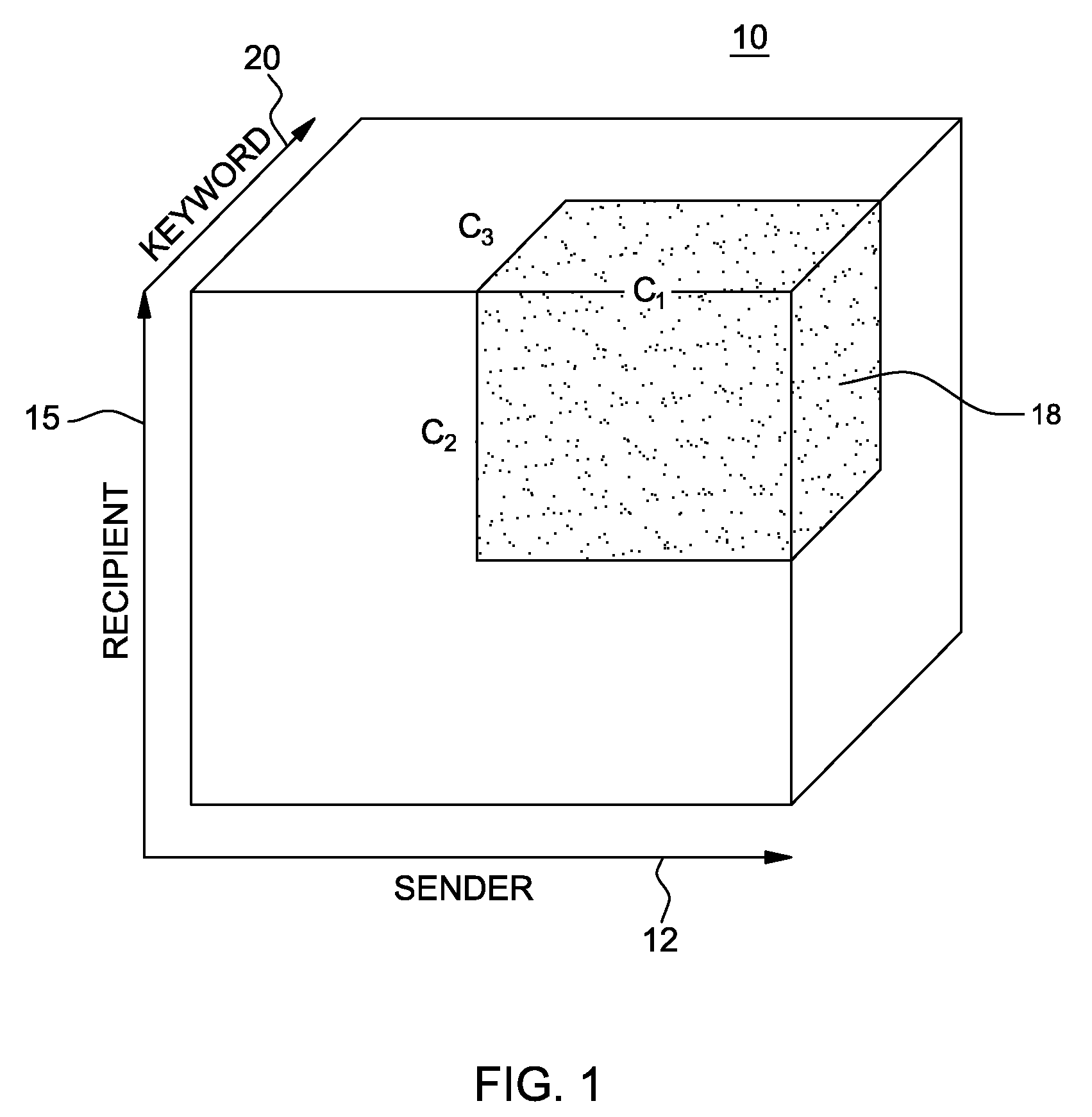

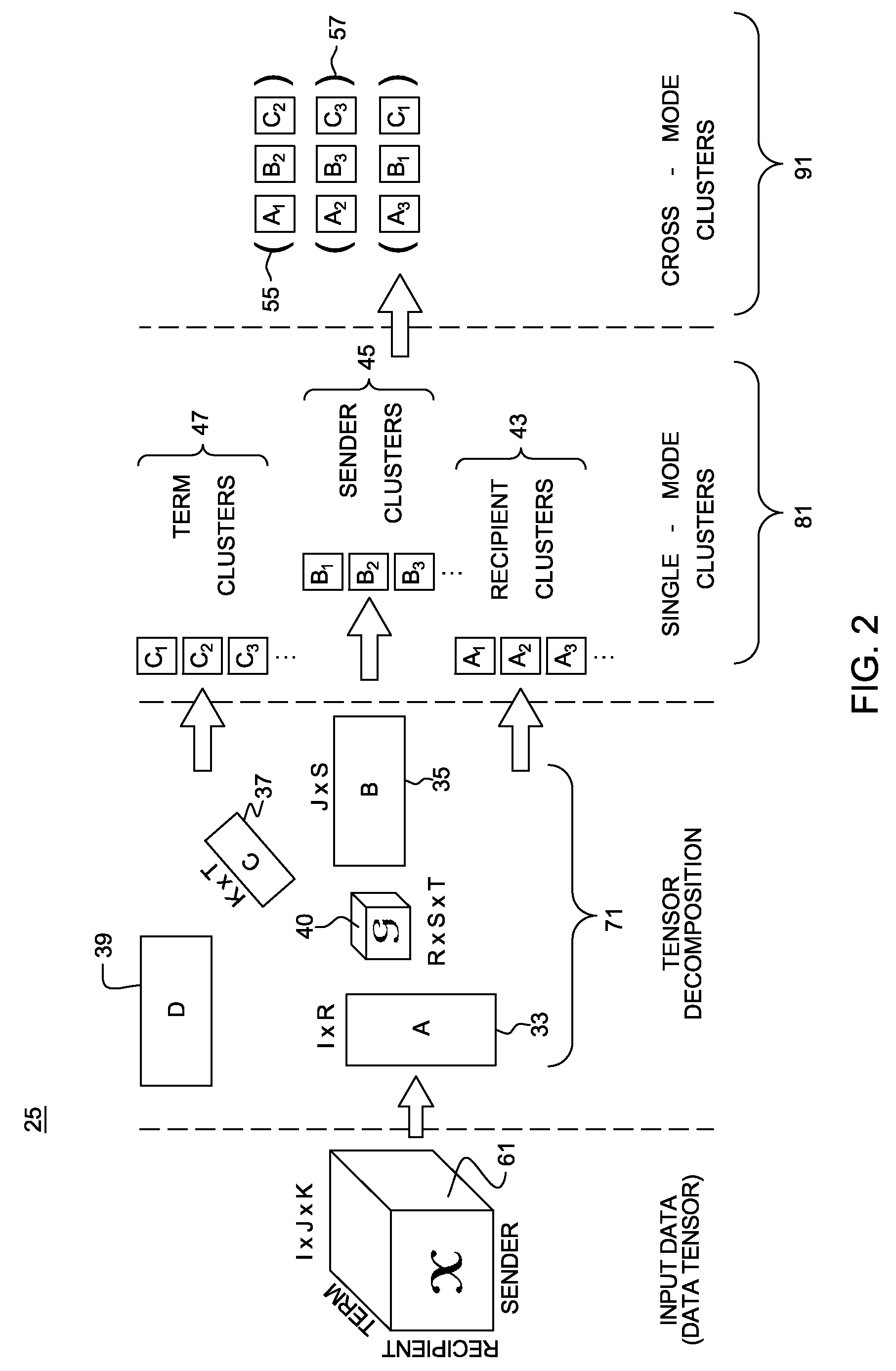

Content-based and time-evolving social network analysis

ActiveUS20110055379A1Easy to deriveReduced dimensional representationDigital computer detailsCharacter and pattern recognitionContent based networkingTime evolution

System and method for modeling a content-based network. The method includes finding single mode clusters from among network (sender and recipient) and content dimensions represented as a tensor data structure. The method allows for derivation of useful cross-mode clusters (interpretable patterns) that reveal key relationships among user communities and keyword concepts for presentation to users in a meaningful and intuitive way. Additionally, the derivation of useful cross-mode clusters is facilitated by constructing a reduced low-dimensional representation of the content-based network. Moreover, the invention may be enhanced for modeling and analyzing the time evolution of social communication networks and the content related to such networks. To this end, a set of non-overlapping or possibly overlapping time-based windows is constructed and the analysis performed at each successive time interval.

Owner:IBM CORP

Correction of presbyopia using adaptive optics and associated methods

InactiveUS20060017883A1Easy to deriveImprove aberrationRefractometersSkiascopesLight spotComputer science

Devices, systems, and methods measure, diagnose, and / or treat one or both eyes of a patient. Adaptive optics systems (such as those having a deformable mirror) may be configured to an aspherical or multi-spherical presbyopia-mitigating prescriptive shape to allow objective and / or subjective measurements of a candidate prescription. A plurality of viewing distances allow subjective and / or objective evaluations of performance using a light spot or a test viewing image. Measurements of aberrations at selected viewing conditions (including distances and / or brightness) with correlating pupil sizes may also be provided. Wavefront measurement systems and methods may help position and isolate the eye from ambient light.

Owner:AMO MFG USA INC

Method and Apparatus for Providing Requirement Driven Static Analysis of Test Coverage for Web-Based, Distributed Processes

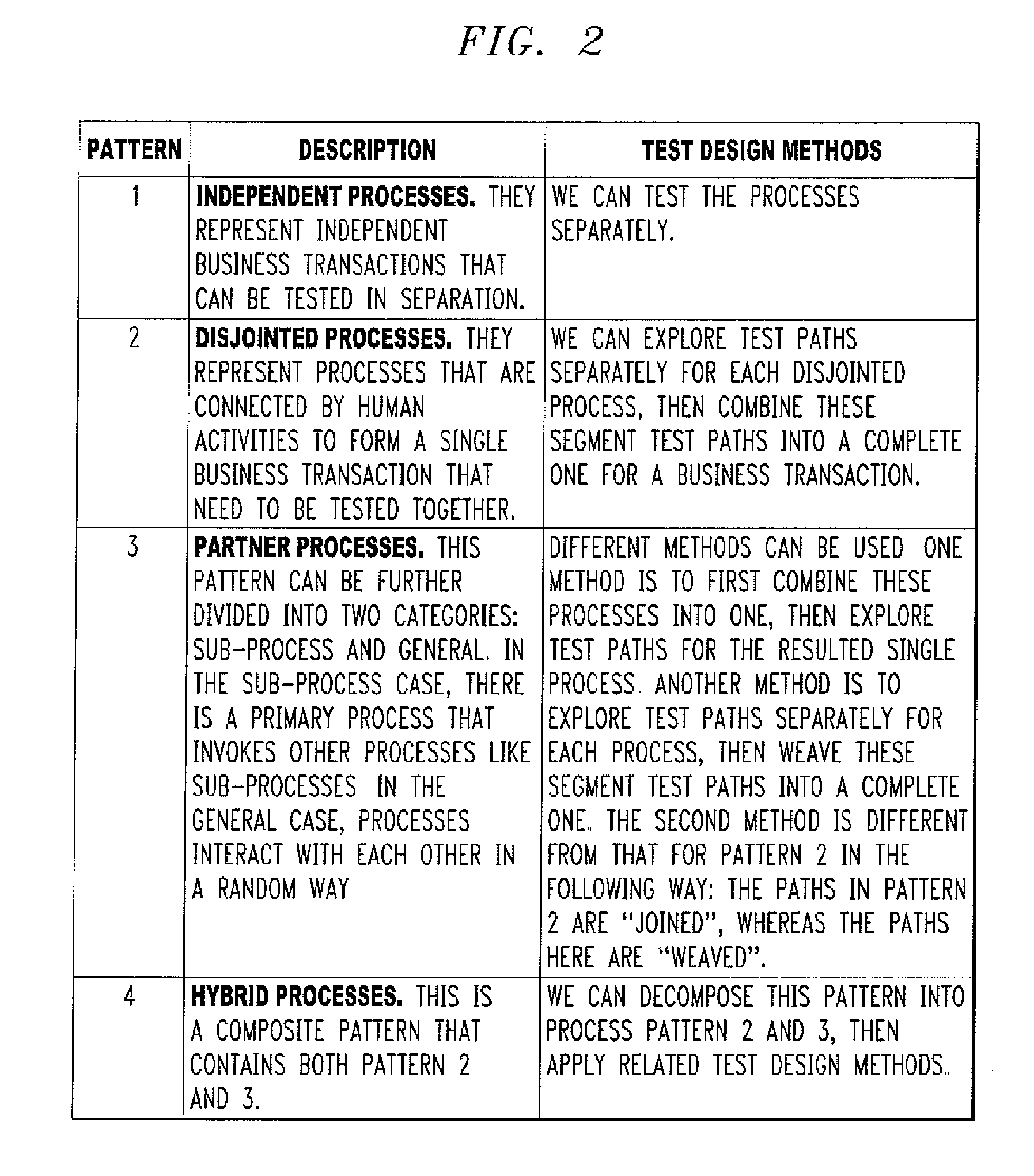

InactiveUS20090019427A1Improve test coverageEasy to testError detection/correctionSpecific program execution arrangementsSpecific testTest case

A method (which can be computer implemented) for analyzing test coverage of distributed processes includes the steps of identifying at least one of the processes that is invoked by a test case, mapping at least a portion of the test case to a plurality of specific test paths in the at least one of the processes, and identifying given ones of the test paths as possibly relevant in at least one of the processes, if the test paths are not infeasible.

Owner:IBM CORP

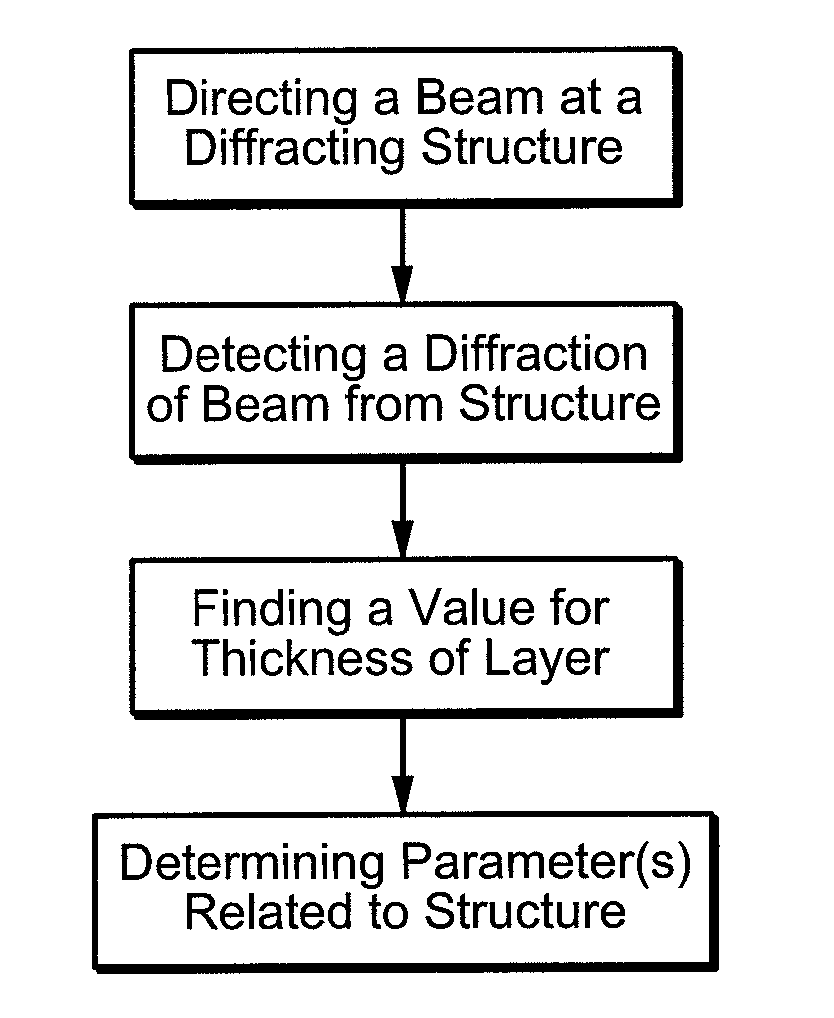

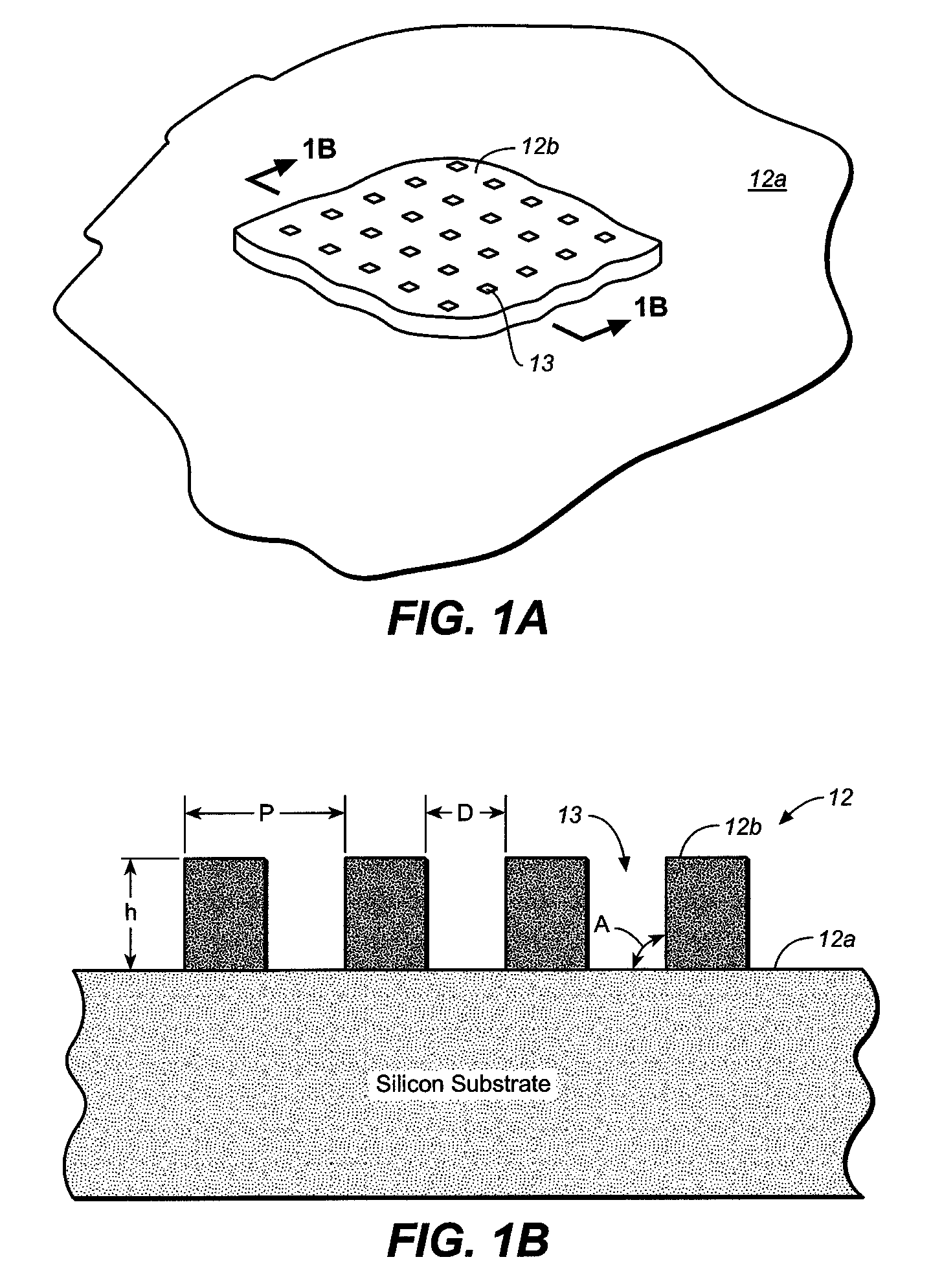

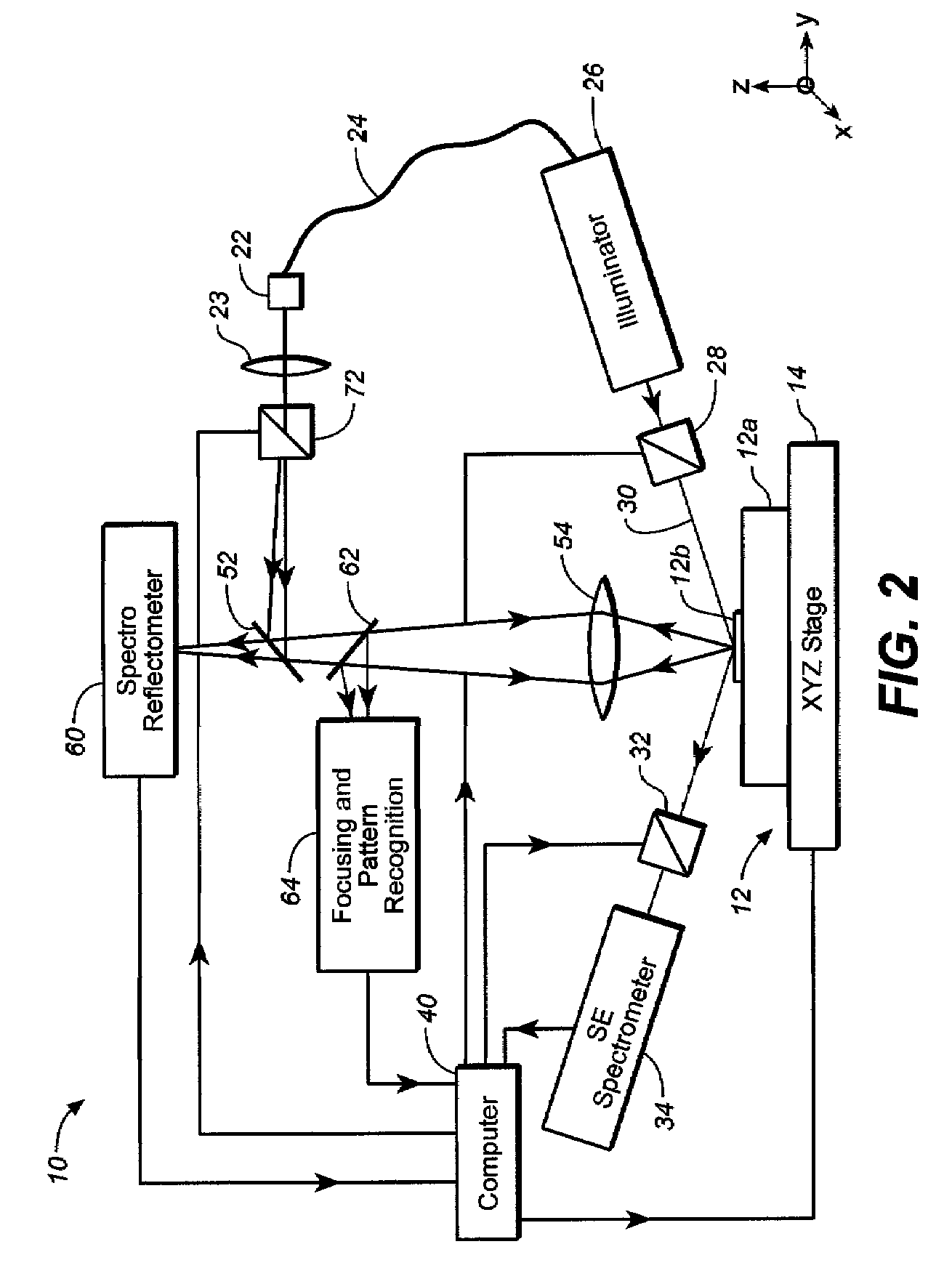

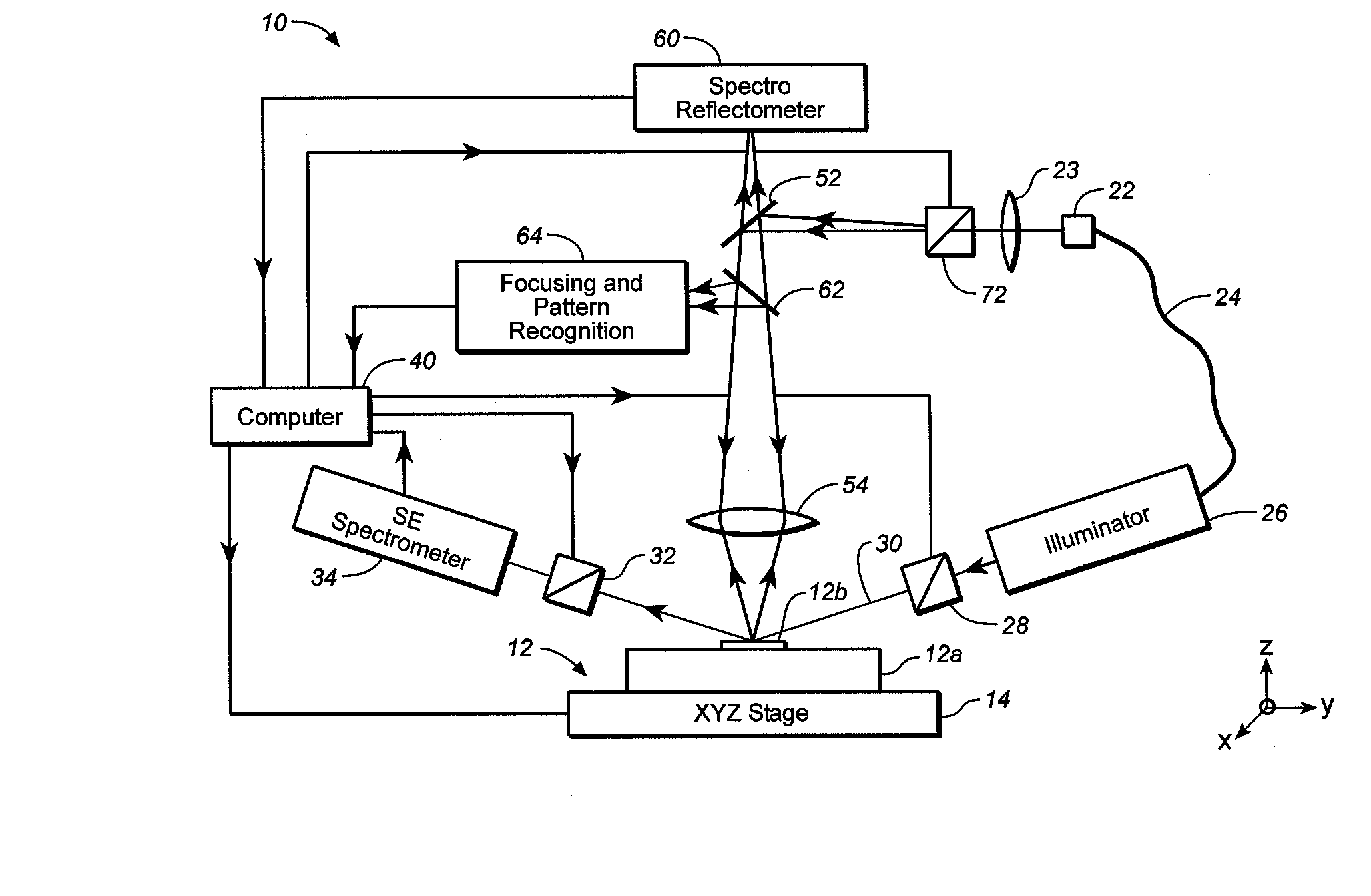

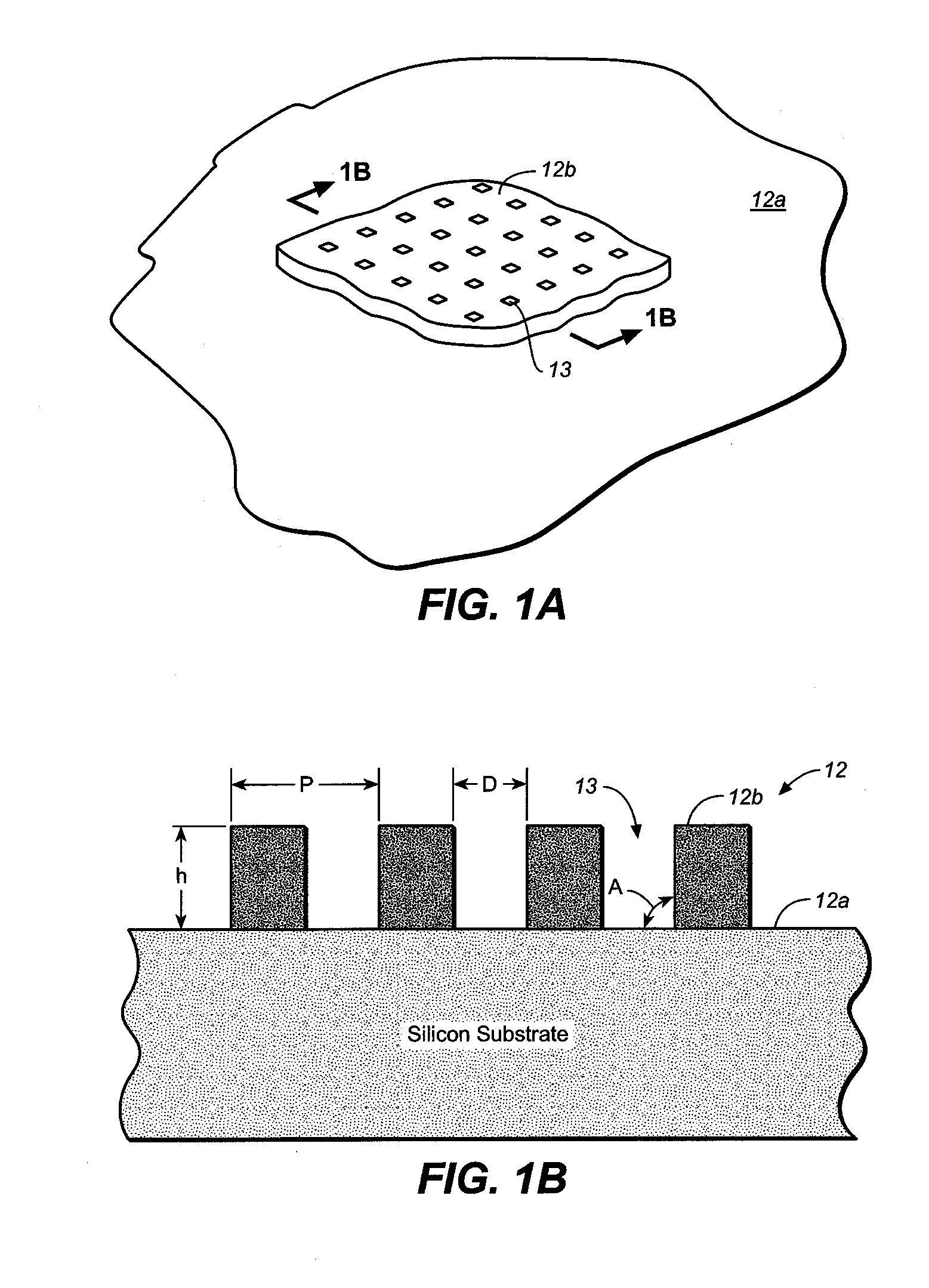

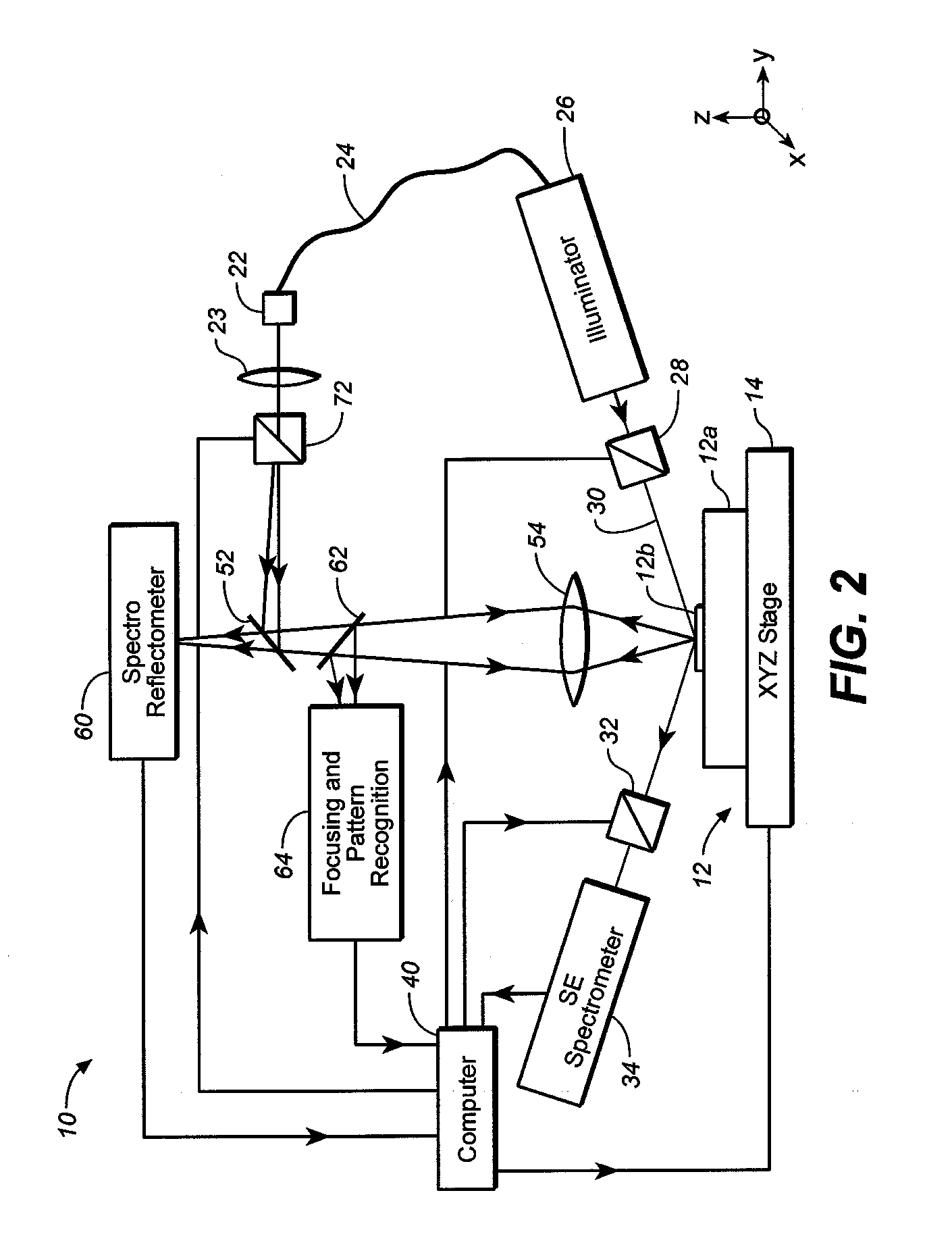

System for measuring a sample with a layer containing a periodic diffracting structure

ActiveUS7515253B2Easy constructionEasy to deriveRadiation pyrometrySpectrum investigationCritical dimensionPhysics

To measure the critical dimensions and other parameters of a one- or two-dimensional diffracting structure of a film, the calculation may be simplified by first performing a measurement of the thickness of the film, employing a film model that does not vary the critical dimension or parameters related to other characteristics of the structure. The thickness of the film may be estimated using the film model sufficiently accurately so that such estimate may be employed to simplify the structure model for deriving the critical dimension and other parameters related to the two-dimensional diffracting structure.

Owner:KLA TENCOR TECH CORP

Embryonic stem cells

InactiveUS20050164383A1Easy to deriveMicroorganism based processesArtificial cell constructsMolecular biologySomatic cell

The present invention relates to undifferentiated human embryonic stem cells, methods of cultivation and propagation, production of differentiated cells and in particular the production of human embryonic stem cells capable of yielding somatic differentiated cells in vitro, as well as committed progenitor cells capable of giving rise to mature somatic cells and uses thereof. The present invention also provides a purified preparation of undifferentiated human embryonic stem cells capable of proliferation in vitro. Furthermore, the present invention provides a somatic cell differentiated in vitro from an undifferentiated embryonic stem cell. There is also provided a committed progenitor cell capable of giving rise to mature somatic cells.

Owner:REUBINOFF BENJAMIN +4

Production of reprogrammed cells with restored potential

InactiveUS7601699B2Differentiation potential in differentiatedMaintain their viabilityBiocideSugar derivativesNuclear transferGenome

A method for treating cells and / or nuclear transfer units and / or stem cells in culture with such compounds, individually or in combinations, is described. The method results in a globally hypomethylated genome and a restoration of cell differentiation and / or developmental potential, or potentiality. In addition, a method for the in vitro production of reprogrammed cells which have had differentiation potential (totipotential, pluripotential, or multipotential) restored by demethylating the genome is described.

Owner:NUPOTENTIAL INC

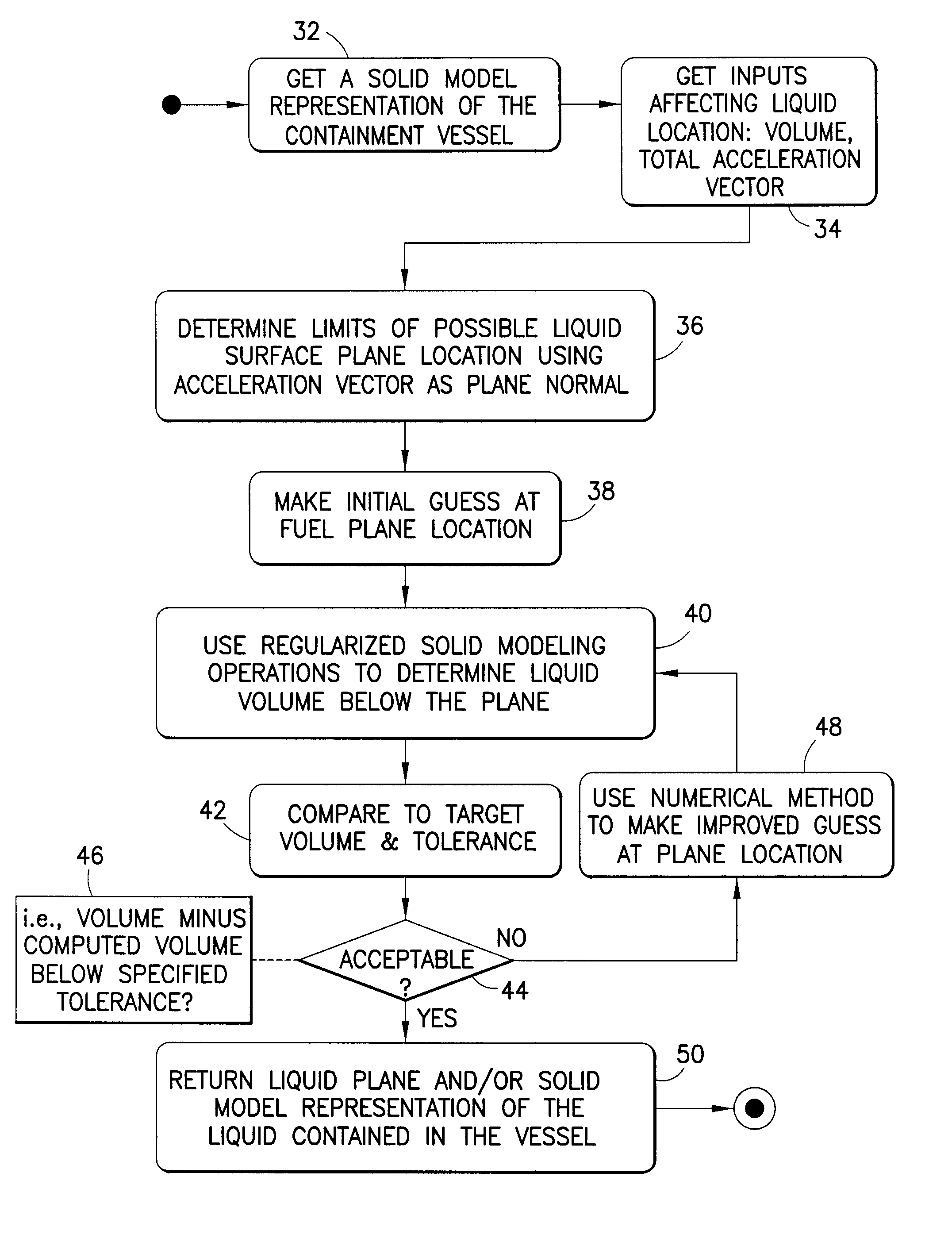

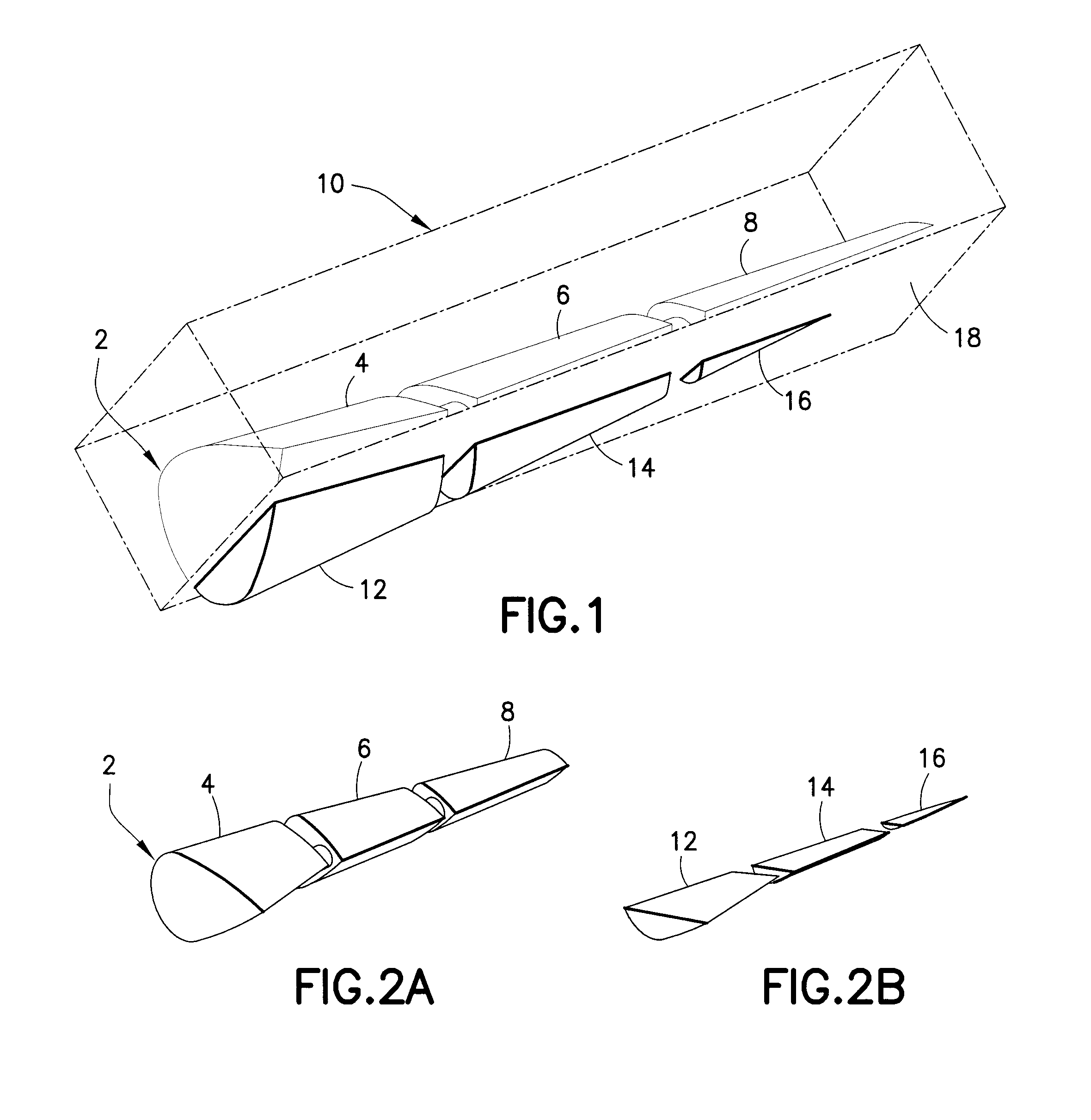

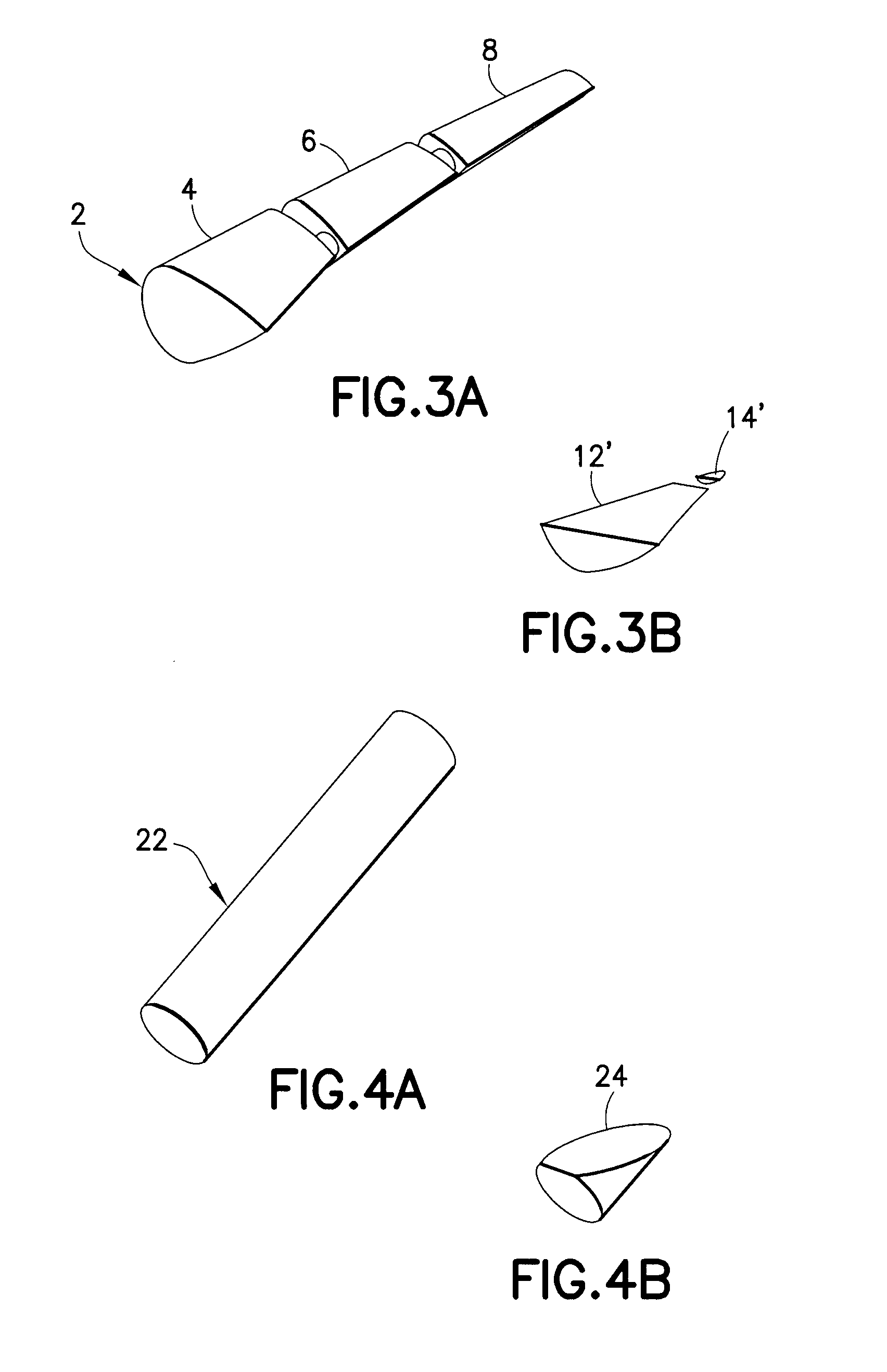

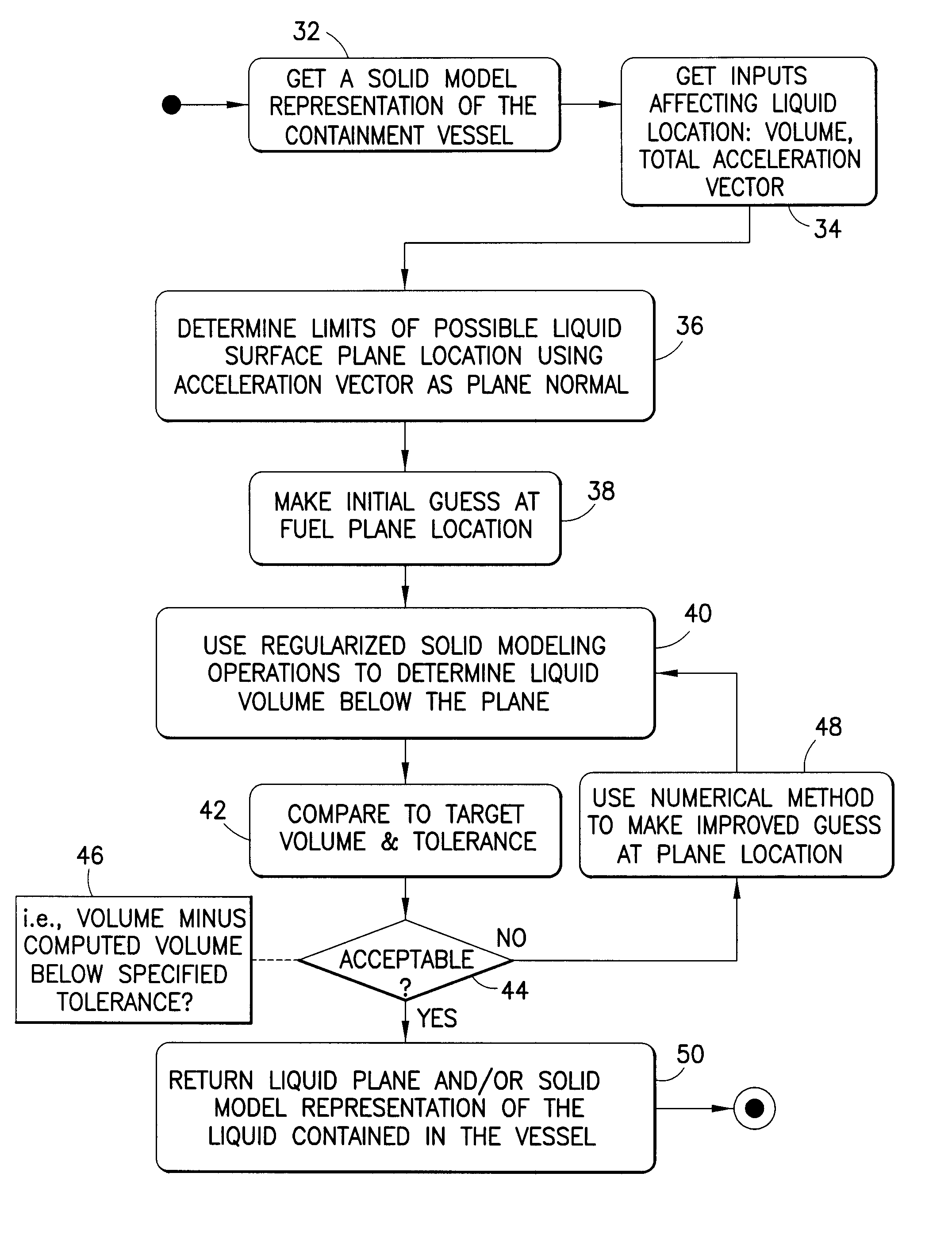

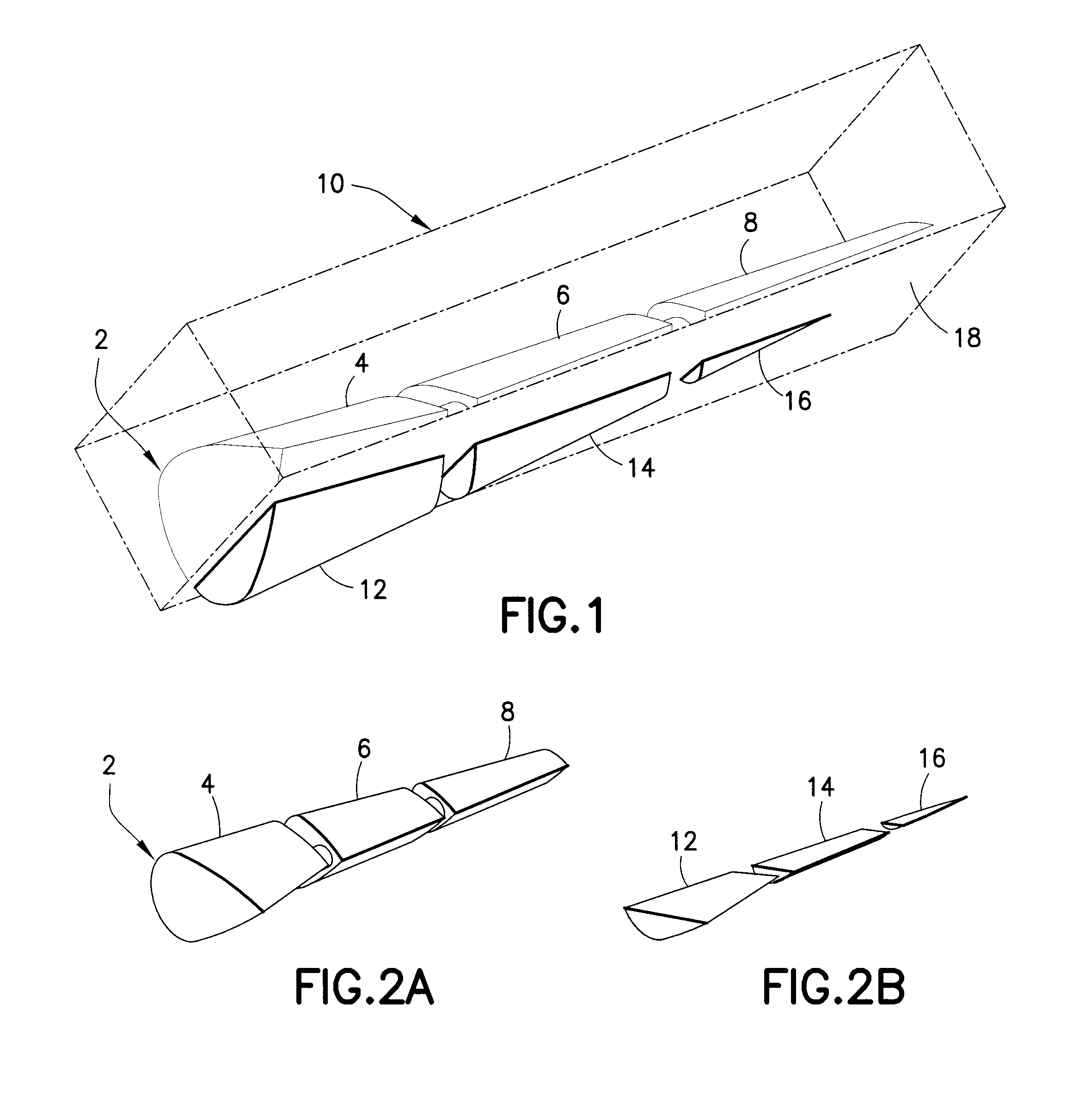

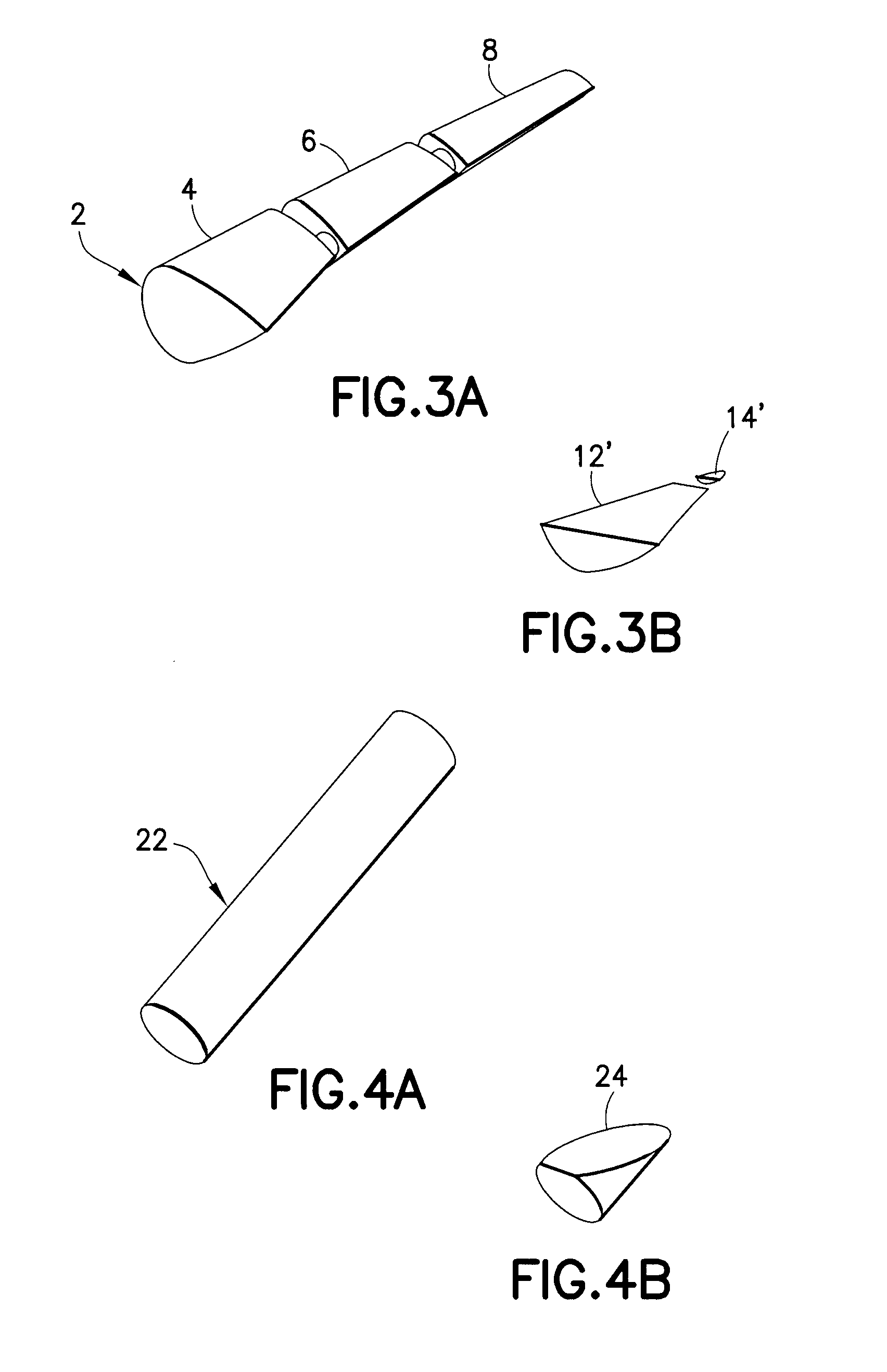

Calculating Liquid Levels in Arbitrarily Shaped Containment Vessels Using Solid Modeling

ActiveUS20120150517A1Reduce the amount requiredSimple calculationGeometric CADDesign optimisation/simulationEngineeringSolid modeling

Systems and method for simulating liquid containment behavior. The system comprises a solid modeler and a nonlinear equation solver. The nonlinear equation solver takes as input the solid model representation of the containment vessel from the solid modeler, a desired orientation in space, dynamic conditions (e.g., lateral acceleration) and an amount of liquid. To find the level of liquid in the vessel, the system solver iteratively performs successive Boolean subtractions using an infinite horizontal half-space that represents the liquid level of the vessel. The resulting sliced solid model is used to compute the volume of the liquid at that level. The iterative system solver terminates when the computed volume of the sliced containment vessel matches the specified volume of liquid (e.g., fuel) within a given tolerance. To accommodate dynamic situations, e.g., when acceleration is present, the horizontal liquid plane is replaced with a plane at an angle that corresponds to the total acceleration.

Owner:THE BOEING CO

Content-based and time-evolving social network analysis

ActiveUS8204988B2Easy to deriveReduced dimensional representationDigital computer detailsCharacter and pattern recognitionTime evolutionContent based networking

System and method for modeling a content-based network. The method includes finding single mode clusters from among network (sender and recipient) and content dimensions represented as a tensor data structure. The method allows for derivation of useful cross-mode clusters (interpretable patterns) that reveal key relationships among user communities and keyword concepts for presentation to users in a meaningful and intuitive way. Additionally, the derivation of useful cross-mode clusters is facilitated by constructing a reduced low-dimensional representation of the content-based network. Moreover, the invention may be enhanced for modeling and analyzing the time evolution of social communication networks and the content related to such networks. To this end, a set of non-overlapping or possibly overlapping time-based windows is constructed and the analysis performed at each successive time interval.

Owner:IBM CORP

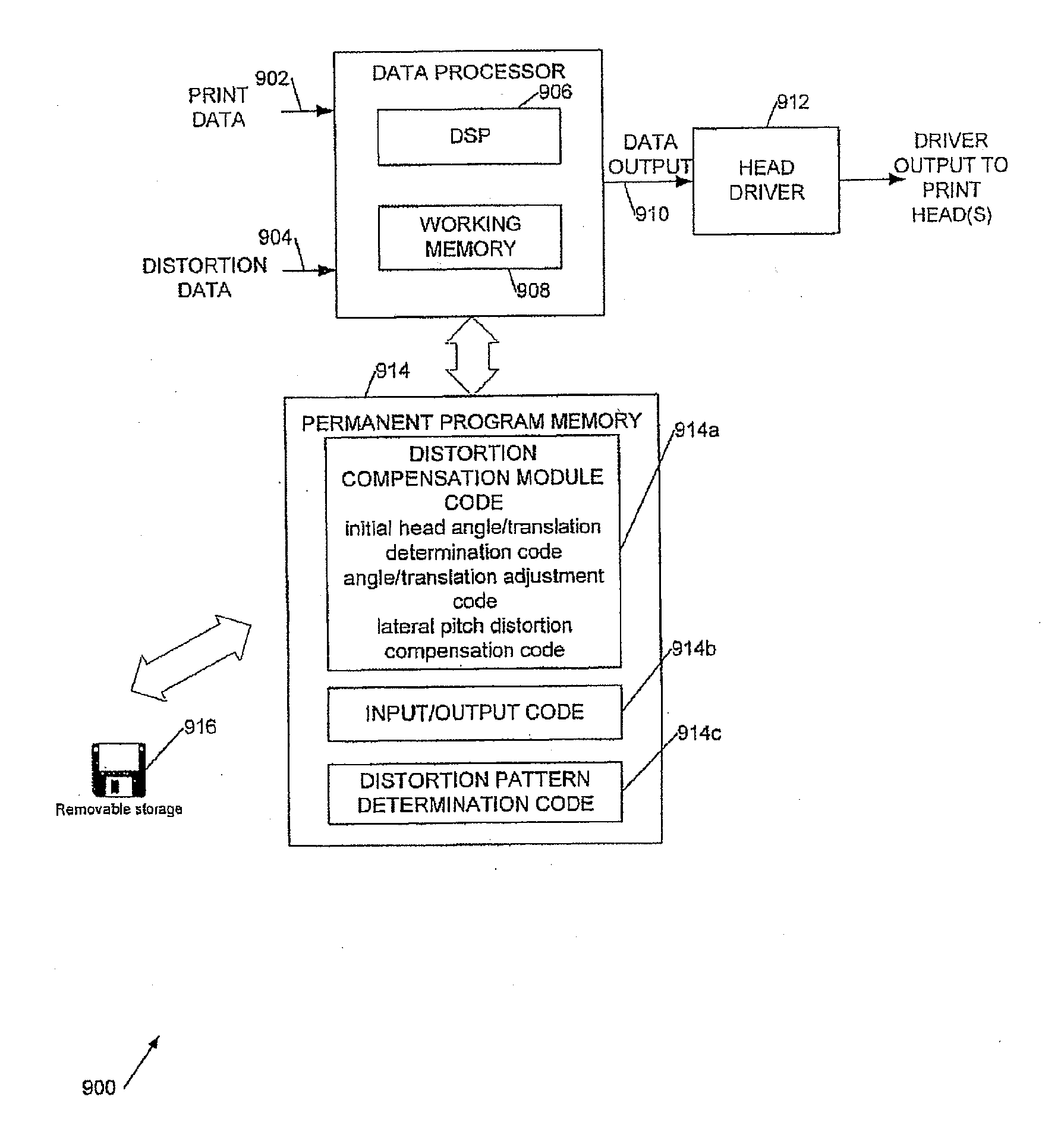

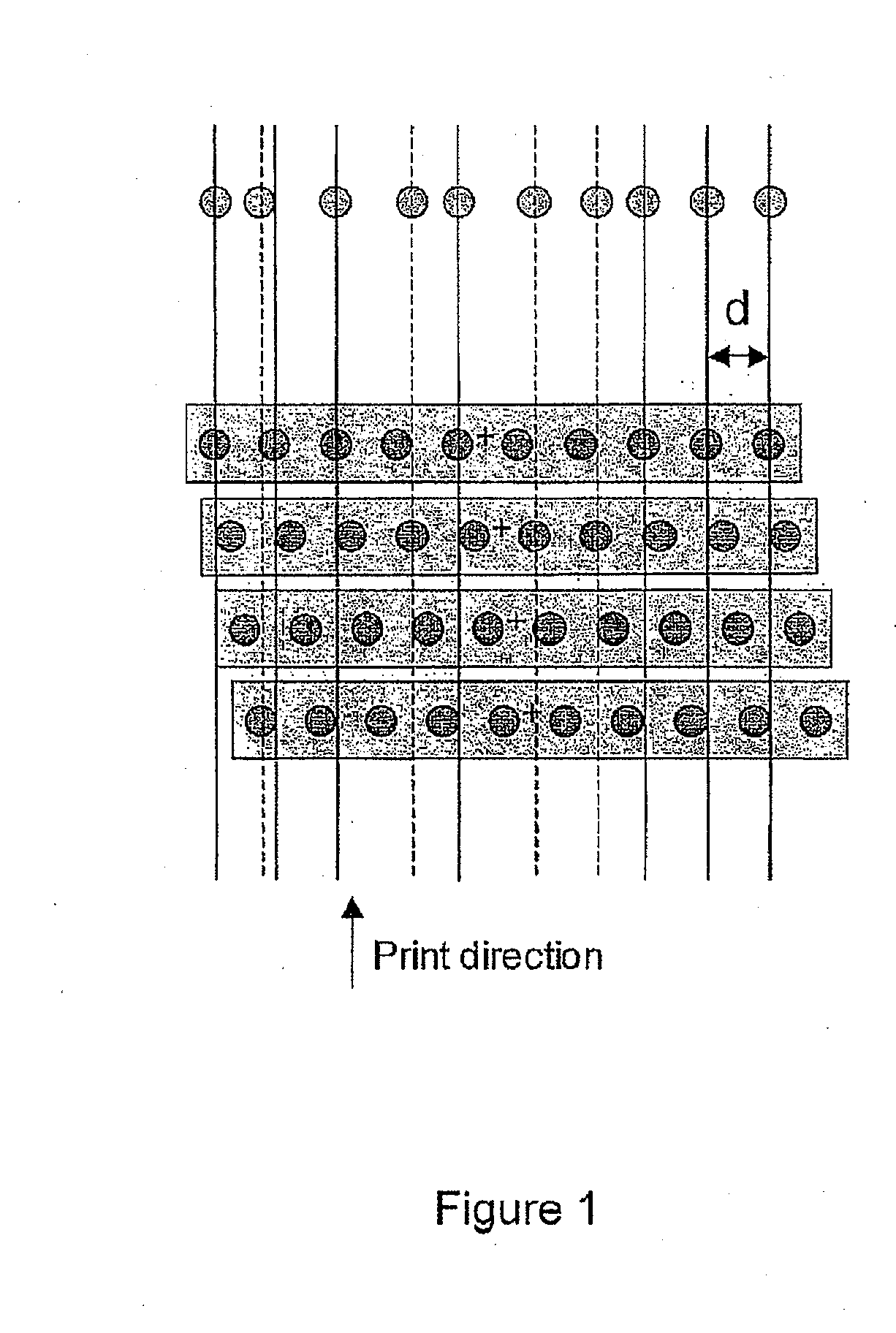

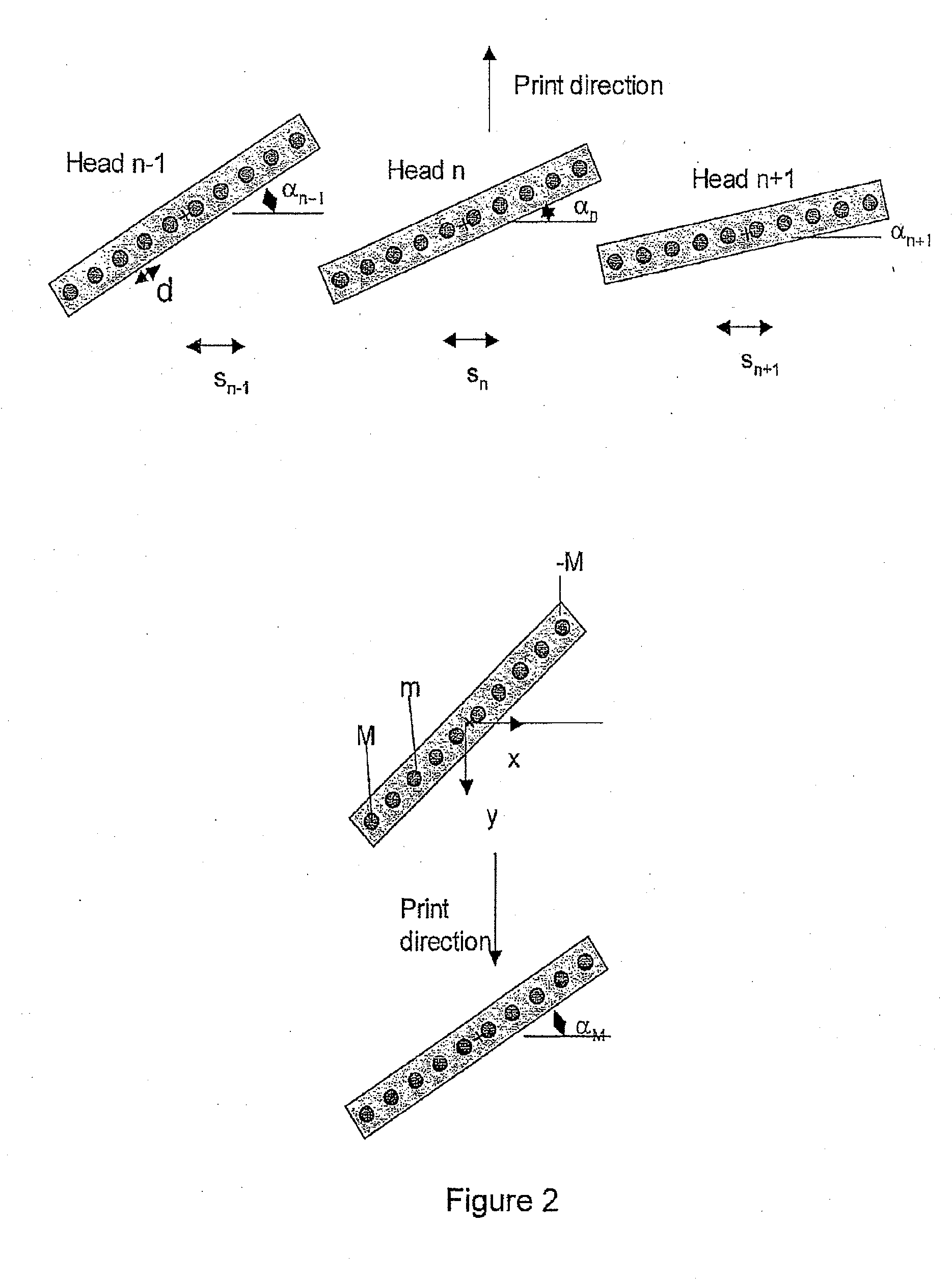

Distortion compensation for printing

InactiveUS20130027458A1Easy to deriveCompensation DistortionPrinted circuit manufactureOther printing apparatusPrinting pressMechanical engineering

A printing machine includes a substrate and at least one printhead with at least two material deposition channels which are movable with respect to the substrate, wherein the printhead is mounted on a stage which allows rotation of the printhead around an axis perpendicular to the substrate and translation in a direction perpendicular to the print direction, and wherein during each print swath, the rotation angle and translation values of the printhead are varied in order to change the pitch and the lateral position in the direction perpendicular to the print direction of material deposited from the different deposition channels; and an algorithm which computes the required rotation angles and translation values for a given pattern of substrate distortion.

Owner:FLEXENABLE LTD

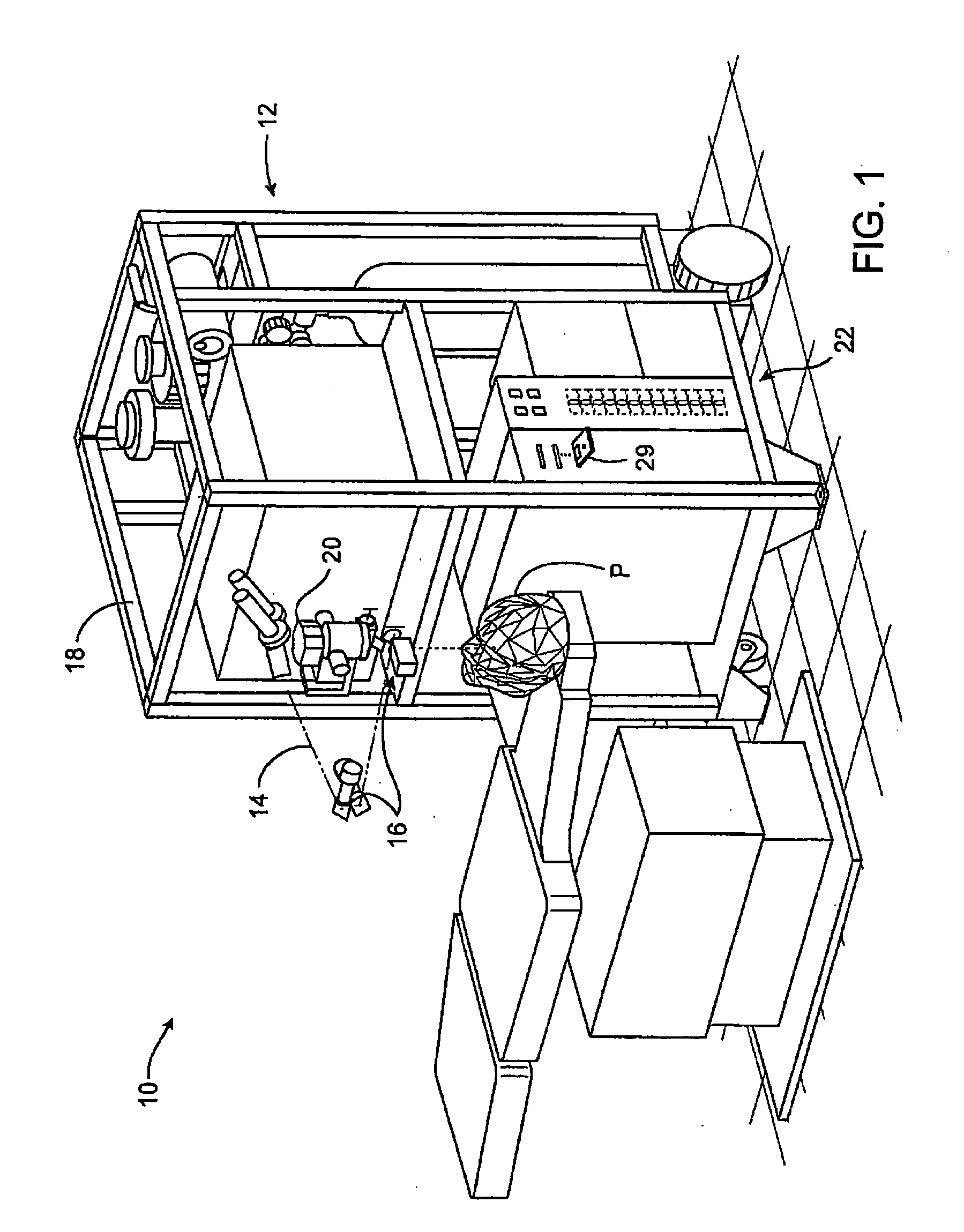

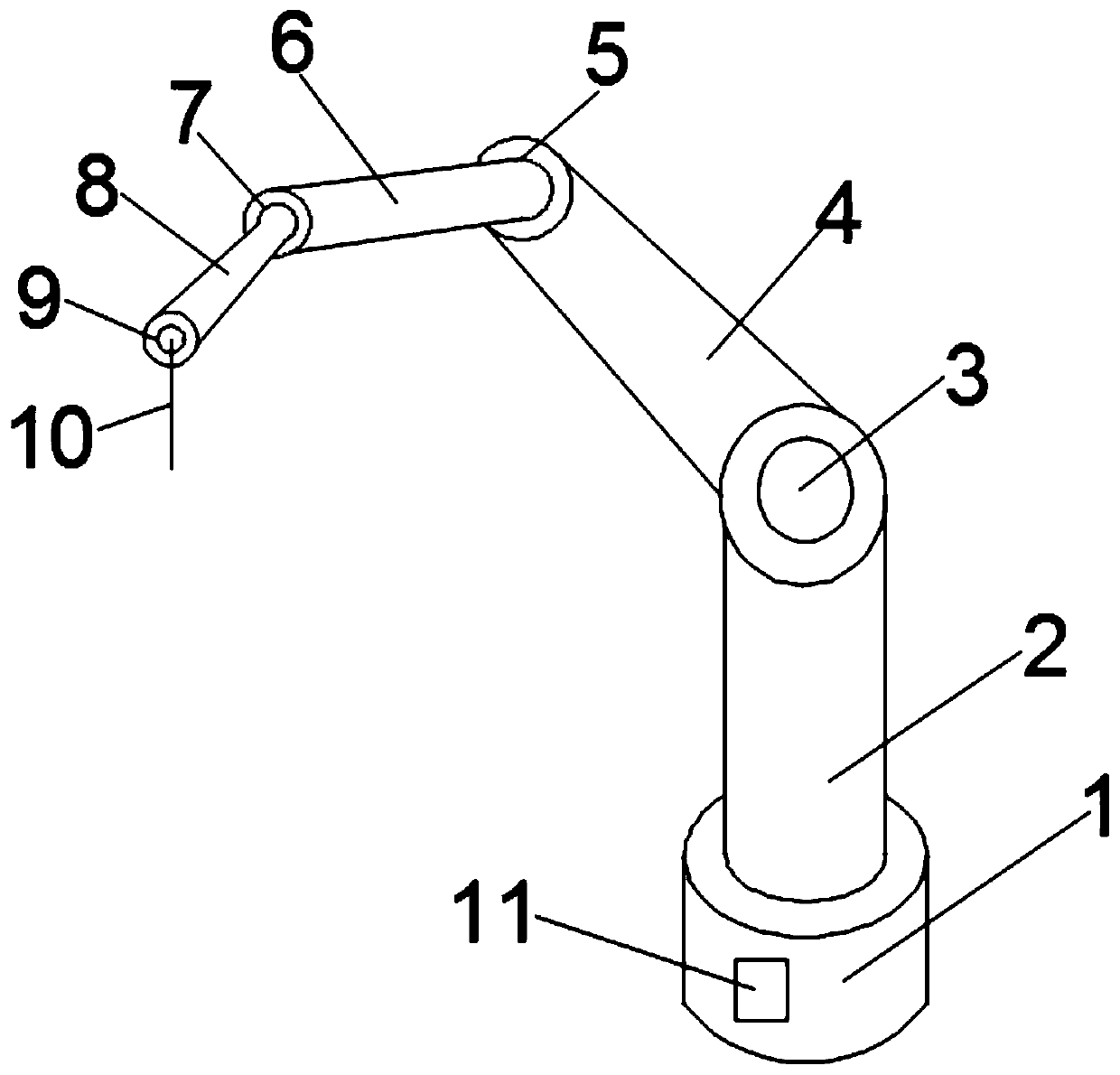

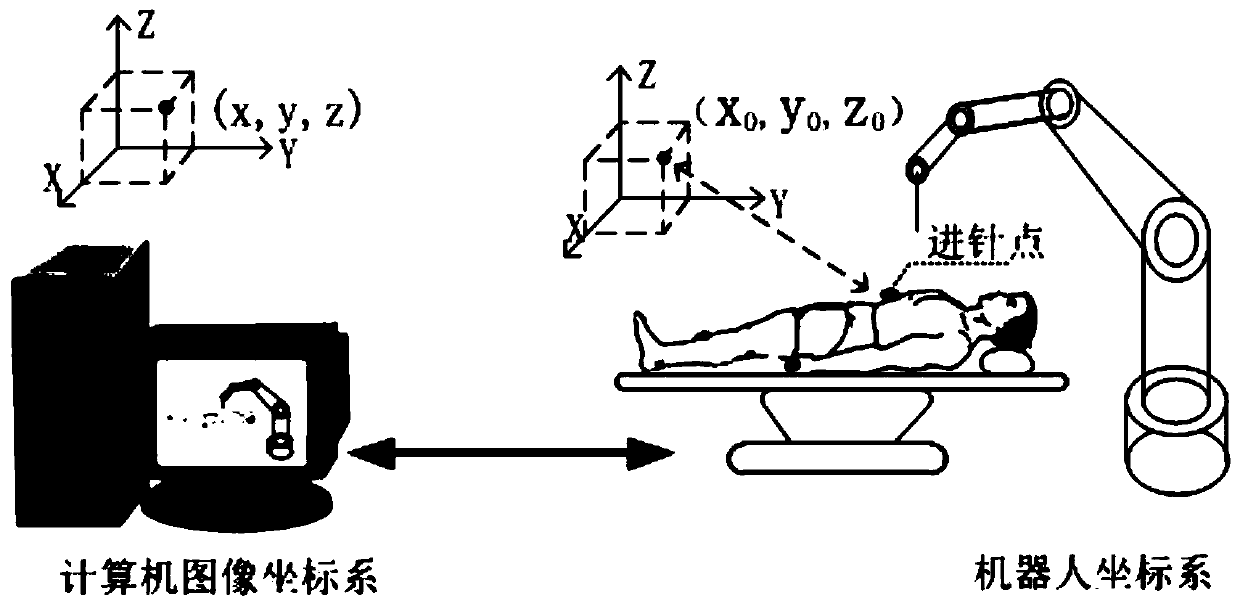

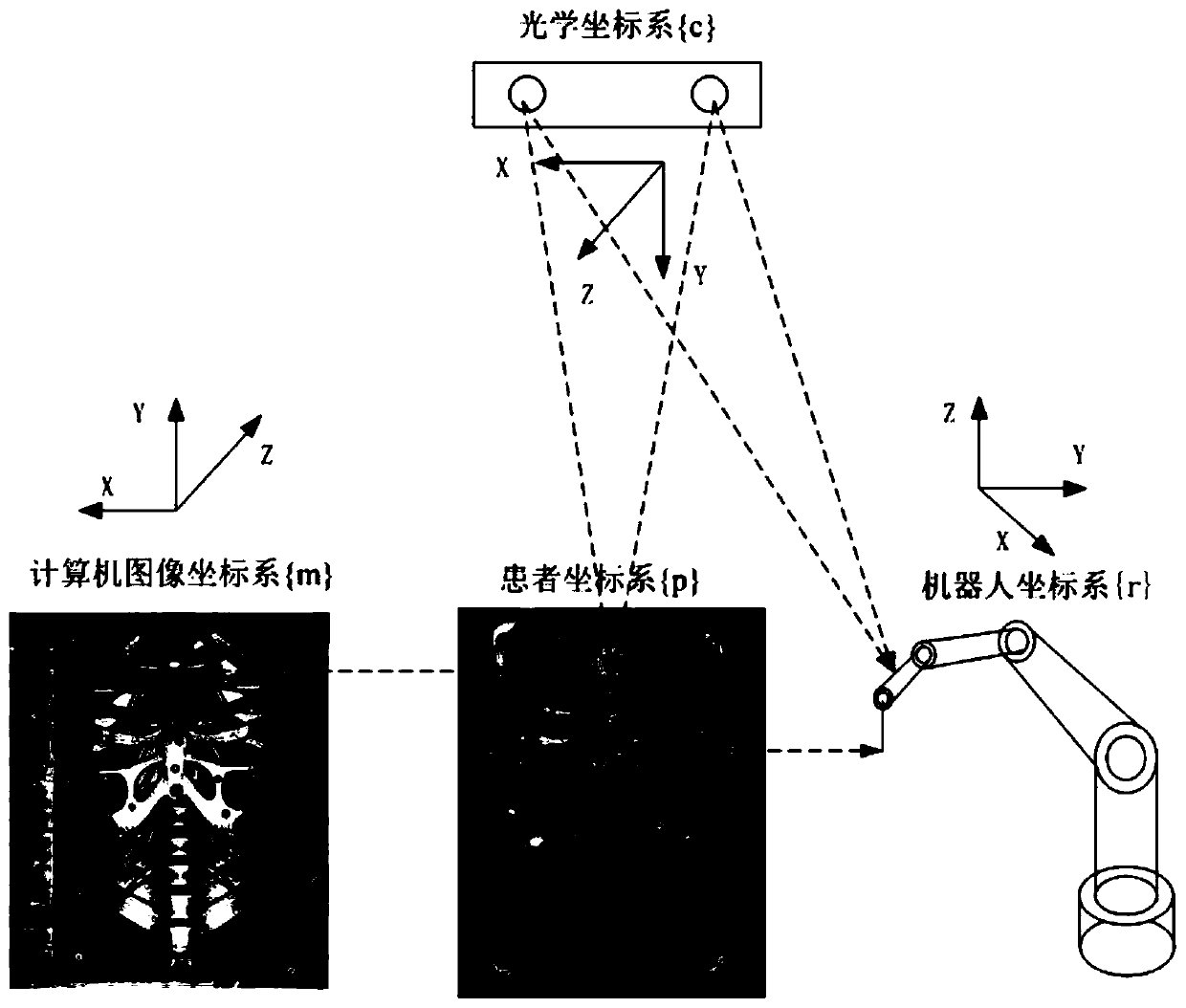

Puncture robot navigation system with dynamic compensation function based on binocular vision

PendingCN109864806AHigh positioning accuracyGuaranteed uptimeSurgical needlesSurgical navigation systemsEngineeringNavigation system

The invention discloses a puncture robot navigation system with a dynamic compensation function based on binocular vision, and belongs to the technical field of navigation. The system comprises a base, the top of the base is provided with a support column, the top of the support column is hinged to a first link block, the outer side of the first link block is provided with a first connecting arm and one end of the first connecting arm is hinged to a second link block, the outer side of the second link block is provided with a second connecting arm and the outer side of the second connecting arm is hinged to a third link block, the outer side of the third link block is provided with a third connecting arm and one end of the third connecting arm is hinged to a fourth link block, the outer side of the fourth link block is provided with a puncture needle, and a mechanical arm control device is arranged in the base. The system can reduce errors caused by artificial puncture, and solves theproblem of auxiliary accurate positioning in the medical surgery minimally invasive puncture operation by virtue of the characteristics of high positioning accuracy, stable operation, safety and reliability of a robot.

Owner:INST OF INTELLIGENT MFG TECH JITRI

System for measuring a sample with a layer containing a periodic diffracting structure

ActiveUS20080037005A1Easy constructionEasy to deriveRadiation pyrometrySpectrum investigationCritical dimensionPhysics

To measure the critical dimensions and other parameters of a one- or two-dimensional diffracting structure of a film, the calculation may be simplified by first performing a measurement of the thickness of the film, employing a film model that does not vary the critical dimension or parameters related to other characteristics of the structure. The thickness of the film may be estimated using the film model sufficiently accurately so that such estimate may be employed to simplify the structure model for deriving the critical dimension and other parameters related to the two-dimensional diffracting structure.

Owner:KLA TENCOR TECH CORP

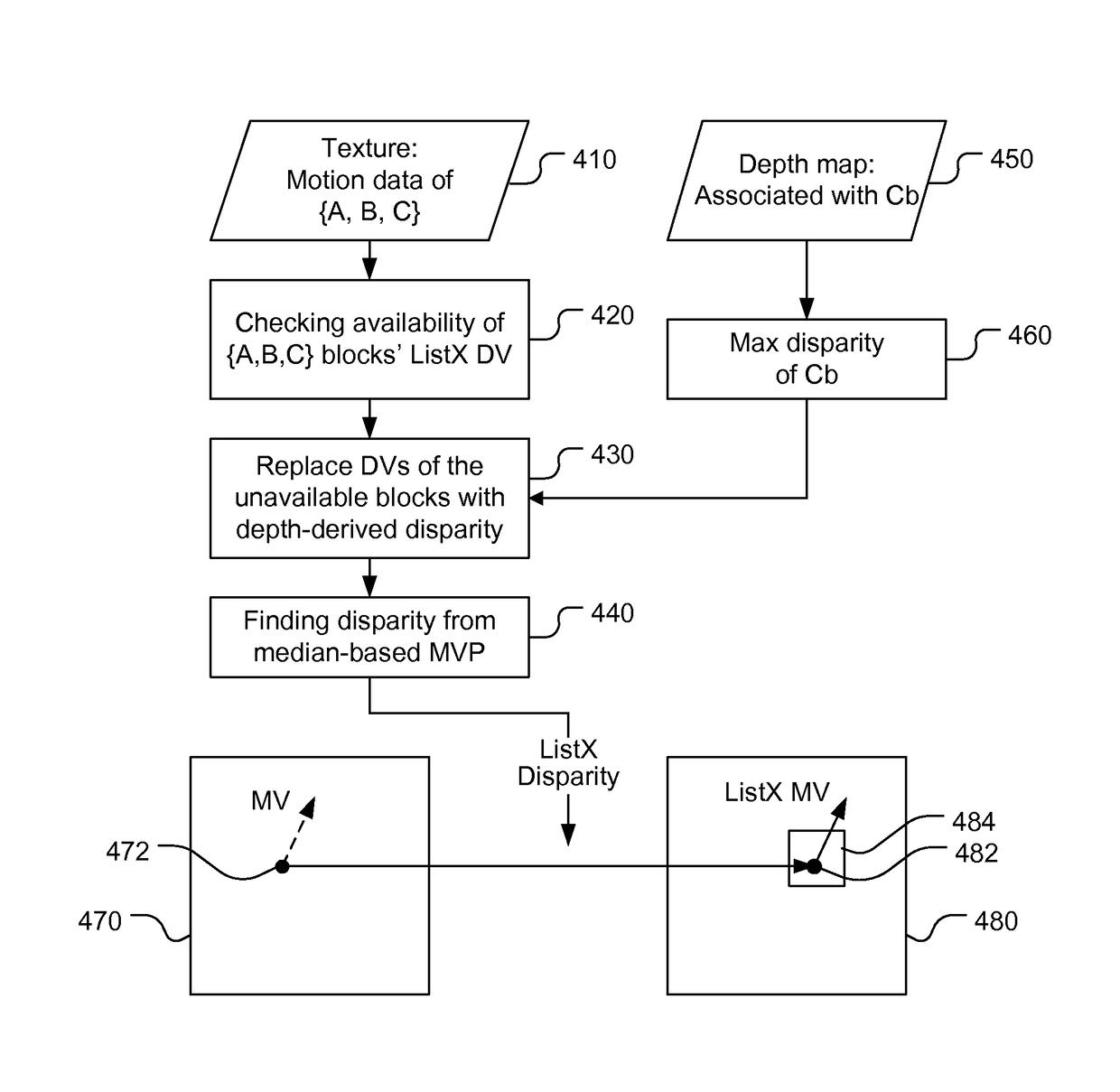

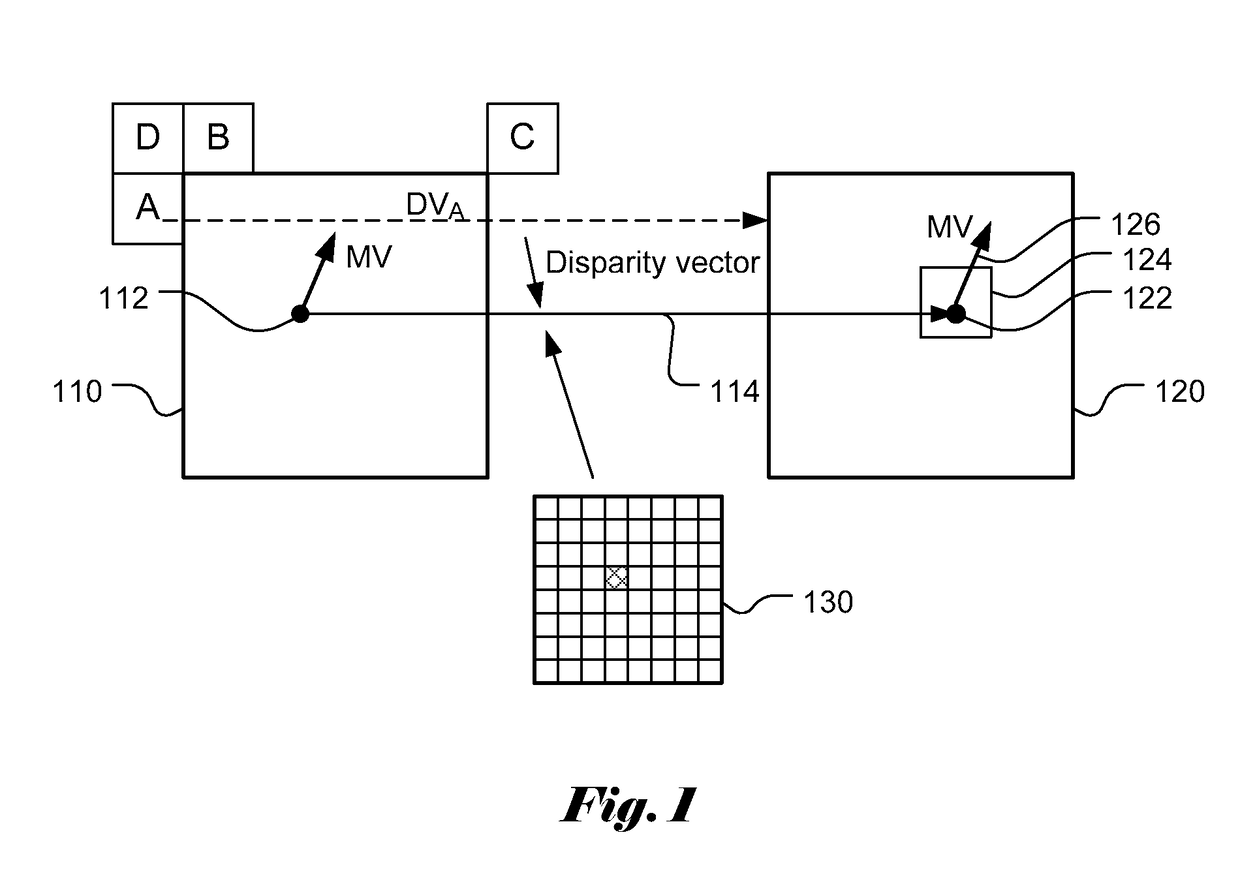

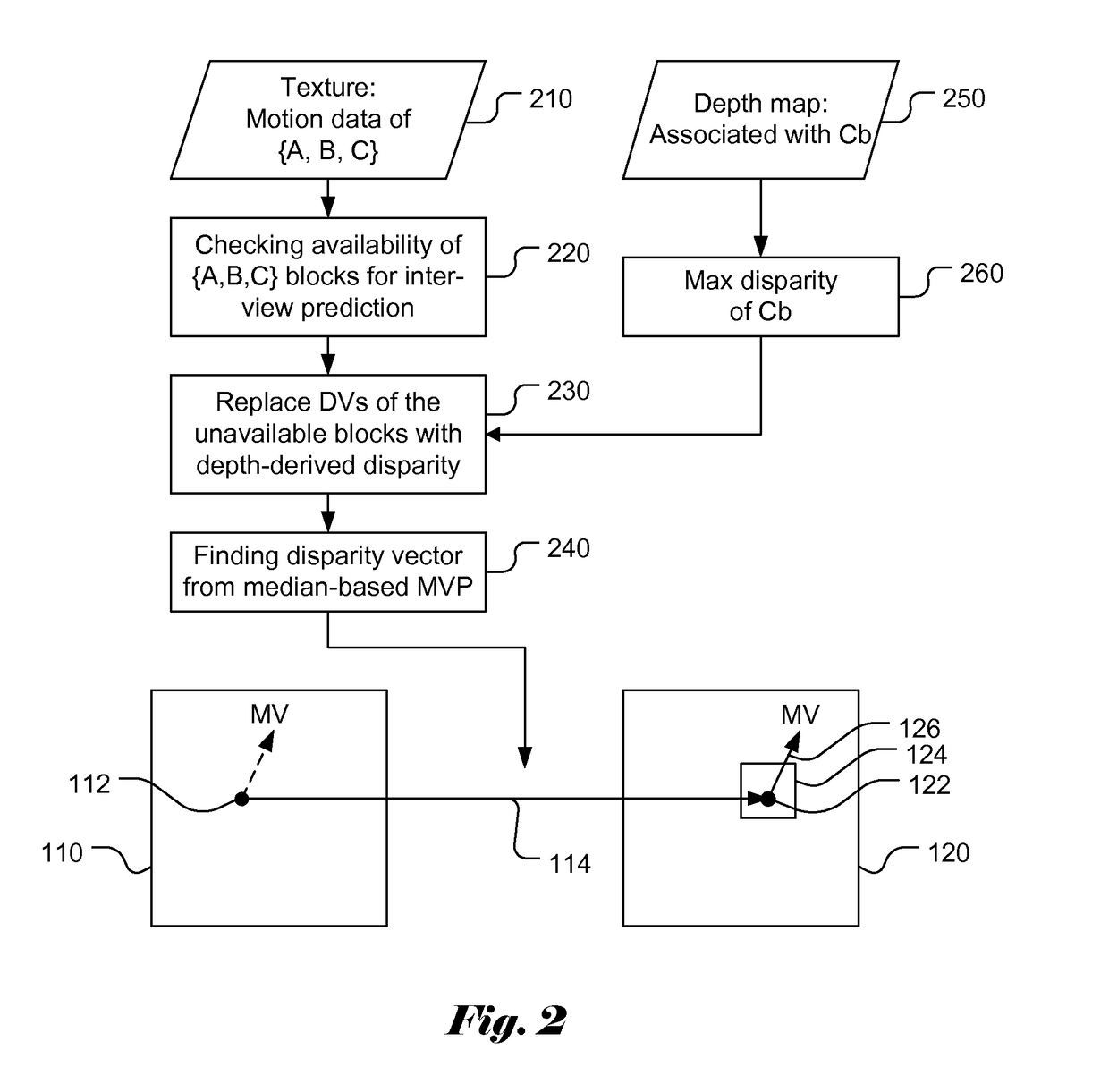

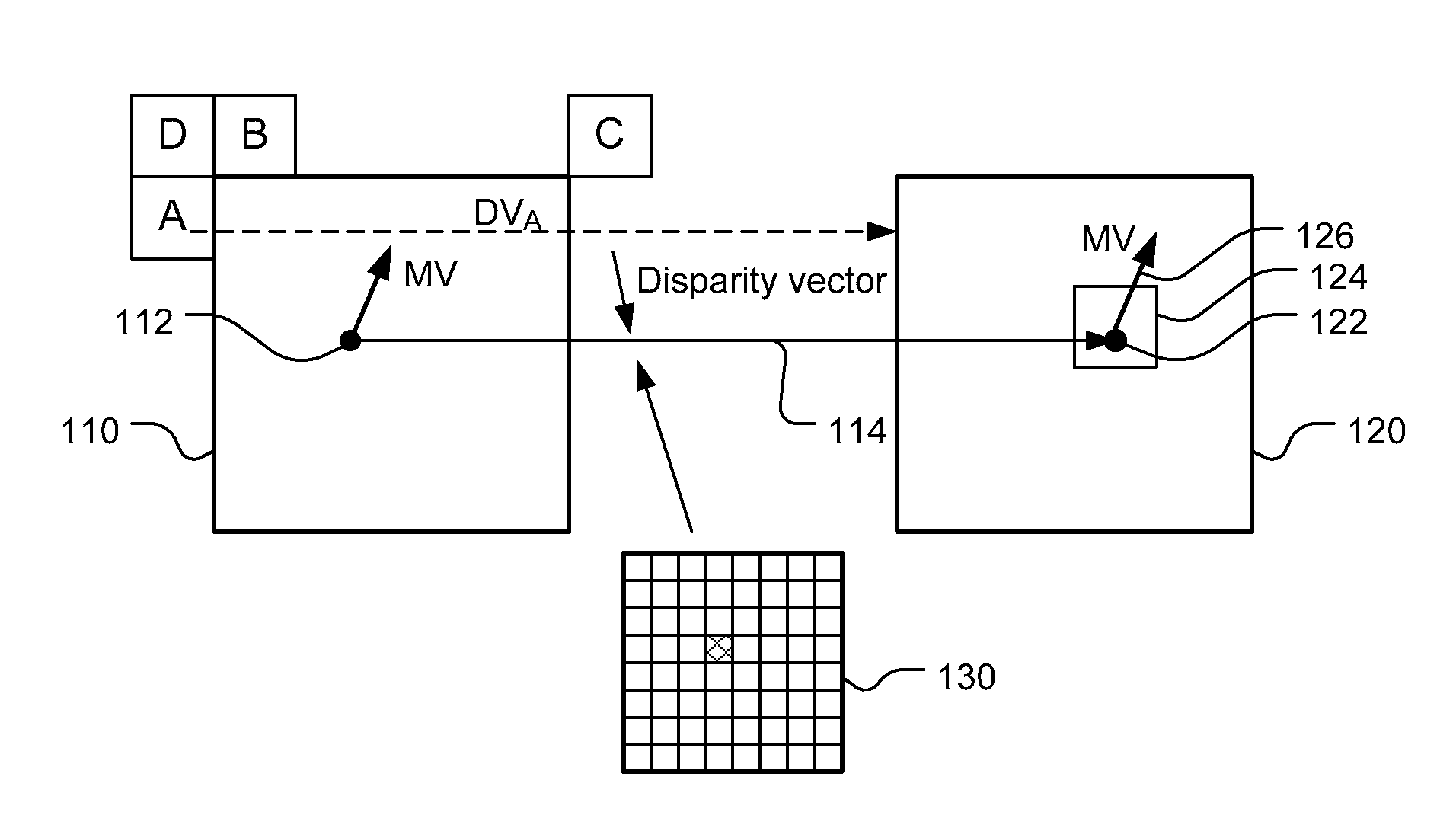

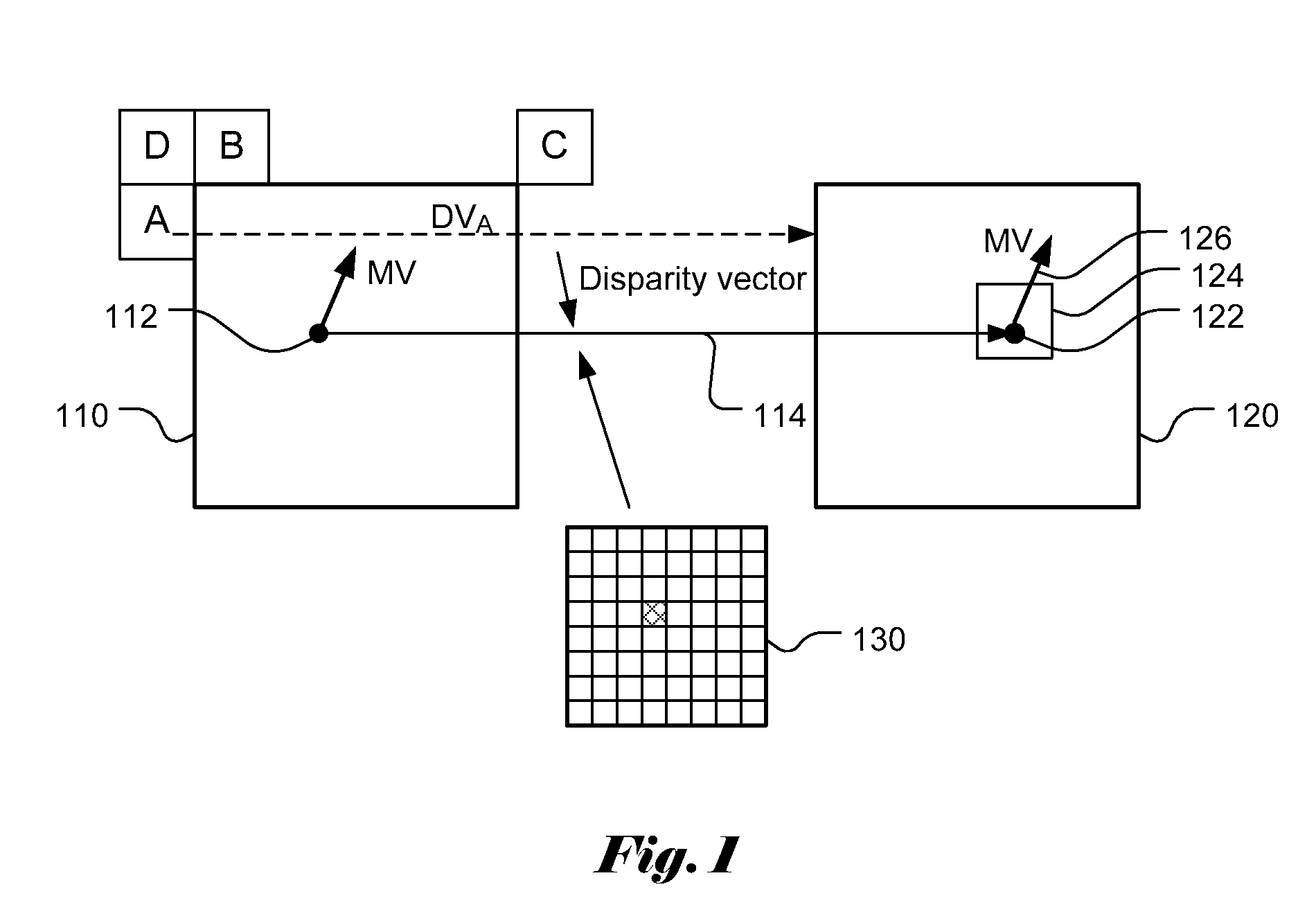

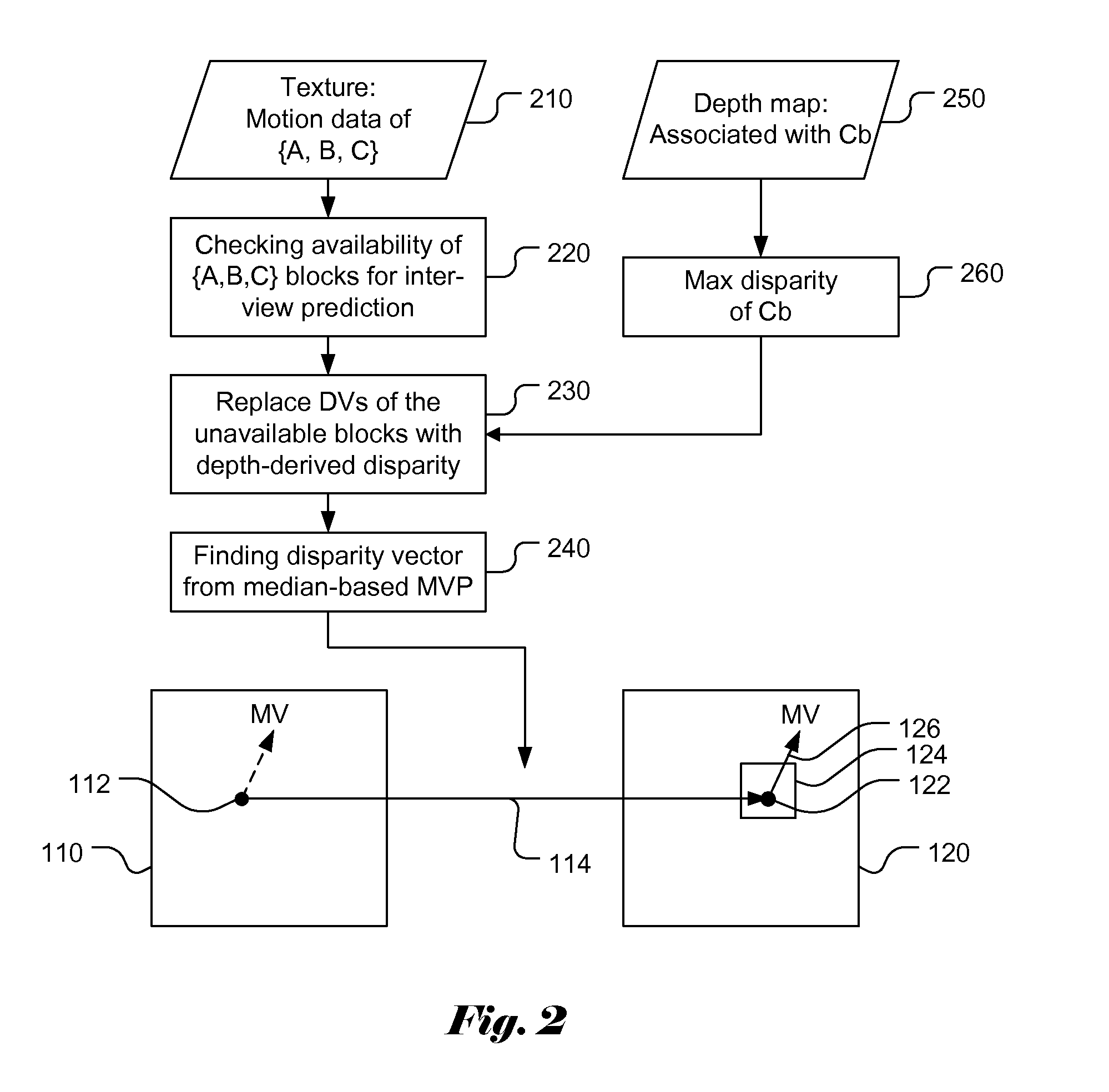

Method and apparatus of disparity vector derivation and inter-view motion vector prediction for 3D video coding

ActiveUS9736498B2Improve coding efficiencyDerivation is simpleDigital video signal modificationSteroscopic systemsParallaxVideo encoding

A method and apparatus for three-dimensional video coding and multi-view video coding are disclosed. Embodiments according to the present invention derive a unified disparity vector (DV) based on neighboring blocks of the current block or depth information associated with the current block and locate a single corresponding block in a reference view according to the unified DV. An inter-view motion vector prediction (MVP) candidate is then derived for both list0 and list1 from the single corresponding block. List0 and list1 MVs of the inter-view MVP candidate are derived from the single corresponding block located according to the unified DV.

Owner:HFI INNOVATION INC

Method and apparatus of disparity vector derivation and inter-view motion vector prediction for 3D video coding

ActiveUS20150264397A1Improve coding efficiencyDerivation is simpleColor television with pulse code modulationColor television with bandwidth reductionParallaxMotion vector

A method and apparatus for three-dimensional video coding and multi-view video coding are disclosed. Embodiments according to the present invention derive a unified disparity vector (DV) based on neighboring blocks of the current block or depth information associated with the current block and locate a single corresponding block in a reference view according to the unified DV. An inter-view motion vector prediction (MVP) candidate is then derived for both list0 and list1 from the single corresponding block. List0 and list1 MVs of the inter-view MVP candidate are derived from the single corresponding block located according to the unified DV.

Owner:HFI INNOVATION INC

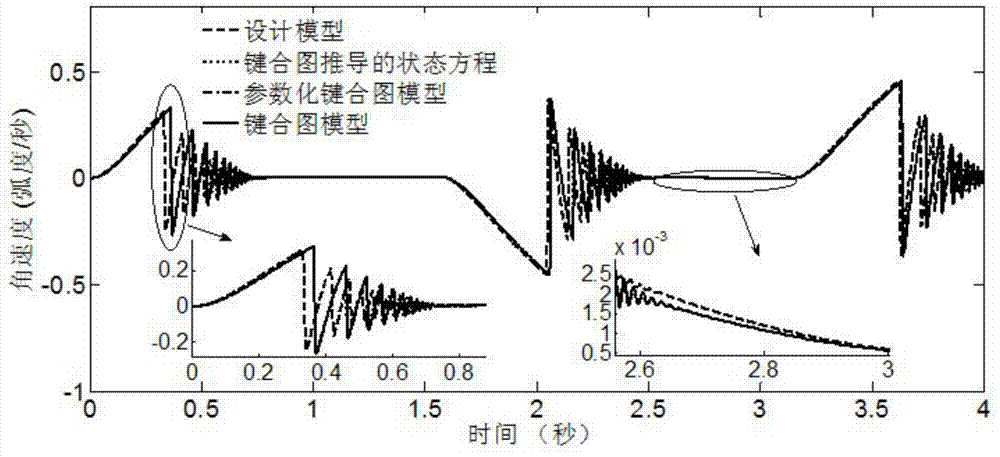

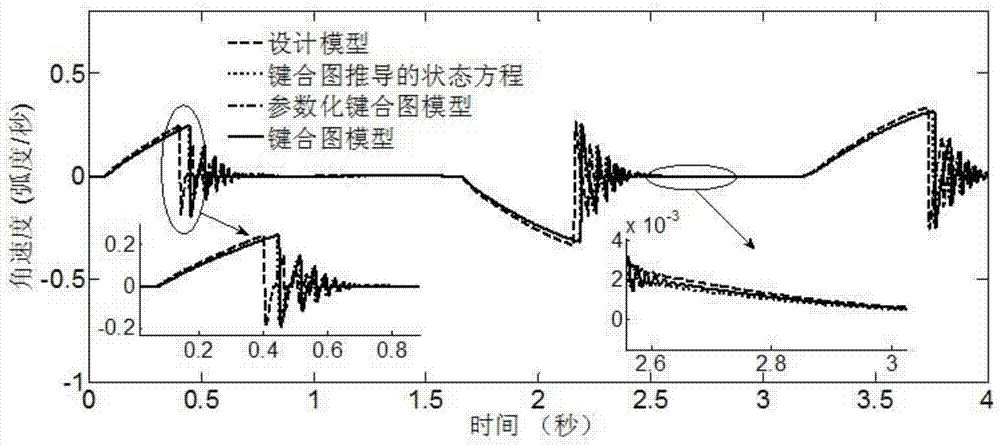

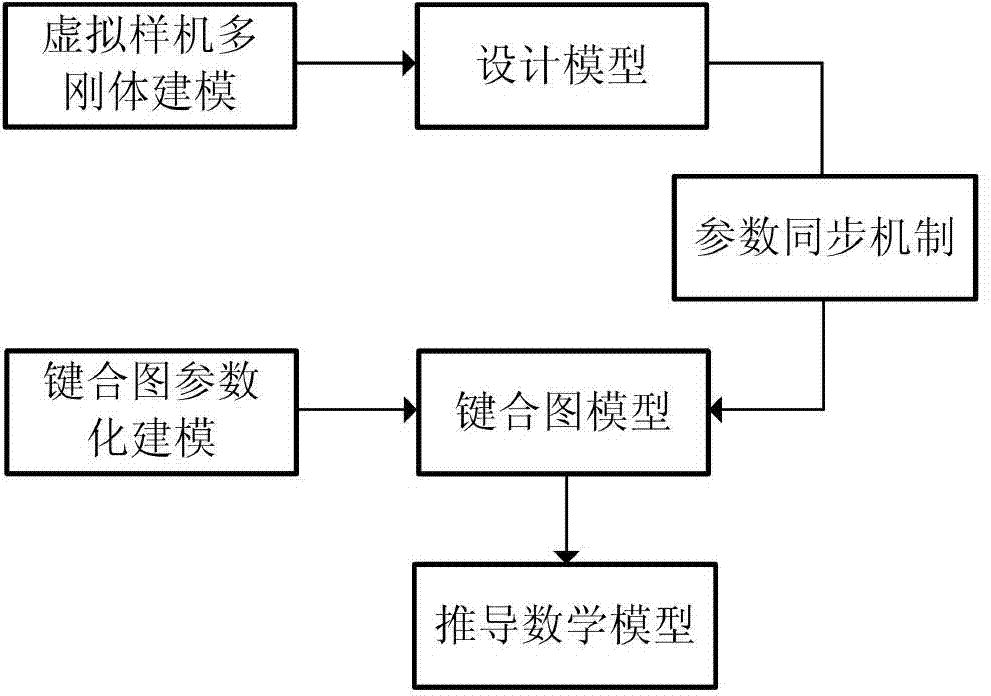

Quick simulation analysis method for radar antenna servo system

ActiveCN104298812AImprove modeling efficiencyAccelerate Simulation AnalysisSpecial data processing applicationsSystems designRadar

The invention discloses a quick simulation analysis method for a radar antenna servo system. The quick simulation analysis method includes the steps that (1) parametric modeling of a bond graph is carried out, components in the system are simplified according to the modeling sequence of a drive motor, a transmission mechanism and a reflecting surface body and accordingly a bond graph model of the antenna servo system is built; (2) virtual prototype multi-rigid-body modeling is carried out, part rigid-body models in all links are sequentially built on the basis of the modeling theory that each solid body in the system corresponds to one rigid body in a multi-rigid-body model, the corresponding rigid bodies are combined according to a parametric model of the bond graph and accordingly a system design model is obtained; (3) a parameter synchronization mechanism is introduced, and design model parameters are transferred to the bond graph model synchronously by means of a design model information file; (4) a system mathematic model is deducted according to the system bond graph model. Mathematical modeling simulation, multi-rigid-body modeling simulation and bond graph modeling simulation methods are well combined, advantages are made use of and defects are avoided.

Owner:XIDIAN UNIV

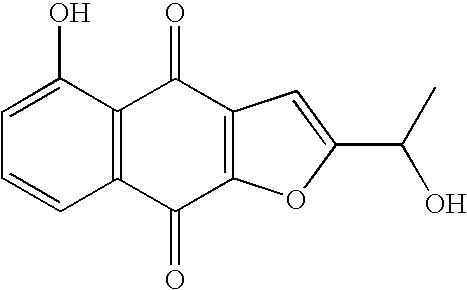

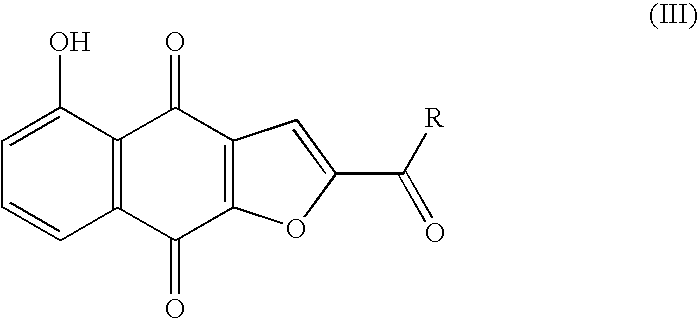

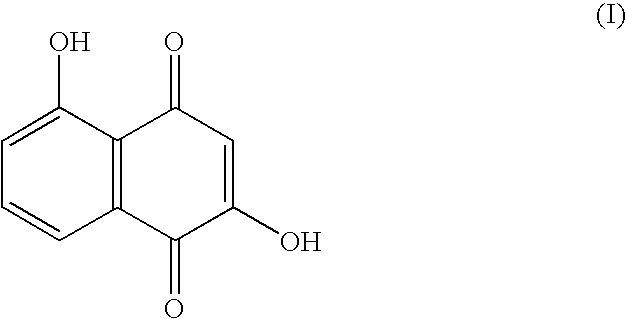

Anticancer compound, intermediate therefor, and processes for producing these

The present invention provides a method for easily and inexpensively preparing a racemate or an optically-active 2-(1 -hydroxyethyl)-5-hydroxynaphtho[2,3-b]furan-4,9-dione in high yields, 2-acetyl-2,3-dihydro-5-hydroxynaphtho[2,3-b]furan-4,9-dione which is useful as an intermediate for preparing NFD, and an anticancer agent comprising 2-(1-hydroxyethyl)-5-hydroxynaphtho[2,3-b]furan-4,9-dione as an active ingredient.Said 2-(1-hydroxyethyl)-5-hydroxynaphtho[2,3-b]furan-4,9-dione is obtained in 4 or 5 steps by using comparatively inexpensive 5 -hydroxynaphthalene-1,4-dione (also referred to as juglone) as a starting material.

Owner:TAHEEBO JAPAN

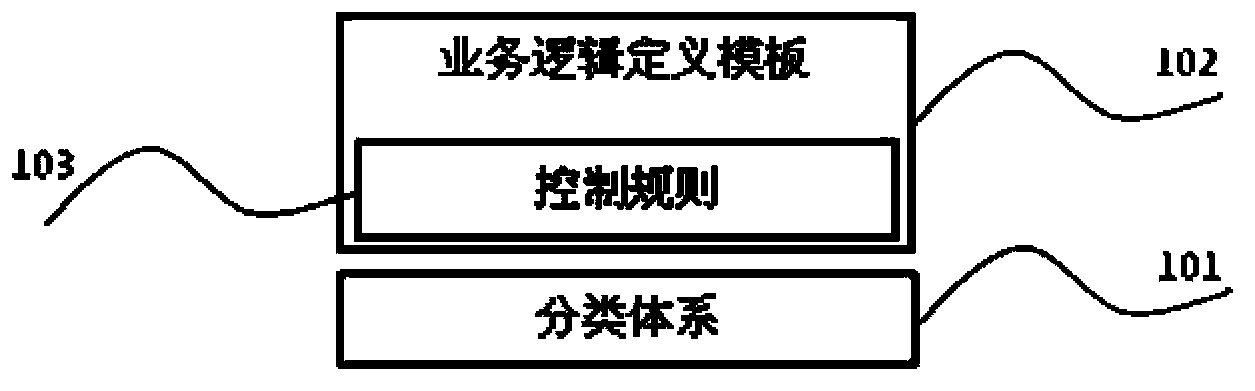

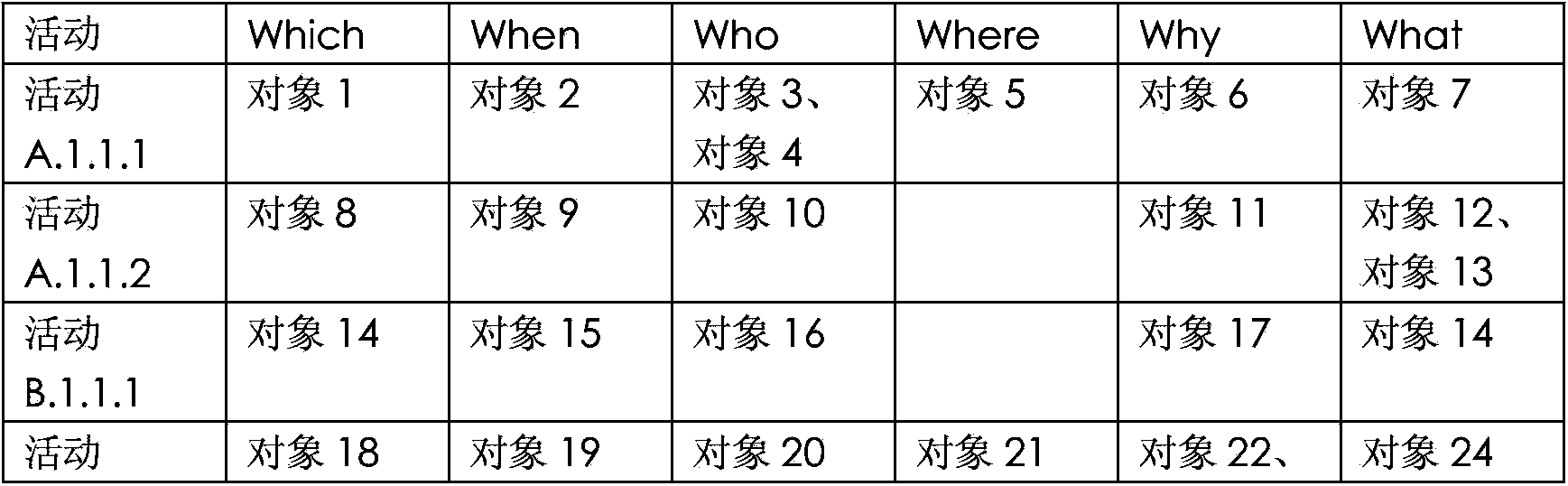

Business logic modeling system based on 6W

InactiveCN104346669AThe modeling process is clear and simpleRich in designResourcesLogical analysisComputer science

The invention relates to the technical field of computer information, and particularly discloses a business logic modeling system based on 6W.The business logic modeling system comprises a business logic modeling system based on 6W and a business logic model definition template, wherein a classification system uses activities as a center to organize the relations among various classifications, the classification system covers all related concepts in a business process, and the division of the classifications is not intersected; relation types among the concepts in the classification system are unified; a user finishes business logic analysis and model definition work under the constraint and guidance of predefined modeling rules in the template. The classification system covers all of the related concepts in the business process, and the division of the classifications is definite and is not intersected. The relation types among the concepts in the classification system are standard and are unified. The invention provides the business logic model definition template, and the user finishes the business logic analysis and the model definition work under the modeling rules provided by the template.

Owner:KARAMAY HONGYOU SOFTWARE

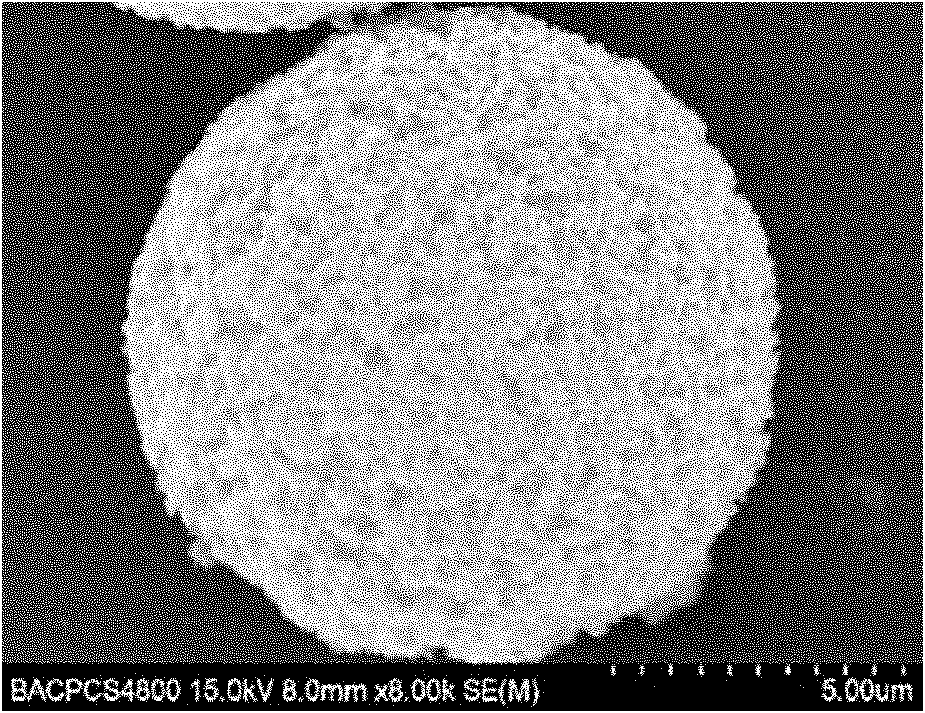

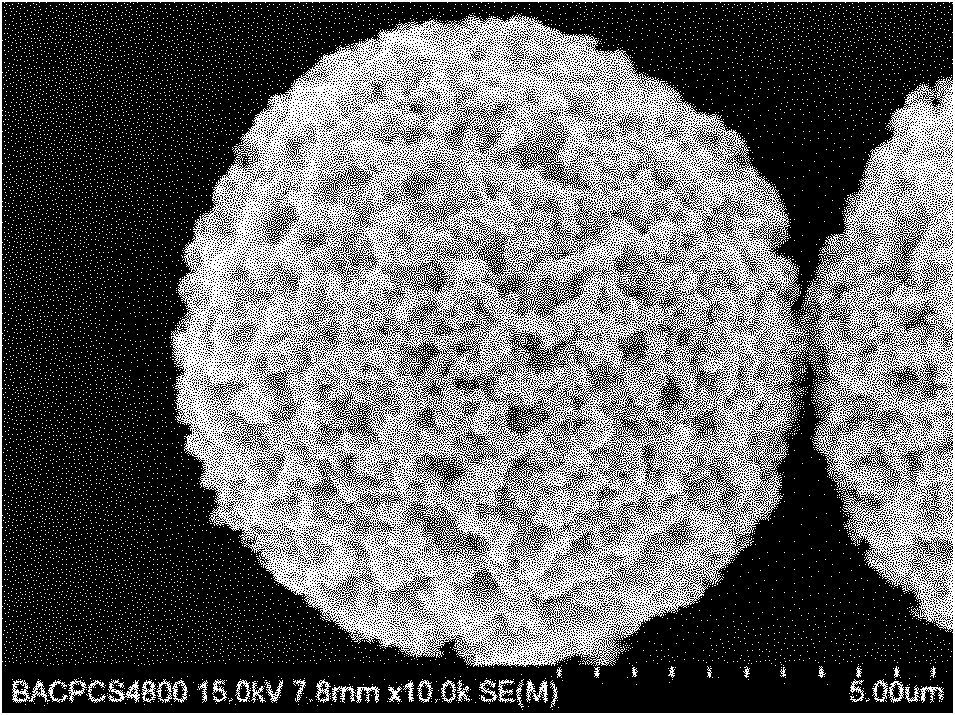

Diplopore nanoscale poly(glycidyl methacrylate)-ethylene glycol dimethacrylate (PGMA-EDMA) cross-linked microballoons and preparation method thereof

The invention discloses diplopore nanoscale poly(glycidyl methacrylate)-ethylene glycol dimethacrylate (PGMA-EDMA) cross-linked microballoons and a preparation method thereof. The diplopore nanoscale PGMA-EDMA cross-linked microballoons have ultra-macroporous and mesoporous double structures uniformly arranged in the interiors and the exteriors of the diplopore nanoscale PGMA-EDMA cross-linked microballoons, diameters of 3 to 20 micrometers, dispersion coefficients of 2.5 to 5%, ultra-macroporous diameters of 200 to 600 nanometers and mesoporous diameters of 30 to 60 nanometers. The preparation method has the advantages that linear PGMA seeds obtained by dispersion polymerization and having uniform aperture sizes are utilized as templates and undergo a one-step swelling polymerization reaction, wherein formation and distribution of diameters are adjusted by a binary pore-foaming system and a phase-separation technology, and thus the diplopore nanoscale PGMA-EDMA cross-linked microballoons which are all-poly(glycidyl methacrylate) (PGMA-EDMA) microballoons having ultra-macroporous and mesoporous double structures, uniform aperture sizes and good biocompatibility are obtained. Therefore, the preparation method realizes high-efficiency, rapid and high-flux biochemical separation analysis.

Owner:INST OF CHEM CHINESE ACAD OF SCI

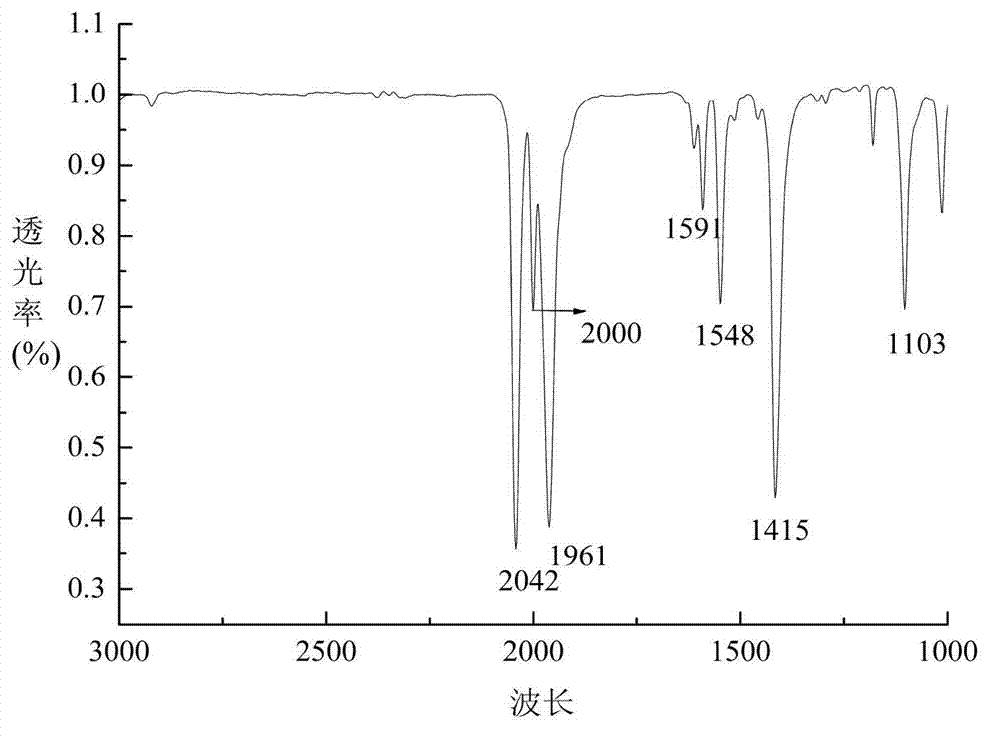

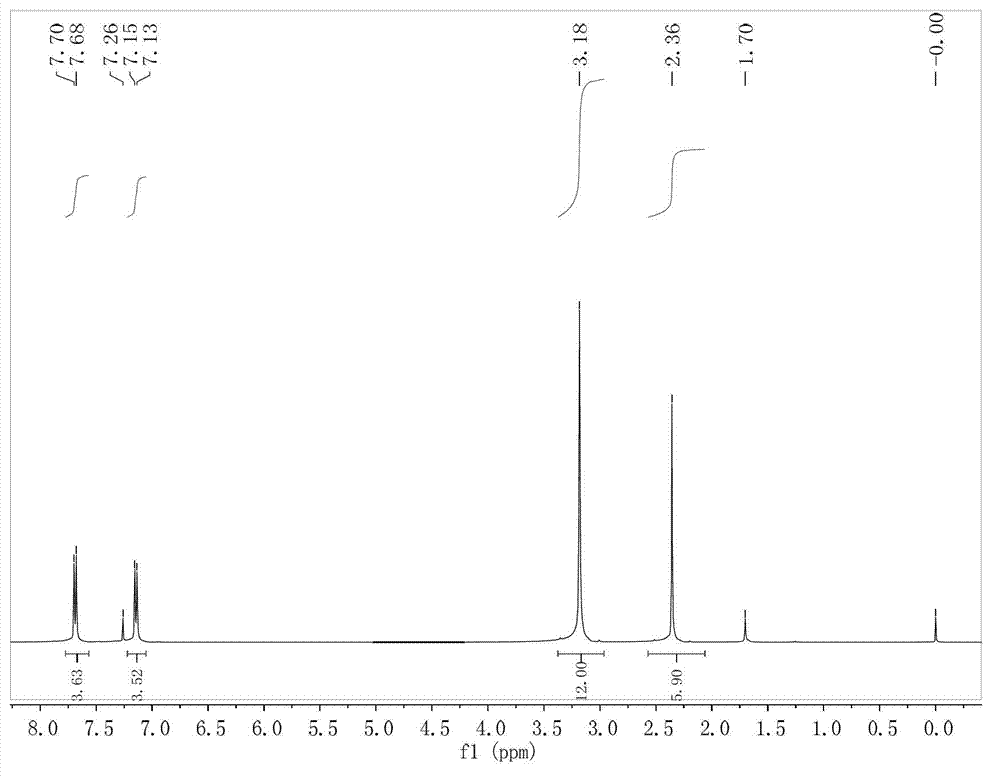

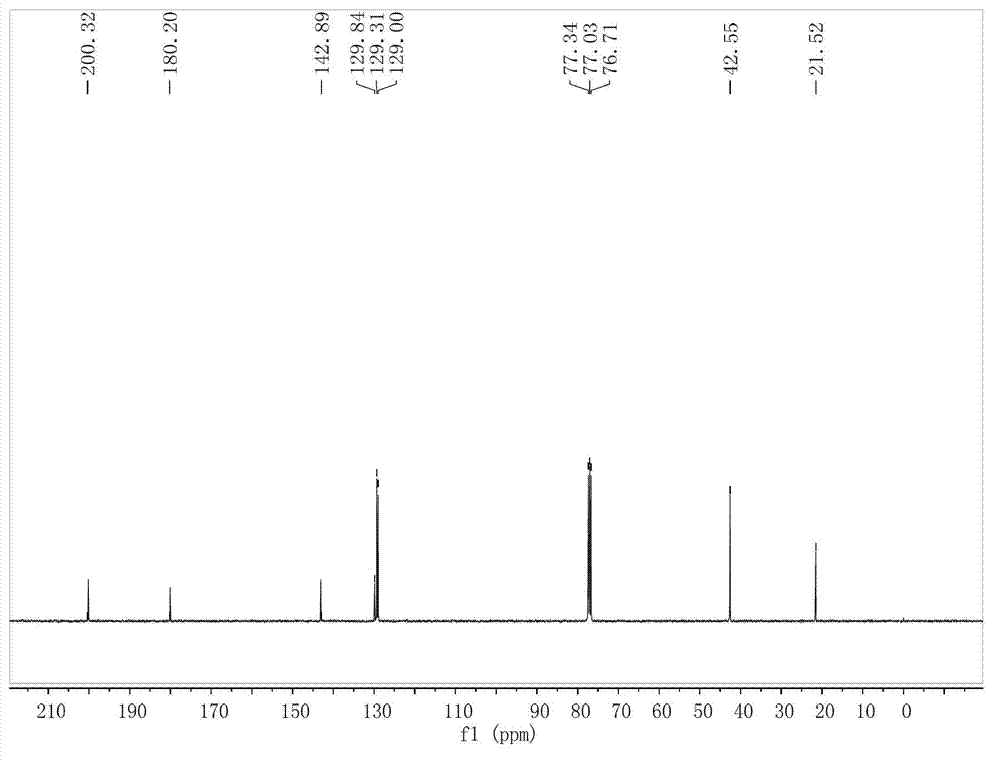

Saw horse carbonyl ruthenium compound and preparation method thereof

InactiveCN103087110AHigh bonding strengthGood water solubilitySugar derivativesGroup 8/9/10/18 element organic compoundsSolubilityRuthenium

The invention relates to a saw horse carbonyl ruthenium compound which is a carboxylic acid group and an axial 2 electronic ligand through connecting a bridging on a double-ruthenium tetracarbonyl saw horse skeleton structure, the bridged carboxylic acid group is coordinated with metal ruthenium through O, the bond strength of Ru-Co is improved by utilizing center metal Ru (I) with low price, the saw horse carbonyl ruthenium compound has good stability under physiological conditions and is beneficial to target release, CO release is controllable, and the water solubility of molecular and the CO release speed can be improved by changing bridging carboxylic acid group R1CO2 and the axial 2 electronic ligand, so that the saw horse carbonyl ruthenium compound can be functionalized efficiently and is easy to derive. The synthetic process is simpler and easy to obtain, and an efficient functionalization method for saw horse carbonyl ruthenium is provided.

Owner:SHAANXI NORMAL UNIV

Calculating liquid levels in arbitrarily shaped containment vessels using solid modeling

ActiveUS8521495B2Reduce the amount requiredSimple calculationGeometric CADFlow propertiesEngineeringModel representation

Systems and method for simulating liquid containment behavior. The system comprises a solid modeler and a nonlinear equation solver. The nonlinear equation solver takes as input the solid model representation of the containment vessel from the solid modeler, a desired orientation in space, dynamic conditions (e.g., lateral acceleration) and an amount of liquid. To find the level of liquid in the vessel, the system solver iteratively performs successive Boolean subtractions using an infinite horizontal half-space that represents the liquid level of the vessel. The resulting sliced solid model is used to compute the volume of the liquid at that level. The iterative system solver terminates when the computed volume of the sliced containment vessel matches the specified volume of liquid (e.g., fuel) within a given tolerance. To accommodate dynamic situations, e.g., when acceleration is present, the horizontal liquid plane is replaced with a plane at an angle that corresponds to the total acceleration.

Owner:THE BOEING CO

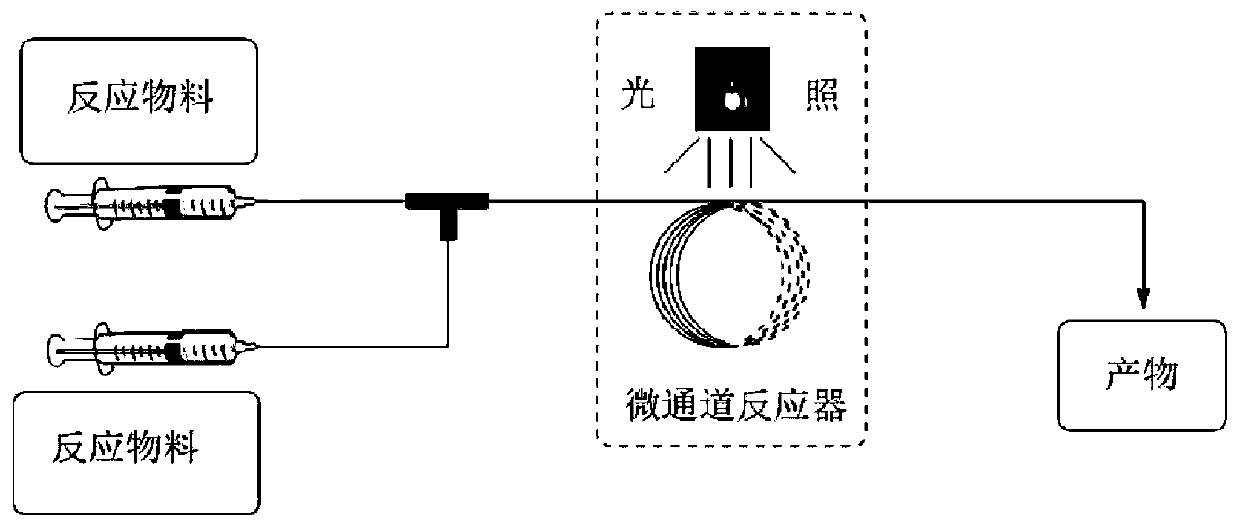

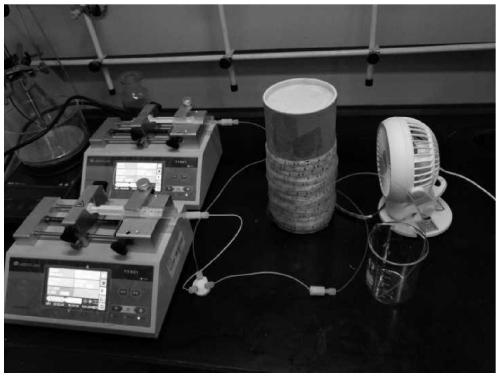

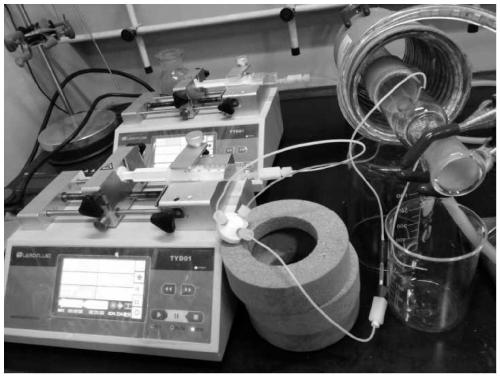

Method for preparing 3,4-dihydroisoquinoline-2(1H)-one compound through photocatalytic micro-channel

ActiveCN110105277AHigh reaction yieldEasy to operateOrganic chemistryChemical/physical/physico-chemical microreactorsPhotocatalytic reactionChemical compound

The invention discloses a method for preparing a 3,4-dihydroisoquinoline-2(1H)-one compound through a photocatalytic micro-channel. The 3,4-dihydroisoquinoline-2(1H)-one compound is efficiently synthesized in one step through a visible light induced tandem radical dual-functionalized reaction. A related reaction device makes a photocatalytic reaction technology combined with a micro-flow-field reaction technology, and the problems that the illumination of a traditional photocatalytic reactor is not uniform, a transfer medium is poor in heat transfer, the reaction time is long and energy is wasted are solved. The reaction device is easy to construct, reaction components are cheap and easy to obtain, and the method has the foundation of industrial amplification.

Owner:NANJING UNIV OF TECH

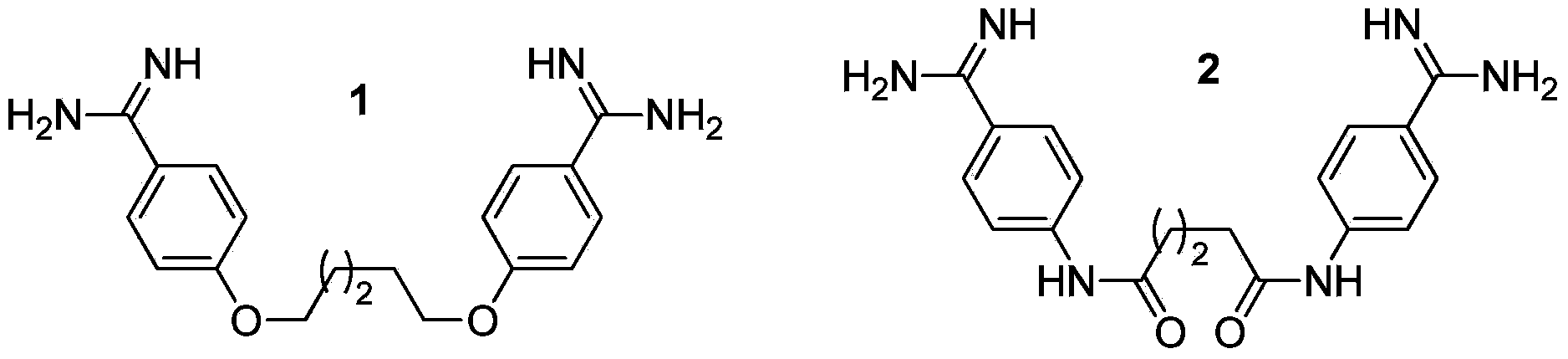

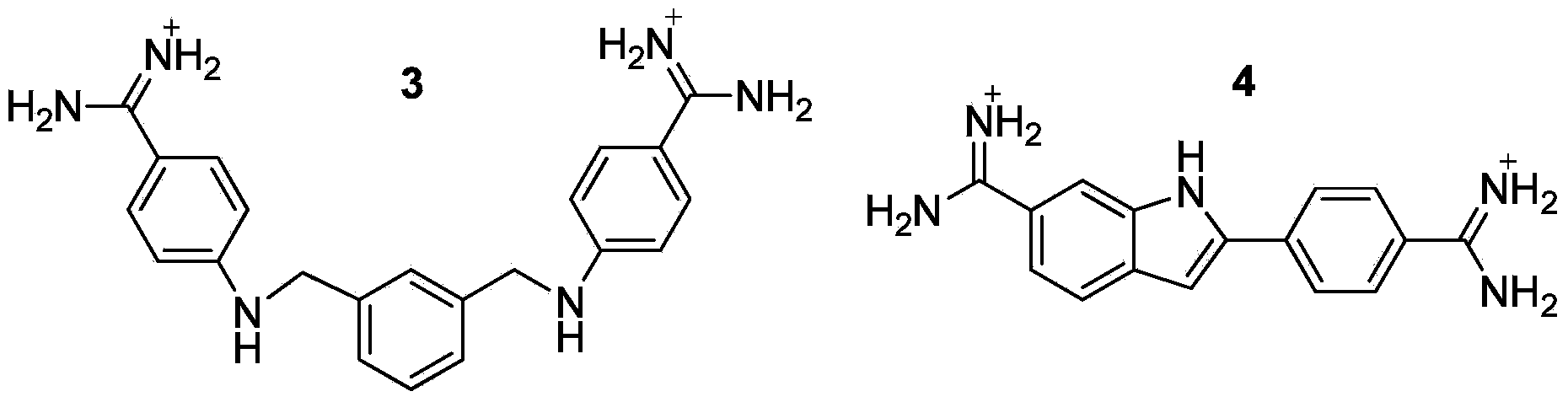

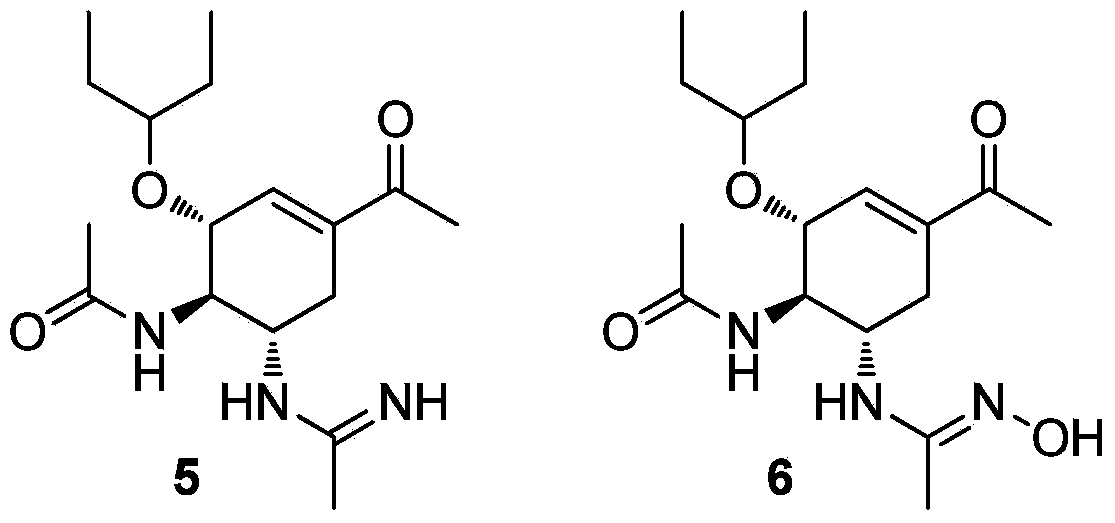

Multi-substituted amidine compound as well as preparation method and application thereof

ActiveCN104016904ANovel structureEasy to deriveSulfonic acid amide preparationAntineoplastic agentsDrug biological activityFine chemical

The invention discloses a multi-substituted amidine compound, a preparation method and an application thereof and relates to the technical field of pharmaceutical chemistry. The biological activities of the two types of amidines are also subjected to a simple test. The multi-substituted amidine compound disclosed by the invention provides an idea to design amidines drug molecules, broadens the chemical space and diversity of amidine compounds and provides a technical route for the preparation of functionalized amidine derivatives and the multi-substituted amidine compound has vast applications in the technical fields such as biochemical pharmacy and fine chemical industry.

Owner:山东雪地铝业科技有限公司

Method and system for controlling access to communication networks, related network and computer program therefor

InactiveUS8561200B2Easy to deriveDigital data processing detailsNetwork topologiesAuthenticationComputer program

A system for controlling access of a mobile terminal to a communication network including a set of terminals, wherein said mobile terminal obtains access to the network as a result of a successful authentication procedure. The system includes an authenticator module for performing the authentication procedure of the mobile terminal and a communication mechanism configured for making the successful outcome of the authentication procedure known to the terminals in the set. The mobile terminal is thus permitted to access the network via any of the terminals in the set based on the authentication procedure.

Owner:TELECOM ITALIA SPA

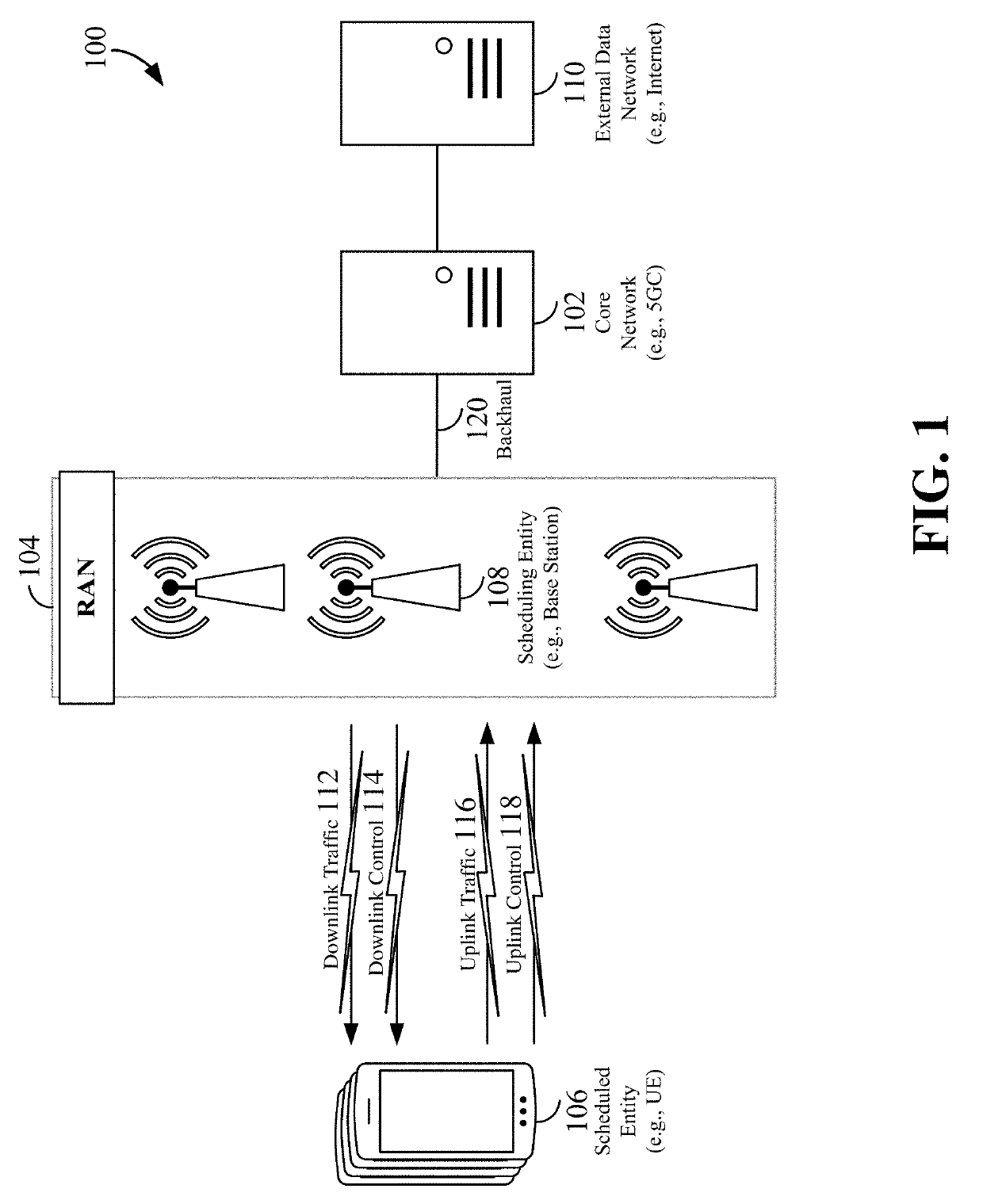

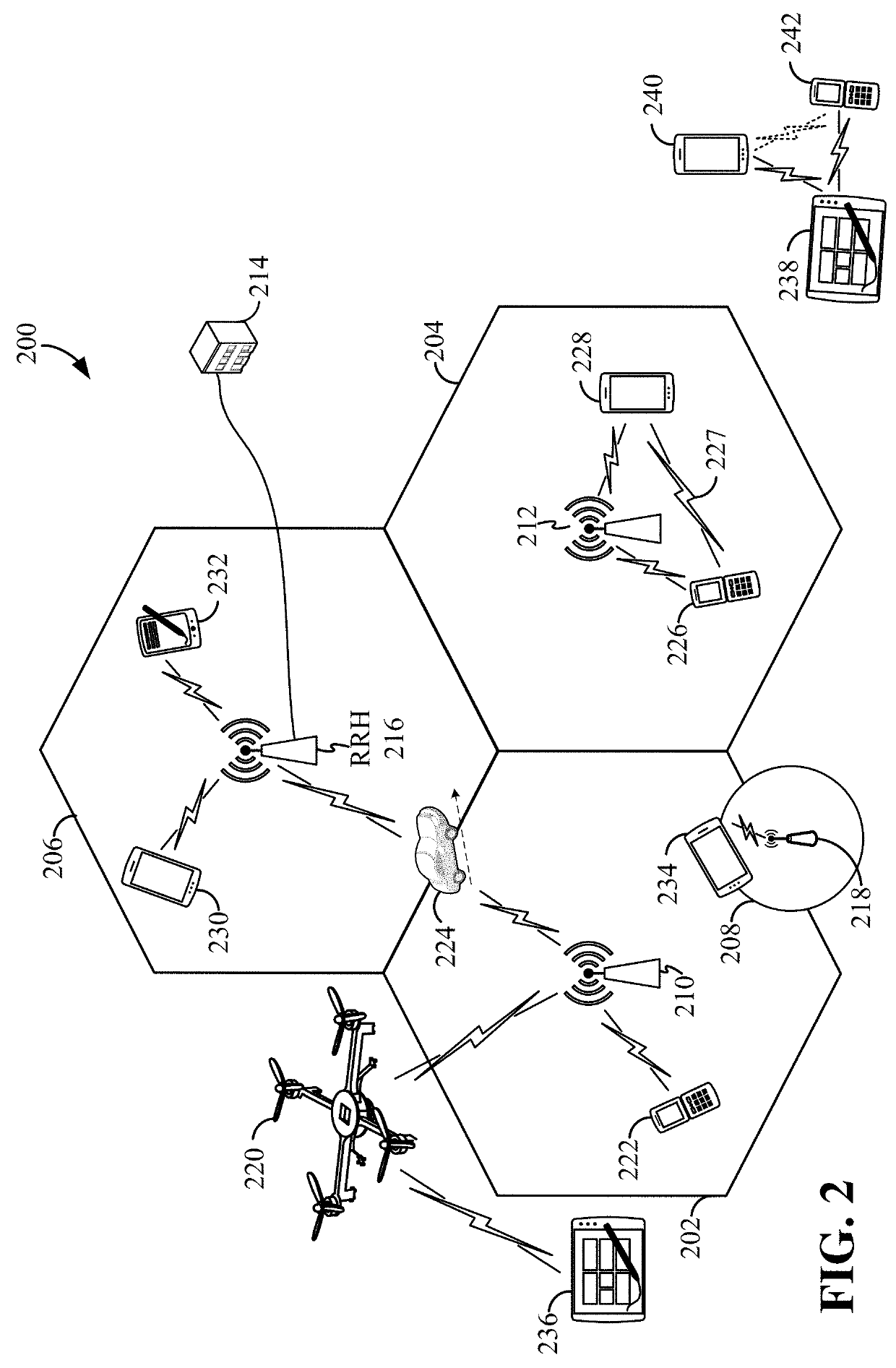

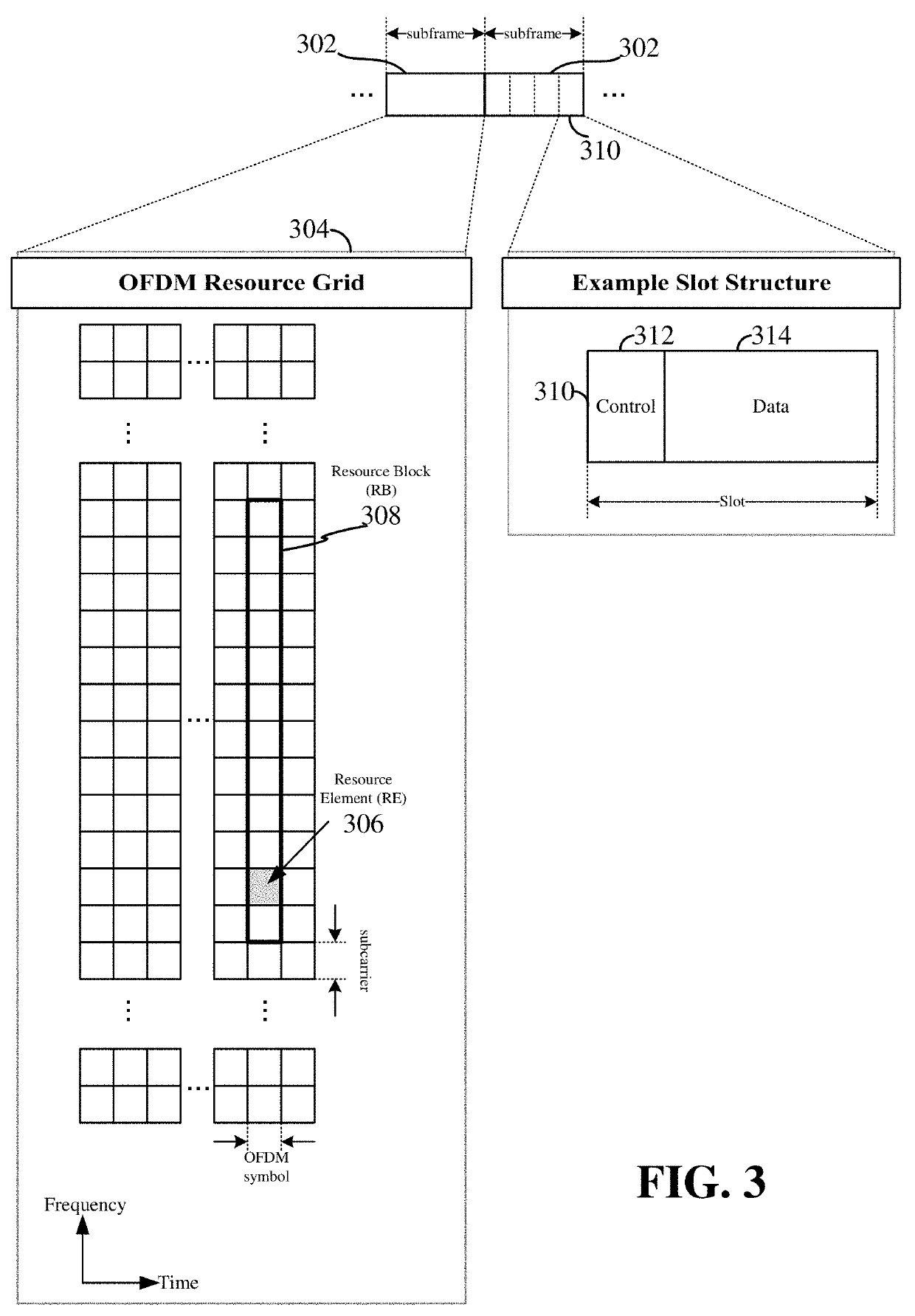

Resource allocation for the physical uplink control channel

ActiveUS20190261353A1Well formedEasy to identifyError prevention/detection by using return channelTransmission path divisionControl channelData mining

Aspects of the disclosure relate to allocating resources for a physical uplink control channel (PUCCH). In a first example, a subset of a resource set corresponding to a PUCCH is identified based on an explicit mapping of acknowledgment resource indicator (ARI) values, and a resource index corresponding to a resource within the subset is derived based on an implicit mapping of the resource index. A PUCCH communication is then transmitted via the resource. In another example, a user equipment (UE) is configured to ascertain resources for a PUCCH in accordance with an explicit mapping of ARI values and an implicit mapping of a resource index such that the explicit mapping facilitates an identification of a subset of a resource set, whereas the implicit mapping facilitates a derivation of the resource index to identify a corresponding resource within the subset.

Owner:QUALCOMM INC

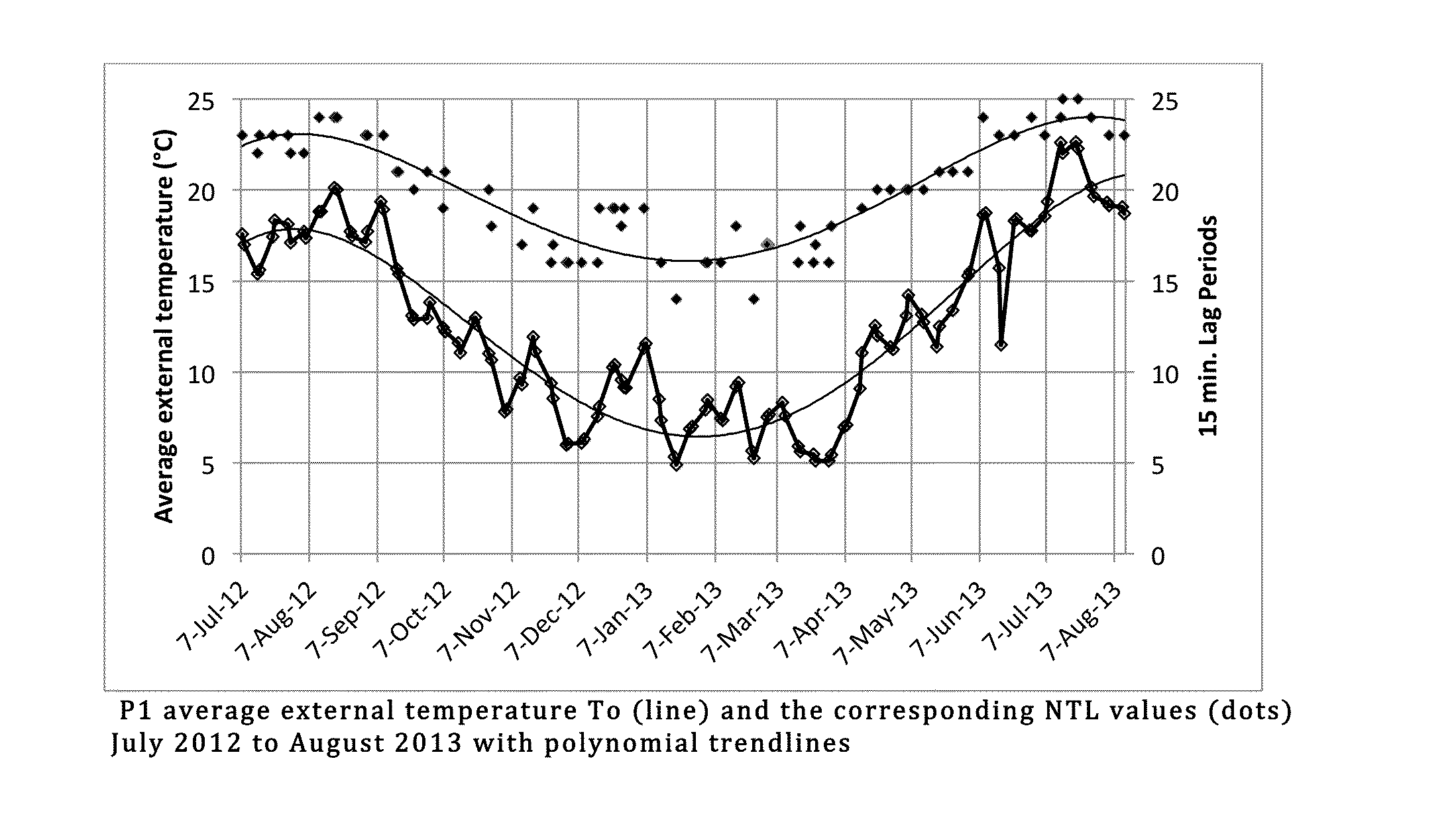

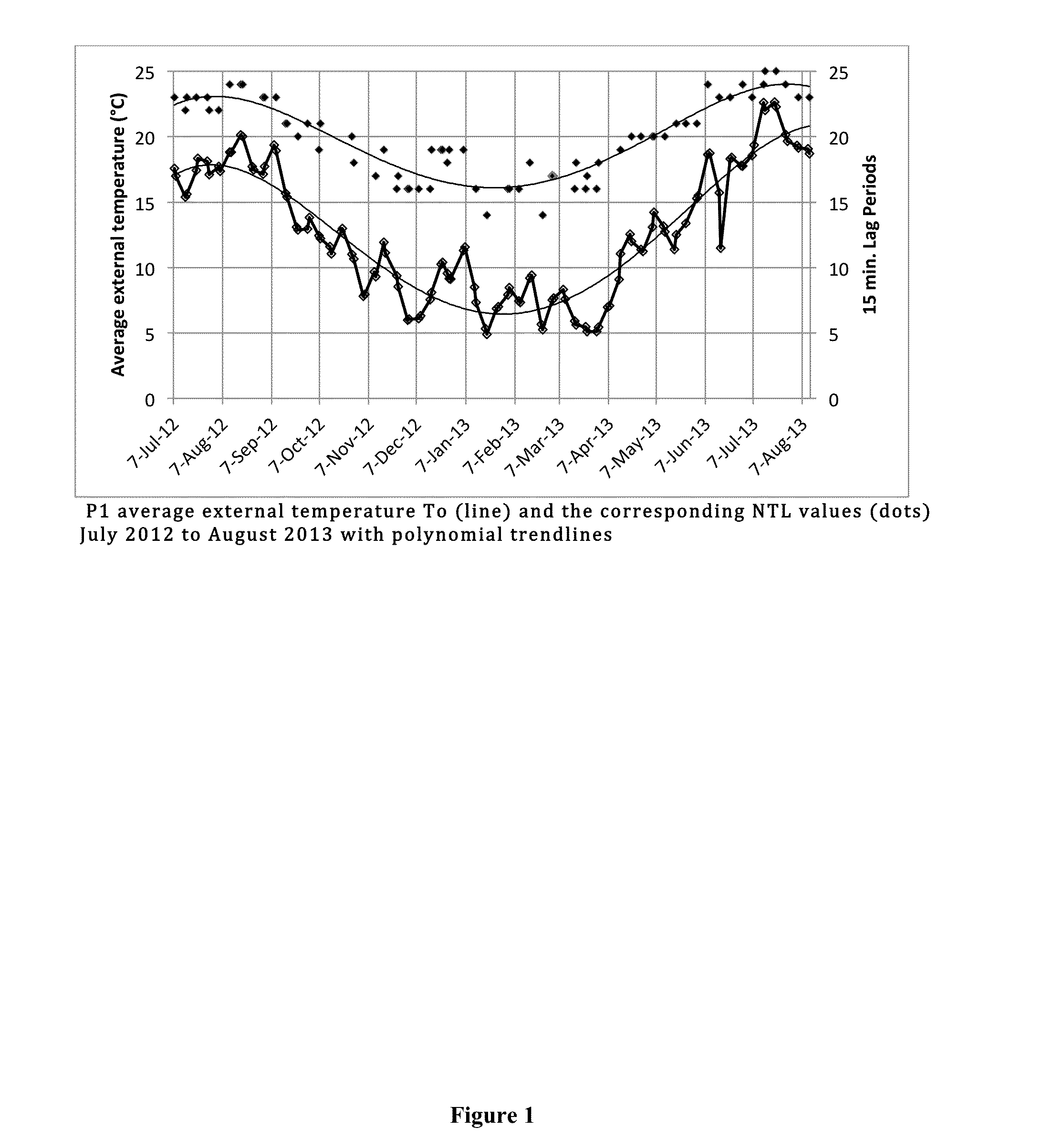

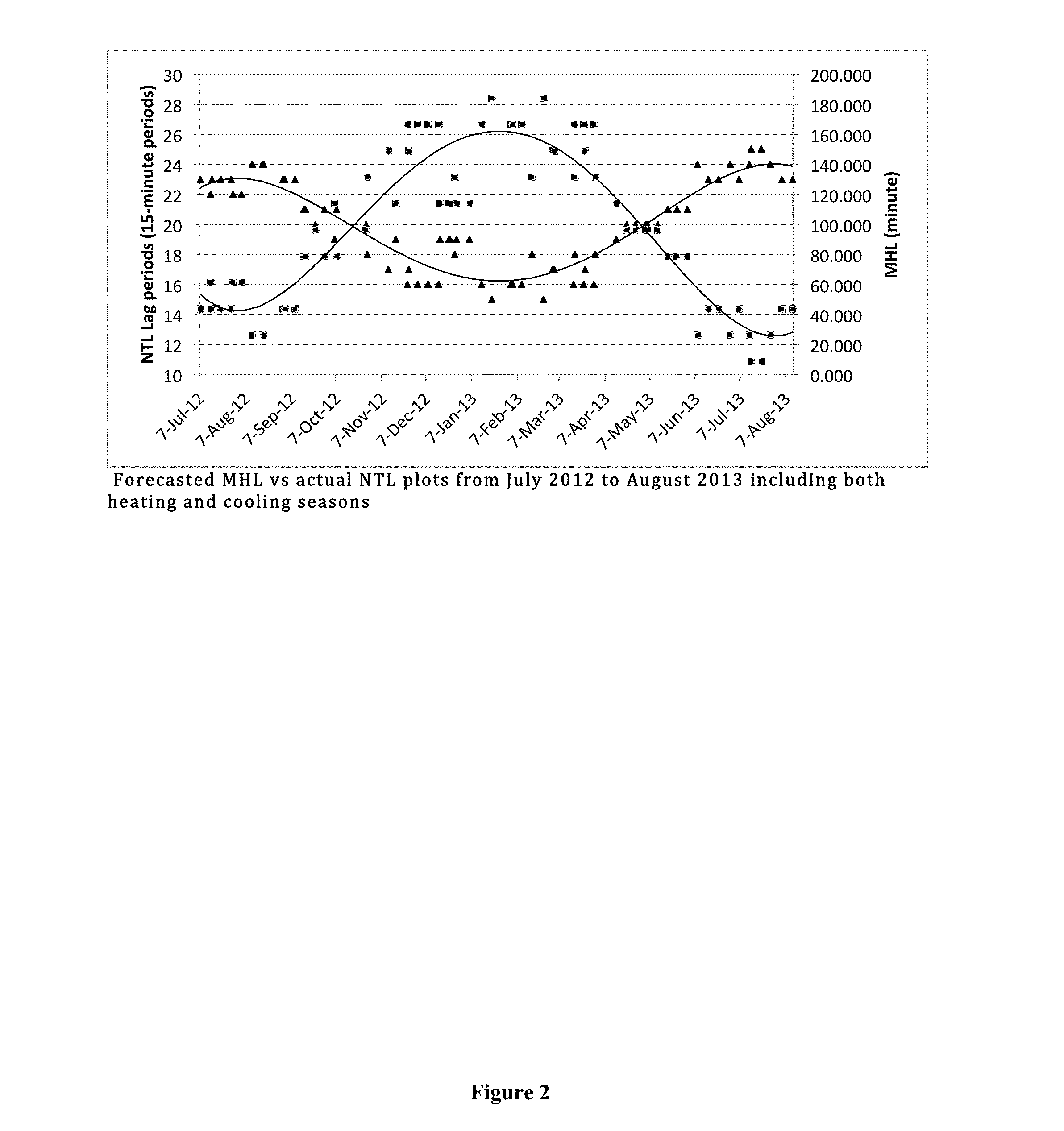

Method for determining mechanical heat-up lag (MHL) of a building from the building's natural thermal lag (NTL)

InactiveUS20150142368A1Save energySimple methodGeometric CADMechanical apparatusTime lagCombined use

The invention provides an improved method for determining the mechanical heat-up lag of a building. The time lag for the heating system to reach its set point, which is referred to as the Mechanical Heat-up Lag (MHL) is dependent on the natural thermal lag (NTL) of a building. The invention provides a determination of the MHL as it relates to the NTL. The invention is very useful in reducing energy usage in commercial buildings when used in combination with a short term weather forecast.

Owner:SHIEL PATRICK ANDREW

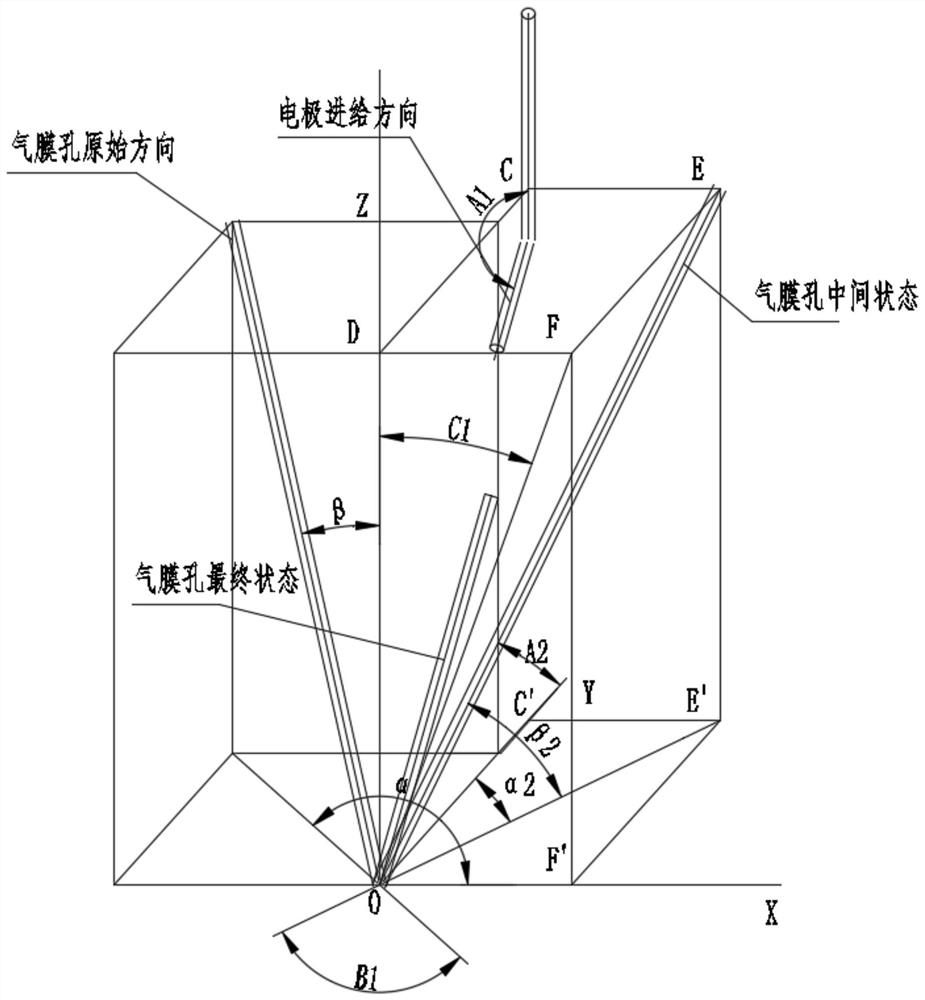

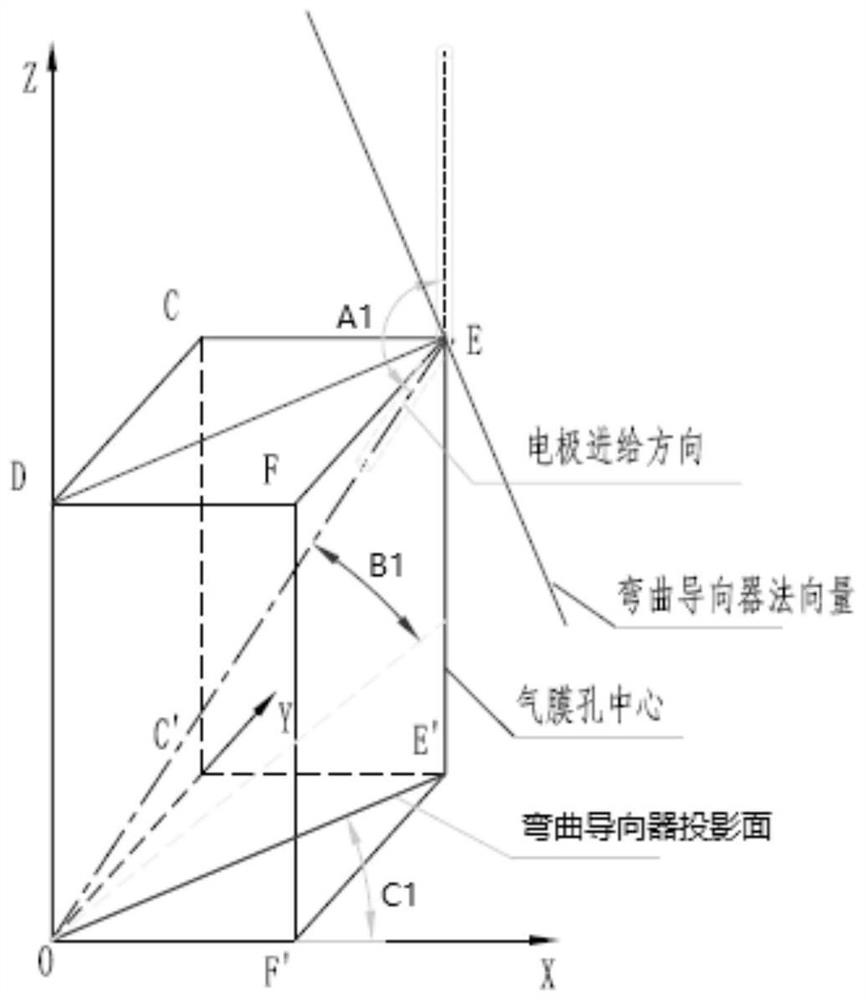

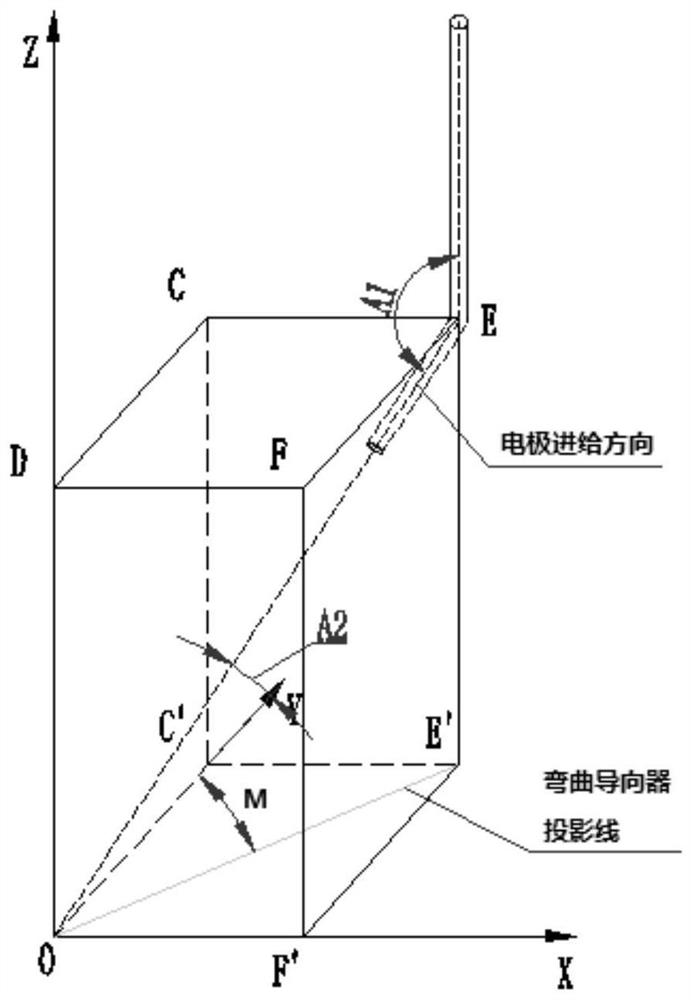

Determination method for interference film hole machining angle

ActiveCN113042838AImprove processing accuracyEasy to processProgramme controlComputer controlTurbine bladeEngineering

The invention relates to a determination method for an interference film hole machining angle, and belongs to the technical field of aero-engine turbine blade machining. The determination method comprises the following steps that, a machine tool coordinate system (x, y, z) is established according to a position axis of a machine tool, a horizontal rotation axis of the machine tool serves as a B axis, and a vertical rotation axis of the machine tool serves as a C axis; according to the machine tool coordinate system (x, y, z), an initial coordinate of the interference air film hole and an initial coordinate of a bending guider are determined; and according to the initial coordinate of the interference film hole and the initial coordinate of the bending guider, when the B axis and the C axis are rotated to drive the interference film hole to rotate towards the bending guider, the rotation angle of the B axis and the rotation angle of the C axis are the machining angle of the interference film hole. According to the determination method, on the premise that the design performance of a turbine blade air cooling system is not reduced, shielding of a blade structure is effectively avoided, electric spark machining of the interference film hole is achieved, and therefore the design performance of an advanced aero-engine is met.

Owner:GUIYANG AVIC POWER PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com