Diplopore nanoscale poly(glycidyl methacrylate)-ethylene glycol dimethacrylate (PGMA-EDMA) cross-linked microballoons and preparation method thereof

A technology of polyglycidyl methacrylate and ethylene glycol diester of methacrylate is applied to double-porous micron-scale polyglycidyl methacrylate-ethylene glycol diester cross-linked microspheres and In the field of preparation, it can solve the problems of residual hydrophobicity, high cost, unfavorable separation of biological macromolecules, etc., and achieve the effects of avoiding non-specific adsorption, improving separation load, and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

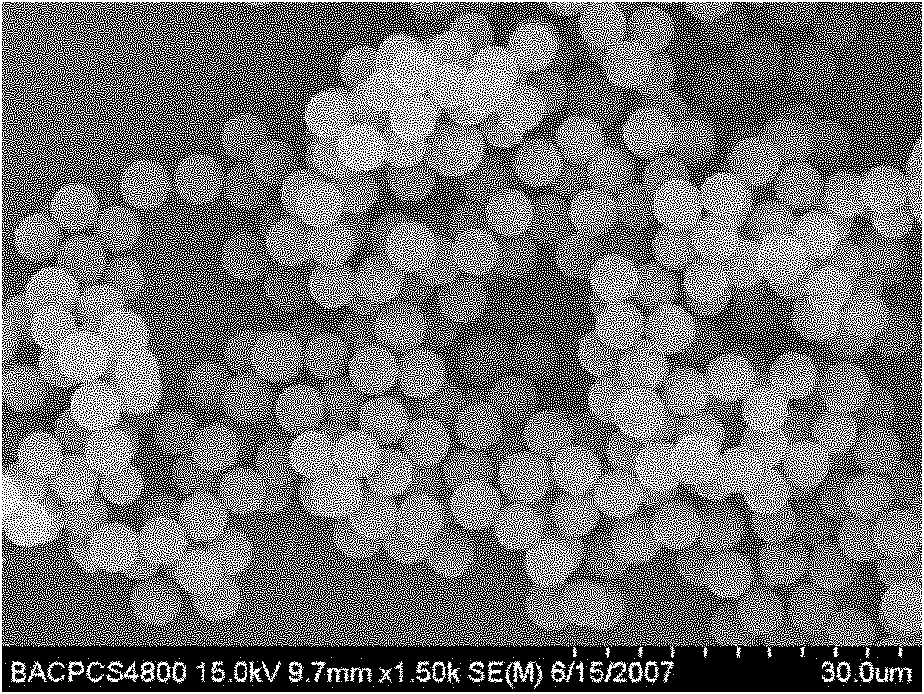

[0024] Example 1, Preparation of linear 1 μm polyglycidyl methacrylate seed microspheres

[0025] Add 5ml of GMA, 0.10g of azobisisobutyronitrile, 1.25g of PVP and 50ml of absolute ethanol into a 100ml flask, and ultrasonically dissolve it for 10min to form a homogeneous solution. Nitrogen was introduced to remove the oxygen in the system. Rotate and heat in a constant temperature oil bath at 70°C. After 30 hours of reaction, the product settles and the supernatant is discarded. The precipitate was washed with absolute ethanol and settled three times. Then washed with secondary water and settled three times to obtain polyglycidyl methacrylate microspheres provided by the present invention, stored in PVA aqueous solution, and dispersed into a 0.1 g / ml homogeneous state.

[0026] The diameter of polyglycidyl methacrylate seed microspheres observed by scanning electron microscope was 1 μm, and the diameter was uniform.

Embodiment 2

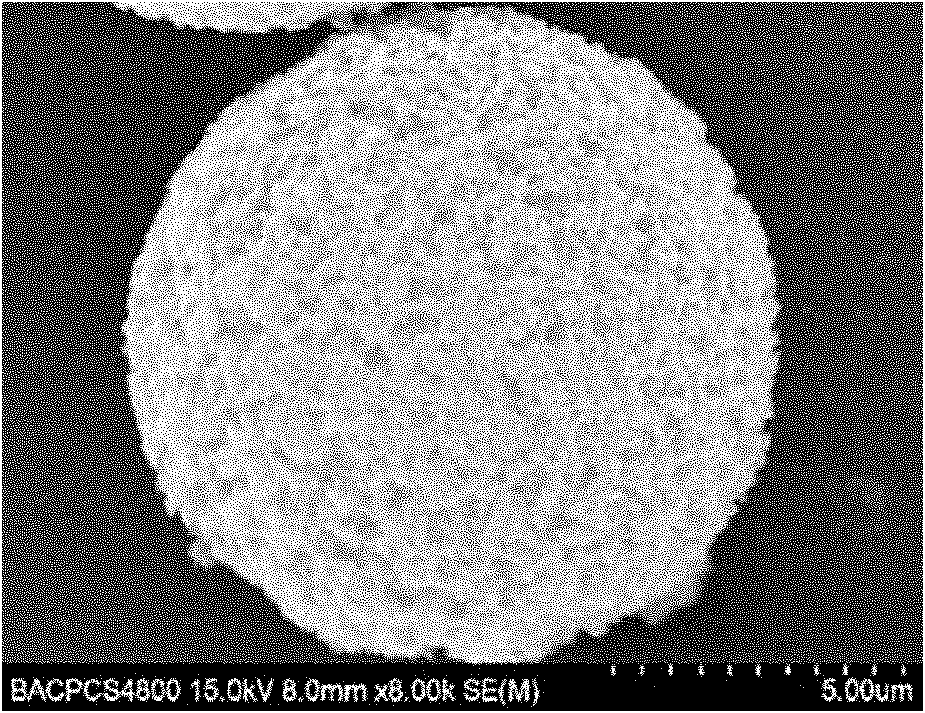

[0027] Example 2, Preparation of linear 2.5 μm polyglycidyl methacrylate seed microspheres

[0028] Add 5ml of GMA, 0.15g of azobisisobutyronitrile, 0.5g of PVP and 50ml of absolute ethanol into a 100ml flask, and ultrasonically dissolve it for 10min to form a homogeneous solution. Nitrogen was introduced to remove the oxygen in the system. Rotate and heat in a constant temperature oil bath at 75°C. After 12 hours of reaction, the product settles and the supernatant is discarded. The precipitate was washed with absolute ethanol and settled three times. Then washed with secondary water and settled three times to obtain polyglycidyl methacrylate seed microspheres provided by the present invention, stored in PVA aqueous solution, and dispersed into a 0.1 g / ml homogeneous state.

[0029] The diameter of polyglycidyl methacrylate seed microspheres observed by optical microscope was 2.5 μm, and the pore size was uniform.

Embodiment 3

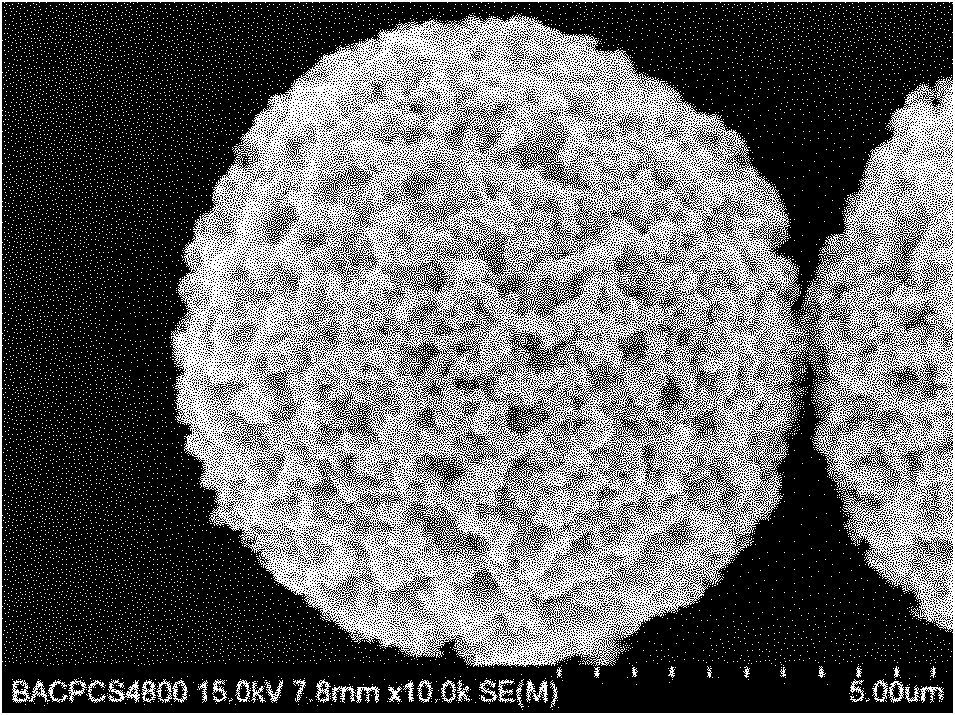

[0030] Example 3, Preparation of linear low molecular weight 3.5 μm polyglycidyl methacrylate seed microspheres

[0031] Add 5ml of GMA, 0.15g of azobisisobutyronitrile, 0.5g of PVP, 2.5ml of toluene and 47.5ml of absolute ethanol into a 100ml flask, and ultrasonically dissolve it for 10min to form a homogeneous solution. Nitrogen was introduced to remove oxygen in the system. Rotate and heat in a constant temperature oil bath at 70°C. After reacting for 24 hours, centrifuge at 3000rpm to settle the product microspheres, and pour off the supernatant. The precipitate was washed with absolute ethanol and settled three times. Then washed and settled three times with secondary water to obtain polyglycidyl methacrylate seed microspheres provided by the present invention, stored in PVA aqueous solution, and dispersed into a 0.1 g / ml homogeneous state.

[0032] The diameter of polyglycidyl methacrylate seed microspheres was 3.5 μm and the pore size was uniform according to optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com