Device for self-arranging and bonding battery

An automatic arrangement and battery technology, which is applied in the direction of secondary batteries, battery components, primary batteries to battery groups, etc., can solve the problems of low production efficiency and high error rate, and achieve the effect of improving production efficiency and eliminating arrangement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

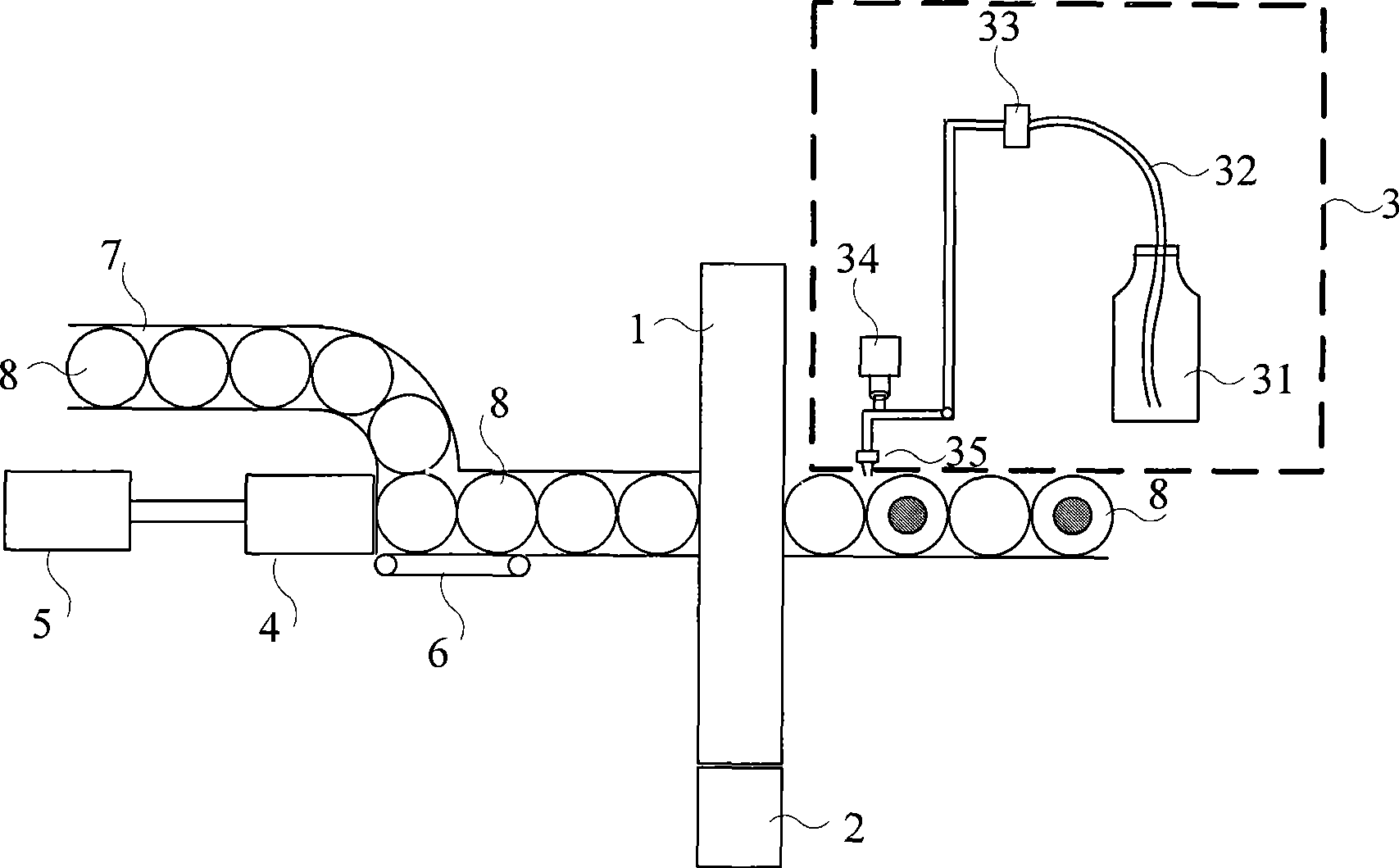

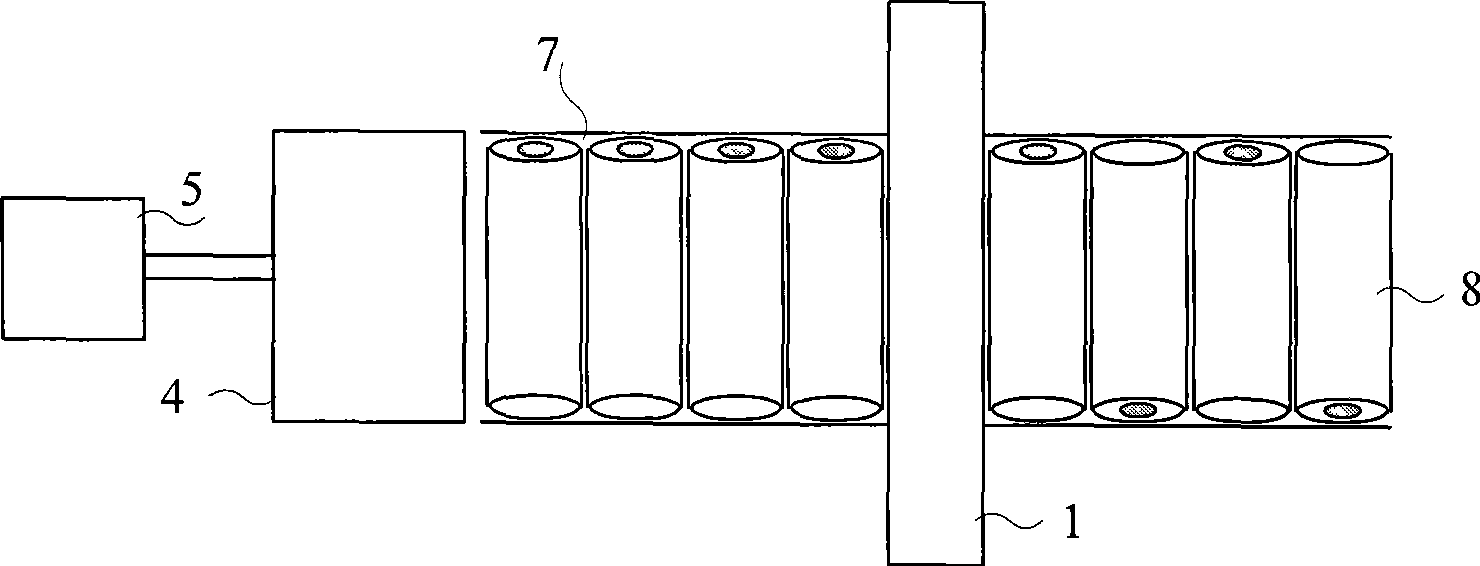

[0016] like figure 1 , figure 2 As shown, the AAA type batteries 8 to be packaged are placed in the battery slot 7, when placed, the positive poles of all the batteries 8 are all facing the same direction, and of course, the negative poles of all the batteries 8 are also all facing the same direction. The side of battery tank 7 horizontal section by battery 8 entrance has a push block 4, and push block 4 links to each other with cylinder 5, and cylinder 5 drives push block 4 to do reciprocating motion. There is a belt conveyor 6 at the bottom of the tank near the battery tank 7 horizontal section of the push block 4. The middle part of the horizontal section of the battery tank 7 is disconnected, and a rotating disk 1 is located therebetween. Battery dispensing is realized by a glue dispenser 3 , which includes a glue bottle 31 , a glue delivery tube 32 , a peristaltic pump 33 , an air cylinder 34 and a glue dispensing head 35 .

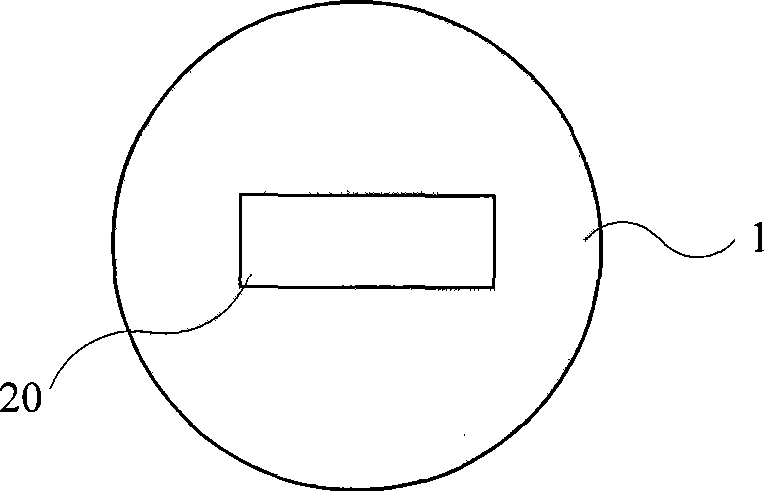

[0017] like image 3 As shown, the rotati...

Embodiment 2

[0023] like Figure 5 , Figure 6 As shown, the AA-type batteries 18 to be packed are placed in the battery slot 17. When placed, the positive poles of all the batteries 18 are all facing the same direction, and of course, the negative poles of all the batteries 18 are also all facing the same direction. The battery tank 17 horizontal section has a push block 15 by the side of the battery 18 inlet, and the push block 15 links to each other with the cylinder 16, and the cylinder 16 drives the push block 15 to reciprocate. There is a belt conveyor 19 at the bottom of the tank near the battery tank 17 horizontal sections of the push block 15. The middle part of the horizontal section of the battery groove 17 is disconnected at two places, and the rotating disk 9 and the rotating disk 12 are respectively located therebetween. The battery groove is connected between the rotating disk 9 and the rotating disk 12, and the length of the battery groove is equal to the width of an AA ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com