Slide fastener

A technology for zippers and zipper tapes, applied in the field of zippers, which can solve problems such as unstable locking and worn locking claws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

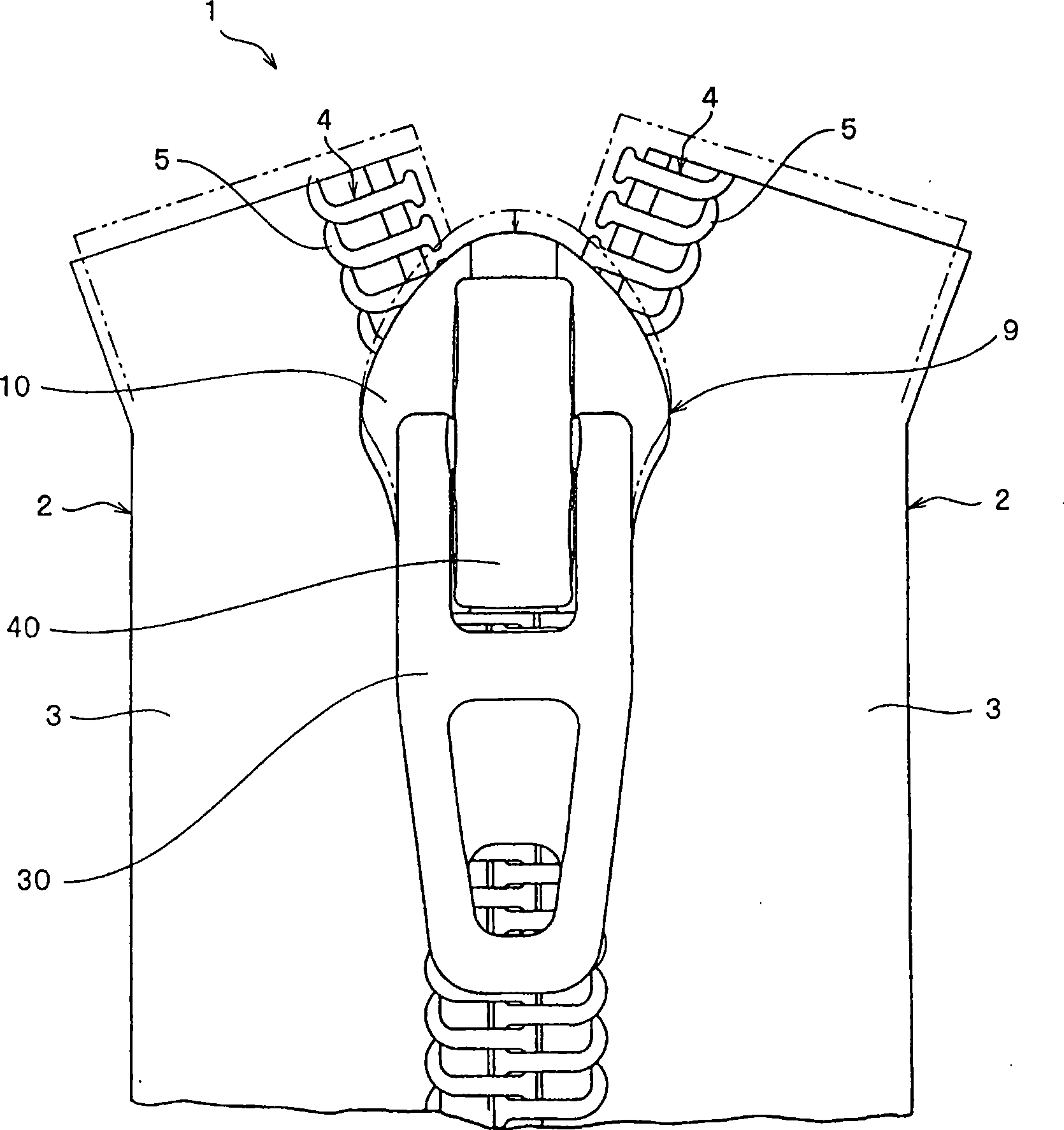

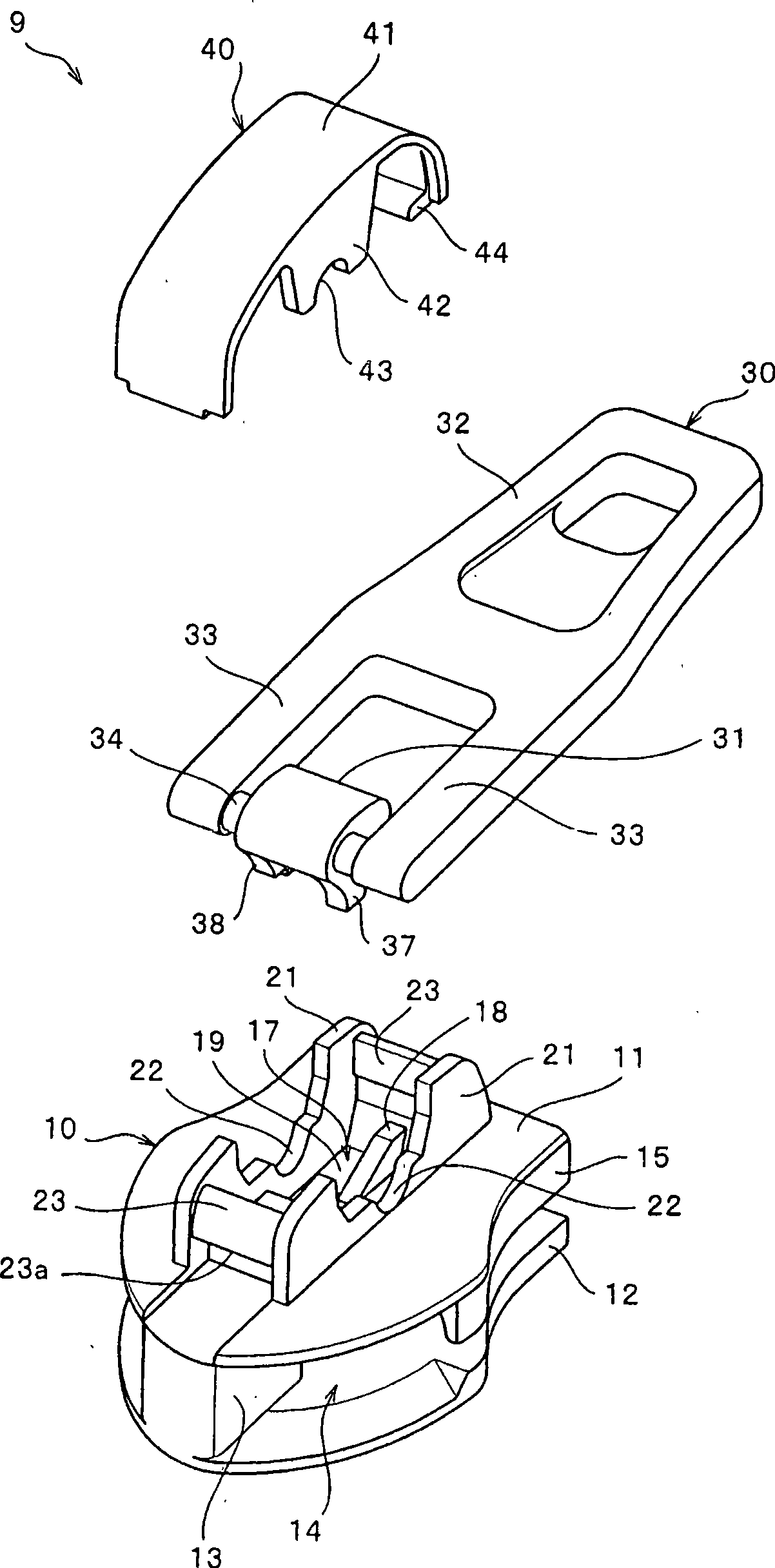

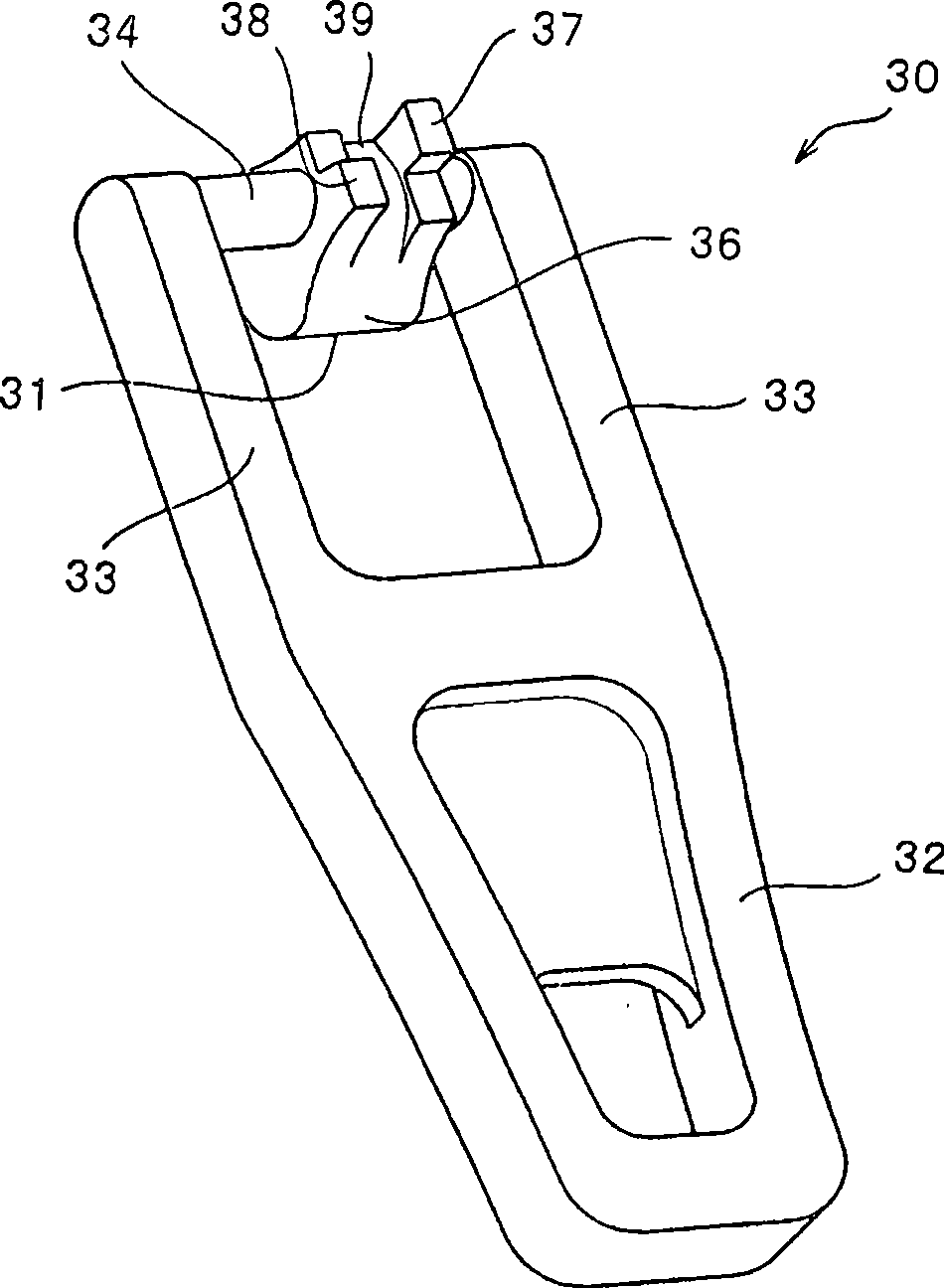

[0051] Figures 1 to 5 The slide fastener of 1st Embodiment of this invention is shown. figure 1 is the front view of the zipper. figure 2 is an exploded perspective view showing a slider provided on a slide fastener in a disassembled state, and image 3 It is an enlarged perspective view showing a pull piece and a locking claw of a slider enlarged. and, Figure 4 is the longitudinal section of the slider, Figure 5 is along Figure 4 Sectional view taken along the midline V-V.

[0052] Such as figure 1 As shown, the slide fastener 1 of the first embodiment includes a pair of left and right fastener chains 2 and a slider 9 .

[0053] The fastener chain 2 includes a pair of left and right fastener tapes 3 and coil-shaped elements 5 forming left and right element rows 4 attached to opposite tape-side edge portions of the fastener tape 3 . In this case, the coiled element 5 is formed of a monofilament of synthetic resin such as polyamide or polyester, and as Figure 5...

no. 2 approach

[0088] Figure 12 is an exploded perspective view showing a slider used in a slide fastener according to a second embodiment of the present invention in a disassembled state.

[0089] The slide fastener of the second embodiment is provided with a pair of left and right fastener chains (not shown) and a slider 51 . As the fastener chain in 2nd Embodiment, the fastener chain similar to 1st Embodiment is used.

[0090] The slider 51 of the second embodiment includes two components—a slider body 60 and a pull tab 70 rotatably mounted to the slider body 60 . The pull tab 70 has left and right locking claws 71 a , 71 b integrally formed for locking the slider 51 . These two components 60, 70 are formed into a predetermined shape by an injection molding device or an extrusion molding device using a thermoplastic resin such as polyamide, polyoxymethylene, polypropylene, polybutylene terephthalate.

[0091] In the slider main body 60, an upper piece 61 and a lower piece 62 are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com