Roll bending side-discharging carriage

A rolling plate type and carriage technology, applied in the field of transportation, can solve the problems of bulk cargo loss, slow unloading, large inclination angle of the carriage body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

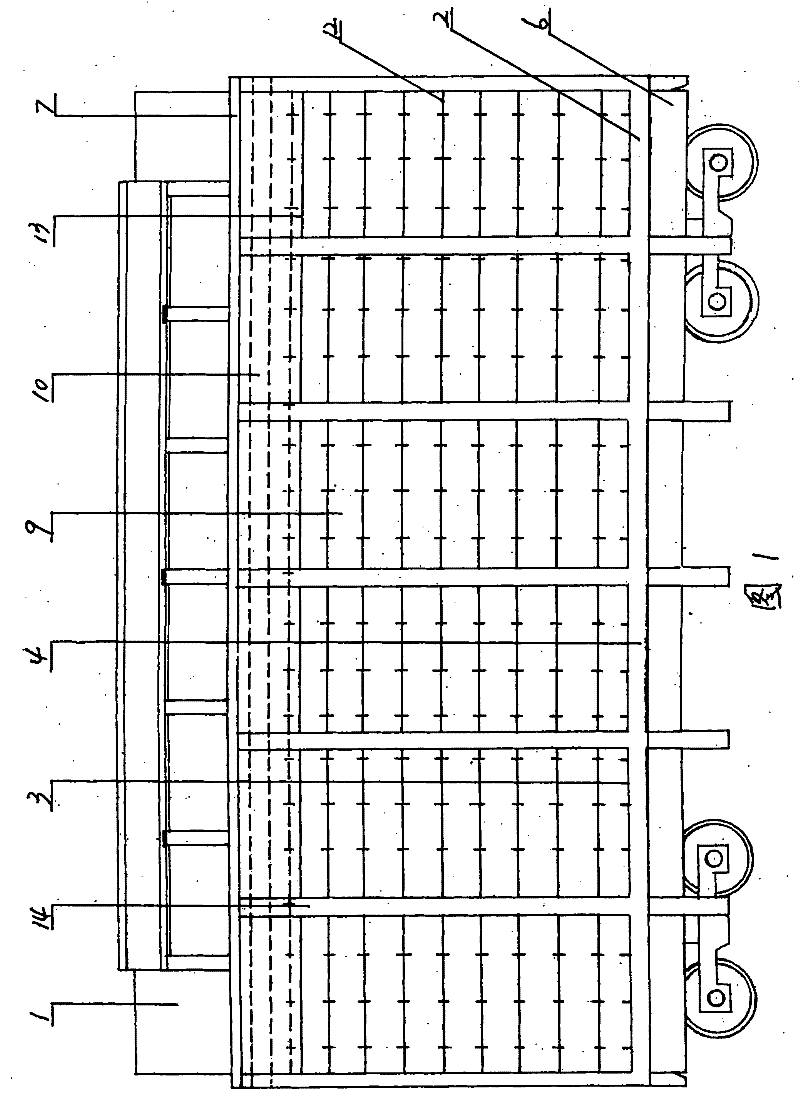

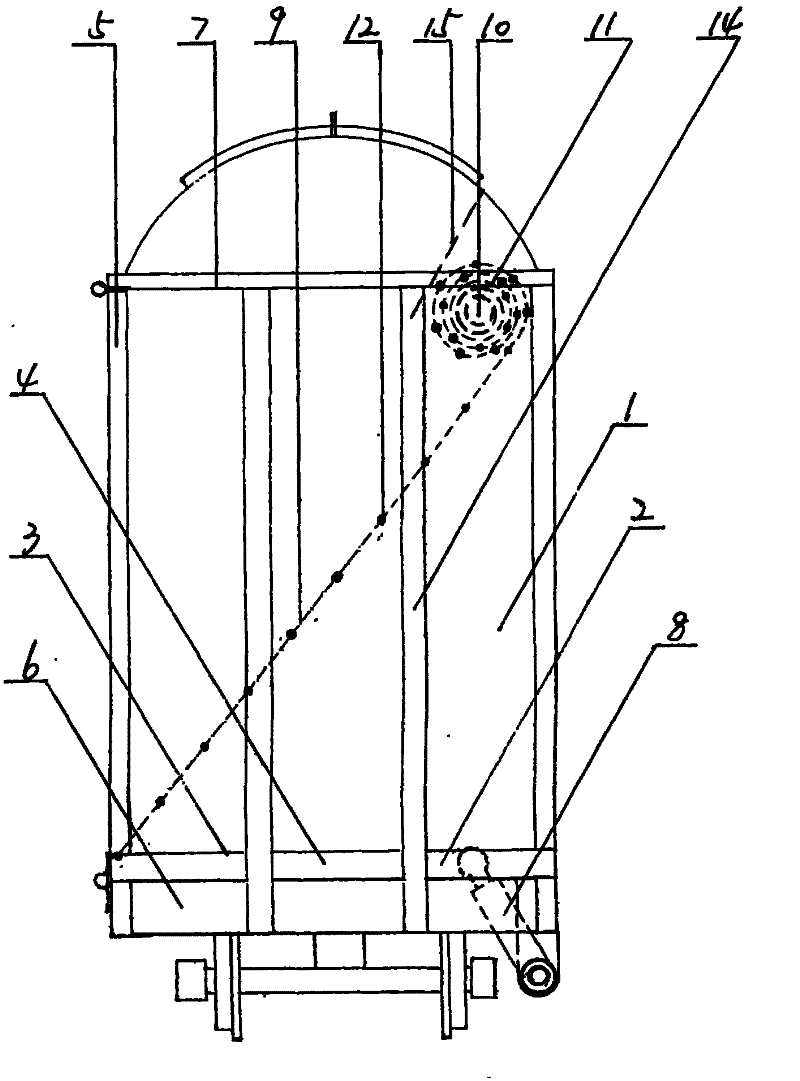

[0008] figure 1 , Front view of the back of the roll-type side unloading compartment image 3 , Front view of coiling system

[0009] figure 2 , side view of the rolling plate side unloading car Figure 4, side view of the rolling plate system

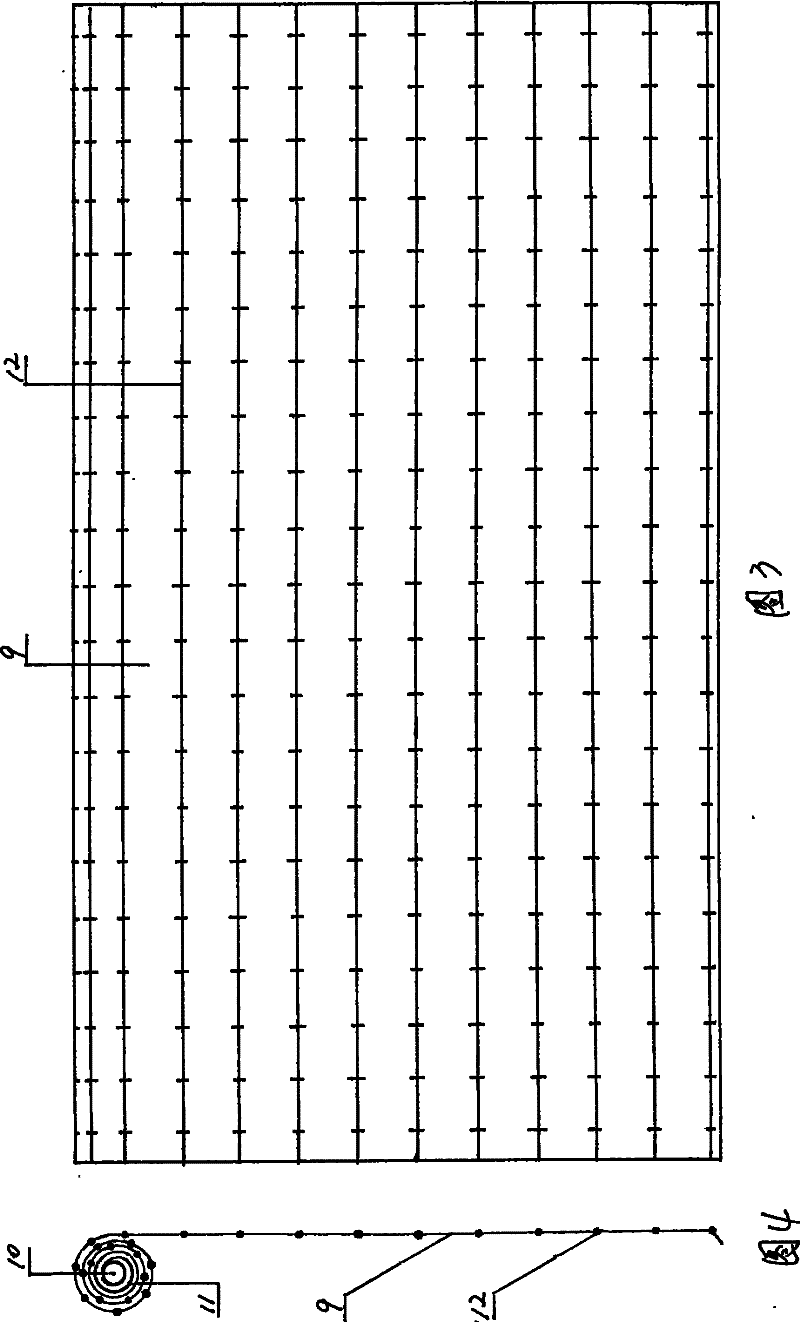

[0010] 1. Box body, 2. Box body ring beam, 3. Box floor, 4. Box bottom beam, 5. Door leaf. 6. Bottom ring beam, 7. Carport ring beam, 8. Hydraulic cylinder, 9. Coiled plate, 10. Coiled plate shaft, 11. Coiled plate spring, 12. Hinge shaft 13, side plate 14, car body vertical support, 15. Baffle.

[0011] Such as figure 1 , 2 , 3, and 4, remove all of the bottom plate 3 of the car body 1 and a part of the bottom of the side plate 13, replace the whole of the bottom plate 3 and a part of the bottom of the side plate 13 with a live coiled plate 9, and the coiled plate system The structure is made up of coiled plate 9, coiled plate spring 11 and coiled plate shaft 10. One end of the coiled plate 9 is fixed on the top of the car bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com