Multi-component cartridge

A multi-component, cartridge technology, applied in the direction of containers, containers, packaging, etc. with multiple items, can solve the problem of narrowing of the outlet flow section, and achieve the effect of improving the interception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

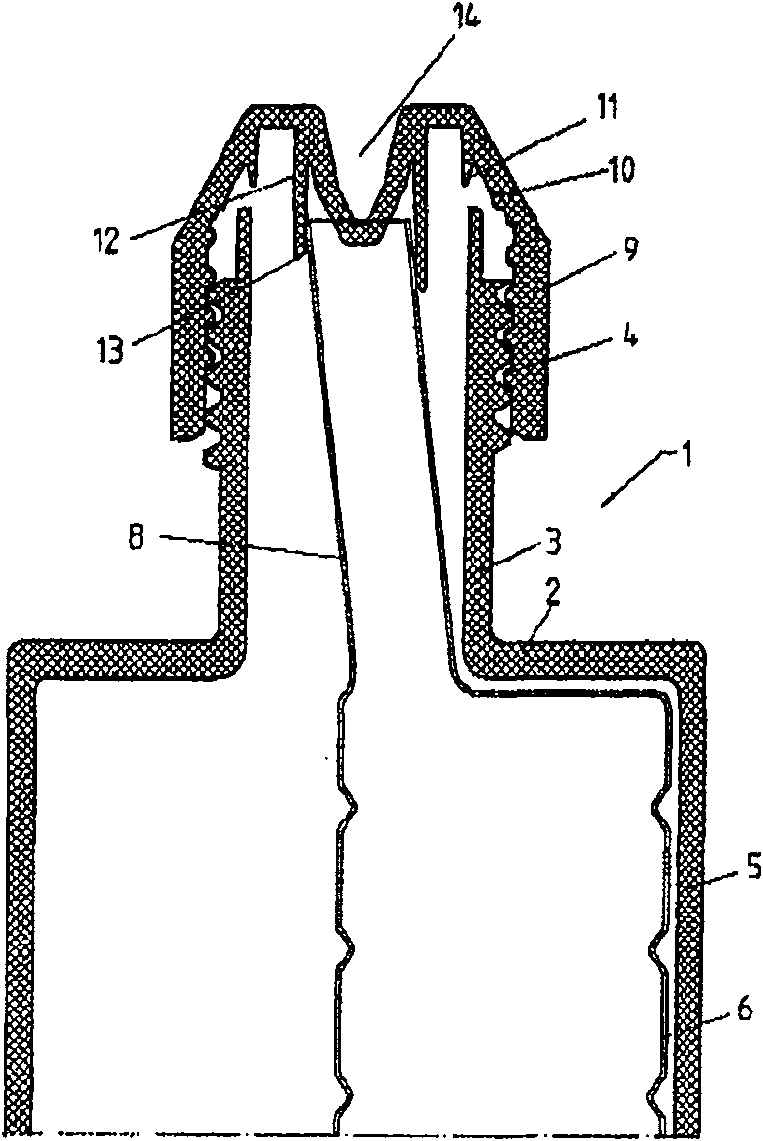

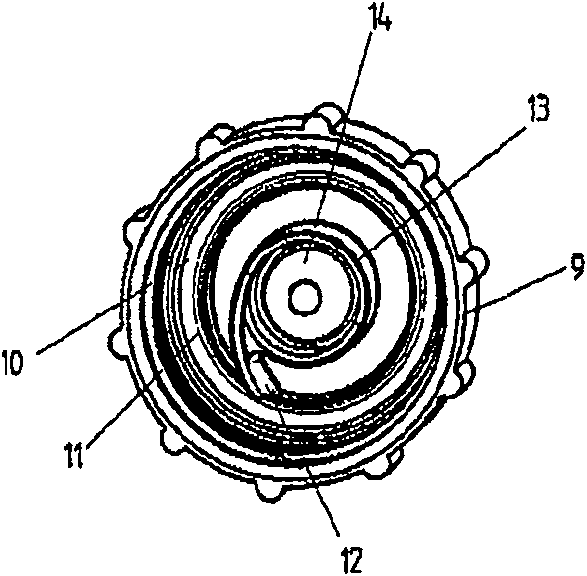

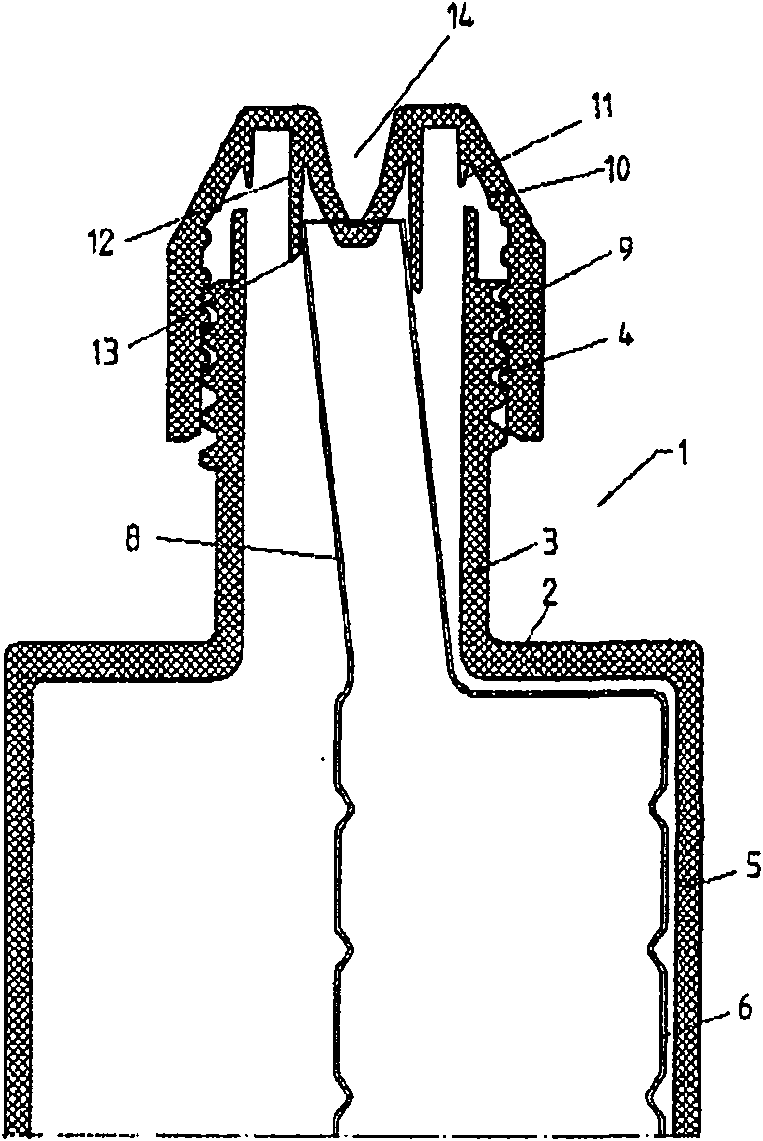

[0014] figure 1 The illustrated multicomponent cartridge 1 according to the invention is of tubular design. Its front end in the figure has an orifice-shaped end wall 2 with a tubular outlet 3 provided with an external thread 4 . The multicomponent cartridge 1 forms an outer container 5 into which an inner container 6 is inserted. The inner container 6 is a blow molded part. The two containers 5 , 6 each contain a component of a two-component substance, for example a glue and a hardener, which are stored separately from one another in the cartridge 1 . Thus in the illustrated and described embodiment the multi-component cartridge 1 is a two-component cartridge. In order to eject these components, the inner container 6 can be compressed axially. By means of a piston (not shown) of a spray gun (not shown), the components, which harden after mixing, can be sprayed out of the outlet 3 of the cartridge 1 . The cross-sections of the containers 5, 6 are constant along the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com