Separation device of products of different size

A separation device and product technology, used in solid separation, classification, chemical instruments and methods, etc., can solve the problems of inability to sort out, incomplete sorting, etc., and achieve a simple structure, high work efficiency, and improved sorting rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

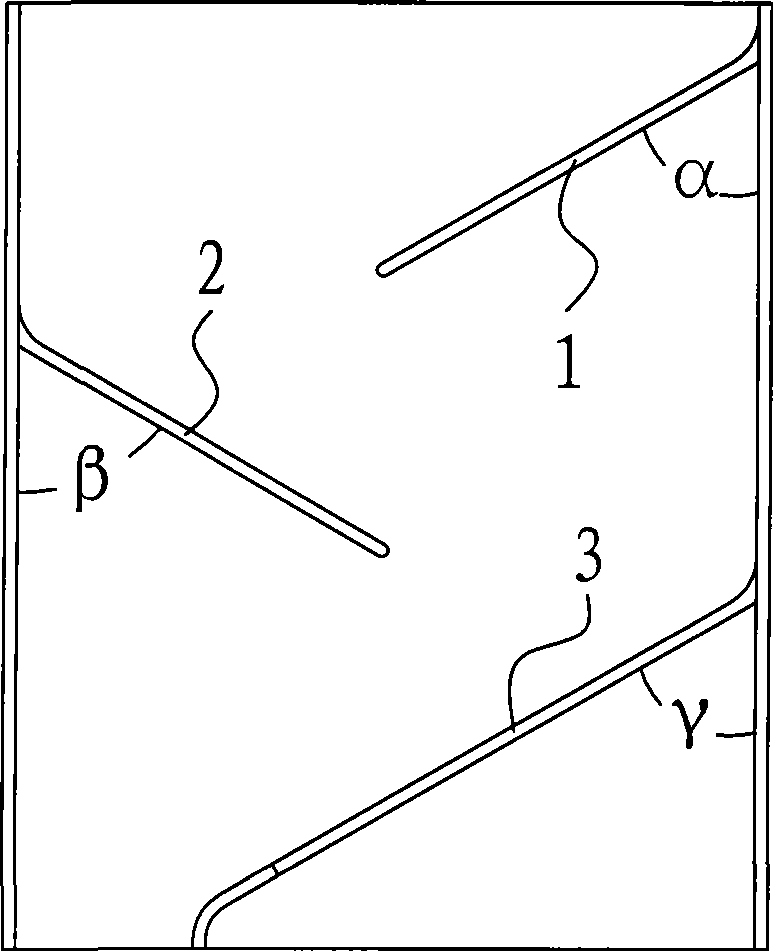

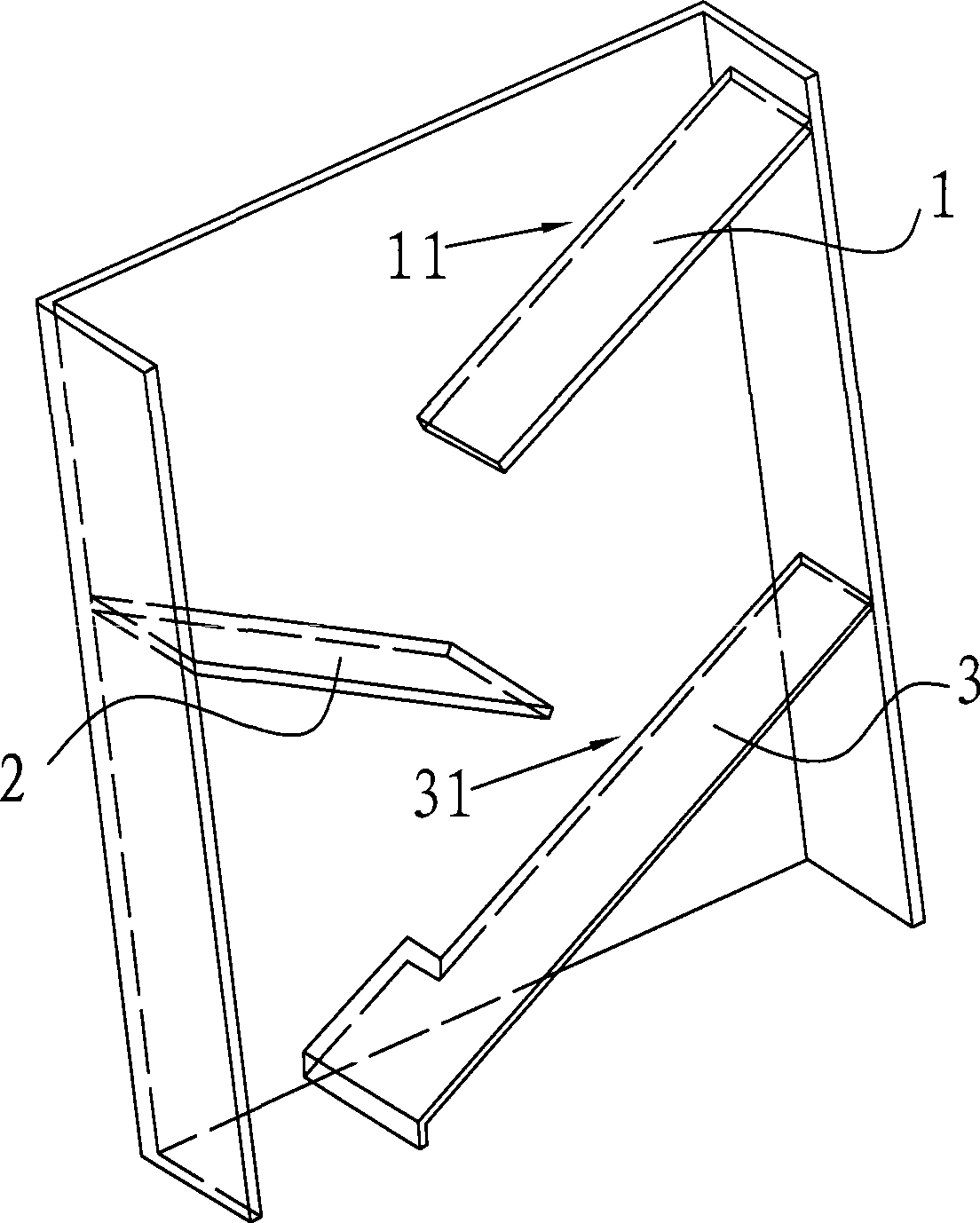

[0012] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail: see figure 1 , figure 2 The shown separation device comprises a first ramp 1, a second ramp 2 and a third ramp 3 arranged from top to bottom, wherein the first ramp 1 and the third ramp 3 are connected to On the right side wall of the separating device, the second chute 2 is connected on the left side wall of the separating device.

[0013] The first chute 1 is inclined from top to bottom to the interior of the separation device, and the first chute 1 is provided with a first gap 11, and the first slit 11 is along the first chute. The length direction of 1 is opened and runs through the length of the first chute 1.

[0014] The second chute 2 is inclined toward the inside of the separation device from top to bottom.

[0015] The third chute 3 slopes toward the inside of the separation device from top to bottom. The third chute 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com