Mold for preparing variable diameter glass fibre reinforced plastic pipeline

A technology of glass fiber reinforced plastics and moulds, which is applied in the field of molds for preparing variable-diameter FRP pipes, and can solve problems affecting the service life of variable-diameter FRP pipes, leakage of FRP pipes, and complicated manufacturing processes for variable-diameter FRP pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

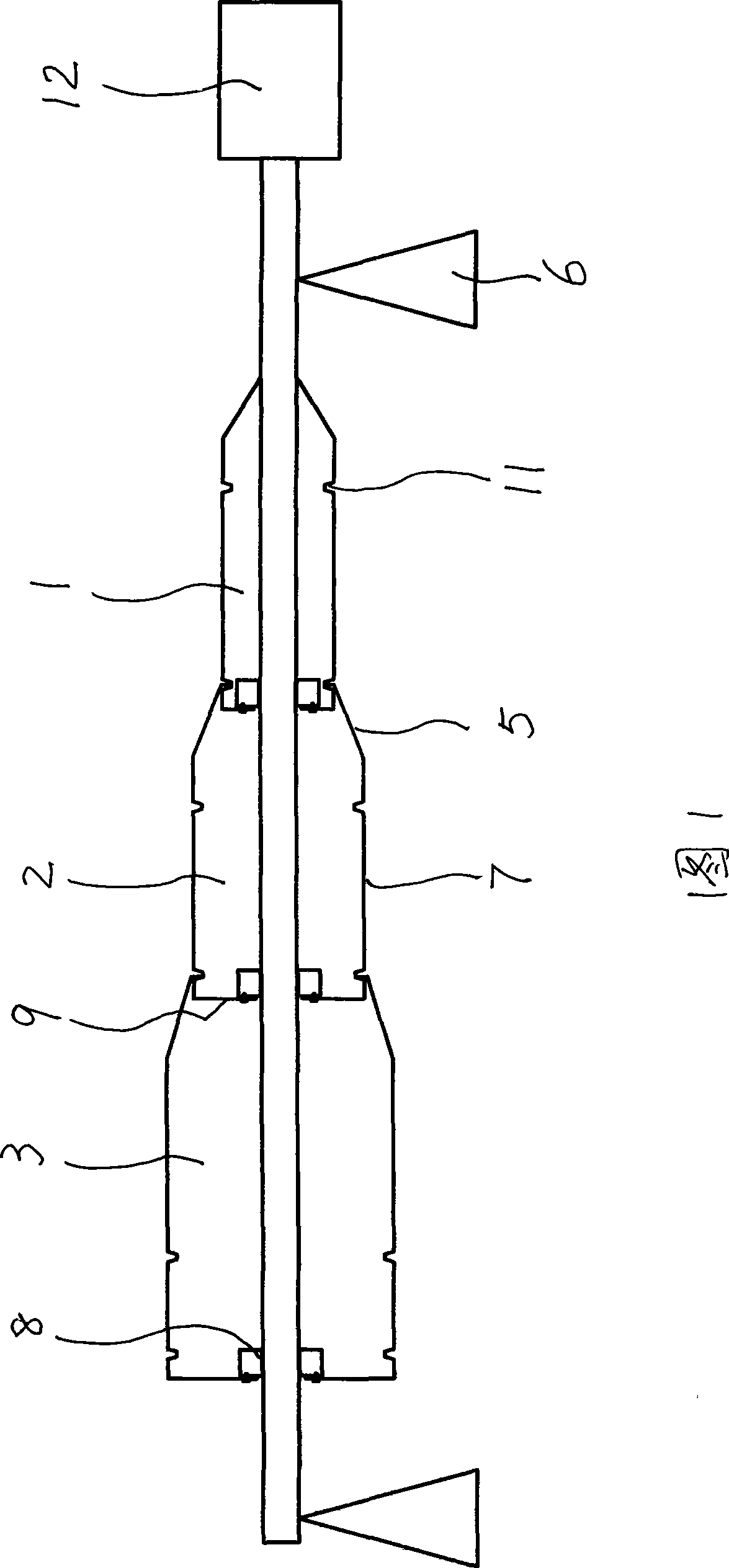

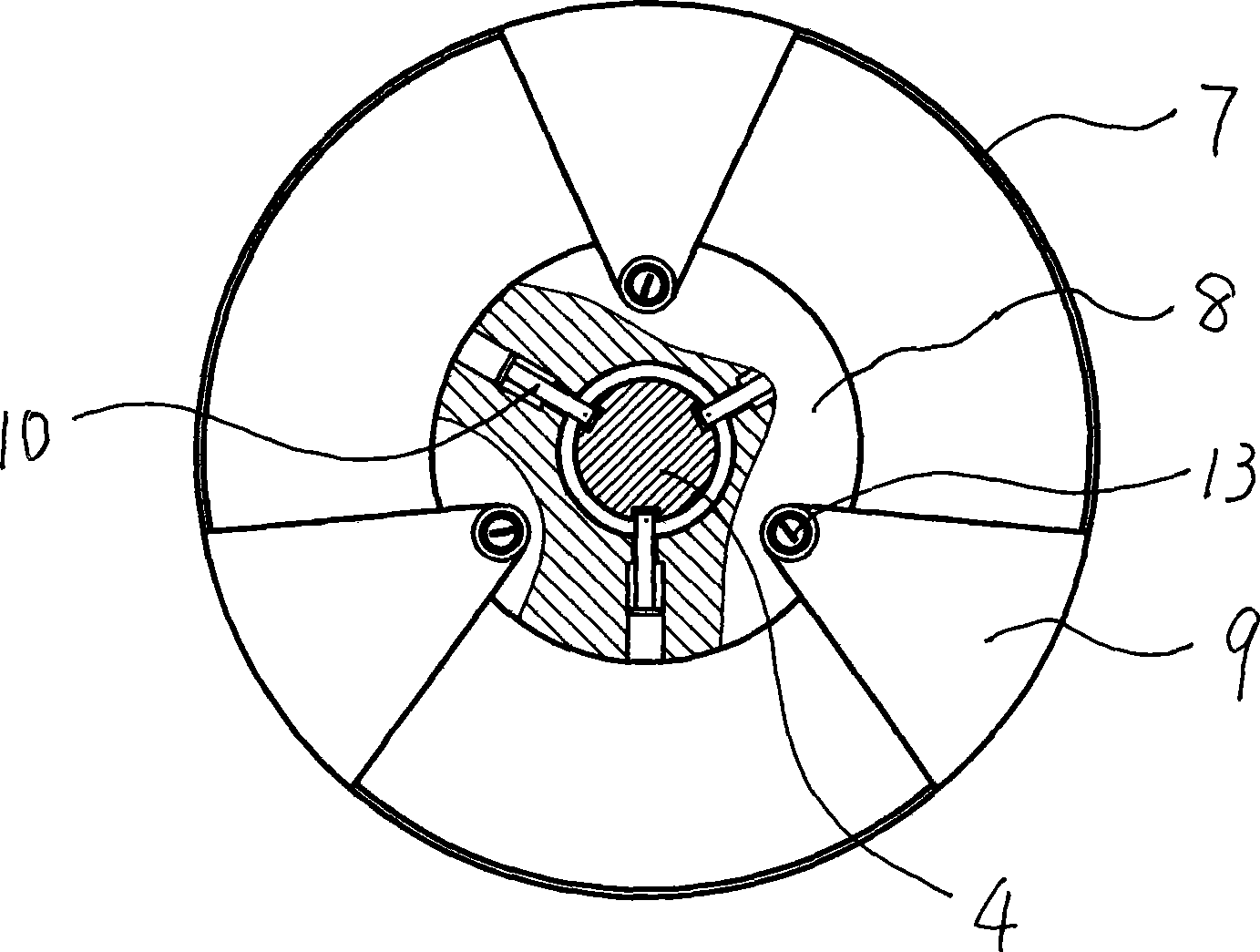

[0016] The structure of the mold for preparing variable-diameter FRP pipes provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] As shown in FIG. 1 , it is a structural schematic diagram of a mold for preparing variable-diameter FRP pipes provided by the present invention. Its structure includes a long rotating shaft 4 that can be driven by a motor and a speed change mechanism 12 to rotate on the mold frame 6, and three cylindrical molds 1, 2 and 3 are set on the rotating shaft. The cylindrical portion 7 and the end portion are in the shape of a truncated cone 5; the frustum of the first cylindrical mold 1 is fitted on the rotating shaft 4, and the frustum of the second and third cylindrical molds 2 and 3 are respectively fitted. On the cylindrical parts of the first and second cylindrical molds 1 and 2, the other ends of the three cylindrical molds are relatively fixed to the rotating shaft respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com