Supporting wheel hub and manufacture method thereof

A manufacturing method and technology of wheel hubs, which are applied in the directions of wheel hubs, transportation and packaging, vehicle parts, etc., can solve the problems of high installation and maintenance costs, harsh use environment, damage to metal mining wheels, etc., and achieve simple disassembly and maintenance process and reduce rigidity. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

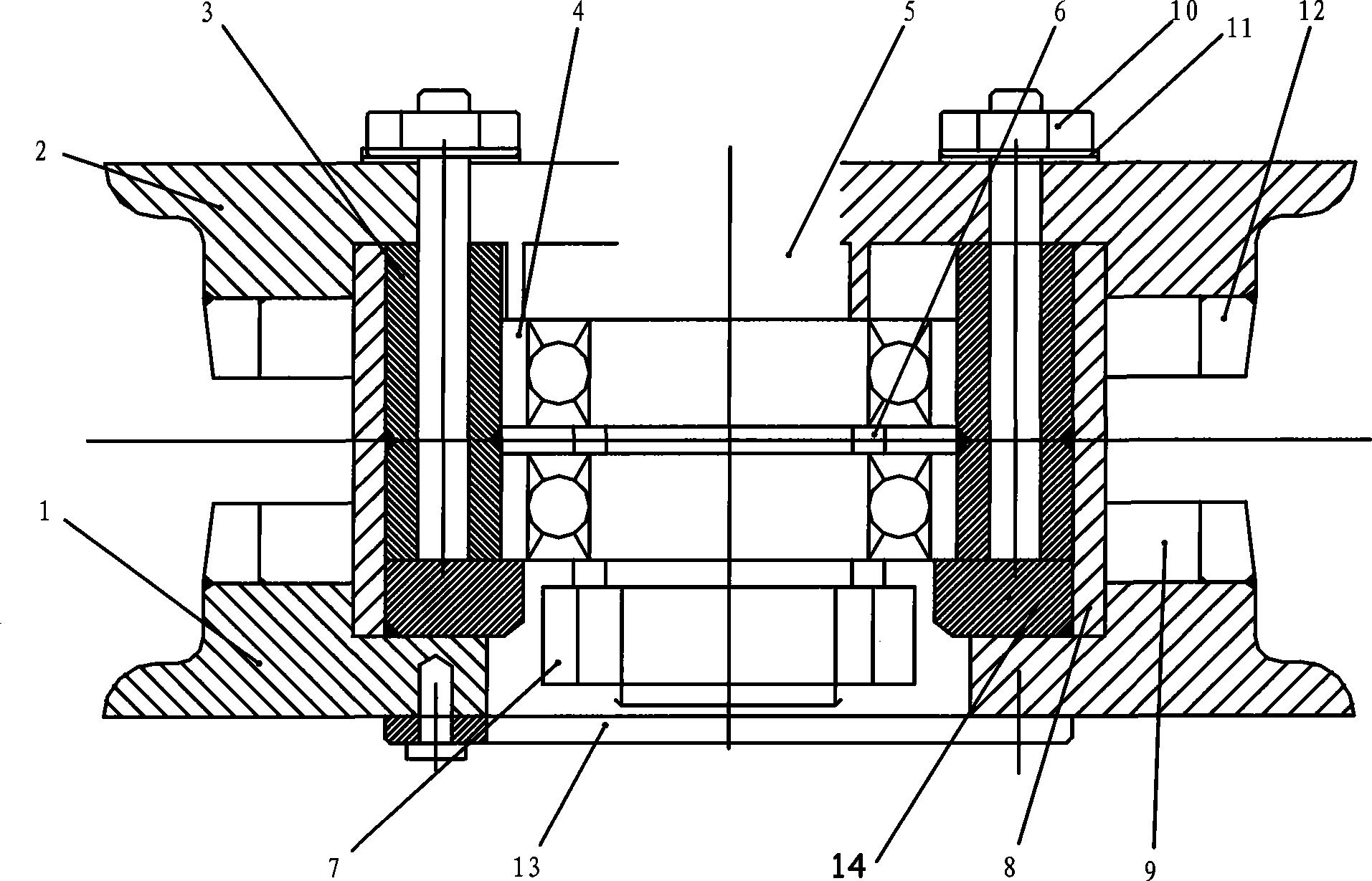

[0018] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0019] Such as figure 1 As shown, the present invention includes outer wheel drum 1, inner wheel drum 2, bearing sleeve 3, ball bearing 4, shaft 5, nut 7, steel pipe sleeve 8, hub ring 9, bolt 10, cover plate 13, outer wheel drum 1 and The inner wheel drum 2 is arranged oppositely, the bearing sleeve 3 is arranged between the outer wheel drum 1 and the inner wheel drum 2, the bearing sleeve 3 is connected with the inner wheel drum 2 through bolts 10, the ball bearing 4 is arranged in the bearing sleeve 3, and the ball bearing 4 is arranged Shaft 5, the nut 7 is set on the side of the shaft 5 close to the outer wheel drum 1, the steel pipe sleeve 8 is set on the outer side of the bearing sleeve 3, the hub ring 9 is set on the outer side of the steel tube sleeve 8, and the hub ring 9 is located between the outer wheel drum 1 and the inner wheel drum 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com