Reducing moire effect in an LCD device comprising a light control film

A technology of ripple effect and light control film, which can be used in measurement devices, optics, nonlinear optics, etc., and can solve problems such as complex processes and difficult to manufacture displays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

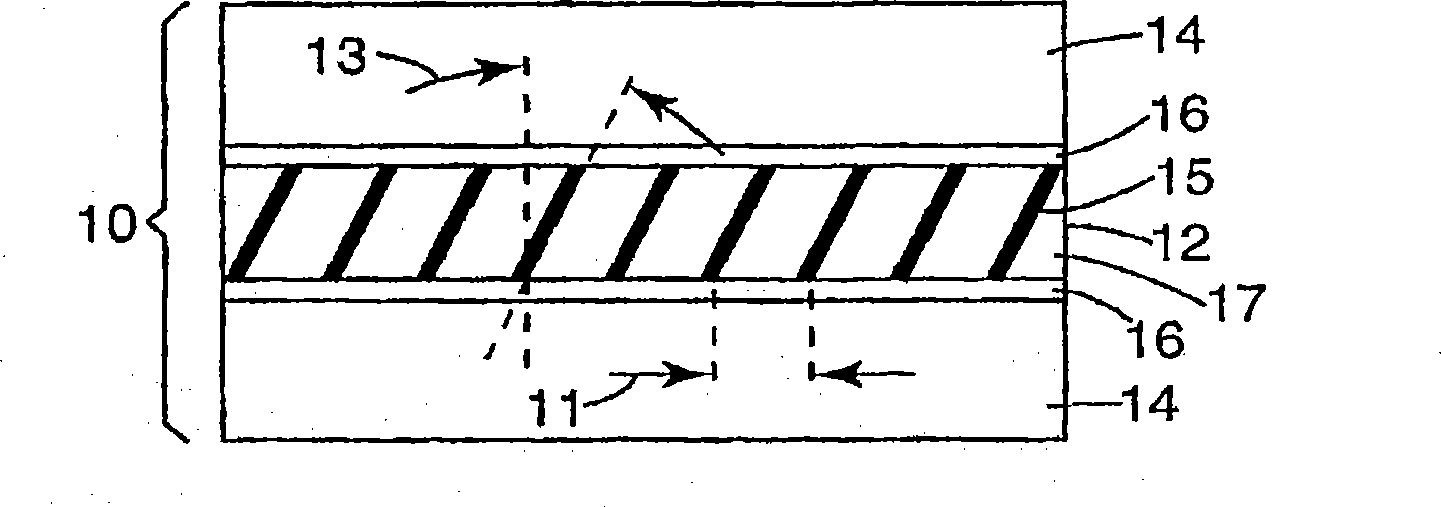

[0015] As mentioned above, when a light control film including a grid layer is used in an LCD device, the film will have moire interference with the LCD pixel pitch. Therefore, there is a need to reduce the moiré effect.

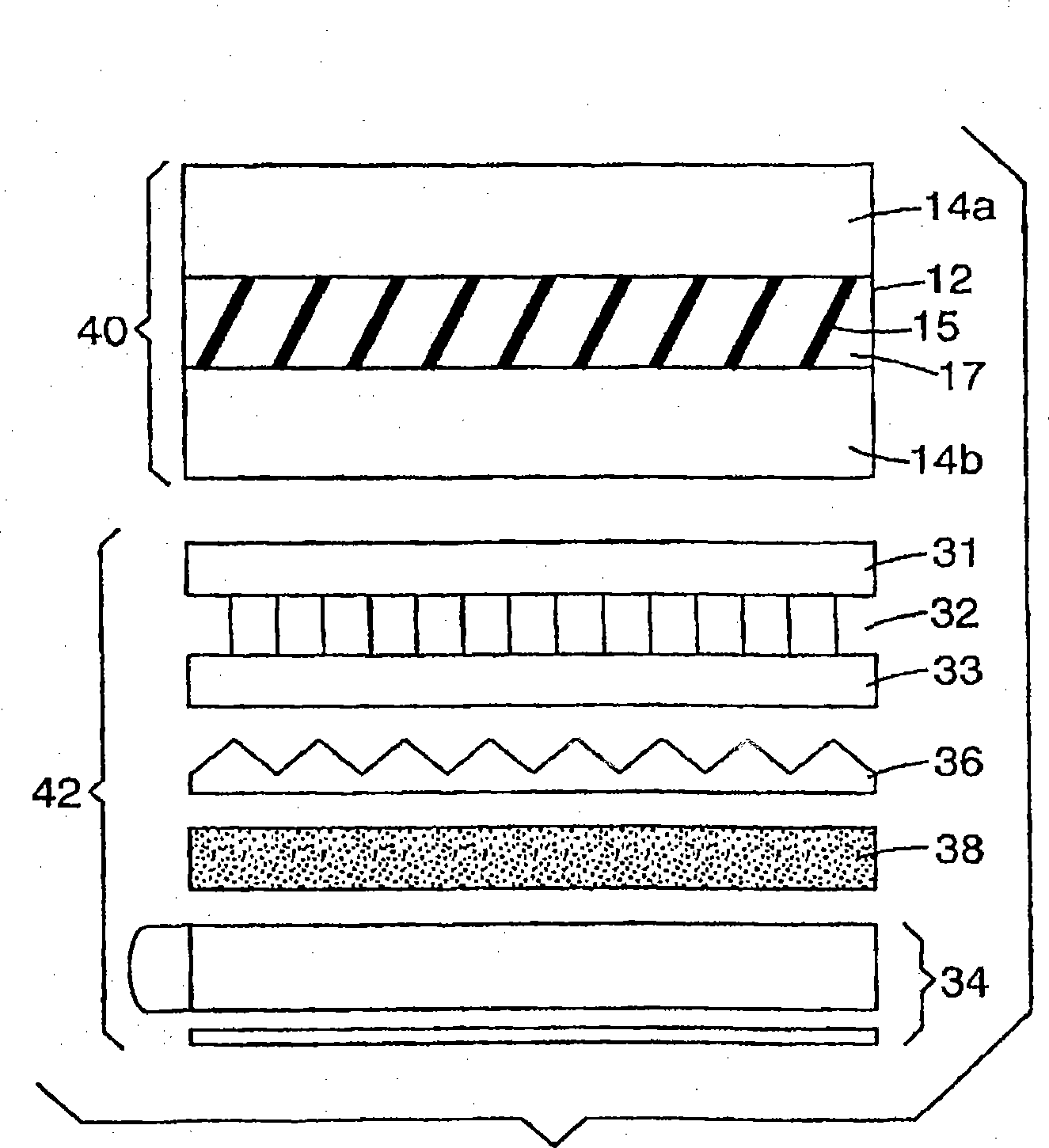

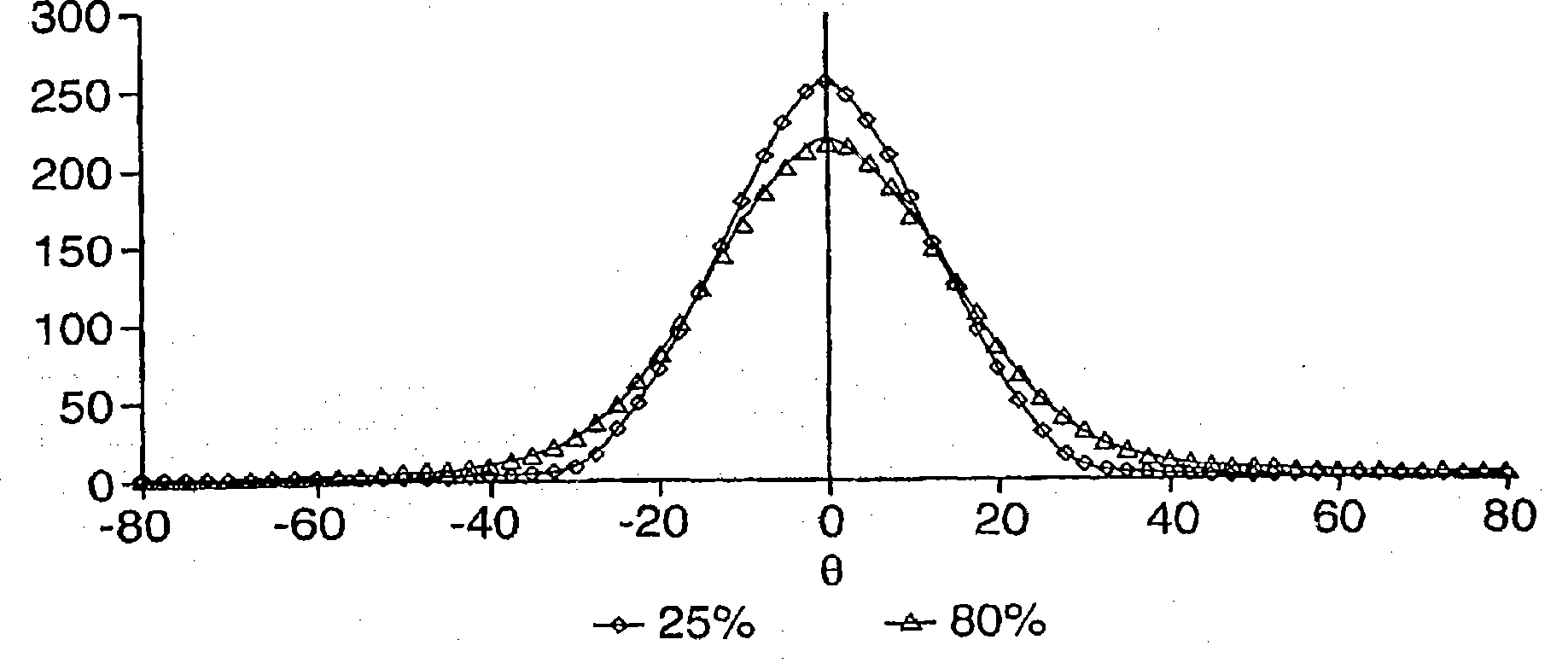

[0016] The present invention relates to a method of reducing the pixel moiré effect that may occur in an LCD device comprising a light control film having a louver element. In particular, the present invention relates to a method of reducing pixel moiré effects using a haze treatment on a layer or film disposed in front of an LCD device.

[0017] As previously mentioned, moiré effects can be observed when using LCFs with regularly arranged grid elements in LCD displays. In an LCD device, since LCD pixels have a regular pitch, it is particularly difficult to avoid moire interference when the optical adjustment film includes a regular repeating structure. In particular, when a film with regularly repeating grid elements, such as a light control film, is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com