Anastomat

A stapler and a matching technology, applied in the field of staplers, can solve the problems of inconvenient operation, operation failure, etc., and achieve the effect of convenient operation and labor-saving cutting operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

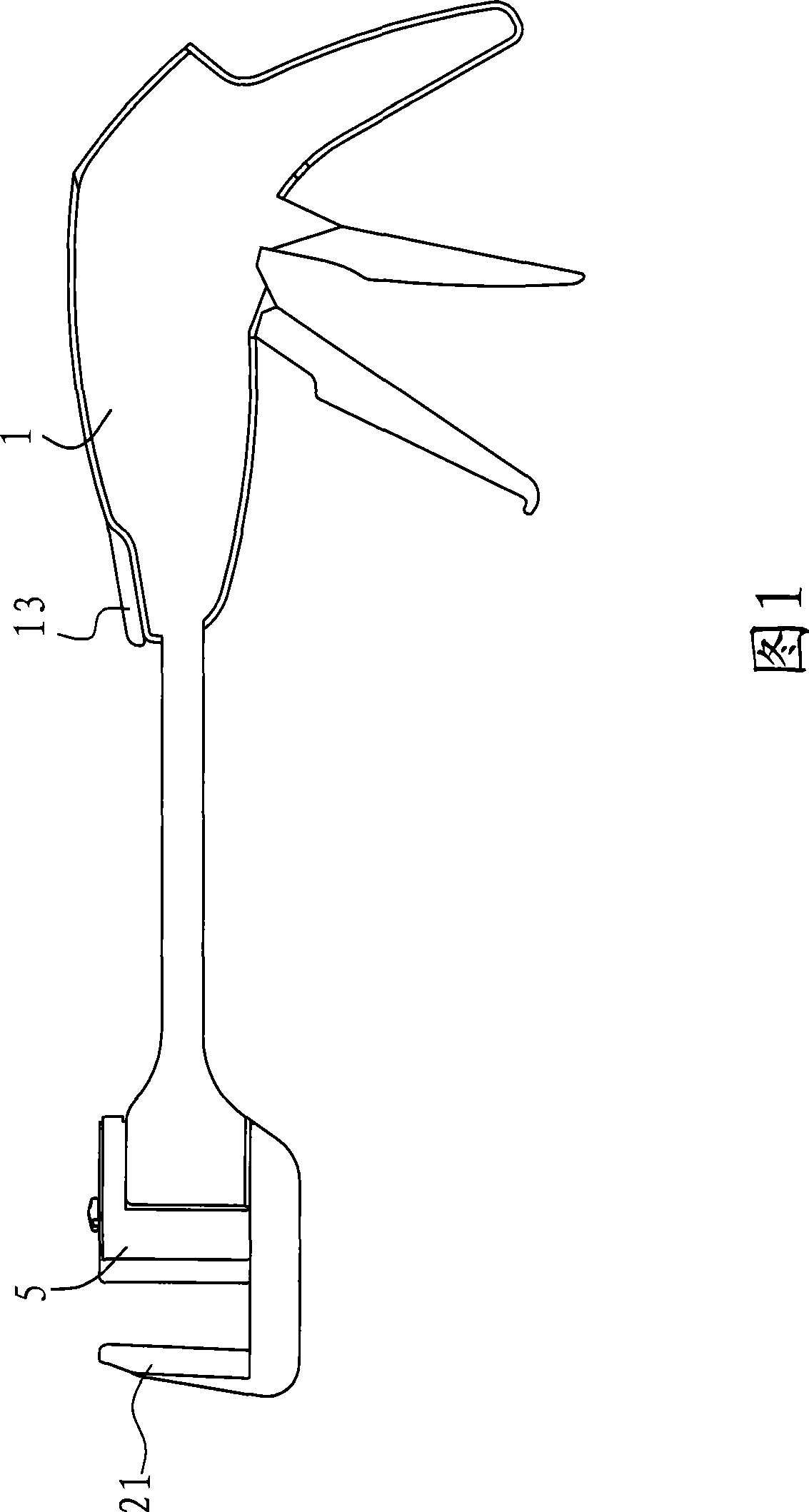

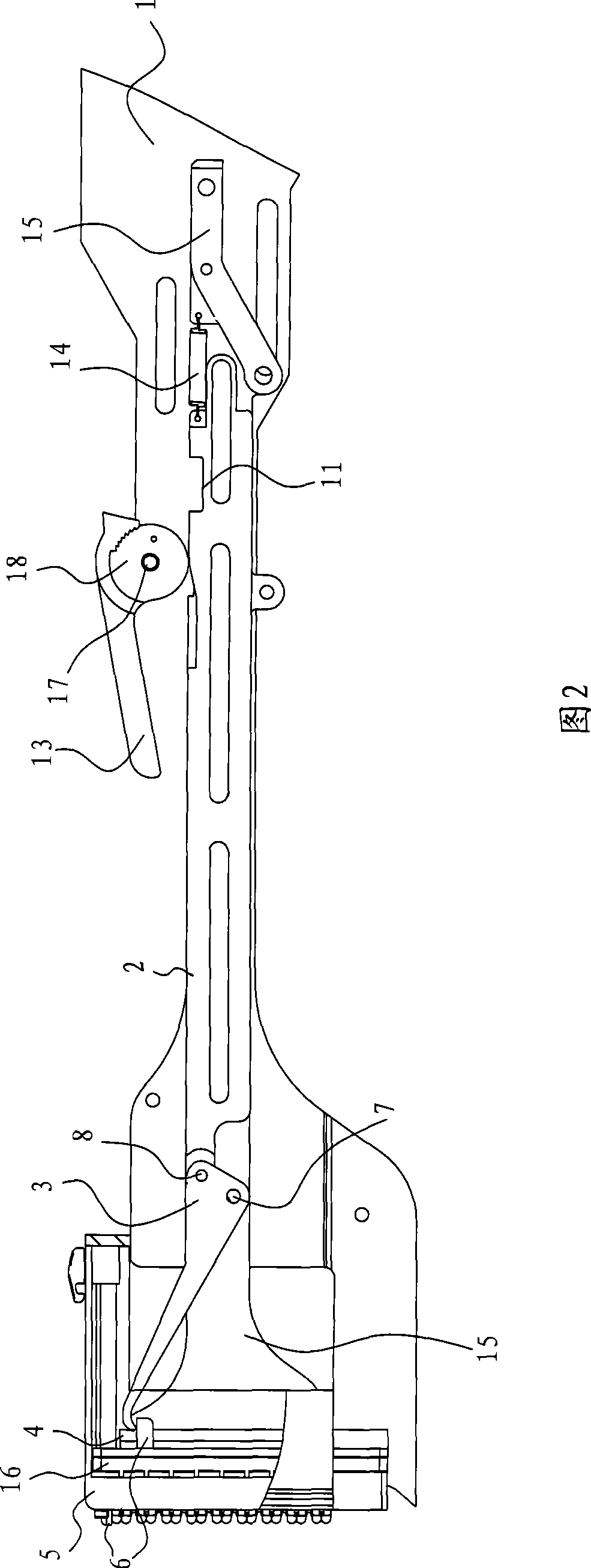

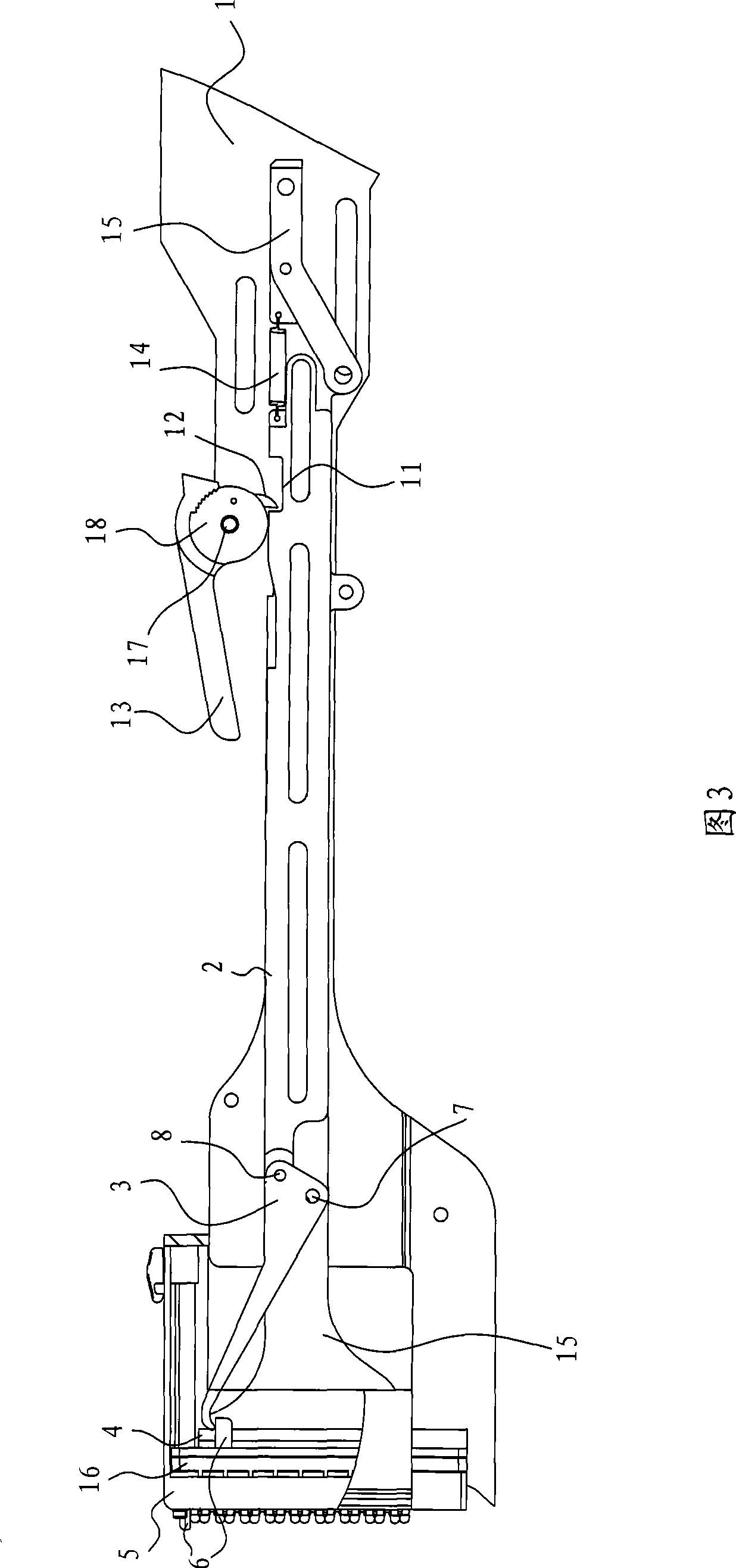

[0017] As shown in FIG. 1 , a stapler includes a main body 1 , a staple cartridge 5 arranged on the main body 1 , a staple pushing piece 16 and a cutter 6 arranged in the staple cartridge 5 , a stapler 6 arranged on the main body 1 for The cutter pushing mechanism that pushes the cutter 6 to move, the nail magazine 5 is provided with multiple rows of nail holes 9 and knife grooves 10, and there are at least one row of nail holes 9 on both sides of the knife groove 10, as shown in the appendix. Figure 5 As shown, in order to save labor during cutting and make the cutting operation more convenient, the main body 1 is provided with a cutting wrench 13 that can push the connecting rod 2 through the third rotating shaft 17 .

[0018] The cutting wrench 13 is provided with a push block 12 , and the connecting rod 2 is provided with a groove 11 . When the push block 13 is located in the groove 11 , the connecting rod 2 can be pushed by rotating the cutting wrench 13 .

[0019] The cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com