Anti-rolling limiting type floor type pipe cutting machine

A pipe cutting machine, floor-standing technology, applied in the direction of pipe shearing device, shearing device, shearing machine accessories, etc., can solve the problems of inconvenient use, easy rolling of pipes, time-consuming and labor-intensive collection process, etc., and achieve labor-saving cutting operation , stable clamping and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

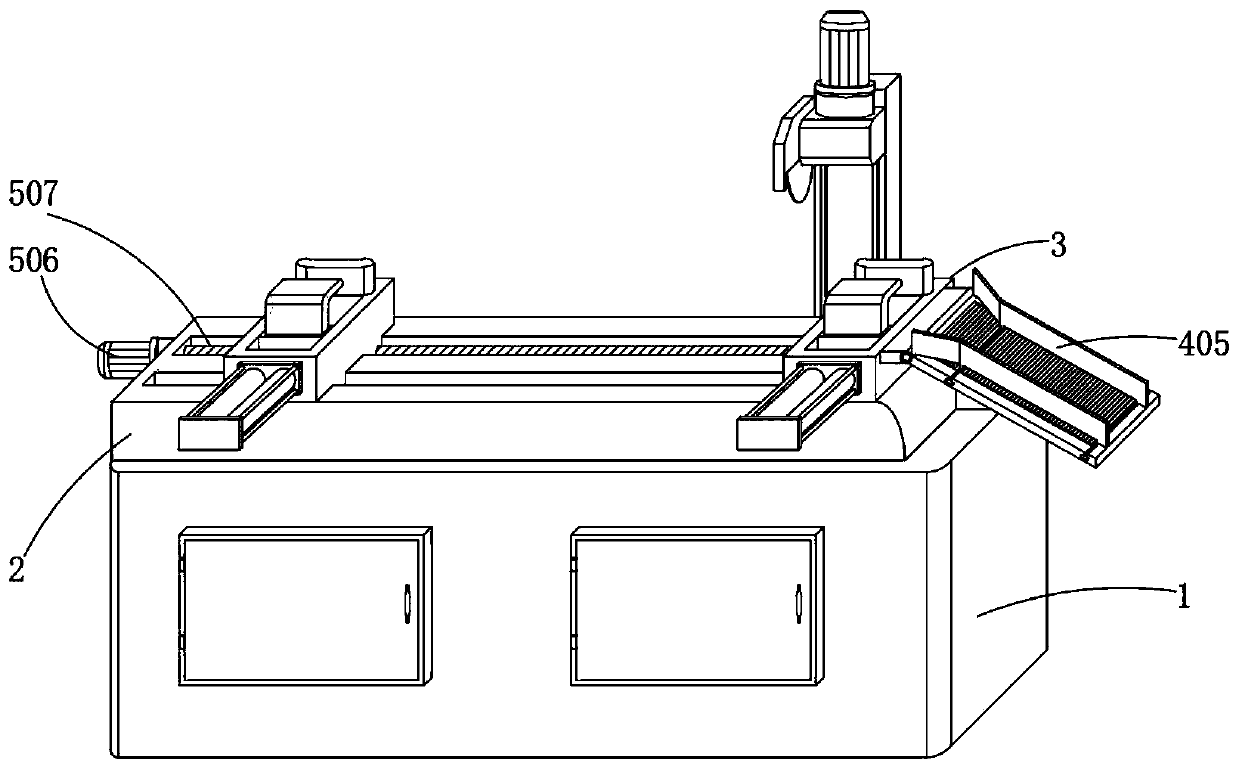

[0029] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a limited-type floor-standing pipe cutting machine with anti-rolling, including a pipe cutting machine body 1, a worktable 2 is installed on the top surface of the pipe cutting machine body 1, and the top surface of the workbench 2 is A fixed seat 3 is installed at one end of the surface;

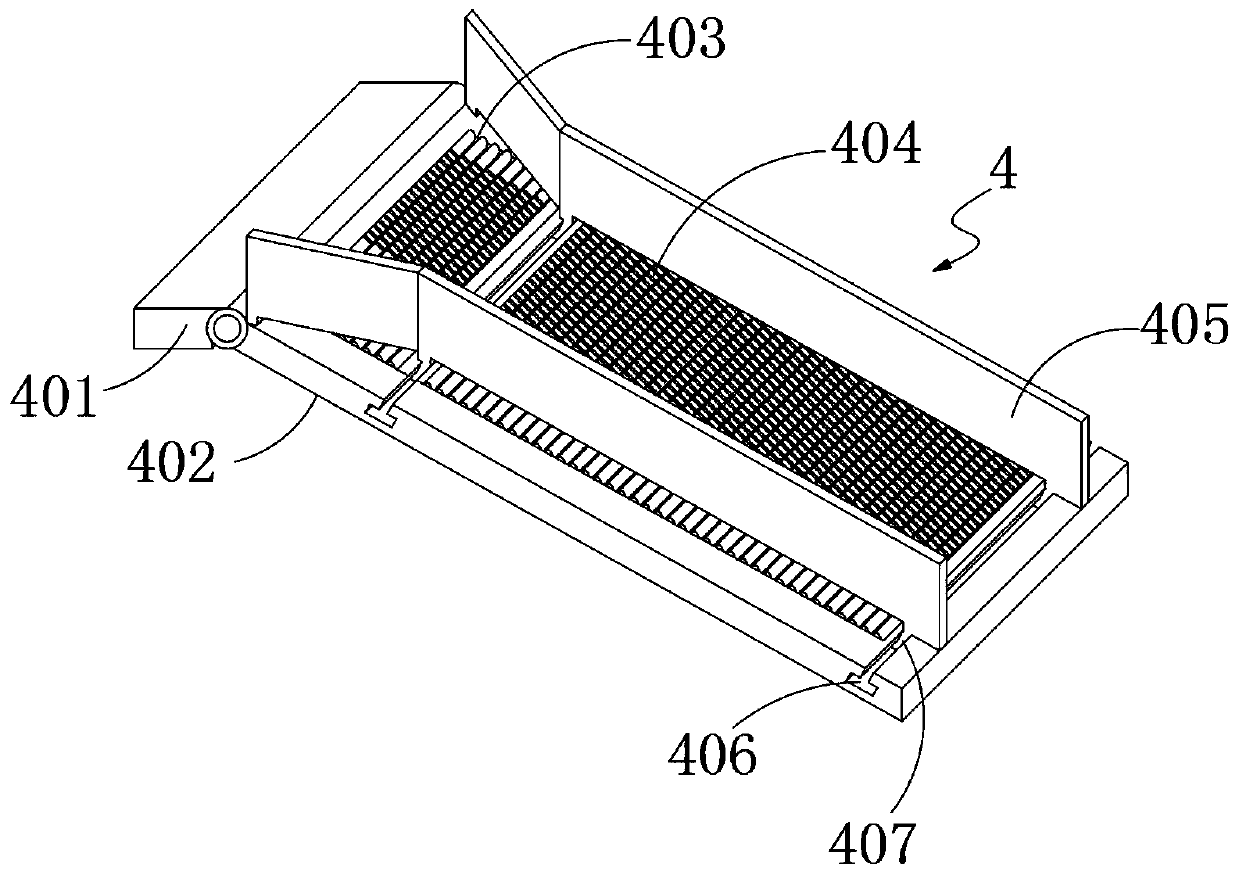

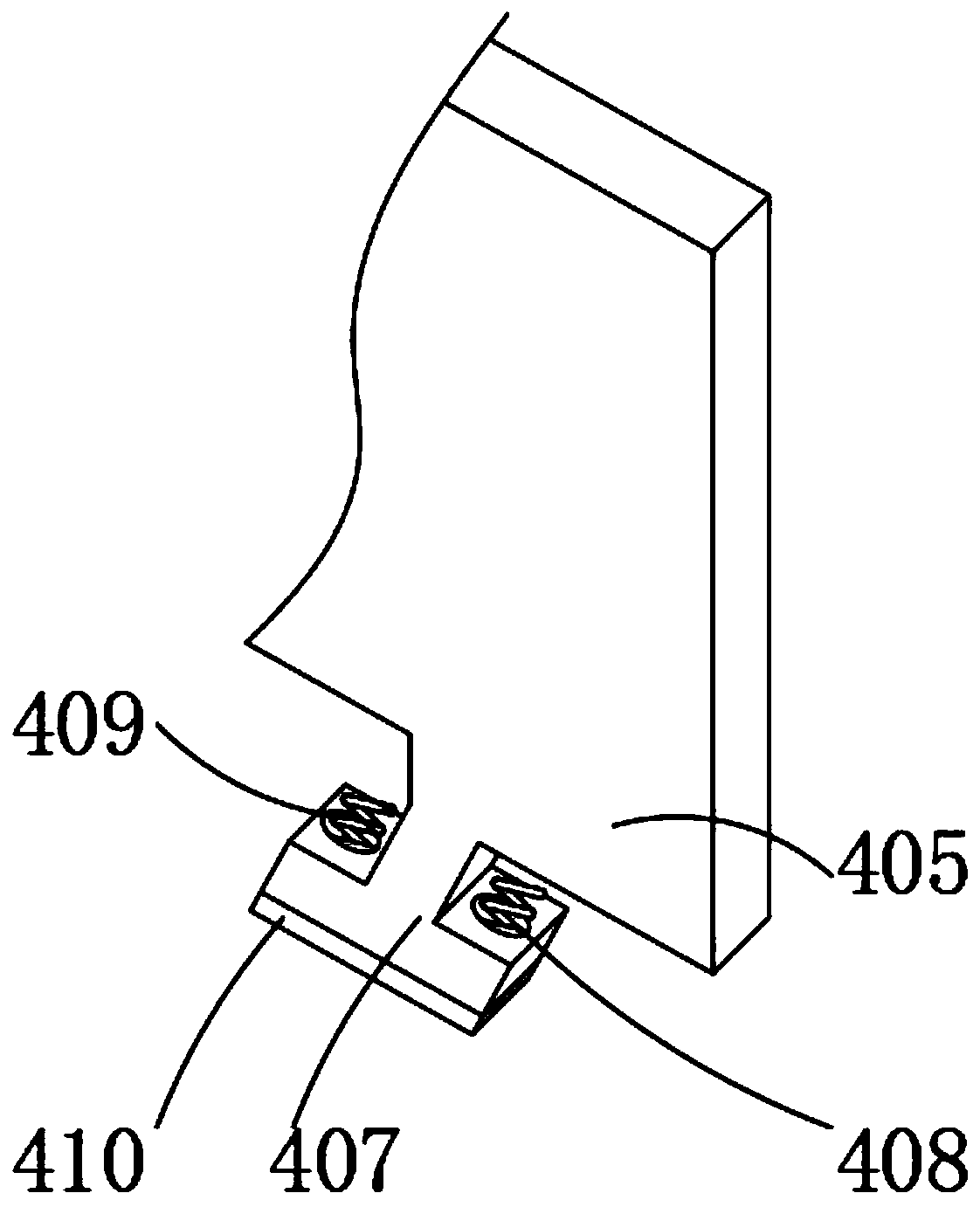

[0030] A guide assembly 4 is installed on the top of the side of the fixed seat 3, and the guide assembly 4 includes a connecting plate 401, an inclined plate 402, a mounting groove 403, a roller shaft 404, a guide plate 405, a T-shaped groove 406, a T-shaped block 407, a spring groove 408, a spring 409 and anti-slip mat 410;

[0031] The connecting plate 401 is welded to the top of the side of the fixing seat 3, one end of the connecting plate 401 is hinged with a slanting plate 402, and one end of the top surface of the pipe cutting machine body 1 is placed at the bottom of the sloping plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com