Booth frame machine

A greenhouse skeleton and outer cylinder technology, which is applied in the field of extrusion machinery, can solve the problems of failing to meet the needs of the market leap, short life, affecting the operation, lighting, and farming in the greenhouse, and achieves high mechanical production stability, strong resistance and durability. Compressibility and elasticity, the effect of flexible construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

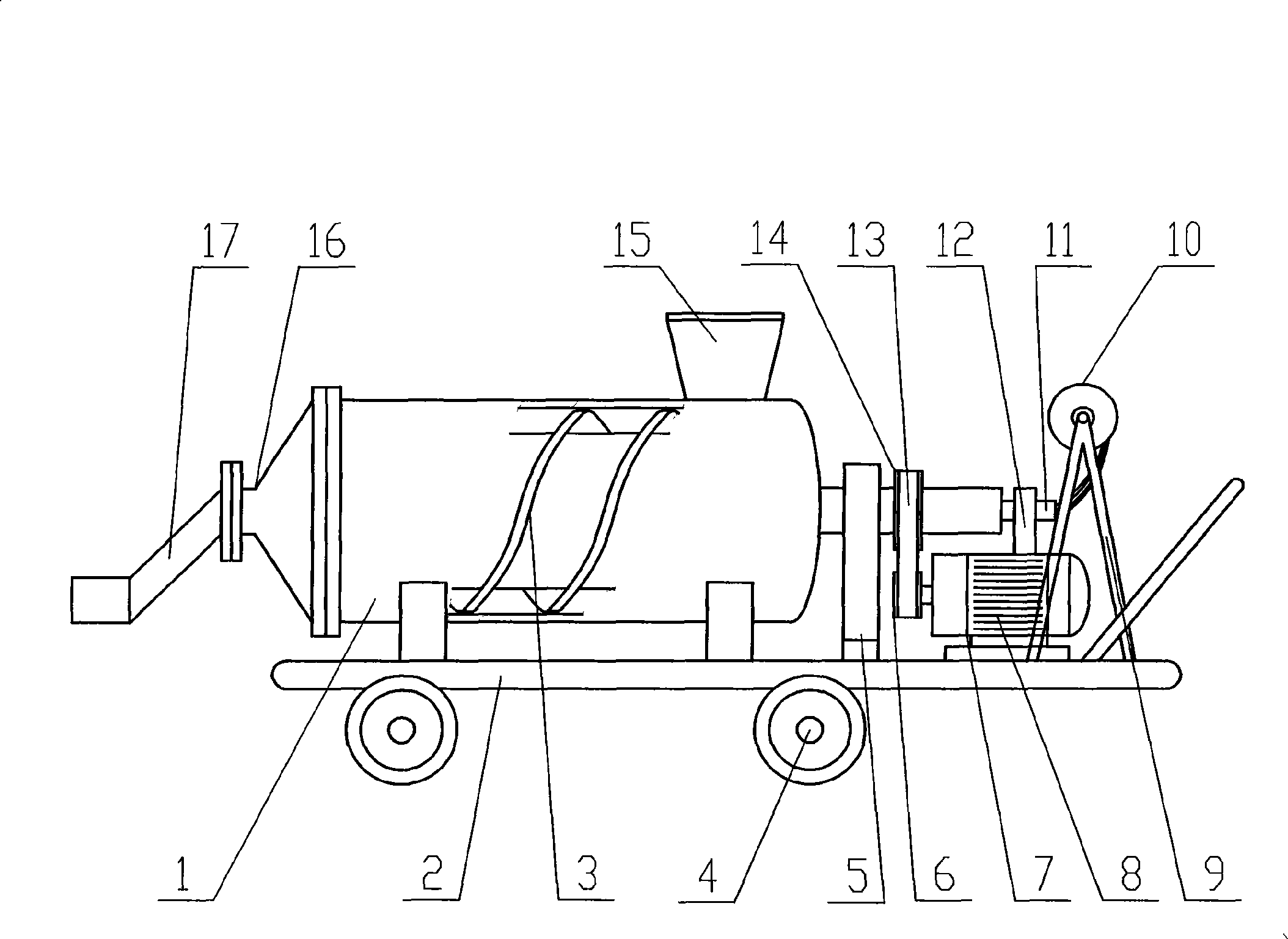

[0013] In the figure, the present invention mainly includes an outer cylinder 1, a base 2 for fixing the outer cylinder, a screw shaft 3 inside the outer cylinder 2, and a transmission part that drives the screw shaft to rotate. 1 There is a discharge port 16 at the lower part of the front end, the transmission part is fixed on the base 2, the screw shaft 3 is supported by the bearing support 5 on the base 2, and the other end is supported by the sealed bearing support fixed inside the outer cylinder 1, the screw shaft 3 is Hollow shaft, a hollow tube shaft 11 is installed on the hollow part of the screw shaft 3, one end of the hollow tube shaft 11 is fixed on the base 2 by a fixed seat 12, and there is a bearing support between the other end and the screw shaft 3, and the base 2 A bracket 9 is also installed, and a glass cloth wheel 10 is installed on the support 9. The glass cloth on the glass cloth wheel 10 is passed through the hollow tube 11. When the screw shaft 3 is fed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap