Insulating cantalever component of traffic contact system

A catenary and cantilever technology, applied in the field of machinery, can solve the problems affecting the use stability of the catenary, cumbersome operation, laborious and other problems, and achieve the effects of diversifying adjustment methods, reducing vibration, and using high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

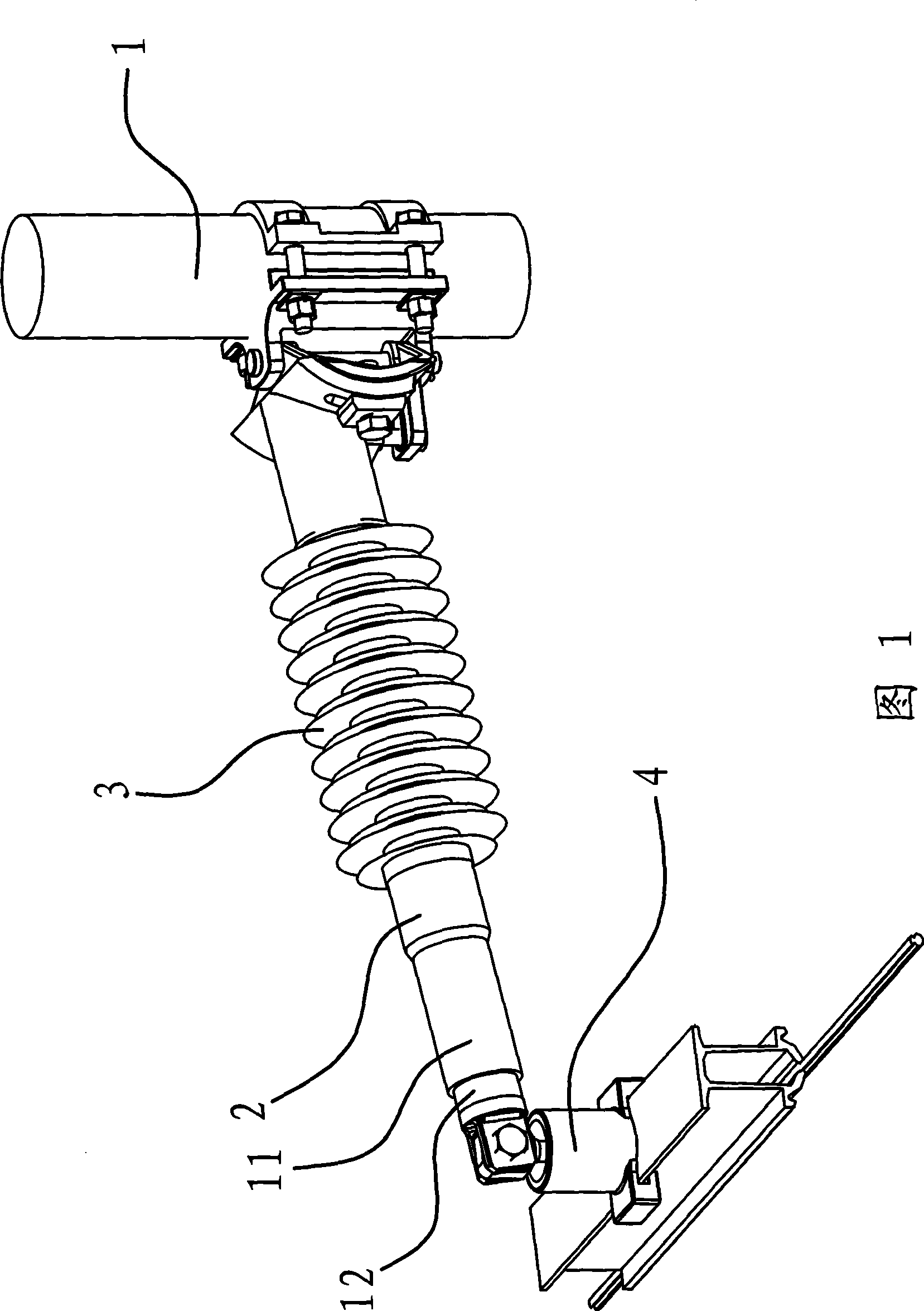

[0035] As shown in Figure 1, the insulating cantilever assembly in the traffic catenary is located between the column 1 of the traffic catenary and the locomotive pantograph.

[0036] The middle part of the cantilever 2 has an insulator 3, and the insulator 3 is in the shape of an umbrella group. The inner end of the cantilever 2 is connected with the column 1, and the outer end of the cantilever 2 is hinged with a wire clamp 4. The wire clamping part 4 is used for clamping the power supply wire. The insulator 3 can prevent the current from being connected to the connection between the cantilever 2 and the column 1 .

[0037] An adjustment mechanism is provided between the inner end of the cantilever 2 and the column 1, through which the position of the cantilever 2 can be adjusted. Simultaneously, the cantilever 2 is also provided with a telescopic mechanism capable of adjusting its length.

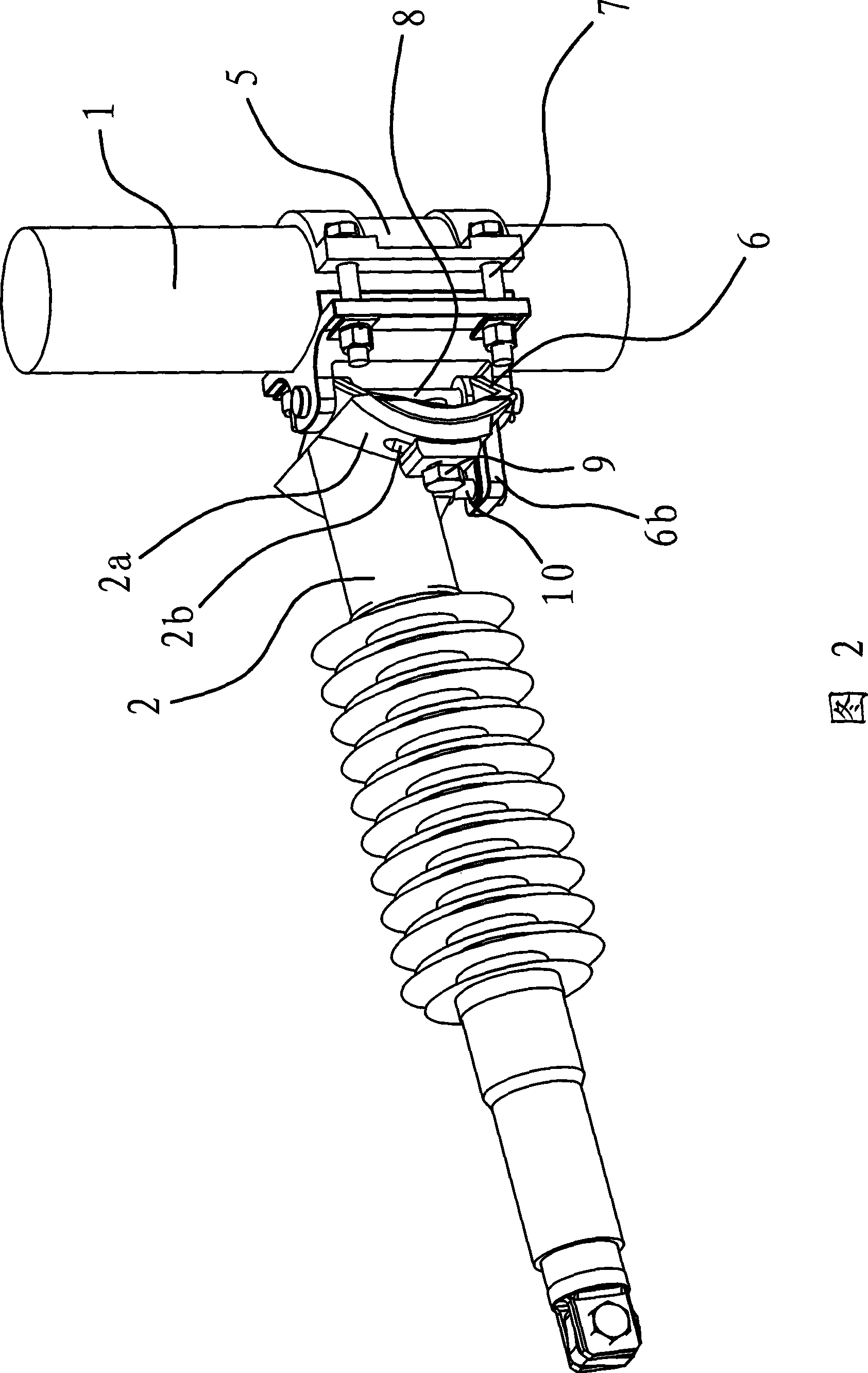

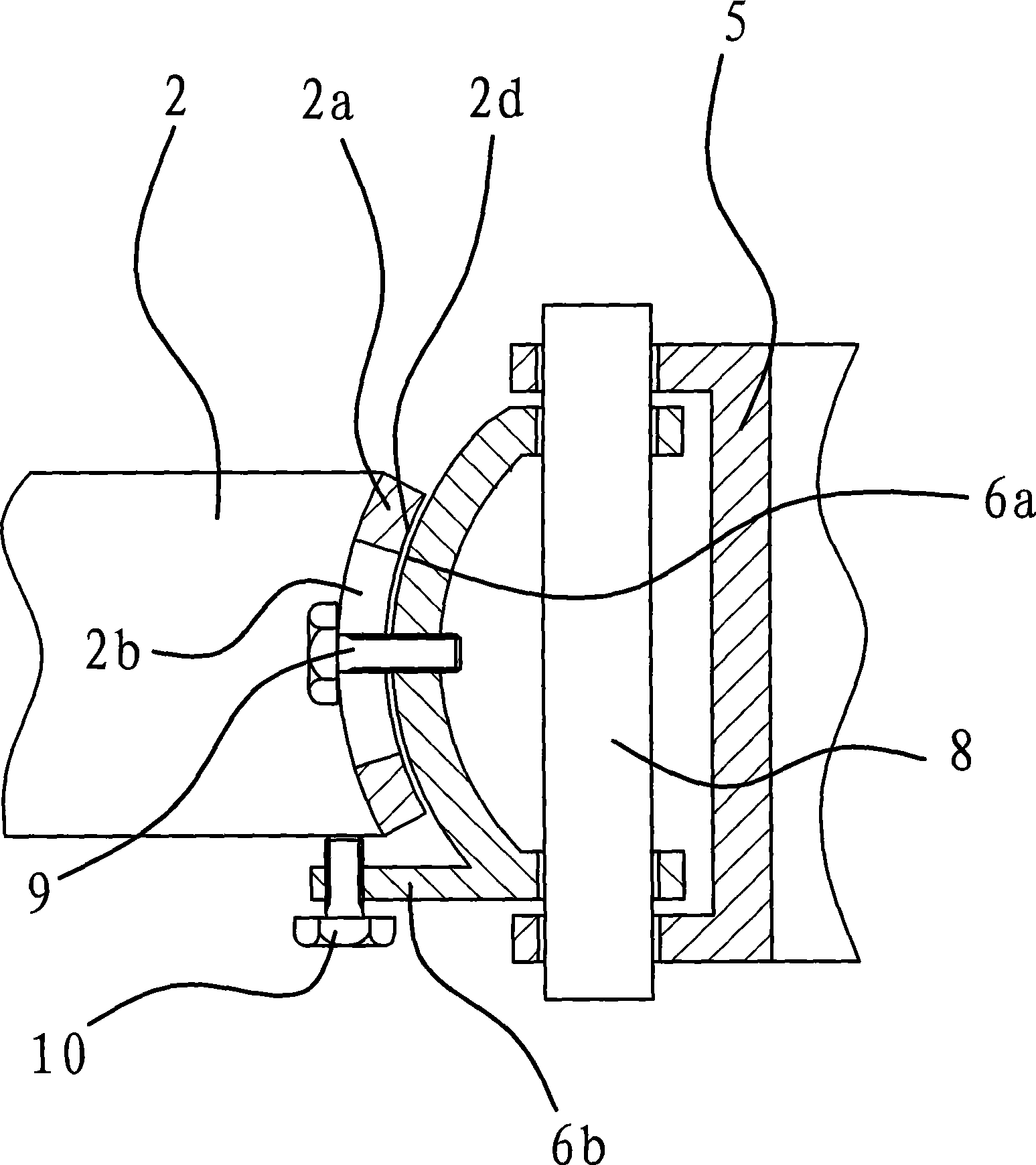

[0038] Figure 2 and image 3 As shown, the adjustment mechanism includes a base c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com