Self-contained system for drilling a drainhole

A discharge hole and motorized technology, which is applied to drilling equipment and methods, driving devices for drilling in boreholes, earthwork drilling, etc., and can solve problems such as damage to discharge ditch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

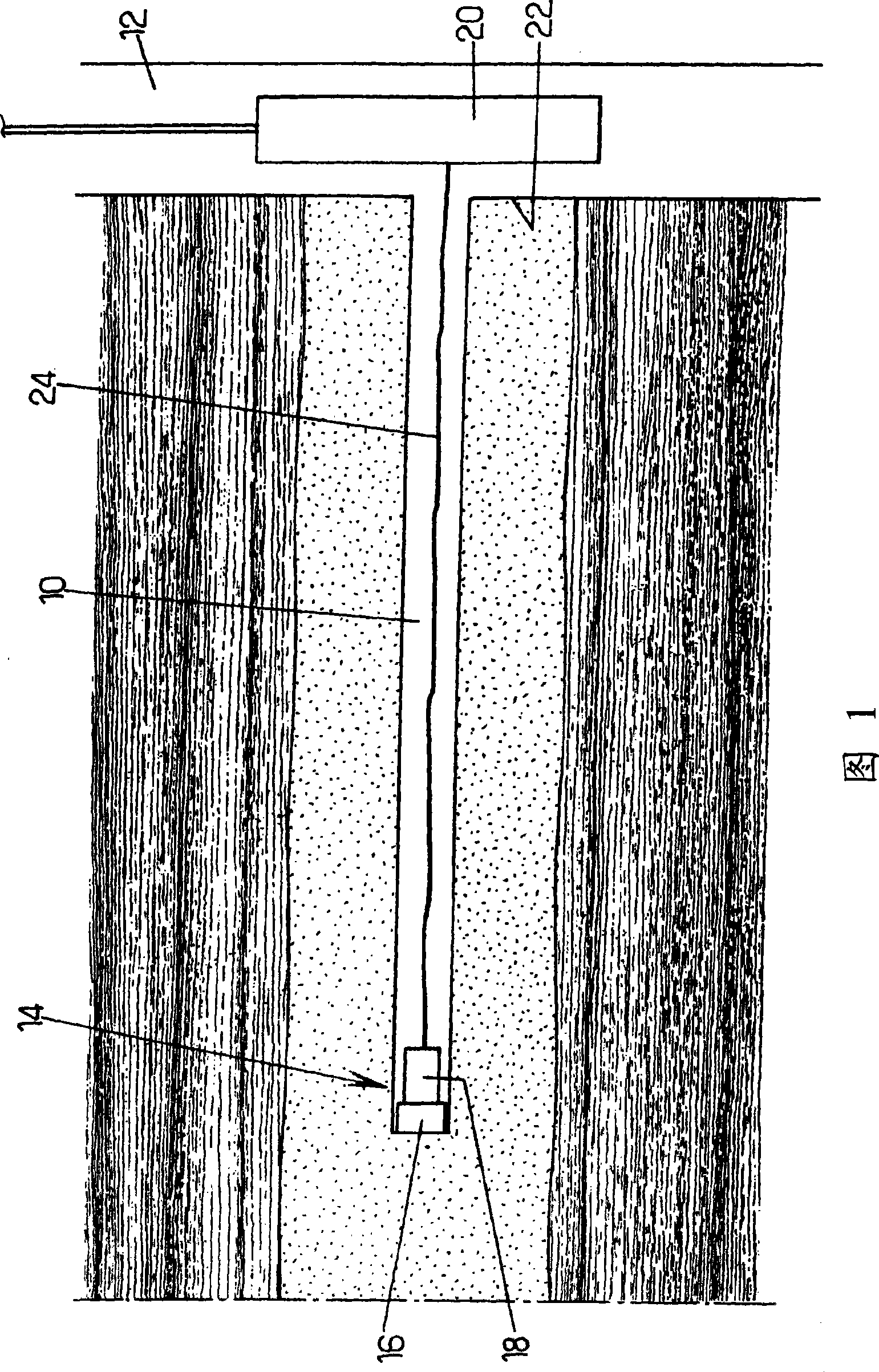

[0041] Figure 1 shows a mobile system for drilling a drainage hole 10 transverse to a wellbore 12 in a tight gas reservoir according to a first embodiment of the present invention.

[0042] Typically the wellbore has a diameter of about 10 to 50 cm and a depth of several hundreds or thousands of meters. The discharge holes 10 drilled by the system according to the invention have a diameter of less than 10 cm, preferably less than 5 cm, along a length of about 200 m.

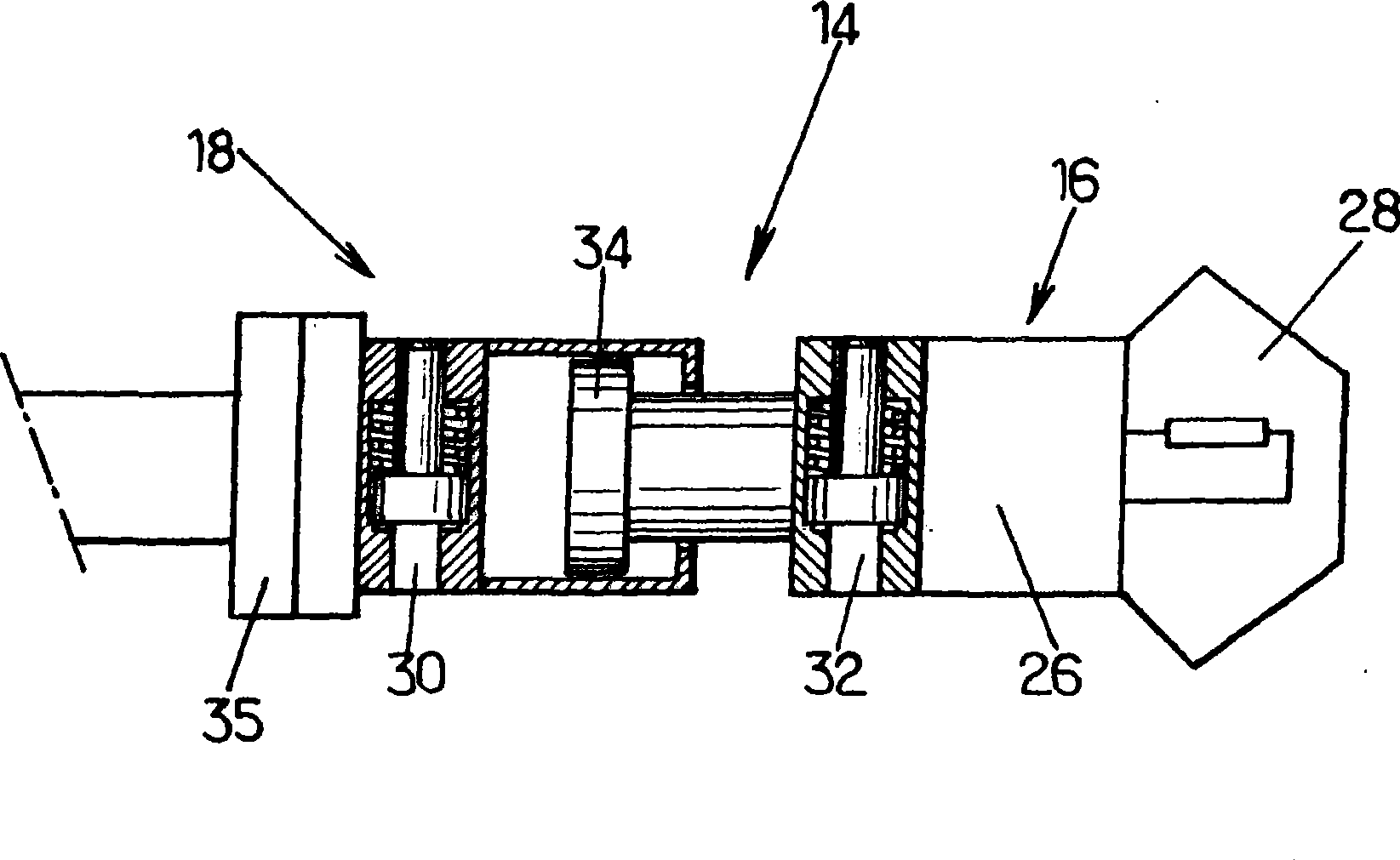

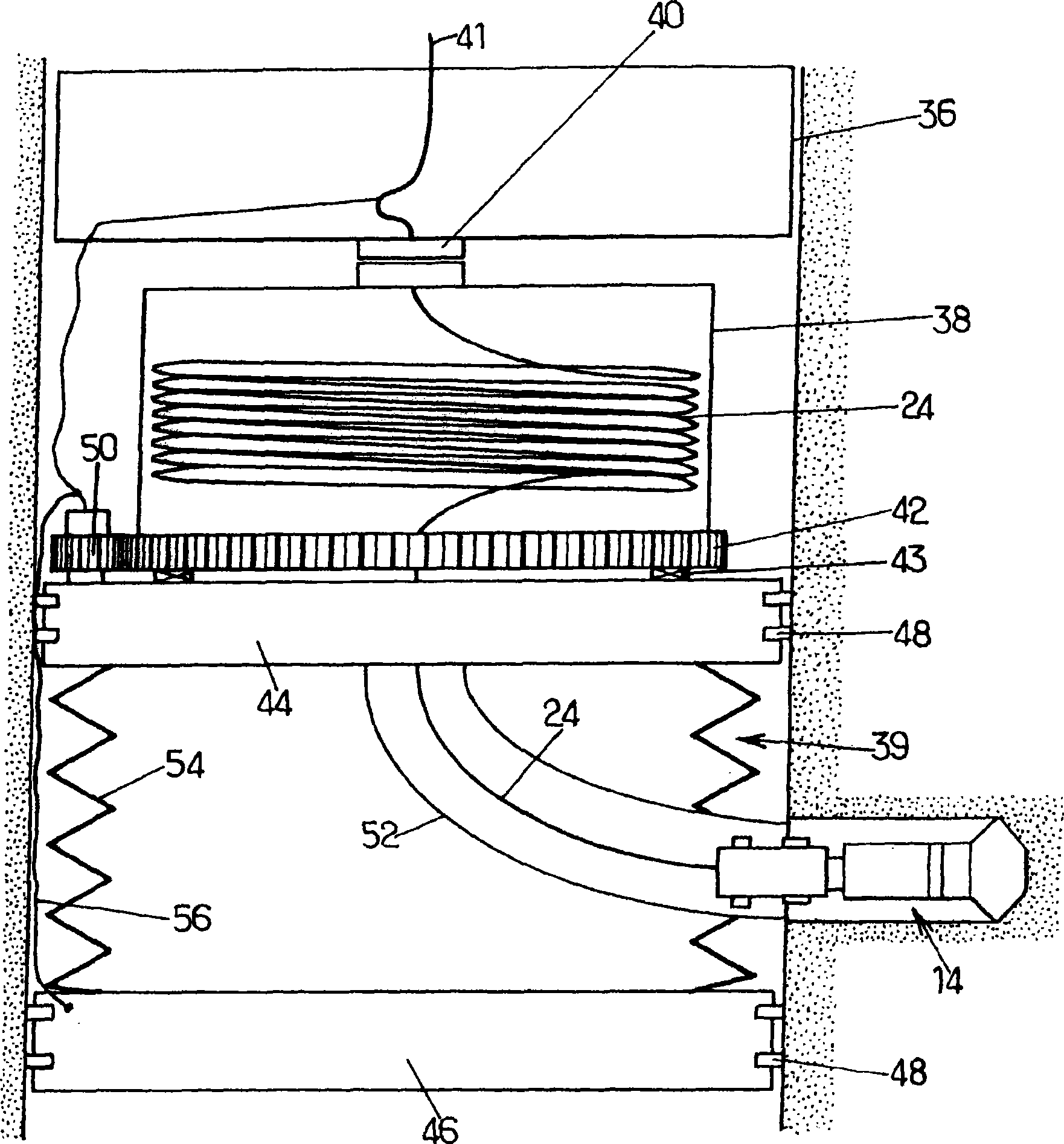

[0043] In this first embodiment, the motorized drilling system includes a drill bit 14, wherein the drill bit 14 includes a tool 16 for drilling the discharge hole 10, and is adapted to power the drill bit 14 into the discharge hole 10 during drilling. The self-propelled device 18. The system according to the invention further comprises a relay unit 20 which is lowered into the wellbore 12 and arranged to be able to place the drill bit 14 against the sidewall of the wellbore 12 in order to initiate the spud of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com