Blowout prevention on-off connector

A disconnecting and blowout prevention technology, which is applied in wellbore/well parts, earthwork drilling, sealing/isolation, etc., can solve environmental pollution and other problems, and achieve the effect of preventing falling and avoiding ground and water source pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

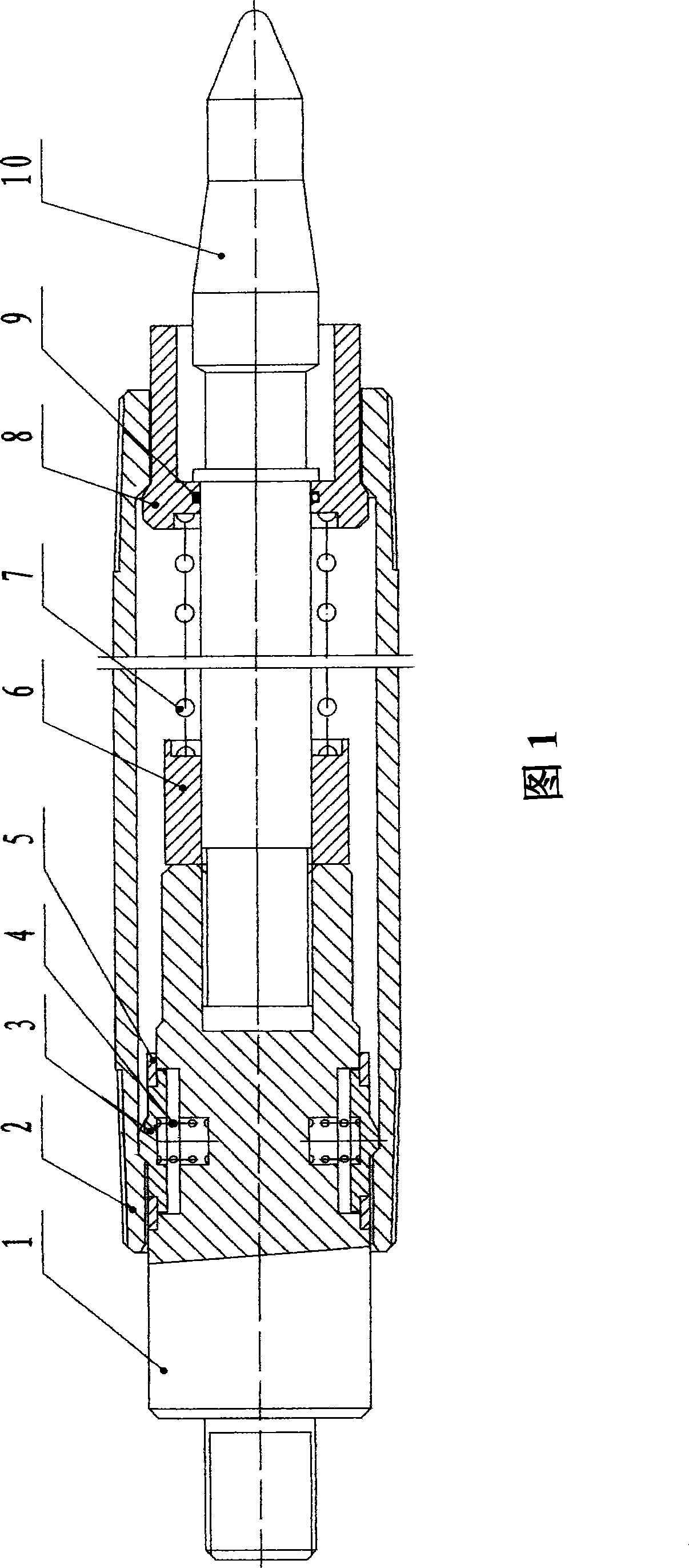

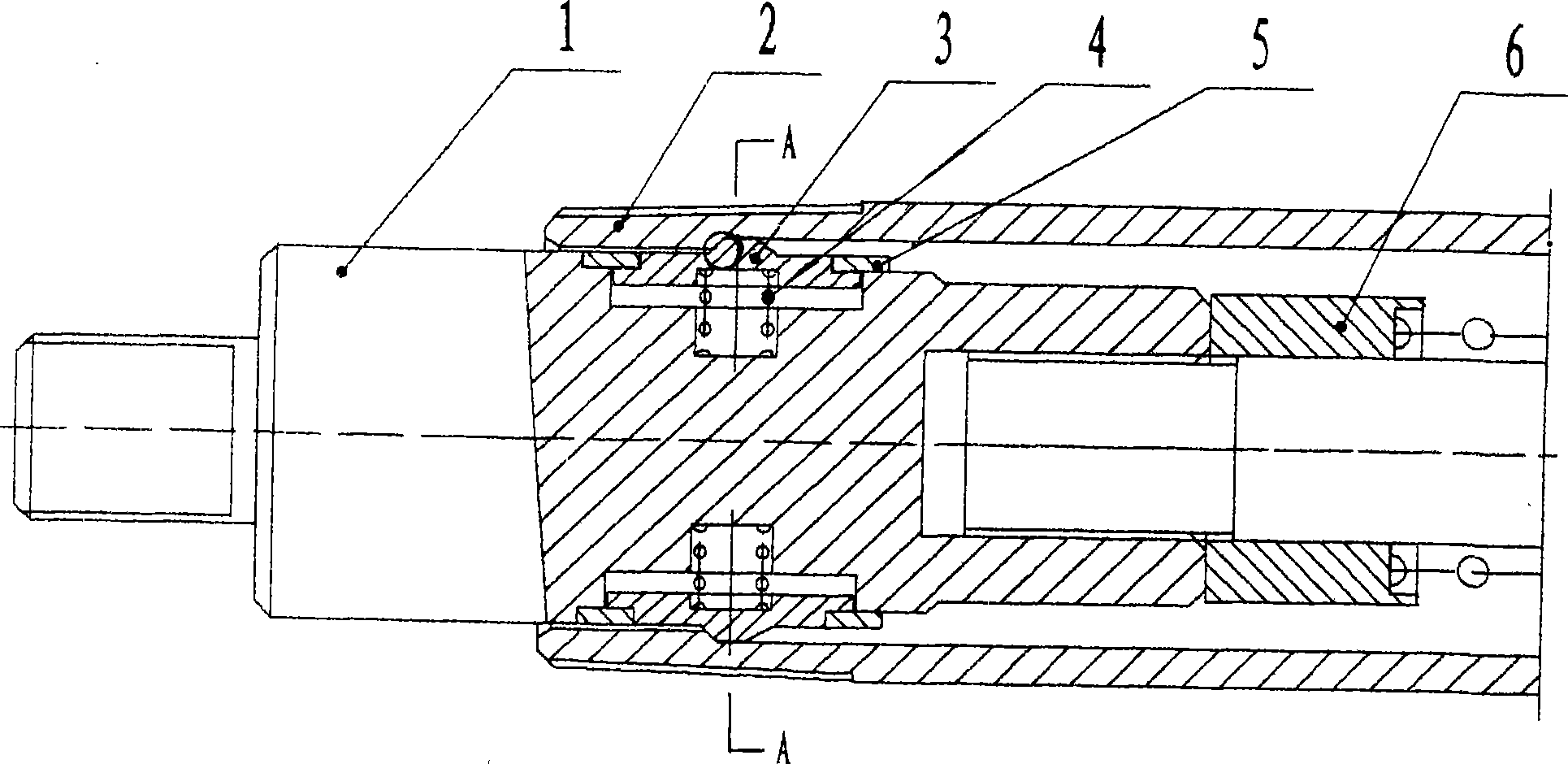

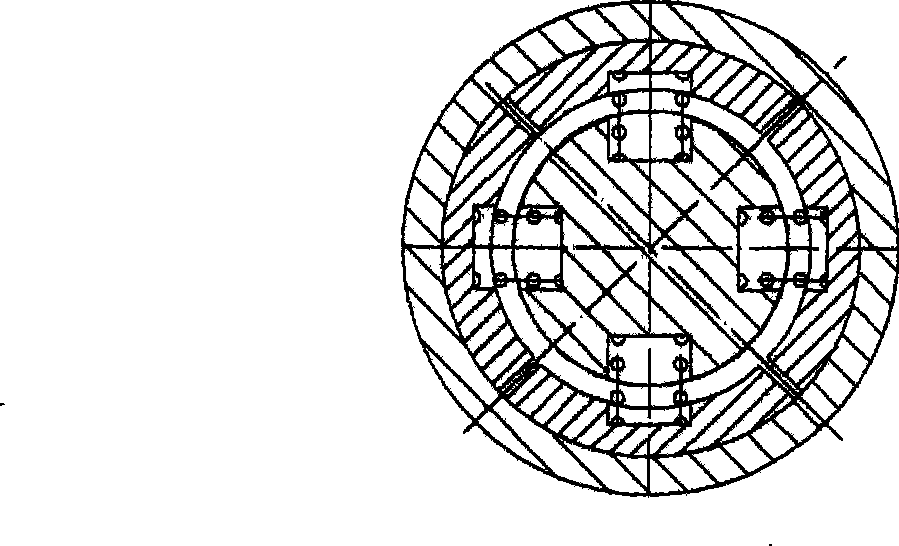

[0011] See Figures 1-4, the specific structure is as follows: the two ends of the inner circle of the jacket 2 are respectively provided with a positioning boss and a sealing boss, and the end surface of the sealing boss is a tapered surface. Assemble the main body 1 in the casing 2, the main body 1 is connected to the central rod 10 of the disconnecting device, the nut 6 and the sealing lock sleeve 8 are assembled on the central rod 10 of the disconnecting device, and the sealing ring 9 is assembled between the sealing locking sleeve 8 and the central rod 10 of the disconnecting device . A large compression spring 7 is assembled between the nut 6 and the sealing lock sleeve 8 . The sealing lock sleeve 8 is provided with a sealing tapered surface in contact with the sealing boss at one end of the jacket 2 . 4-6 fan-shaped clamping blocks 3 are assembled on the outer periphery of the main body 1, and sheaths 5 are arranged on the outer peripheries of both ends of each fan-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com